The Signal, Spring 2008

FHWA-INDUSTRY PARTNERSHIPS TEST WORK ZONE SAFETY INNOVATIONS

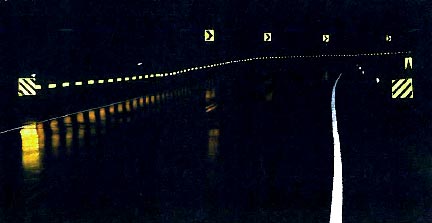

Photo Credit: 3M. 3M is adapting its all-weather pavement marking system, which maintains visibility under wet conditions, to enhance safety in highway work zones.

Under the program, FHWA awarded grants to five companies to further develop technologies now at the prototype stage in partnership with transportation agencies. The goal is to test promising technologies designed to cut congestion or boost highway quality and safety in real-world settings and move them closer to market.

FHWA also provided funds to companies to refine and test an asphalt binder cracking device, an intelligent asphalt compaction analyzer and an aggregate imaging system. It's the first time the federal agency has awarded grants directly to industry.

"The highway industry has been evolving over the past few years to be more welcoming of private sector innovations, especially in the safety sector. With the array of challenges facing the highway industry today, the time is ripe to leverage private sector ingenuity," said FHWA Associate Administrator King Gee. "Through the Technology Partnerships Program, we hope to accelerate that engagement."

All-Weather Pavement Marking System

Wet conditions reduce the retroreflectivity of conventional pavement markings, which have glass beads dropped onto the paint, making it difficult for drivers to see the markings on rainy nights. This is particularly dangerous in work zones, where drivers may encounter unfamiliar traffic patterns.

3M has developed an all-weather paint system that is highly reflective in both dry and rainy conditions. The system consists of high-build waterborne paint, typical glass beads, and optical elements made of a ceramic core surrounded by high-refractive index beads that provide retroreflectivity under wet conditions, especially rain. With its FHWA grant, the company plans to customize the product for use in work zones.

"Safety is a critical issue in work zones, and when it rains it gets even riskier," said Dr. Fuat Aktan of 3M's Traffic Safety Systems Division. "The last thing drivers in a work zone want to deal with is not seeing their lane. Our system sustains visibility of pavement markings in wet and dry conditions so drivers can deal effectively with the other challenges of work zones."

The company plans to adapt the pavement marking system so that it maintains optimal visibility, but also meets work zone requirements such as flexible durability and faster application and drying times, Aktan said.

By changing variables in the paint mixture, the company developed more than 20 different samples that are being evaluated on a New Orleans, Louisiana, roadway under normal traffic conditions. Next, three refined samples will undergo visibility and human-factor experiments at a testing facility operated by project partner Texas Transportation Institute in College Station, Texas.

In the second phase of the project, subject to FHWA approval, the final product will be evaluated in real-world work zones. A few state highway agencies have already expressed interest in participating in tests of the pavement marking system, Aktan said, and 3M is contacting additional agencies to improve the chances of having rainy conditions during field evaluations.

Automated Pavement Marker Placement System

Raised reflective pavement markers enhance roadway safety by enabling drivers to see lanes at night, but the process of installing them manually exposes highway workers to safety risks. Typically, a worker rides on a cantilever seat under a truck, inches from oncoming traffic, and installs the markers by hand one by one.

Stay Alert is working in partnership with the Illinois Institute of Technology and Detail Technologies Inc. of Wyoming, Michigan, to develop an automated system to make installation of pavement markers safer. The prototype system, which fits on the back of a flatbed truck, applies adhesive and drops markers into place with a robotic arm.

"The entire system is operated by a computer in the cab, which removes workers from the danger of direct exposure to oncoming traffic," said Stay Alert Project Manager Tony Collins.

While the number-one goal in developing the system is to improve safety, Collins said, initial tests showed that it also has the potential to reduce construction time and the resulting congestion.

System refinements are aimed at improving the efficiency and reliability of the system components that hold and dispense the markers, apply the adhesive, mount the hardware components on the truck, and operate the system from the truck cab. Once the refinements are completed, Collins said, the company plans to conduct tests on the system components and then full-scale field tests on projects to install pavement markers.

Not only are state highway agencies anxious to see the automated system in action, Collins said, other companies that install pavement markers have also expressed interest in the technology because of its potential to improve work zone safety.

"They recognize that manual installation of pavement markers is a serious safety risk to their employees," he said. "Not many people want to get under that truck."

To Learn More

For more information on the FHWA Technology Partnerships Program, contact Julie Zirlin at (202) 366-9105 or julie.zirlin@dot.gov.

For more information on 3M's all-weather pavement marking system, contact Fuat Aktan at (651) 733-5041 or faktan@mmm.com. For more information on Stay Alert's automated pavement marker placement system, contact Jim Babcock at (336) 993-2828 or jbabcock@stayalertsafety.com, or Tony Collins at (336) 993-2828 or tcollins@stayalertsafety.com.