[Archived] Major Types of Transportation Construction Specifications

A Guideline to Understanding Their Evolution and Application

A Report of the AASHTO Highway Subcommittee on Construction Quality Construction Task Force

August 2003

Introduction

This guideline to Major Types of Transportation Construction Specifications is published as a report of the Quality Construction Task Force of the AASHTO Highway Subcommittee on Construction. Because it has not been ballotted by the AASHTO Standing Committee on Highways and the AASHTO Board of Directors, it is not considered an official AASHTO guide or voluntary standard.

This Task Force Report was prepared by the Quality Construction Task Force of the AASHTO Highway Subcommittee on Construction. The Task Force principal author of the report is Mr. Gregory Doyle, Federal Highway Administration. The material in this document was adapted from the New England Transportation Technician Certification Program (NETTCP) Quality Assurance Technologist Pilot Course Manual (February 2001), co-authored by Mr. Robert Christman, Vanasse, Hangen, Brustlin, Inc. and Mr. Doyle. Photos, graphics, and assistance with document layout were provided by Mr. Richard Hamilton, Atech Center, Inc. Formal definitions have been included for each type of specification along with other minor revisions, based on feedback from members of the Subcommittee. The definitions were developed or modified using the most recent "Glossary of Highway Quality Assurance Terms" (TRB Circular No. E-C037, April 2002) and were reviewed by Mr. Peter Kopac, Secretary of the TRB Committee on Management of Quality Assurance (A2F03).

The initial draft document was presented at the August 2001 Subcommittee on Construction meeting. The members of the Construction Quality Task Force voted during the August 2002 Subcommittee meeting to publish this Task Force Report and authorized its distribution.

The Subcommittee on Construction welcomes comments on this Task Force Report, and will consider all that are received. The report may be updated as needed and published as an official AASHTO guide document in the future. Comments on this Task Force Report should be sent directly to AASHTO at the address provided below.

AASHTO Subcommittee on Construction

August 2003

American Association of State Highway and Transportation Officials

444 North Capitol Street, NW, Suite 249

Washington, D.C. 20001

Major Types of Transportation Construction Specifications

Guideline Overview

This document has been prepared to assist Transportation Agency and Contractor personnel in understanding different types of specifications that may be used. Over the past few decades, many transportation Agencies have moved from "Method Specifications" to "Quality Assurance Specifications". More recently, national research efforts have focused on the development and implementation of "Performance Related Specifications" and "Performance Based Specifications". These different specification types are sometimes not completely understood and are frequently referred to interchangeably.

Accordingly, this document explains how these different major types of transportation construction specifications have evolved as well as how they should be properly developed and applied. The following specification types are specifically presented:

- Method Specifications

- End-Result Specifications

- Quality Assurance Specifications

- Performance-Related Specifications

- Performance-Based Specifications

Method Specifications

Definition of Method Specifications

Most Transportation Agencies historically have used what are referred to as Method Specifications (Also called Materials & Methods Specifications, Recipe Specifications, or Prescriptive Specifications). Method Specifications are defined as follows:

Most Transportation Agencies historically have used what are referred to as Method Specifications (Also called Materials & Methods Specifications, Recipe Specifications, or Prescriptive Specifications). Method Specifications are defined as follows:

Method Specifications = "Specifications that require the Contractor to produce and place a product using specified materials in definite proportions and specific types of equipment and methods under the direction of the Agency."

Overview of Method Specifications

Method Specifications, which have been commonly used since the 1940's, place maximum control and responsibility in the hands of the specifying Agency. Typically, these types of specifications:

- Provide a "cookbook" with specific "recipes" for the Contractor to follow

- Utilize Agency inspection, sampling, and testing to control the work

- Base Acceptance on "reasonable conformance" or "substantial compliance"

- Pay 100% across a range of Quality

A Method Specification spells out exactly the equipment, methods, materials, and techniques a Contractor will be required to use. The Contractor or Producer is directed to combine specified materials in definite proportions and use specific types of equipment and methods in order to place the materials or product in a prescribed way. Each step is controlled and in many cases directed by a Transportation Agency representative. In effect, the Agency rents the Contractor's personnel and equipment. This type of specification does not allow the Contractor to be innovative.

A Method Specification spells out exactly the equipment, methods, materials, and techniques a Contractor will be required to use. The Contractor or Producer is directed to combine specified materials in definite proportions and use specific types of equipment and methods in order to place the materials or product in a prescribed way. Each step is controlled and in many cases directed by a Transportation Agency representative. In effect, the Agency rents the Contractor's personnel and equipment. This type of specification does not allow the Contractor to be innovative.

Some version of Method Specifications is still used today by many Agencies, but it usually includes a greater degree of materials testing than in the 1950's. In the early use of Method Specifications, little or no testing was done. The specifying Agency based acceptance primarily on inspection and did not, in many cases, have any defensible means to have production facilities producing non-compliant materials shut down, require correction or removal of deficient materials, or have payment adjusted. Acceptance was determined based upon "substantial compliance" with the specification requirements. Acceptance decisions under Method Specifications are rather arbitrary since there is no established quality level defined by the specification. Typically Method Specifications require only that the product "must conform reasonably or substantially". A specification under these terms is difficult to uniformly enforce and has questionable legality if the Contractor has met the materials and methods requirements, but is told that the work is not acceptable.

Some version of Method Specifications is still used today by many Agencies, but it usually includes a greater degree of materials testing than in the 1950's. In the early use of Method Specifications, little or no testing was done. The specifying Agency based acceptance primarily on inspection and did not, in many cases, have any defensible means to have production facilities producing non-compliant materials shut down, require correction or removal of deficient materials, or have payment adjusted. Acceptance was determined based upon "substantial compliance" with the specification requirements. Acceptance decisions under Method Specifications are rather arbitrary since there is no established quality level defined by the specification. Typically Method Specifications require only that the product "must conform reasonably or substantially". A specification under these terms is difficult to uniformly enforce and has questionable legality if the Contractor has met the materials and methods requirements, but is told that the work is not acceptable.

Even though today's Method Specifications may make greater use of test results for acceptance, they usually focus on test results for individual Field Samples. Each test result is usually checked against the specification values (typically a maximum and minimum value is specified). It must be recognized that focusing on individual test results ignores the inherent Variability in construction materials and relies on that single test result to determine the acceptability of large quantities of material. When an individual test "fails" under Method Specifications, it is difficult to determine whether to correct the process, shut down production, or reject/remove material placed. Many materials engineers have been faced with the dilemma of having to render a product acceptance or rejection based upon one sample. In short, it is like playing Russian Roulette! The one Field Sample could, just by chance, be an acceptable product representation or, just by chance, be representative of an inferior product.

Even though today's Method Specifications may make greater use of test results for acceptance, they usually focus on test results for individual Field Samples. Each test result is usually checked against the specification values (typically a maximum and minimum value is specified). It must be recognized that focusing on individual test results ignores the inherent Variability in construction materials and relies on that single test result to determine the acceptability of large quantities of material. When an individual test "fails" under Method Specifications, it is difficult to determine whether to correct the process, shut down production, or reject/remove material placed. Many materials engineers have been faced with the dilemma of having to render a product acceptance or rejection based upon one sample. In short, it is like playing Russian Roulette! The one Field Sample could, just by chance, be an acceptable product representation or, just by chance, be representative of an inferior product.

The inherent problems posed by acceptance based upon "substantial compliance" and/or individual test results make it difficult to establish any objective procedures for price adjustment. Method Specifications do not usually indicate whether or how contract prices should be adjusted for non-specification materials. Likewise, Method Specifications do not allow the Contractor to be rewarded for providing a higher quality product than called for in the specification. Under a method specification, Contractors typically receive 100% payment for the work completed, regardless of the level of quality.

Disadvantages of Method Specifications

In summary, the principal disadvantages of Method Specifications include:

In summary, the principal disadvantages of Method Specifications include:

- The Agency controls each step of the Contractor's operation.

- The Contractor may not be allowed to use the most economical or innovative procedures and equipment to produce the product sought.

- Materials Acceptance is based on inspection for "substantial conformance".

- Decisions based on test results of individual Field Samples can increase disputes and confrontation between the Contractor and Agency.

- Contractor payment is not linked to product quality or long-term performance.

End-Result Specifications

Definition of End-Result Specifications

The construction of the AASHO Road Test in 1958 provided the first step toward End-Result Specifications. End-Result Specifications are defined as follows:

The construction of the AASHO Road Test in 1958 provided the first step toward End-Result Specifications. End-Result Specifications are defined as follows:

End-Result Specifications = "Specifications that require the Contractor to take the entire responsibility for producing and placing a product. The Agency's responsibility is to either accept or reject the final product or to apply a price adjustment commensurate with the degree of compliance with the specifications."

Overview of End-Result Specifications

End-Result Specifications typically:

- Assign the Contractor complete responsibility and latitude in determining the procedures and equipment used to produce the product.

- Leave Quality Control sampling, testing, and inspection entirely at the discretion of the Contractor or Producer.

- Base Agency Acceptance on sampling and testing of the final in-place product.

- Determine a price adjustment based upon the degree of compliance with the specification criteria.

Under End-Result Specifications, the Contractor or Producer takes the entire responsibility for supplying a product or an item of construction. This type of specification does have the advantage of affording the Contractor the greatest amount of flexibility in exercising options for developing new techniques and procedures to perform the work and improve the quality of the end product. True End-Result Specifications place no restrictions on the materials to be used or the methods of incorporating them into the completed product. This is a well-meaning consideration, but is definitely outweighed by the inherent disadvantages.

Under End-Result Specifications, the Contractor or Producer takes the entire responsibility for supplying a product or an item of construction. This type of specification does have the advantage of affording the Contractor the greatest amount of flexibility in exercising options for developing new techniques and procedures to perform the work and improve the quality of the end product. True End-Result Specifications place no restrictions on the materials to be used or the methods of incorporating them into the completed product. This is a well-meaning consideration, but is definitely outweighed by the inherent disadvantages.

End-Result Specifications stress sampling and testing, as opposed to inspection, as the main measure of Agency Acceptance. "End-Result" is a term that defines the desired quality of the finished product. The specification either accepts or rejects the final product, or applies a penalty system that accounts for the degree of non-compliance. One of the principal objections to this type of a specification in the transportation construction industry is that a large quantity of material may be found to be defective after it is already in place, when there is very little opportunity for correction. This is very risky from the standpoint of the specifying Agency accepting undesirable product. It also discourages accumulating testing results throughout construction to obtain a more representative estimate of the product quality. Practically speaking, it is difficult to enforce such a specification and the implications are involved with legal procedures and concepts rather than sound engineering considerations.

Another problem with this type of specification is determining reasonable levels of acceptance and determining relationships between the materials properties and final product performance. The Acceptance limits used on the AASHO Road Test were developed by a panel of engineers who used their expertise to determine limits that they thought could be met by the Contractor and which would lead to the desired performance of the product. The testing from the AASHO Road Test, however, proved that the limits could not be met consistently. Specifications that have Acceptance limits based solely on subjective judgment are often difficult to meet due to a lack of definition of the capabilities of the production process and the desired product. An estimate of the desired target value and the variability that can be tolerated are necessary to establish realistic specification limits. However, a valid acceptance plan must be based on a scientific and engineering analysis of historical production data to establish practical target values and to identify inherent Normal Variability. Only when this is done can the specification be considered truly attainable and defensible.

Another problem with this type of specification is determining reasonable levels of acceptance and determining relationships between the materials properties and final product performance. The Acceptance limits used on the AASHO Road Test were developed by a panel of engineers who used their expertise to determine limits that they thought could be met by the Contractor and which would lead to the desired performance of the product. The testing from the AASHO Road Test, however, proved that the limits could not be met consistently. Specifications that have Acceptance limits based solely on subjective judgment are often difficult to meet due to a lack of definition of the capabilities of the production process and the desired product. An estimate of the desired target value and the variability that can be tolerated are necessary to establish realistic specification limits. However, a valid acceptance plan must be based on a scientific and engineering analysis of historical production data to establish practical target values and to identify inherent Normal Variability. Only when this is done can the specification be considered truly attainable and defensible.

One approach that can often lead to problems is to combine a Method Specification with End-Result testing. This is potentially a very controversial specification and very dangerous. If the Contractor is directed as to what equipment to use and how to use it, and an End-Result requirement is also imposed on the product, disputes frequently result. Combining stipulated methods with required end results may render such a specification legally indefensible.

Disadvantages of End-Result Specifications

The primary disadvantages of End-Result Specifications include:

The primary disadvantages of End-Result Specifications include:

- The responsibility for Quality Control is often not clearly defined.

- Acceptance decisions based on the results of limited testing of the in-place product do not provide for timely identification and correction of non-compliant material and may unfairly reject acceptable material.

- The specification Acceptance target values and limits are often based on subjective "experience" rather than an analysis of historical data.

Quality Assurance Specifications

Definition of Quality Assurance Specifications

The use of Quality Assurance Specifications, which were initially called "Statistically-Based Specifications", began in the 1960's. Quality Assurance Specifications are defined as follows:

Quality Assurance Specifications = "Specifications that require Contractor Quality Control and Agency Acceptance activities throughout production and placement of a product. Final acceptance of the product is usually based on a statistical sampling of the measured quality level for key Quality Characteristics."

Overview of Quality Assurance Specifications

The Quality Assurance Specification is a more rational form of specification that clearly delineates Contractor and Agency responsibilities and determines payment on the measured construction quality level. Quality Assurance Specifications:

The Quality Assurance Specification is a more rational form of specification that clearly delineates Contractor and Agency responsibilities and determines payment on the measured construction quality level. Quality Assurance Specifications:

- Recognize the inherent Variability of materials

- Assign Quality Control (QC) sampling, testing, and inspection to the Contractor

- Include Acceptance sampling, testing, and inspection by the Agency

- Identify the specific Quality Characteristics to be measured for Acceptance

- Provide price adjustments related to quality level of the product

Quality Assurance specifications are to be both practical and realistic because they are to provide a rational means for achieving the highest overall quality of the material or construction, while recognizing and providing for the Variability of the process and product. Quality Assurance Specifications for transportation construction were derived from U.S. Department of Defense specifications (Military Standard 414 - Sampling Procedures and Tables for Inspection by Variables for Percent Defective). This was the introduction of the Quality Assurance Specification as we know it today. This type of specification is based on proven mathematical probability (statistical) principles for Normal Variability that provides for a more realistic assessment of the degree of conformance to the specification criteria.

Under a Quality Assurance Specification, the Contractor is responsible for Quality Control (QC) and the Transportation Agency is responsible for Acceptance of the product. Placing responsibility for Quality Control sampling, testing, and inspection in the hands of the Producer and Contractor is consistent with what is normally required in virtually all other business sectors that manufacture or produce products (e.g. electronics, appliances, automobiles, airplanes, food items). As part of their Acceptance responsibilities, Agency technicians and inspectors must monitor the Contractor's QC activities and still have a responsibility for Acceptance sampling, testing, and inspection.

The specifying Agency must determine what material attributes (Quality Characteristics) are essential to good performance and what the limits are within which the material or work can be produced to assure good performance over the design life of the transportation product. This requires astute materials engineering. For Hot Mix Asphalt (HMA) pavements, an example of two principal Quality Characteristics that can be measured, which are critical to good pavement performance, are the density of the compacted pavement and pavement smoothness. For Portland Cement Concrete (PCC) structures and pavements, we can use compressive strength, air content and smoothness. Soils properties that can be measured for good performance may include in-place density and gradation.

Quality Assurance Specifications normally determine price adjustment based upon a mathematical assessment of the measured Variability of the product. Although pay factors have sometimes been included in Quality Assurance Specifications due to the concerns of Contractors, it cannot be overemphasized that pay adjustment linked to measured quality levels is intended to provide both the Contractor and the Agency with a more equitable measure of value received. Usually, Quality Assurance Specifications provide:

Quality Assurance Specifications normally determine price adjustment based upon a mathematical assessment of the measured Variability of the product. Although pay factors have sometimes been included in Quality Assurance Specifications due to the concerns of Contractors, it cannot be overemphasized that pay adjustment linked to measured quality levels is intended to provide both the Contractor and the Agency with a more equitable measure of value received. Usually, Quality Assurance Specifications provide:

- Increased payment (typically 101-105%) for superior quality work.

(Note: Some Agencies may pay as much as 110-115%) - Reduced payment (typically 0-99%) for lesser quality work.

Work that is determined to be below a minimum quality level is normally rejected by the Agency and may be subject to reduced payment, removal and replacement, or some other corrective action.

Advantages of Quality Assurance Specifications

As briefly discussed above, some of the key features and corresponding advantages of Quality Assurance Specifications include the following:

As briefly discussed above, some of the key features and corresponding advantages of Quality Assurance Specifications include the following:

- QA Specifications are mathematical probability based specifications that utilize Random Sampling and Lot-by-Lot testing.

- QA Specifications let the Contractor know if his operations are producing an acceptable product on a real-time basis.

- QA Specifications do not state the percentage of the individual measurements or individual test results that must be in compliance (This is an important distinction, because in the mathematical probability approach, individual measurements are not the most significant item. It is the information gained from the multiple measurements within an entire Lot that is important).

- QA Specifications use Limits of Acceptance (LOA) derived using mathematical probability principles and the actual Normal Variability of local materials.

- QA Specifications specify, for each Quality Characteristic, the percentage of material in a Lot that must be within the specified limits in order for the Lot to be considered acceptable (Under the old Method Specifications, as well as some End-Result Specifications, it was not possible, or at best difficult, to know the percentage of the material not complying with the specifications).

- QA Specifications provide a rational mechanism to award increased payment for higher quality work and to apply reduced payment or corrective action for lesser quality work.

Performance-Related Specifications

Definition of Performance-Related Specifications

Since the late 1980's, the evolution of transportation construction specifications has focused on the development of Performance-Related Specifications. At a May 2000 workshop conducted by the Florida DOT, FHWA, and the NQI, the following technical definition of Performance-Related Specifications emerged:

Performance-Related Specifications = "Specifications that use quantified Quality Characteristics and Life Cycle Cost (LCC) relationships that are correlated to product performance."

From a management standpoint, Performance-Related Specifications are seen as "the bridge between construction quality and long-term product performance".

Overview of Performance-Related Specifications

Simply put, Performance-Related Specifications are improved Quality Assurance Specifications. The major distinguishing features of Performance-Related Specifications include:

Simply put, Performance-Related Specifications are improved Quality Assurance Specifications. The major distinguishing features of Performance-Related Specifications include:

- Acceptance based on key Quality Characteristics that have been found to correlate with fundamental engineering properties that predict performance.

- Mathematical models used to quantify the relationship between key materials and construction Quality Characteristics and product performance.

- Price adjustments related to the expected Life-Cycle Cost (LCC) of the constructed transportation facility.

Performance-Related Specifications attempt to relate the material attributes (Quality Characteristics) being measured to the likely performance of the in-place product. Like Quality Assurance Specifications, however, they specify only the product Quality Characteristics measured at the time of construction, and do not specify the desired long-term product performance.

The tests used to determine Acceptance with Performance-Related Specifications are selected because the Quality Characteristics being measured relate in some way to the performance of the product. Some examples of Quality Characteristics that relate to the long-term performance of transportation facilities include:

- The total in-place Air Voids or Ride Smoothness of Hot Mix Asphalt pavements.

- The Permeability or the Strength of Portland Cement Concrete.

These Quality Characteristics lend themselves to Acceptance sampling and testing at the time of construction.

True Performance-Related Specifications not only describe the desired levels of these Quality Characteristics, but also employ the quantified relationships (i.e., mathematical models) containing the characteristics to predict subsequent product performance. The use of quantifiable models is a feature that distinguishes Performance-Related Specifications from other transportation construction specifications. The models are based on data and present a much clearer picture of what influences a constructed product's performance than can be visualized through engineering judgment and intuition alone. With recent research that has been conducted under the Strategic Highway Research Program (SHRP), and by the FHWA and the National Cooperative Highway Research Program (NCHRP), it is now possible to relate the specifications to the predicted performance of the product.

True Performance-Related Specifications not only describe the desired levels of these Quality Characteristics, but also employ the quantified relationships (i.e., mathematical models) containing the characteristics to predict subsequent product performance. The use of quantifiable models is a feature that distinguishes Performance-Related Specifications from other transportation construction specifications. The models are based on data and present a much clearer picture of what influences a constructed product's performance than can be visualized through engineering judgment and intuition alone. With recent research that has been conducted under the Strategic Highway Research Program (SHRP), and by the FHWA and the National Cooperative Highway Research Program (NCHRP), it is now possible to relate the specifications to the predicted performance of the product.

Performance-Related Specifications contain two types of models:

- Performance-prediction Models

- Maintenance-cost Models

Performance-prediction Models predict when and to what extent a construction product (such as a pavement) will exhibit a given type of distress, such as fatigue cracking or joint spalling. Maintenance-cost Models estimate the post-construction Life-Cycle Cost (LCC), which is the cost of maintenance and rehabilitation necessary throughout the projected life of the product. Inputs for these models include design variables (such as traffic loading, climatic factors, drainage, soil factors) and Quality Characteristics (such as Asphalt Binder Content & Air Voids, Concrete Permeability & Strength, and Ride Smoothness).

These models provide the basis for rational acceptance and/or pay adjustment decisions. Pay adjustments are determined by determining two different LCCs:

- The "As-Designed LCC"

- The "As-Constructed LCC

The As-Designed LCC is determined by using the target values of the specified Quality Characteristics as inputs to the Models. The As-Constructed LCC is determined by using the actual measured values of a construction project's Quality Characteristics as input. The difference between the As-Designed LCC and the As-Constructed LCC is the basis for any pay adjustment.

Development of Performance-Related Specifications

To date, only a handful of Transportation Agencies have developed true Performance-Related Specifications. Obviously, the ability to develop and utilize valid Performance-Related Specifications is dependent upon having reasonable Performance-prediction Models and Maintenance-cost Models. These models can only be developed and validated through good quality data, including:

To date, only a handful of Transportation Agencies have developed true Performance-Related Specifications. Obviously, the ability to develop and utilize valid Performance-Related Specifications is dependent upon having reasonable Performance-prediction Models and Maintenance-cost Models. These models can only be developed and validated through good quality data, including:

- Pavement and Bridge performance data

- Construction quality data

- Construction cost data

- Maintenance cost data

Transportation Agencies should utilize their Management Systems (Pavement, Bridge and Maintenance) to collect this data and generate the required Performance-prediction Models and Maintenance-cost Models. Unfortunately, many Management Systems do not include all of the above data files and the related LCC data. Many Management Systems cannot relate loss in performance (as measured by condition deterioration, ride, and structural value) to a particular construction specification family or to the measured "as-built" material/construction Quality Characteristics. In the absence of Agency specific data, recent and ongoing research by the FHWA and NCHRP has generated some models for the development of Performance-Related Specifications.

Performance-Based Specifications

Definition of Performance-Based Specifications

Sitting much further on the horizon in the evolution of transportation construction specifications are Performance-Based Specifications. Transportation Research Circular Number E-C037 (April 2002) formally defines Performance-Based Specifications as follows:

Performance-Based Specifications = "Quality Assurance Specifications that describe the desired levels of fundamental engineering properties (e.g. resilient modulus, creep properties, and fatigue) that are predictors of performance and appear in primary prediction relationships (i.e. models that can be used to predict stress, distress, or performance from combinations of predictors that represent traffic, environment, supporting materials, and structural conditions)."

Overview of Performance-Based Specifications

Performance-Based Specifications are different from Performance-Related Specifications in that they specify the desired levels of the actual fundamental engineering properties (not the key Quality Characteristics) that are predictors of performance. The fundamental engineering properties specified (e.g., resilient modulus, creep properties, and fatigue properties) are used in performance prediction relationships (i.e., mathematical models) that can be used to predict stress, distress, or performance from combinations of predictors that represent traffic, environmental, and structural conditions. In the true sense, Performance-Based Specifications are concerned with the performance of the final in-place product and not how it was built.

Performance-Based Specifications are different from Performance-Related Specifications in that they specify the desired levels of the actual fundamental engineering properties (not the key Quality Characteristics) that are predictors of performance. The fundamental engineering properties specified (e.g., resilient modulus, creep properties, and fatigue properties) are used in performance prediction relationships (i.e., mathematical models) that can be used to predict stress, distress, or performance from combinations of predictors that represent traffic, environmental, and structural conditions. In the true sense, Performance-Based Specifications are concerned with the performance of the final in-place product and not how it was built.

The primary features of Performance-Based Specifications include:

- Acceptance based on measurement of the finished product's fundamental engineering properties that predict performance.

- Acceptance limits which are established using a statistically valid basis.

- Mathematical models used to quantify the relationship between the fundamental engineering Properties measured and product performance.

- Price adjustments based on the expected Life-Cycle Cost (LCC) of the constructed transportation facility.

Status of Performance-Based Specifications

Complete Performance-Based Specifications do not yet exist. The Superpave Performance Graded Asphalt Binder (PGAB) specifications, which were developed through the SHRP research program, are an example of a partial Performance-Based Specification. However, PGAB is only one component of the final product. All of a product's constituent materials and their related fundamental engineering properties must be included in order to have complete models to predict performance of that product. Other performance-based test methods have not been fully developed. Performance-based test methods that have been developed are not yet user-friendly enough to permit timely Acceptance testing. Further development and validation of performance-based tests is currently underway through FHWA, NCHRP, and TRB research programs.

Complete Performance-Based Specifications do not yet exist. The Superpave Performance Graded Asphalt Binder (PGAB) specifications, which were developed through the SHRP research program, are an example of a partial Performance-Based Specification. However, PGAB is only one component of the final product. All of a product's constituent materials and their related fundamental engineering properties must be included in order to have complete models to predict performance of that product. Other performance-based test methods have not been fully developed. Performance-based test methods that have been developed are not yet user-friendly enough to permit timely Acceptance testing. Further development and validation of performance-based tests is currently underway through FHWA, NCHRP, and TRB research programs.

In addition, true Performance-Based Specifications will require good Management System data to generate and validate the models required to determine price adjustments based on expected Life-Cycle Costs. As discussed, previously, most Agency Management Systems do not presently collect and evaluate all of the data necessary to develop the required performance and cost models. Accordingly, Performance-Based Specifications have not yet emerged as a viable tool for Transportation Agencies.

Development of Quality Assurance Specifications

Quality Assurance requires engineering up front. Before a valid Quality Assurance Specification can be developed and implemented with incentive/disincentive provisions, a considerable amount of materials engineering must be utilized. Quality Assurance Specifications require more engineering knowledge of the product than do Method Specifications or End-Result Specifications.

The development of a Quality Assurance Specification requires six principal steps:

- Identify the Contractor QC and Agency Acceptance responsibilities and procedures.

- Define the material attributes (Quality Characteristics) which should be sampled, tested, and inspected for QC and Acceptance.

- Identify the Measure of Quality (MOQ) to be applied for acceptance of the Quality Characteristics (e.g. Mean, Percent Defective, Percent Within Limits).

Develop and validate mathematical probability based Limits of Acceptance (LOA) for each Quality Characteristic.

Develop and validate mathematical probability based Limits of Acceptance (LOA) for each Quality Characteristic.- Develop and validate procedures for determining pay adjustments linked to the measured quality level for each Quality Characteristic.

- Assign and validate the Acceptance risks for both the Agency (Buyer) and the Contractor (Seller).

These six steps are necessary for the initial drafting of a Pilot Quality Assurance Specification and are briefly described below.

Step #1 - Identify QC and Acceptance Responsibilities

First, Quality Assurance Specifications should clearly state the Contractor Quality Control and Agency Acceptance responsibilities and procedures. Key Items that should be addressed include:

First, Quality Assurance Specifications should clearly state the Contractor Quality Control and Agency Acceptance responsibilities and procedures. Key Items that should be addressed include:

- QC Plan requirements

- Contractor Mix Design submittal and Agency verification

- Plant and Field production verification (Control Strips)

- Use of QC test results, QC Inspection, and Control Charts to monitor work

- Use of QC test results for Acceptance

- Agency Inspection and Acceptance procedures

Step #2 - Define Sampling & Testing Requirements

In the second step, the material attributes (Quality Characteristics) that are required to be sampled, tested, and inspected for Contractor Quality Control and for Agency Acceptance must be determined and clearly stated in the Quality Assurance Specification. The information that should be specified includes:

- The individual Quality Characteristics to be sampled and tested

(e.g. PG Binder, HMA Air Voids, PCC Strength, Ride Smoothness) - The location of sampling

- The test methods to be used

- The frequency of Quality Control and Acceptance sampling and testing

- The Quality Characteristics selected should be related to product performance. They should also be measurable.

The method of test to judge compliance and the point of sampling must be stated in the specification. The method of test must be stated because different methods have different within-test Variability. This impacts the Limits of Acceptance (LOA). While there may be several choices for the point of sampling, a single point must be specified for each Quality Characteristic. The test methods and sampling locations ultimately specified in a Quality Assurance Specification should be the same as those used for the Pilot Project data evaluated to establish the Limits of Acceptance in the specification.

The method of test to judge compliance and the point of sampling must be stated in the specification. The method of test must be stated because different methods have different within-test Variability. This impacts the Limits of Acceptance (LOA). While there may be several choices for the point of sampling, a single point must be specified for each Quality Characteristic. The test methods and sampling locations ultimately specified in a Quality Assurance Specification should be the same as those used for the Pilot Project data evaluated to establish the Limits of Acceptance in the specification.

The proper number of Field Samples (frequency) required for QC and Acceptance is associated with the risk that the specification writer selects in the specification development. It should be recognized that one or two Field Samples do not present a valid picture of the associated Variability of a particular Quality Characteristic being tested. Sound mathematical (statistical) procedures require a minimum of three Field Samples to present a valid picture of the Quality Characteristic being measured.

Step # 3 - Identify the Measure of Quality for Acceptance

In the third step, the Measure of Quality (MOQ) to be used for acceptance must be selected. The term Measure of Quality (also referred to as the "Quality Measure") is defined as follows:

Measure of Quality = "Any one of several mathematical tools that are used to quantify the level of quality of an individual Quality Characteristic."

Typical MOQs used in Quality Assurance Specifications are selected because they quantify the average quality, the variability, or both.

Measures of Quality that may be used include:

- The Mean

- The Standard Deviation

- The Percent Defective (PD)

- The Percent Within Limits (PWL)

- The Average Absolute Deviation (AAD)

- The Moving Average

- The Conformal Index (CI)

For example, the Mean of all strength test results might be specified as the Measure of Quality for a Lot of Portland Cement Concrete. Or, the Percent Within Limits (PWL) of all in-place density test results might be used as the MOQ for a Lot of Hot-Mix Asphalt. PWL is the Measure of Quality that is most often recommended for use in Quality Assurance Specifications.

Step #4 - Develop and Validate Limits of Acceptance

The fourth step requires the development and validation of mathematical probability based Limits of Acceptance (LOA) for each Quality Characteristic. The two types of LOA that are typically included in Quality Assurance Specifications are:

The fourth step requires the development and validation of mathematical probability based Limits of Acceptance (LOA) for each Quality Characteristic. The two types of LOA that are typically included in Quality Assurance Specifications are:

- Specification Limits

- Engineering Limits

Specification Limits are statistical limits that are applied when evaluating the quality of a Lot using some Measure of Quality such as PWL. They are usually comprised of an Upper Specification Limit (USL), a Lower Specification Limit (LSL), or both. It is important to recognize that since these are statistical limits, individual Field Sample test results may fall beyond the USL or LSL and still be included in the Acceptance determination.

Engineering Limits are sometimes used in conjunction with Specification Limits. They may also be applied without the use of Specification Limits. As an example, strength test results for Portland Cement Concrete are typically evaluated using the Mean of three consecutive test results, but still require that no individual test result falls below a specified Engineering Limit. An Engineering Limit provides an absolute threshold value for individual Field Samples. Engineering Limits are established to identify material that does not provide the minimum required engineering properties. They usually have an Upper Engineering Limit (UEL), a Lower Engineering Limit (LEL), or both. Individual Field Sample test results that fall beyond the Engineering Limits are considered to represent material that appears to be below an acceptable level and which should be further evaluated to determine an appropriate disposition.

One of the challenges of transitioning into Quality Assurance Specifications is that much of an Agency's past historic test data cannot be used to establish the LOA. Although many Agencies do use this past data to set the initial targets and limits for the various Quality Characteristics, it must be realized that these test results were often based upon Representative, Uniform Interval, or Quota Sampling. This non-random data will present bias, which may result in Limits of Acceptance that are too loose or too stringent.

One of the challenges of transitioning into Quality Assurance Specifications is that much of an Agency's past historic test data cannot be used to establish the LOA. Although many Agencies do use this past data to set the initial targets and limits for the various Quality Characteristics, it must be realized that these test results were often based upon Representative, Uniform Interval, or Quota Sampling. This non-random data will present bias, which may result in Limits of Acceptance that are too loose or too stringent.

To develop appropriate mathematical probability based LOA, an Agency must have representative data that reflects the known Variability of the materials produced. What is needed to properly determine the targets and limits for each Quality Characteristic is data collected using multiple Random Field Samples under controlled conditions.

Pilot Specification Limits of Acceptance have to be tried and tested using Pilot Projects in order to establish a substantial database of product Variabilities. The materials and construction quality level from various Pilot Project Contractors and Producers will have to be analyzed to determine representative inherent Normal Variability. The final Quality Assurance Specification Limits of Acceptance should be established using known local Variability, in conjunction with good national industry standards, for each Quality Characteristic.

Step #5 - Develop and Validate Pay Adjustments

Step number five in preparing Quality Assurance Specifications requires the development and validation of pay adjustment procedures that are linked to the computed quality level for each Quality Characteristic. The Measure of Quality typically specified by Agencies to compute the quality level is known as Quality Level Analysis (QLA) - Standard Deviation Method.

QLA is a mathematical (statistical) procedure that estimates the percent of a Lot that is within the Specification Limits which is referred to as the "Percent Within Limits" (PWL). The PWL for each Quality Characteristic is calculated using the arithmetic Mean and Standard Deviation of the Acceptance Field Sample test results for a given Lot of material.

QLA is a mathematical (statistical) procedure that estimates the percent of a Lot that is within the Specification Limits which is referred to as the "Percent Within Limits" (PWL). The PWL for each Quality Characteristic is calculated using the arithmetic Mean and Standard Deviation of the Acceptance Field Sample test results for a given Lot of material.

The Quality Assurance Specification then assigns a specific Pay Factor (typically ranging from 0.75 to 1.05), which may be related to the number of Acceptance samples, for each PWL value. The Pay Factor is subsequently applied to the Lot quantity and corresponding contract unit price to compute a pay adjustment.

Pay adjustment procedures in a Quality Assurance Specification should be simulated on early Quality Assurance Pilot Projects. Once a sufficiently large pool of Pilot Project Acceptance Field Sample test results has been collected, the PWL values and corresponding pay adjustments, both within and across all Pilot Projects, should be evaluated. This will provide an objective assessment of the reasonableness of the pay adjustments compared to the established specification targets and limits.

Pay adjustment procedures in a Quality Assurance Specification should be simulated on early Quality Assurance Pilot Projects. Once a sufficiently large pool of Pilot Project Acceptance Field Sample test results has been collected, the PWL values and corresponding pay adjustments, both within and across all Pilot Projects, should be evaluated. This will provide an objective assessment of the reasonableness of the pay adjustments compared to the established specification targets and limits.

Based upon the analysis of Pilot Project price adjustments, Specification Limits and/or Pay Factors may be revised to ensure that payment is properly related to the constructed quality level and expected product performance. Accordingly, price adjustments should only be simulated on early Pilot Projects and should then be gradually phased in over several years.

Step #6 - Assign and Validate Buyer and Seller Risks

In the last step, the specifying Agency should analyze and set the Acceptance risks involved in performing work under a Quality Assurance Specification. The Agency (Buyer) can evaluate their risk of accepting what is actually bad material against the Contractor (Seller) who stands a risk of having good material rejected. These risks are generally defined by the following terms:

In the last step, the specifying Agency should analyze and set the Acceptance risks involved in performing work under a Quality Assurance Specification. The Agency (Buyer) can evaluate their risk of accepting what is actually bad material against the Contractor (Seller) who stands a risk of having good material rejected. These risks are generally defined by the following terms:

- Seller's (Contractor's) Risk = Alpha (a)

- Buyer's (Agency's) Risk = Beta (b)

The Alpha and Beta risks must be analyzed and in a well-written Quality Assurance Specification are, ideally, balanced. These risks are typically set in the 5% plus or minus range for both the Agency and the Contractor. Suggested Alpha and Beta risk levels are provided in the AASHTO Standard Recommended Practice for Acceptance Sampling Plans for Highway Construction (AASHTO R 9-97).

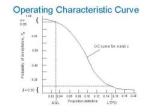

Operating Characteristic (OC) Curves and Expected Pay (EP) Curves can assist in establishing a balanced sharing of risk. An OC Curve provides a graphical presentation of the relationship between the quality level (PWL) of a Lot versus the probability of acceptance. An EP Curve provides a graphical presentation of the quality level (PWL) versus the expected Pay Factor.

Operating Characteristic (OC) Curves and Expected Pay (EP) Curves can assist in establishing a balanced sharing of risk. An OC Curve provides a graphical presentation of the relationship between the quality level (PWL) of a Lot versus the probability of acceptance. An EP Curve provides a graphical presentation of the quality level (PWL) versus the expected Pay Factor.

The Contractor's Risk (a) can be determined on the OC Curve at the Acceptable Quality Level (AQL), where AQL is defined as:

AQL = Minimum level of acceptable quality (PWL) for 100% payment

The Agency's Risk (b) can be determined on the OC Curve at the Rejectable Quality Level (RQL), where RQL is defined as:

RQL = Minimum level of quality (PWL) at which work may be accepted

The smaller the Acceptance Population Sample size (number of Field Samples) the greater the Agency risk (b). Increasing the Acceptance Population Sample size will reduce the Agency's Risk. The only way to reduce both the Agency's Risk and Contractor's Risk is to increase the number of Field Samples used for Acceptance.

Each of the six steps, particularly the last three, should be revisited through a phased implementation of Pilot Specifications as discussed above. Full implementation of a Quality Assurance Specification will take at least five years. Pilot Quality Assurance Specifications are needed during this time to:

- Collect meaningful data on local material variability

- Develop appropriate Acceptance targets and limits

- Assess Agency and Contractor risks

- Implement price adjustments that are fair

In time, with a large database of good random test results, Quality Assurance Specification targets and limits can be developed around known product Normal Variabilities. Also in time, risks will be assigned that will be fair to both the Contractor (Seller) and the Agency (Buyer).

Transportation Construction Specifications Summary

The evolution of transportation construction specifications began with prescriptive and inspection-intensive Method Specifications. Some Agencies considered but eventually dismissed End-Result Specifications. Due to a shortcoming of End-Result Specifications in relating quality to known Variability and expected product performance, Quality Assurance Specifications have evolved. The future will see Performance-Related Specifications and perhaps Performance-Based Specifications.

With Quality Assurance Specifications, transportation products can be evaluated using material Quality Characteristics that are related to long-term product performance. As Transportation Agencies collect and evaluate actual performance data against as-constructed quality levels, Quality Assurance Specifications can be continually improved.

Agencies should establish an ultimate goal of implementing Performance-Related Specifications, eventually followed by true Performance-Based Specifications. Before this can be achieved, however, it is necessary to first implement a properly developed Quality Assurance Specification.

| Contents |