U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

| This report is an archived publication and may contain dated technical, contact, and link information |

|

All materials expand and contract to some extent as their temperatures rise or fall. The coefficient of thermal expansion (CTE) is a measure of a material's expansion or contraction with temperature. Because the length changes associated with thermal expansion are very small, the CTE is usually expressed in microstrains per unit temperature change.

The CTE of Portland cement concrete (PCC) ranges from about 8 to 12 microstrains/°C. The range of CTE values for different concretes reflects the variation in CTE of concrete's component materials. For example, concrete containing limestone aggregate has a lower CTE than concrete containing siliceous aggregate. Because aggregate comprises about 70% of the concrete, aggregate type has the greatest effect on the CTE of concrete. The CTE of hardened cement paste, which is a function of factors such as w/c ratio, cement fineness, cement composition, and age, also affects the CTE of concrete.

The CTE is one of the factors to be considered in the design of PCC pavements. During pavement design, this variable is normally represented as an average value rather than a mix-specific one, even though it may vary significantly depending on factors such as type of aggregate used in a mix. Using an average value may therefore lead to erroneous assumptions about the pavement's thermal response and possible distress. For example, one of the keys to characterizing the effects of thermal properties on a concrete pavement's structure is to account for thermal movements. Accurate values of the CTE are needed to predict potential thermally-induced movements in a concrete pavement.

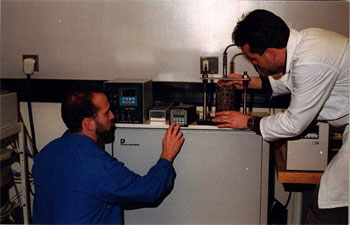

The PCCP Team has developed equipment and a standard test method (adopted by AASHTO as TP60-00) for determining the CTE of PCC. The test method determines the CTE of a cylindrical concrete specimen, maintained in a saturated condition, by measuring the length change of the specimen over a specified temperature range (10°C to 50°C). A picture of the test apparatus is shown below. Length changes are measured using an LVDT. Corrections are made for the expansion or contraction of the test frame.

The CTE is calculated according to the following formula:

CTE = (ΔL/L0) / ΔT

where ΔL = length change of specimen, L0 = initial measured length of specimen, and ΔT = temperature change.

The PCCP Team has been using this test method to measure CTEs for over 2000 cores from across the country collected as part of the Long Term Pavement Performance (LTPP) program. These data will become part of the LTPP database and will be used to investigate the impact of CTE on the response and performance of pavements.

The CTE is an important factor in optimizing concrete joint design, calculating stresses, joint sealant design, and selecting sealant materials. The results of the analyses will help engineers modify the procedures for PCC pavement design to more accurately predict the impact of mix-specific CTEs on pavement behavior. The modified design procedures will result in pavement designs that are more compatible with the environmental conditions at a particular paving site. Ultimately, the use of the modified design procedures will result in improved pavement performance.

The new (2002 Guide) pavement design procedures under development through NCHRP 1-37A consider the effects of thermal expansion and contraction. The CTE research completed by the PCCP Team has made this possible by providing a standard test method that agencies can use to determine CTE for their concrete mixes and CTE data for the LTPP test sections. The LTPP CTE data are being used in the development of the 2002 Guide, and may also be used by future users of the guide to estimate appropriate CTE input values when material-specific data are not available. Based on draft preliminary Information on PCC CTE Input in the 2002 Guide, determination of CTE for the different levels as defined in Guide are as follows:

Level 1 of the CTE determination involves direct measurement of the change in length of laboratory specimens subjected to changes in temperatures, using AASHTO TP60, "Standard Test Method for CTE of Hydraulic Cement Concrete."

Level 2 of CTE determination uses a weighted average of the constituent values based on the relative volumes of the constituents. The table below provides typical ranges of a for various common PCC mix components.

Typical α ranges for common PCC components.

| Coefficient of Thermal Expansion | ||

|---|---|---|

| 10-6/°C | 10-6/°F | |

| Aggregate | ||

| Granite | 7-9 | 4-5 |

| Basalt | 6-8 | 3.3-4.4 |

| Limestone | 6 | 3.3 |

| Dolomite | 7-10 | 4-5.5 |

| Sandstone | 11-12 | 6.1-6.7 |

| Quartzite | 11-13 | 6.1-7.2 |

| Marble | 4-7 | 2.2-4 |

| Cement Paste (saturated) | ||

| w/c = 0.4 | 18-20 | 10-11 |

| w/c = 0.5 | 18-20 | 10-11 |

| w/c = 0.6 | 18-20 | 10-11 |

| Concrete | 7.4-13 | 4.1-7.3 |

| Steel | 11-12 | 6.1-6.7 |

Level 3 of CTE estimation is based on historical data. The greatest potential for error is associated with this option, because PCC materials vary considerably. Realistic data for the types of materials being used in concrete mixtures are rarely available and, if they are available, they are likely to be based on a specific PCC mix design or aggregate type. However, an agency could test typical mixes containing a range of aggregate types to obtain typical values for their materials.