National Fuel Cell Bus Program

This chapter summarizes accomplishments of fuel cell transit bus research and demonstration projects supported by the Federal Transit Administration (FTA) through 2011. It describes fuel cell electric bus (FCEB) research projects in the United States and describes their impact on commercialization of fuel cell power systems and electric propulsion for transit buses in general.

FTA conducts most of its FCEB research under the National Fuel Cell Bus Program (NFCBP), a cooperative research, development, and demonstration program to advance commercialization of FCEBs. The NFCBP is a part of a larger FTA research program to improve transit efficiency and contribute to environmentally sustainable transportation. The FTA conducts the NFCBP in partnership with industry. Projects target research to improve performance and lower costs of next-generation fuel cell systems for transportation.

|

Transit buses are well suited to demonstrating fuel-cell applications in transportation because:

|

Congress established the NFCBP in the Safe, Accountable, Flexible, Efficient Transportation Equity Act: A Legacy for Users (SAFETEA-LU). FTA’s research to develop FCEBs has been under way since 2006. The NFCBP requires an equal cost share by project teams for each Federal dollar invested, bringing the size of the program to more than $150 million through FY 2011.

NFCBP objectives, which apply to all FTA-funded FCEB research, are:

- Significantly advance development of FCEBs and related infrastructure through innovation of FCEB design, component development, improved systems integration, and real-world implementation and demonstration

- Document the state of FCEB technologies development, and examine requirements and next steps for market introduction

- Enhance awareness and education related to FCEBs and related infrastructure.

Value and Challenges of Fuel Cell Electric Propulsion for Transit Buses

U.S. interest in hydrogen FCEBs has grown over the past 20 years, driven primarily by the desire to reduce both petroleum-based fuel consumption and emissions, particularly greenhouse gas emissions. In October 2010, the U.S. Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) introduced a program to reduce greenhouse gas emissions and improve fuel efficiency of medium- and heavy-duty trucks and buses. These federal programs will significantly impact transit bus propulsion products in the future.

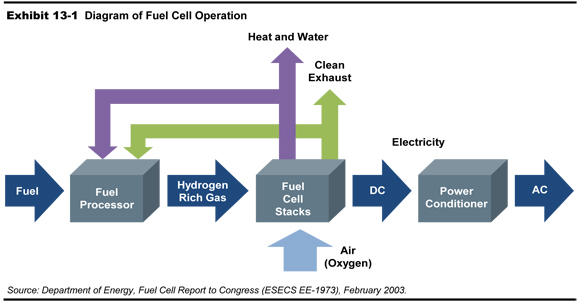

Exhibit 13-1 illustrates fuel cell operation. Fuel cell electric technology for transit buses can produce benefits such as:

- Zero tailpipe emissions

- Improved fuel economy

- Reduced dependence on foreign oil

- Quiet, smooth ride

- Creation of green technology jobs

- Technologies for better-performing, more-efficient hybrid and electric buses

- Demonstration of the value of fuel cell technology to a larger, heavy-duty vehicle market.

The major barriers to reaching full commercialization of FCEBs are:

- Durability – The useful life of fuel cell power systems is increasing, but more work is needed to meet transit requirements.

- Initial purchase costs – The cost of buses and infrastructure is decreasing, but to become competitive the market will need to realize economies of scale through greatly expanded production.

- Delivery of “green” hydrogen – The availability and cost of hydrogen for FCEB operations remain significant barriers. Hydrogen is produced by electrolysis or through natural gas reforming, or it is trucked as a liquid into operating locations. These production and delivery methods all pose cost and greenhouse gas emission issues that must be resolved before FCEBs are fully commercialized.

|

Accomplishments from FTA research on Fuel Cell Bus Technology:

|

History and Status of FCEB Research

FTA FCEB propulsion and infrastructure demonstrations began in the early 1990s with buses developed at Georgetown University. These 30- and 40-foot buses were fueled by methanol that was reformed into hydrogen onboard and used in the buses’ electric fuel cell propulsion systems. Between 1998 and 2000, the FTA supported a second major demonstration of three, 40-foot hydrogen fuel cell buses, with Ballard fuel cells, operated at Chicago Transit Authority (CTA). During this same time period, three fuel cell buses of the same generation also operated in Vancouver, Canada.

FTA’s early demonstrations proved the feasibility of fuel cell propulsion for transit buses and identified research needed to:

- Reduce the size of fuel cell stacks and balance-of-plant onboard buses

- Increase power density of the fuel cell power system

- Reduce the weight of fuel cell and electric propulsion systems

- Develop a hydrogen fueling infrastructure suitable for transit bus operations.

The first “next-generation” FCEB, a 40-foot bus with a Ballard fuel cell power system, operated at SunLine Transit Agency (SunLine) during 2000 and 2001. A second “next-generation” FCEB, a 30-foot bus with a UTC Power fuel cell power system, operated first at SunLine and then at Alameda-Contra Costa Transit District (AC Transit) during 2002 and 2003.

In August 2005, Congress established the National Fuel Cell Bus Technology Development Program to facilitate development of commercially viable FCEB propulsion technologies. The FTA released the initial competitive solicitation for the NFCBP on April 10, 2006. A multi-department technical team recommended 14 projects for funding under the program. Projects included partners from industry, government, and transit and provided a balanced portfolio for the NFCBP to advance FCEB commercialization. The NFCBP continued beyond its initial four years, funded through extensions of SAFETEA-LU for FY 2010 and FY 2011. Each annual extension added approximately $13.5 million, for a total of nearly $76 million in federal funding through FY 2011. The 50 percent cost share requirement was also continued for all projects, bringing funding for the program to more than $150 million.

NFCBP projects are managed through one of three non-profit consortia:

- CALSTART – a nonprofit consortium headquartered in Pasadena, California. CALSTART represents more than 140 firms. It provides services and consulting to develop clean, advanced transportation technologies for all types of vehicles, including trucks, buses, and military vehicles.

- Center for Transportation and the Environment (CTE) – a nonprofit consortium headquartered in Atlanta, Georgia. CTE provides research, training, and information exchange for improving transportation infrastructure while preserving the integrity of the environment.

- Northeast Advanced Vehicle Consortium (NAVC) – a nonprofit, public-private partnership headquartered in Boston, Massachusetts. NAVC conducts research and technology analysis and fosters information sharing and collaboration on advanced vehicle technology projects.

Current FTA FCEB research focuses on developing transit buses that demonstrate full transit operation and service. Current bus configurations have either large fuel cell power systems in hybrid electric propulsion systems or smaller fuel cell power systems in plug-in/battery dominant hybrid electric propulsion systems. Ongoing research also includes electrifying accessories (e.g., air conditioning) and, in some cases, adding small fuel cell auxiliary power units (APUs) to power the electric accessories.

The U.S. Department of Energy (DOE) also funds FCEB research. Most of DOE’s fuel cell and hydrogen research is done through the Fuel Cell Technologies Program within the Office of Energy Efficiency and Renewable Energy (EERE). DOE’s research in fuel cells and hydrogen complements FTA’s transit bus research and demonstration, usually through DOE’s investment in developing technologies used in the demonstrations. For example, the DOE supported hydrogen fueling stations at several demonstration locations in California. In addition, DOE’s Clean Cities program provides grants for clean energy projects that include a hydrogen fueling station planned for CTTRANSIT in Hartford, Connecticut.

In March 2012, the FTA released a report, FTA Fuel Cell Bus Program: Research Accomplishments through 2011, (http://www.fta.dot.gov/documents/FTA_Report_No._0014.pdf) that summarizes 42 research projects, including NFCBP projects, other FTA research, and supporting research funded by the DOE. To date, 17 of these projects have been completed and 25 are ongoing FTA and DOE projects.

Research Accomplishments

Research under the NFCBP shows progress toward commercialization and readiness for implementation of FCEBs in transit operations. The NFCBP has seven performance objectives for the research projects it funds. Exhibit 13-2 lists these objectives and summarizes progress toward meeting them. Although progress is significant, more investment is needed to meet the objectives.

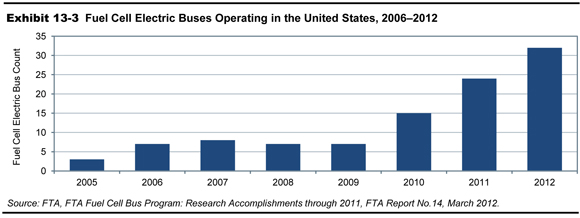

Exhibit 13-3 shows the number of FCEBs operating in the United States. Between 2005 and 2009, potential regulation by the California Air Resources Board was the impetus for FCEB research, and the first seven FCEBs operated in California at SunLine, Santa Clara VTA, and AC Transit. Beginning in 2007, one FCEB began operating at CTTRANSIT in Hartford, Connecticut.

| NFCBP Performance Objective | Progress Through FY 2011 |

|---|---|

| 1. Less than five times the cost of a conventional (commercial diesel) transit bus | Cost reductions from more than $3.0 million per bus in 2006 to $2.3 million for last bus ordered. Battery dominant bus with smaller fuel cell power system significantly less than $2.3 million. |

| 2. Four to six years or 20,000 to 30,000 hours of durability for the fuel cell power system | 10,000+ hours achieved on fuel cell power system, with durability warranties at 10,000 to 12,000 hours. |

| 3. Double the fuel economy compared to commercial (diesel transit) bus | Exceed two times conventional (diesel transit) bus fuel economy, but depends on route. |

| 4. Bus performance equal to or greater than equivalent commercial (diesel transit) bus | Operated up to 19 hours/day, with good availability, and miles between road calls at 4,000 miles. Better acceleration. Quiet operation. Weight is still high. |

| 5. Exceed current emissions standards | Zero emissions. |

| 6. Foster economic competitiveness in FCEB technologies | Multiple manufacturers and platforms demonstrating buses. |

| 7. Increase public acceptance for FCEB technologies | Continued progress. |

Funding though the NFCBP was available starting in 2006. However, its influence becomes apparent only in 2010, due to the lag time between designing and building FCEBs and getting them into operation. The projected number (32) of FCEBs that will be in operation by the end of 2012 is conservative.

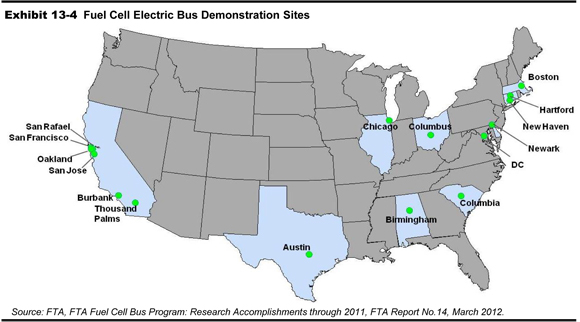

Exhibit 13-4 is a map of current or planned FCEB operating locations. FCEB demonstrations have expanded and are now located across the United States, not just in California.

The 42 projects discussed in the FTA report represent multiple design configurations for FCEBs. Exhibit 13-5 shows the current fully integrated FCEB configurations and their manufacturers. Three are fuel cell dominant configurations, and four are battery dominant fuel cell configurations. The design configurations represent seven bus manufacturers and three fuel cell power system manufacturers. Another FCEB is planned with a fourth fuel cell power system manufacturer, Nuvera. In addition to those listed in the table, one existing hybrid electric bus design, Orion VII, BAE Systems, was modified using all-electric accessories powered by a small fuel cell power system by Hydrogenics. This modified design also provides some power for all-electric operation of the power plant dominant hybrid.

| Bus Manufacturer | Fuel Cell System | Hybrid System | Hybrid Configuration | Energy Storage | Status |

|---|---|---|---|---|---|

| Van Hool 40-ft | UTC Power | Siemens ELFA | Fuel cell dominant | Lithium-based batteries | Operational |

| ElDorado 40-ft | Ballard | BAE Systems | Fuel cell dominant | Lithium-based batteries | Operational |

| New Flyer 40-ft | Ballard | Siemens ELFA | Fuel cell dominant | Lithium-based batteries | Operational |

| Proterra 35-ft | Hydrogenics or Ballard | Proterra integration | Battery dominant | Lithium-based batteries | Operational |

| DesignLine 35-ft | Ballard | DesignLine integration | Battery dominant | Lithium-based batteries | Under development |

| Ebus 22-ft | Ballard | Ebus integration | Battery dominant | Nickel cadmium batteries | Operational |

| EVAmerica 30-ft | Ballard | EVAmerica integration | Battery dominant | Lithium-based batteries | Under development |

In 2007, Proterra, a new “green” bus manufacturer, started design of and delivered its first bus, a battery dominant hybrid fuel cell bus, for demonstration in Columbia, South Carolina (completed in 2010), and Austin, Texas (planned to start in 2012). The NFCBP helped Proterra acquire the start-up capital to begin manufacturing this bus. Since then, Proterra has built and delivered two more FCEBs that are essentially the same as the first one. Proterra based its propulsion system on an all-electric design with the capability to add a fuel cell power system as a range extender. Its buses are also designed for opportunity charging while on route. Foothill Transit (West Covina, California) purchased three electric buses with one of Proterra’s fast charging stations. Proterra is assembling another 10 or more buses for transit operations in other locations.

Several transit agencies in California began testing FCEBs because of potential state regulation and purchase requirements for zero-emission buses. Beginning in 2005, this testing included an FCEB design from Van Hool, UTC Power, and ISE (now Bluways), with energy storage in ZEBRA batteries. SunLine operated one of these buses and AC Transit operated three more. Two additional buses of this design operated in Belgium and at CTTRANSIT in Hartford, Connecticut.

The NFCBP funded UTC Power and AC Transit to maximize operation of AC Transit’s three FCEBs (i.e., accelerated testing) to study reliability, durability, and failure modes of the fuel cell power system. This accelerated testing began in late 2007. The lessons learned and improvements to the design of the UTC Power fuel cell power system increased durability so that one of the systems reached 11,000 operating hours without significant maintenance, and two others have accumulated 6,000 and 8,000 operating hours without significant maintenance. Previous fuel cell power systems reached only about 4,000 operating hours before a low power output level indicated the end of useful life for the systems.

Following these initial testing activities, AC Transit, Van Hool, and UTC Power designed and developed an improved “next-design” FCEB for the Zero Emission Bay Area (ZEBA) advanced demonstration in California. AC Transit is leading a group of San Francisco Bay Area (Bay Area) transit agencies in this demonstration. The demonstration includes 12 new FCEBs and two new hydrogen fueling stations at two AC Transit operating depots. UTC Power and CTTRANSIT are demonstrating four more “next-design” FCEBs in Hartford, Connecticut. Demonstration of the “next-design” version of Van Hool/UTC Power FCEBs now includes 16 buses in two locations, making it the largest FCEB demonstration in the United States.

Buy America requirements (Title 49 CFR Part 661), set standards for federally assisted procurements, specifically: “…no funds may be obligated by FTA for a grantee project unless all iron, steel, and manufactured products used in the project are produced in the United States.” In 2008, FTA granted a public interest waiver to the FTA Buy America requirements for NFCBP projects, so that project teams could access all available technologies and components, regardless of origin, in order to hasten the development of fuel cell technology for transit. This allowed teams to access a full slate of technologies, many of which were not readily available domestically, for validating fuel cell bus technology, with the overall goal to stimulate and further expand the U.S. fuel cell bus industry. Over the past few years, FTA and the consortia have made progress toward meeting “Buy America” requirements:

- The FTA-funded ElDorado/BAE Systems/Ballard as new manufacturer partners to develop and demonstrate a new FCEB at SunLine and CTA. The new bus meets Buy America requirements, and is assembled in Riverside, CA.

- Increasing orders for FCEBs in the United States led Canadian-based fuel cell manufacturer, Ballard Power Systems, to establish manufacturing capabilities for fuel cell power systems in Lowell, Massachusetts. Fuel cell power systems are the largest cost component of FCEBs. Their availability in the United States helps bus manufacturers meet Buy America requirements.

- The UTC Power fuel cell power system is currently only available in Van Hool buses from Belgium. The NFCBP funded a project with Connecticut-based fuel cell manufacturer, UTC Power, to engineer, package, and test a further optimized fuel cell power system that can be installed easily into U.S. bus manufacturer models.

Hybrid electric propulsion for transit buses increases energy efficiency for the buses, but it also increases complexity. Hybrid electric propulsion has the potential to reduce maintenance costs through fewer moving parts, battery energy storage, and regenerative braking, which reduces both brake wear and brake maintenance. The challenges for hybrid electric propulsion for buses are reliability and durability of the major components and optimized integration, especially software integration.

FTA funding for FCEB research enabled several bus manufacturers and integrators to gain experience in building and optimizing electric propulsion systems. It also enabled BAE Systems, a commercial electric propulsion manufacturer/supplier, to enter the FCEB market. With NFCBP funding, BAE Systems electrified accessories in its Compound Bus 2010 project, which led to an electric accessory package that will be integrated into its commercial hybrid products in the future. In addition, the NFCBP funded development of critical power electronics components for hybrid electric propulsion systems, such as DC-DC convertors. All of this research expands the availability of products to the transit industry.

Hydrogen fuel for FCEB demonstration projects is typically supplied through electrolysis or natural gas reforming, or it is trucked into a fueling site as liquid or high-pressure gas. The FTA has invested in all of these methods to support not only the development of hydrogen fueling infrastructure, but also safe operations in and around transit maintenance, storage, and wash facilities. In addition, the FTA funded the Volpe Center to review safety plans for transit FCEB operations and infrastructure as well as to provide technical assistance to each transit agency operator of FCEBs.

An objective of all FTA research is to share results and lessons learned. Information sharing is a specific objective of the NFCBP, including lessons learned from FCEB and infrastructure research to facilitate technical progress and future research. FCEB development and demonstration reports document implementation to facilitate understanding of the requirements for market introduction.

All NFCBP demonstration projects include an awareness and education component. Transit agencies that operate FCEBs are able to educate their passengers and the communities through outreach and public events. Through FY 2011, the NFCBP has funded and/or produced 10 brochures and 29 reports about FCEB research.

The NFCBP also established both a national and an international working group for information sharing and cooperation. The FTA initiated the International Fuel Cell Bus Working Group and workshops in 2002 to facilitate information sharing on worldwide FCEB demonstrations and to harmonize data collection to better understand the status of the technologies. Since the first workshop in 2002, the FTA has facilitated six more workshops.

The FTA formed the National Fuel Cell Bus Working Group for information sharing about FCEB demonstrations in the United States. To facilitate participation from transit agencies around the country, the working group usually meets in conjunction with American Public Transportation Association (APTA) conferences. The working group was initiated at the 2002 APTA EXPO in Las Vegas, Nevada, and since that time has held three additional meetings to discuss national demonstrations and progress toward commercialization.

The FTA intends to continue efforts to collaborate and coordinate with industry on FCEBs through outreach efforts with CTE to conduct a series of webinars on FCEB for the transit industry, and a new website on worldwide activities and developments on fuel cell buses, that will help facilitate national and international data sharing.

To view PDF files, you need the Acrobat® Reader®.