U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

| This report is an archived publication and may contain dated technical, contact, and link information |

|

Publication Number: FHWA-RD-02-099 Date: January 2005 |

Previous | Table of Contents | Next

The initial curing period is defined in ACI 308 R as the period between placing the concrete and application of final curing.(1) As discussed above, the proper time for application of final curing is approximately at the time of initial setting. Approximate conditions during the initial curing period should be forecast prior to construction, as described in chapter 2. Activities during construction focus on verifying actual conditions and making onsite adjustments. Figure 11 summarizes major action items.

Figure 11. Chart. Major items requiring attention during construction-initial curing period.

During placement operations, verify concrete temperatures, wind velocity, air temperature, and relative humidity. Inexpensive instrumentation is readily available for measuring these properties. From these data, evaporation rates can be calculated to determine whether critical drying rates exist, using the equation 4 shown in figure 6 or the nomograph from ACI 308 shown in figure 7.(4)

As discussed in chapter 2, generally speaking, evaporation rates greater than 0.3 kg/m2/h will present a problem for slip-form pavements. However, exact levels depend on the particular bleeding conditions of the job concrete.

Using the concrete placing temperature, the time of initial setting can be estimated, as described in the equation shown in figure 5. The time of initial setting is the optimal time for application of final curing.

Two onsite adjustments can be useful in reducing evaporation rates of bleed water: reducing concrete placing temperatures and use of evaporation reducers.

Of the variables affecting evaporation rate of bleed water from freshly placed concrete, concrete temperature is one of the most important and probably the only one that can be practically applied at the jobsite for large paving operations. Cooling aggregate stockpiles, cooling mixing water, or using ice for mixing water are very effective ways of reducing concrete temperatures.

The amount of cooling that can be expected from these measures, and its probable effect on evaporation rates, can be estimated from the calculations in ACI 305 R(5) and the evaporation-rate nomograph in ACI 308,(4) both of which can be programmed into a spreadsheet to simplify the calculation. The equation shown in figure 6, above, reproduces the information in the ACI 308 nomograph.(4) The ACI 305 R calculation of concrete placing temperature from ingredient temperatures is reproduced below in figure 12.(5)

![]()

Figure 12. Equation. Temperature of fresh concrete from ingredients.

where:

T = concrete placing temperature

Tca = temperature of coarse aggregate

Tfa = temperature of fine aggregate

Tc = temperature of cement

Tp = temperature of pozzolan

Tw = temperature of mixing water, excluding ice

Ti = temperature of ice

Wca = dry mass of coarse aggregate

Wfa = dry mass of fine aggregate

Wc = mass of cement

Wp = mass of pozzolan

Wi = mass of ice

Ww = mass of mixing water

Wcam = mass of free and absorbed moisture in coarse aggregate

Wfam = mass of free and absorbed moisture in fine aggregate

Evaporation reducers are a relatively new product developed to specifically address the condition of excessive evaporation rates. The approach is to apply evaporation reducers in sufficient quantity and frequency that the concrete does not ever lose critical amounts of water to evaporation. Application is made using the same (or similar) equipment as that used to apply curing compounds.

Evaporation reducers are water emulsions of film-forming compounds. The film-forming compound is the active ingredient that slows down evaporation of water. There is also a benefit from the water fraction of the evaporation reducers, in that it compensates to a small degree for losses of mixing water to evaporation.

Evaporation reducers may need to be applied several times, depending on the conditions. The equation in figure 13, below, yields a conservative estimate of the frequency of application for a given condition.

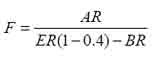

Figure 13. Equation. Frequency of application of evaporation reducer.

where:

F = frequency of application, h

AR = application rate, kg/m2

ER = evaporation rate of bleed water, kg/m2/h

BR = bleed rate of concrete, kg/m2/h

The constant, 0.4, is taken to be the reduction in evaporation rate affected by an

evaporation reducer. The exact value is difficult to know in the absence of test methods

and specifications, but most manufacturers claim at least a 50 percent reduction in

evaporation. Therefore, this equation is probably conservative. An application of 0.2

kilograms per square meter (kg/m2) also expressed as 5 square meters per liter (m2/L), is

a commonly recommended rate. This is also often near the maximum that can be applied

practically without runoff.

The relatively common practice of applying some or all of the curing compound very soon after placing will serve as an effective evaporation reducer. However, there may be problems associated with this practice, as described in chapter 4. If used, this practice should be verified as part of the laboratory verification of curing compound properties, as also described in chapter 4.