Reactive Solutions - An FHWA Technical Update on Alkali-Silica Reactivity

Volume 5, Issue 2, April 2012

Welcome to the newest edition of Reactive Solutions, a Technical Update on Alkali-Silica Reactivity (ASR) issues. This periodical disseminates important ASR subject matter from a variety of sources, including the Federal Highway Administration's ASR Program. The program's goal is to deploy methods that state highway agencies can use to prevent and mitigate ASR. This goal is being achieved through technology transfer, including real-world field trials, demonstration projects, and tools for practitioners to address ASR in their state. This periodical helps achieve the program's goal by providing readers with the tools and information needed to address this complex concrete distress problem.

Inside this Issue:

- Nebraska Department of Roads Evaluating Statewide Aggregate Reactivity

- ASR Discovered at Seabrook Station Nuclear Power Plant

- 14th International Conference on Alkali-Aggregate Reaction Kicks Off May 20th in Austin, TX

- Federal Aviation Administration Updates ASR Specification

- Schedule of Events

Nebraska Department of Roads Evaluating Statewide Aggregate Reactivity

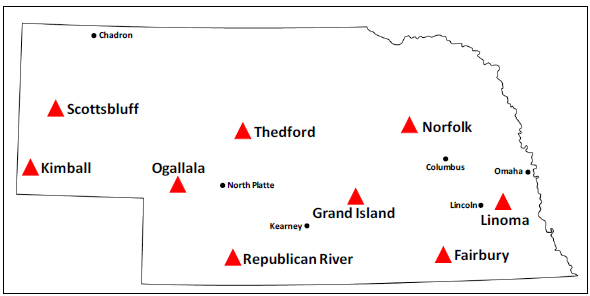

Due to a long history of alkali-silica reactivity (ASR) in Nebraska, the Nebraska Department of Roads (NDOR) began a long-term investigation in 2009 to study the nature of aggregate reactivity from various locations across the state. This research aims to provide NDOR with an overall understanding of the level of aggregate reactivity for each aggregate source shown in Figure 1. In addition, this study will be used to evaluate NDOR's current specifications for ASR testing and potential changes to supplementary cementing material (SCM) replacement levels. A database fully categorizing the reactivity of Nebraska's principal aggregate sources will also be created.

Figure 1. Map of aggregate sources under evaluation.

A laboratory investigation was conducted in two phases. Phase I evaluated nine different aggregates and type of cement (Type I/II) in accordance with ASTM C1293 (Standard Test Method for Determination of Length Change of Concrete Due to Alkali-Silica Reaction). Analysis of the test results was based on the American Association of State Highway and Transportation Officials (AASHTO) PP 65-10 (2010) special provision guide, “Determining the Reactivity of Concrete Aggregate and Selecting Appropriate Measures for Preventing Deleterious Expansion in New Construction.” For each aggregate, this guide was used to classify the degree of aggregate reactivity and ultimately determine the overall level of risk due to ASR. Through the Phase I evaluation, which is summarized in Table 1, it was found that all aggregates resulted in moderate to very high reactivity levels.

| Aggregate Location | ASTM C1293 1-Year Expansion (%) | Description of Aggregate Reactivity | Aggregate Reactivity Class |

|---|---|---|---|

| Grand Island | 0.09 | Moderately Reactive | R1 |

| Kimball | 0.21 | Highly Reactive | R2 |

| Republican River | 0.45 | Very Highly Reactive | R3 |

| Scottsbluff | 0.15 | Moderately Reactive | R2 |

| Ogallala | 0.06 | Moderately Reactive | R1 |

| Thedford | 0.19 | Highly Reactive | R2 |

| Fairbury | 0.10 | Moderately Reactive | R1 |

| Norfolk | 0.30 | Very Highly Reactive | R3 |

| Linoma | 0.15 | Moderately Reactive | R2 |

Phase II of the laboratory investigation is currently underway and serves as a continuation of Phase I. The same aggregate sources analyzed in the initial phase will be tested according to ASTM C1293 using a NDOR specified Type I-P blended cement with 25% Class F fly ash replacement. So far, the current evaluation has proven that NDOR’s standard specification adequately addresses aggregate reactivity across the state.

For more information about this research project, please contact Lieska Halsey (NDOR Research) at Lieska.Halsey@nebraska.gov.

ASR Discovered at Seabrook Station Nuclear Power Plant

Alkali-silica reactivity (ASR) was recently discovered at the Seabrook Station Nuclear Power Plant, becoming the first documented case of ASR at a United States nuclear facility. This plant is operated by NextEra Energy and is located on 900 acres of the southern New Hampshire seacoast, as shown in Figure 2. During a routine inspection, plant officials observed small, shallow cracks on the walls of an electric control tunnel (see Figure 3). The tunnel, which is roughly 100 yards in length and fully encased in concrete, contains electrical wires that connect the control center to machinery located throughout the sprawling plant. After concrete degradation was identified, over 30 core samples were taken and sent to independent labs in New Hampshire, Massachusetts, and Illinois for short and long-term testing. Test results have confirmed the presence of ASR, including a 22% loss in concrete compressive strength. The impact of additional moisture introduced by frequent groundwater infiltration at the exterior walls of the tunnel was also examined. Fortunately, it was found that ASR was not worse in these outermost areas.

Figure 2. Seabrook Station.

Figure 3. Tunnel affected by ASR.

It was not immediately apparent why ASR was discovered only recently. During the construction phase prior to the plant's opening in 1990, ASR was not predicted by the accepted test methods at the time, ASTM C289 (Standard Test Method for Potential Alkali-Silica Reactivity of Aggregates (Chemical Method)) and ASTM C295 (Standard Guide for Petrographic Examination of Aggregates for Concrete). However, ASTM C09.20 Committee on Normal Weight Aggregates has since cautioned that these tests may not accurately predict aggregate reactivity when dealing with a late or slow-expanding aggregate, which Seabrook engineers have confirmed was used to construct the tunnel.

The Nuclear Regulatory Commission (NRC) has concluded that Seabrook Station is currently operable but degraded, and all structures are capable of performing their safety-related functions. However, in order to fully understand the potential impact of ASR on the plant's long-term operability, a comprehensive corrective action plan is being finalized and the areas affected by ASR will continue to undergo comprehensive monitoring and analysis techniques. Potential mitigation strategies, if necessary, are also being evaluated.

An interim report is scheduled to be released in the near future. Key findings will include the rate of progression of ASR and its effect on concrete properties and other structural elements. For more information, please contact Richard Conte (Division of Reactor Safety) at Richard.Conte@nrc.gov.

14th International Conference on Alkali-Aggregate Reaction Kicks Off May 20th in Austin, TX

On May 20th, the 14th International Conference on Alkali-Aggregate Reaction (ICAAR) returns to the United States for the first time in over 30 years. More than 140 papers, spanning topics that range from modeling of alkali-silica reaction (ASR) to prevention and mitigation techniques, will be presented at technical sessions during the five-day conference. A tour of the University of Texas at Austin Concrete Durability Center (CDC) will also be offered to conference registrants. The CDC houses one of the largest outdoor exposure sites dedicated to the study of ASR in the world (see Figure 4). This site contains a series of bridge deck, column, and slab elements constructed in 2008 that have been monitored continuously in order to evaluate a wide variety of treatments, materials, and mitigation techniques.

Figure 4. CDC outdoor exposure site.

In conjunction with ICAAR, the ASR Development and Deployment Program Technical Working Group (TWG) will meet on May 23rd. The ASR TWG will discuss the overall progress of the program and provide an update on FHWA in-house research. Recent developments from the FHWA ASR Broad Agency Announcement (BAA) program, which seeks to advance the fundamental understanding of ASR, improve laboratory and field tests, and identify cost effective preventive and mitigation techniques, will also be presented.

Additional information about ICAAR, including registration details and a tentative program, can be found at the official website: http://icaar2012.org. For more information about the ASR TWG meeting, please visit http://www.asrtwg.com or contact Gina Ahlstrom (FHWA) at Gina.Ahlstrom@dot.gov.

Federal Aviation Administration Updates ASR Specification

The Federal Aviation Administration (FAA) recently updated their Advisory Circular (AC 150/5370-10F: Standards for Specifying Construction of Airports), which reflects updated testing procedures for aggregate reactivity and additional requirements for the use of cementitious materials. The latest specification still requires that coarse and fine aggregate are tested separately in accordance with test method ASTM C1260 (Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method)). The update modifies the duration; for aggregate acceptance, the measured expansion must be less than 0.10% at 28 days, instead of the 14-day exposure time indicated by ASTM C1260. It is important to note that for roadway pavements, the AASHTO PP 65-11 (2011) provisional standard, "Determining the Reactivity of Concrete Aggregate and Selecting Appropriate Measures for Preventing Deleterious Expansion in New Construction," acknowledges that some agencies may choose to implement extended test durations or adjusted expansion limits to meet their needs. If the expansion of any aggregate, coarse or fine, at 28 days is greater than 0.10%, tests of combined materials is carried out in accordance with test method ASTM C 1567 (Standard Test Method for Determining the Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)) using the aggregates, cementitious materials, and/or specific reactivity reducing chemicals in the proportions proposed for the concrete mix design. This test method also specifies an extended test duration of 28 days and a 0.10% expansion limit. In addition, the requirement that the Engineer specify, require, and at a minimum, insert Appendix 1 contained in FAA Engineering Brief No. 70 (EB70 - Accelerated Alkali-Silica Reactivity in Portland Cement Concrete Pavements Exposed to Runway Deicing Chemicals December 13, 2005) when runway deicing chemicals will be used on the pavement has been removed and EB70 has been cancelled.

FAA's Advisory Circular also excludes the use of Class C fly ash, although Class C fly ash may be proposed on a case-by-case basis where innocuous aggregates are used and the pavement is not subjected to airfield pavement de-icers. Any use of Class C fly ash is subject to the approval of the engineer and FAA and a modification to standards will be required. In addition, the use of Class F fly ash or Class N pozzolan is allowed, and guidance is provided for their proper selection.

The new Advisory Circular is currently accessible through the FAA website: http://www.faa.gov/regulations_policies/advisory_circulars/index.cfm/go/document.information/documentID/1019625. For more information, please contact Gregory Cline (FAA Airport Engineering Division) at Gregory.Cline@faa.gov.

Schedule of Events

May

7-10 International Concrete Sustainability Conference, Seattle, Washington

20-25 14th International Conference on Alkali-Aggregate Reaction (ICAAR), Austin, Texas

June

7-10 American Society of Highway Engineers National Conference, Champion, Pennsylvania

24 ASTM Committee C09 Workshop on ASR Testing, Specification Management, and Mitigation from a Ready-Mix Perspective, San Diego, California

July

5-7 Third Advanced Workshop on Innovations and Modeling for Sustainable and Resilient Concrete Pavements, Lac-Delage, Quebec, Canada

8-12 10th International Conference on Concrete Pavements, Quebec City, Quebec, Canada

14-19 13th AASHTO/TRB Maintenance Management Conference, Seattle, Washington

15-18 2012 AASHTO Conference, Phoenix, Arizona

To view this technical update on the web, please go to https://www.fhwa.dot.gov/pavement/concrete/reactive/v05issue02.cfm

This material is based upon work supported by the Federal Highway Administration Alkali-Silica Reactivity (ASR) Development and Deployment Program to share information related to ASR.

If you would like to subscribe to future issues, receive more information on the ASR Program, or receive further details on any of the articles in this issue, email us at asrnewsletter@transtec.us.