U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| TECHBRIEF |

| This techbrief is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-12-042 Date: May 2012 |

Publication Number: FHWA-HRT-12-042 Date: May 2012 |

PDF files can be viewed with the Acrobat® Reader®

FHWA Publication No. of this TechBrief: FHWA-HRT-12-042

NTIS Accession No. of the report covered in this TechBrief: PB2012-107569

FHWA Contact: Ben Graybeal, HRDI-40, (202) 493-3122, benjamin.graybeal@dot.gov.

This document is a technical summary of the unpublished Federal Highway Administration (FHWA) report, Ultra-High Performance Concrete Composite Connections for Precast Concrete Bridge Decks, available only through the National Technical Information Service, www.ntis.gov.

Ultra-high performance concrete (UHPC) has been used to develop a novel composite connection detail for joining precast concrete bridge decks supporting superstructure elements. The results of the research effort and recommendations for the use of this connection detail are provided herein.

There is a growing need for durable and resilient highway bridge construction/reconstruction systems that facilitate rapid completion of onsite activities to minimize the impact on the traveling public. Modular components can provide high-quality, accelerated, and safe construction; however, offsite prefabrication of bridge components necessitates an increased reliance on the long-term performance of field-installed connections between these components. Connections have often proved lacking, resulting in decreased overall system performance.

Prefabricated bridge girders, which are a common and reliable structural component, have been deployed countless times in the highway infrastructure over the past century. In their most common form, these superstructure elements are connected to a cast-in-place concrete deck through the use of discrete steel connectors cast into or welded onto the girder. Construction of such a slab-on-stringer bridge system is straightforward, but it can progress slowly due to the need for field activities related to the casting of the concrete deck. As a result, there is an interest in using precast concrete deck elements to accelerate onsite construction activities while simultaneously increasing the quality of the bridge deck concrete.

One problem with the use of this type of modular decking system is the composite connection that ties the deck panels to the supporting girders. These connections commonly require the interlacement of discrete connecting elements emanating from the prefabricated girders and decks, causing tolerance and fit-up issues in the field. Also, the field-cast grouts that are used to fill the connection voids have displayed less than desirable durability performance at times. Finally, the intermittent full-depth pockets frequently specified for these composite connections lead to aesthetic, rideability, and durability issues in the finished bridge deck.

The intent of this research effort is to redesign the composite connection in a way that provides for simple details, no interference or field fit-up issues, increased long-term durability performance, and reduced aesthetic and rideability concerns. The unique rheological, mechanical, and durability properties of UHPC are particularly well suited to meeting the goals of this research effort.

The concept of using the advanced properties of UHPC to significantly modify the design of connections between precast concrete components is not new. In fact, research and deployments in this area date back to at least 1995.(1) The research, completed at Chalmers University in Sweden, assessed the bonding performance between UHPC and straight lengths of mild steel reinforcement. At that time, two projects were completed at Aalborg University in Denmark wherein a commercially available UHPC was used as a closure fill material in the connection of slab elements in a building.

More recently, the concept of using UHPC properties to redesign connections between modular bridge components has been recognized in North America. As of early 2012, field-cast UHPC connections between prefabricated bridge components were implemented in 18 bridges in the United States and Canada. These bridges use a range of details to connect different precast concrete modular bridge components, including adjacent box beams, full-depth precast deck panels, and deck-bulb-tee girders.

Research at the Federal Highway Administration (FHWA) has addressed the performance of deck-level connections between precast concrete components.(2) This line of investigation is continuing through additional research at FHWA as well as in the current project presented in this TechBrief. Two fundamental differences between the field-cast UHPC connection concept and conventional modular component connection concept are simplicity and performance. The UHPC connection concept allows for small, simple connections while delivering better overall performance.

Advances in concrete materials have led to the development of a new generation of cementitious materials, namely UHPC. As a class, these concretes tend to contain high cementitious materials contents, low water-to-cementitious materials ratios, compressive strengths above 22 ksi (150 MPa), and sustained tensile strength resulting from internal fiber reinforcement. Table 1 presents a select set of material properties for the UHPC investigated in this study. Further details on the mechanical and durability properties of this UHPC can be found in Material Property Characterization of Ultra-High Performance Concrete.(3) An introduction to UHPC can be found in Ultra-High Performance Concrete, while assistance with the construction of field-cast UHPC connections is provided through Construction of Field-Cast Ultra-High Performance Concrete Connections.(4,5)

| Property | Value |

| Unit weight | 158 lb/ft3 (2,535 kg/m3) |

| Modulus of elasticity | 7,500–8,500 ksi (52–59 GPa) |

| Compressive strength | 25–32 ksi (170–220 MPa) |

| Post-cracking tensile strength |

1.0–1.5 ksi (7.0–10.3 MPa) |

| Chloride ion penetrability (ASTM C1202-12)(6) |

Very low to negligible |

The exceptional durability of UHPC has been well documented. Of particular importance, UHPC contains no coarse aggregate, so it does not exhibit early-age microcracking common to conventional concrete. This feature, combined with the discontinuous pore structure in the homogeneous cementitious matrix, results in concrete with an extremely low permeability.

The tensile mechanical response of UHPC also surpasses that of conventional concrete. The discrete steel fiber reinforcement included in UHPC components allows the concrete to maintain tensile capacity beyond cracking of the cementitious matrix. The inelastic straining of the component is resisted by fiber reinforcement that bridges the tight, closely spaced cracks.

The durability and sustained tensile capacity of UHPC present opportunities to rethink common concepts in reinforced concrete structural design. For example, the tensile capacity of UHPC could eliminate the need for discrete mild steel reinforcement in some structural members, and the durability could reduce the cover required for any remaining reinforcement. Of particular interest, UHPC can significantly shorten the development length of embedded discrete steel reinforcement, can exhibit exceptional bond when cast against previously cast concrete, and can display both high and sustained levels of tensile resistance. These properties facilitated the redesign of the modular component connection, leading to simplified construction and enhanced long-term system performance.

The composite connection between a set of precast concrete deck panels and a supporting girder must be capable of carrying significant shear and tensile forces. Traditionally, this has been accomplished by engaging discrete steel elements (rebar or studs) that extend from the girder and pass through the haunch into the deck. The field-cast grout would then provide geometric integrity to the connection but would not be directly assumed to provide significant resistance to applied loads. To eliminate the fabrication, congestion, and assembly issues associated with interlacing these girder connectors into precast deck panel pockets, a novel concept was developed wherein the sustained tensile capacity of UHPC is engaged as a key structural element within the composite connection system. The field-cast UHPC engages discrete connectors both in the deck and on the girder and, through its high sustained tensile capacity, transfers applied forces between the precast components.

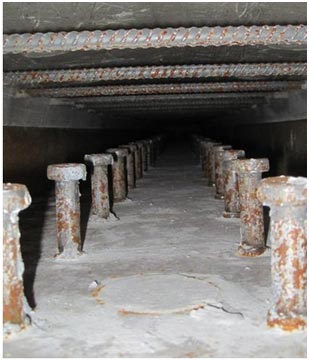

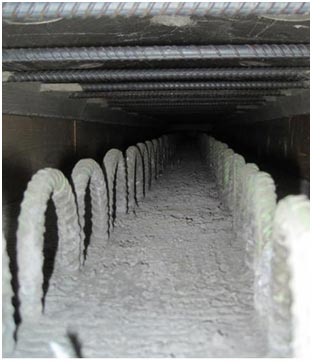

Figure 1 and figure 2 provide schematic illustrations of this connection for precast concrete deck panels supported by steel and concrete girders, respectively. The connection at the girder resembles the traditional connection, with steel studs or rebars passing into the haunch. The primary difference is that the extension height of the connectors is reduced so as to not interfere with the precast deck. The connection at the precast deck is composed of a continuous channel or void cast into the underside of the precast deck panel through which the bottom mat of transverse deck reinforcement passes. The gap between the girder and deck discrete connectors allows for simple assembly of components in the field. The channel void under the precast panel eliminates the need for full-depth pockets and the need to cluster the girder connectors. Figure 3 and figure 4 show the two tested UHPC composite connections immediately before UHPC casting.

Figure 1. Illustration. UHPC composite connection detail for steel girder superstructures.

Figure 2. Illustration. UHPC composite connection detail for concrete girder superstructures.

Figure 3. Photo. UHPC composite connection detail for steel girders.

Figure 4. Photo. UHPC composite connection detail for concrete girders.

After the prefabricated components are assembled in the appropriate configuration and the haunch is formed, the UHPC is cast into the void to completely fill the haunch connection. Vent holes in the deck ensure that the UHPC has fully filled the void. For simplicity of field operations, it is advisable to integrate this composite connection concept with the panel-to-panel non-contact lap splice connection developed in a previous study.(2)

Through its Structural Concrete Research Program, FHWA recently completed an experimental study focused on the performance of field-cast UHPC composite connections between precast modular bridge decks and supporting girders. This study is part of Transportation Pooled Fund Study TPF-5(217), which is being completed in partnership with the New York State Department of Transportation (NYSDOT).

Two full-scale test specimens were designed to mimic the type of slab-on-stringer construction commonly used throughout the United States for highway bridge construction. Although composed of precast deck panels on prestressed concrete girders, the specimens were designed to emulate the composite connections between precast concrete deck elements and both steel and concrete girders. The design of the test specimens mimicked the line-girder design concept commonly implemented in U.S. highway bridge superstructure design. In this test program, individual superstructure elements (i.e., girder-deck systems) were simply supported and subjected to a symmetric four-point bending load. This test setup allowed for the generation of realistic flexure and shear stresses within the test specimen. The test specimens were subjected to loads simulating the types of truck and lane structural loadings that are the primary basis for the structural design of bridge superstructures.

The design of the test specimens was based on preliminary structural designs completed by NYSDOT as part of the Prospect Mountain Interchange Project. This project aims to rehabilitate 11 bridges in the Binghamton, NY, area, including 6 bridges in the I-81/I-86/US-17 interchange over the Chenango River. NYSDOT identified six bridges in this interchange as being potential candidates for the use of this particular accelerated bridge construction technology and as being appropriate structures on which to base the experimental test program. NYSDOT identified a likely structural configuration for each bridge and completed the design according to AASHTO LRFD Bridge Design Specifications.(7) The maximum horizontal shear fatigue range was a critical factor in the design, with the maximum value on any girder line determined to be 0.937 kips/inch (0.164 kN/mm). These loads are attributed to the design bridge, a two-span continuous bridge with 209-ft (63.6-m) spans and 79-inch (2-m)-deep steel plate girders.

The two test specimens had the same basic precast panel and girder designs, but one was built as a conventional specimen with conventional composite connection details, and the other was built as a UHPC specimen with novel connection details. Each specimen included one end that emulated a steel girder connection to precast concrete deck panels and one end that emulated a concrete girder connection to precast concrete deck panels. The emulated steel girder connection was created by embedding a 0.75-inch (19-mm)-thick steel plate with studs attached into the top of the top flange of a prestressed concrete girder. In total, the two test specimens provided results related to two conventional connection designs and two novel UHPC connection designs.

The conventional connection detail test specimen was composed of a 40-ft (12.2-m)-long, 39-inch (0.99-m)-deep prestressed girder, a 3-inch (76-mm)-tall haunch, and 8.5-inch (216-mm)-thick precast deck panels. The emulated steel girder composite connection included sets of four transversely positioned studs with a diameter of 0.75 inches (19 mm) and a height of 6 inches (152 mm) welded to the steel top flange at a longitudinal spacing of 12.6 inches (321 mm). The concrete girder connection included sets of four transversely positioned headed dowel-in rebars with a diameter of 0.75 inches that were longitudinally spaced at 11.8 inches (300 mm). In both cases, the connectors were designed to pass through the haunch into the full-depth pockets in the precast deck elements. The connections were completed through the use of a conventional non-shrink grout.

The novel UHPC connection detail specimen was also composed of a 40-ft (12.2-m)-long, 39-inch (0.99-m)-deep prestressed girder with 8.5-inch (216-mm)-thick precast deck panels. On this test specimen, the haunch height was increased to 4 inches (102 mm) to create a more severe loading condition. Note that this height is the maximum allowed by NYSDOT in conventional composite connections without the use of supplemental mild steel reinforcement. The emulated steel girder composite connection included sets of two transversely positioned studs with a diameter of 0.75 inches (19 mm) and a height of 3 inches (76 mm), which were welded to the steel top flange at a longitudinal spacing of 6.4 inches (162 mm). The concrete girder composite connection included pairs of #4 hairpin reinforcing bars longitudinally spaced 5.1 inches(130 mm) apart. In both connections, the maximum extension height of the connectors was 3 inches (76 mm), meaning that the connectors stopped prior to the bottom of the deck. For both the steel and concrete girder connections, the connection at the deck was created by exposing the bottom #4 transverse reinforcing bars above the girder top flange. These transverse bars were spaced 7.9 inches (200 mm) apart along the length of the test specimen. The connections were completed through the use of a field-cast UHPC.

The test program for each specimen included two phases. First, each test specimen was subjected to cyclic loads in order to simulate the type of service-level fatigue loadings commonly applied to highway bridge structures. Figure 5 shows a photograph of this test setup. Each test specimen was supported on a 39-ft (11.89-m) span by roller supports. Vertical loads were applied symmetrically 13.5 ft (4.11 m) from each roller. Loads were applied by servo-hydraulic controlled actuators operated under load control. The pair of 100-kip (445-kN) capacity actuators applied loads to the top of the deck along the centerline of the girder through 12- by 12-inch (0.3- by 0.3-m) elastomeric pads backed by steel plates.

Figure 5. Photo. Test setup for cyclic loading of composite connection specimens.

The cyclic loading program was designed to generate large horizontal shear force ranges within the composite connection between the girder and the deck. A four-stage loading program was used, as shown in figure 6. The first three stages each subjected a test specimen to more than 2 million cycles of structural loading. The final stage subjected a test specimen to more than 5 million additional cycles of structural loading. The vertical shear force range was increased by approximately one-third at each successive stage, resulting in the final stage applying twice the vertical shear force range as the initial stage. In this final stage, the vertical shear force range was 94 kips (418 kN).

The design of the composite connection in a slab-on-stringer bridge is frequently driven by service level fatigue load considerations. Section 6.10.10 of AASHTO LRFD Bridge Design Specifications provides guidance on the design of a shear stud composite connection.(7) These provisions were used to determine the amount of steel required to cross all of the girder-to-haunch composite connection interfaces, with the goal of simulating the resistance and exceeding the loading of the design bridge. Figure 7 shows that the horizontal shear fatigue load range per unit length generated in the first phase of the cyclic testing exceeded the anticipated load range for the design bridge as well as the design resistances at the girder/haunch and haunch/deck interfaces. In the figure, ΔVf indicates the range of vertical shear force on the beam element.

Figure 6. Graph. Cyclic loading regime.

Figure 7. Graph. Horizontal shear fatigue ranges during cyclic testing.

After the completion of the cyclic loading program, each specimen was subjected to static loading. The basic loading setup was the same as that used for the cyclic loading, with additional static hydraulic actuators added to achieve the necessary higher loads. Eight additional static jacks were used, with four located adjacent to each of the two servo-hydraulic actuators. The test specimens were loaded in a step-wise fashion until failure.

The novel UHPC connections succeeded in resisting all cyclic structural loads to which they were subjected throughout the testing program. No damage was observed within the UHPC composite connection or in the adjoining steel connectors throughout the duration of this testing. During the final phase of the cyclic testing, the cyclic horizontal shear stress in the field-cast UHPC haunch was 168 psi (1.16 MPa), indicating that a minimum shear plane within the composite connection can carry this stress level.

During the static testing to failure, the UHPC test specimen carried a peak applied shear load of 498 kips (2215 kN), which corresponds to a horizontal shear per unit length of 12.0 kips/inch (2.1 kN/mm). At this load, the prestressed girder began to fail in a combination of horizontal and vertical shear in the web and top flange of the girder. Horizontal shear distress was also observed in the precast deck elements adjacent to the haunch. No damage was observed within the UHPC connection or in the discrete steel elements (i.e., rebar or studs) connecting thereto. The peak horizontal shear stress on the otherwise unreinforced field-cast UHPC haunch was 789 psi (5.44 MPa) along the minimum shear plane.

The conventional connection specimen also succeeded in completing the full set of cyclic load applications. However, as the cyclic testing progressed, it was apparent that degradation of the connection between the emulated steel girder top flange and the haunch was occurring. The conventional specimen began to show increasing horizontal movement along the haunch interface per applied load as compared to the UHPC specimen. This increasing movement can be attributed to progressive deterioration of the composite connection along this interface. The deterioration continued to increase as the cycling progressed through the conclusion of this phase. Regardless, the overall performance of the conventional specimen met the design requirements.

The conventional test specimen carried a peak applied shear load of 445 kips (1980 kN), which corresponds to a horizontal shear per unit length of 10.45 kips/inch (1.83 kN/mm). At this load, the composite connection at the emulated steel girder to haunch interface failed, with nearly all of the studs in the shear span detaching from the steel plate at their bases. Note that the post-test assessment of the stud failure surfaces indicated that 10 of the studs had completely detached and 23 had partially detached during the cyclic loading, leaving a reduced number of studs to carry the horizontal shear during the static loading.

Both specimens exhibited static capacities which exceeded the AASHTO LRFD Bridge Design Specifications ultimate design capacities for the critical horizontal shear interfaces.(7) In the UHPC specimen, the horizontal shear at failure exceeded the design capacity of the steel crossing the emulated steel girder/haunch interface by 66 percent and of the steel crossing the haunch/deck interface by 240 percent. In the conventional specimen, the horizontal shear at failure exceeded the design capacity of the steel crossing the emulated steel girder/haunch interface by 45 percent.

This research project demonstrated that the novel field-cast UHPC composite connection details are capable of meeting critical design, construction, and response requirements. The connections withstood loads greater than those required by AASHTO LRFD Bridge Design Specifications and exhibited performance that surpassed the performance of a companion conventional test specimen.(7)

As compared to conventional construction, composite connections designed with these details are simple to fabricate and assemble. The connections can be completed using technologies and materials already available in the U.S. bridge market. No clustering of girder/deck connectors is necessary, and the aesthetic/durability issues commonly cited with regard to full-depth composite connector blockouts are eliminated.

Based on the findings of this study, a set of limited recommendations can be provided to practitioners and researchers interested in engaging the UHPC composite connection detail. These recommendations are conceptual guidance, not formal design specifications.

Figure 8 provides generic, conceptual composite connection details. The first and third details are similar to the details tested in this study. Reliance on the tensile and shear performance of the field-cast UHPC is a prerequisite for engaging these concepts. The second and fourth details require lesser reliance on the tensile and shear performance of field-cast UHPC while still engaging the rheological properties of the UHPC. The second and fourth details do not completely eliminate connector interference issues but, instead, marginalize this issue by providing large spaces for the intermeshing of the connectors.

Figure 8. Illustration. Example composite connection details.

Existing provisions of AASHTO LRFD Bridge Design Specifications should be retained and engaged as appropriate in the design of this detail.(7) Relevant provisions include those in section 6.10.10 pertaining to the design of shear stud connectors on a steel girder and those in section 5.8.4 pertaining to the design of the connection to precast concrete girders.(7) It must be recognized that requirements for extension of girder composite connectors into the deck will not be met if all aspects of this composite connection concept are engaged.

Roughening of the interface surfaces of precast concrete elements provides significant benefits in terms of enhancing the interface resistance to horizontal shear stresses. Roughening of the top flange of a precast concrete girder, as is common practice, provided good interface shear performance. Precasting a roughened surface into the interface on the underside of the precast concrete deck panels would likely provide a similar benefit. A roughened surface at this location would decrease the demand on the bottom mat reinforcing bars crossing this interface and would likely disperse shearing stresses more uniformly into the connecting elements.

Using more smaller bars for the bottom mat reinforcement of the deck is likely beneficial. Larger bars create larger local stresses in the conventional deck concrete, potentially resulting in local failure of that concrete. Similarly, providing longitudinal reinforcement adjacent to the blockout and immediately above the bottom mat of reinforcement is also likely beneficial to the performance of the overall connection.

The horizontal shear resistance of the UHPC must be considered when designing this type of connection. In this study, the monolithic UHPC in the connection was capable of carrying at least 168 psi (1.16 MPa) of cyclic horizontal shear stress and at least 789 psi (5.44 MPa) of static horizontal shear stress. In order to calculate the horizontal shear capacity of any detail, the analysis must consider the minimum shear plane engaged within the detail, which is heavily dependent on the geometry of the connection and the arrangement of the composite connection connectors emanating from the adjoining prefabricated elements. It may be possible to increase the minimum shear plane through careful arrangement of these connectors. The red lines in figure 9 depict some potential horizontal shear planes for a steel girder to precast deck panel composite connection.

Figure 9. Illustration. Minimum shear planes for horizontal shear transfer in the UHPC composite connection.

Quality control is necessary, particularly with regard to ensuring that the prefabricated components are staged properly and that the field-cast UHPC is mixed and cast properly. As compared to conventional concrete, the greater reliance on the inherent structural performance of UHPC requires that the UHPC is mixed and cast according to the design. Field modifications of predefined mixing proportions or casting procedures are not advised. UHPC rheological indicators are frequently used to ensure appropriate mixing and can predict likely success in filling the hidden composite connection voids that are inherent to this connection detail. It is advisable to ensure that the UHPC emanating from vent holes in the deck has retained an appropriate rheology and contains an appropriate volume of steel fiber reinforcement.

|

Researchers—This study was completed by Ben Graybeal at FHWA’s Turner-Fairbank Highway Research Center. For additional information, contact him at (202) 493‑3122 or in the FHWA Office of Infrastructure Research and Development located at 6300 Georgetown Pike, McLean, VA, 22101-2296. Distribution— The unpublished report covered in this TechBrief is being distributed through the National Technical Information Service, www.ntis.gov. Availability— This TechBrief may be obtained from the FHWA Product Distribution Center by email to report.center@dot.gov, fax to (301) 577-1421, phone to (301) 577-0818, or online at https://www.fhwa.dot.gov/research. Key Words—Ultra-high performance concrete, UHPC, Fiber-reinforced concrete, Bridges, Accelerated construction, Durable infrastructure systems, Girder-to-deck composite connection, Precast deck panel connection, Cyclic testing. Notice—This document is disseminated under the sponsorship of the U.S. Department of Transportation in the interest of information exchange. The U.S. Government assumes no liability for the use of the information contained in this document. The U.S. Government does not endorse products or manufacturers. Trademarks or manufacturers’ names appear in this TechBrief only because they are considered essential to the objective of the document. Quality Assurance Statement—The Federal Highway Administration provides high-quality information to serve Government, industry, and the public in a manner that promotes public understanding. Standards and policies are used to ensure and maximize the quality, objectivity, utility, and integrity of its information. FHWA periodically reviews quality issues and adjusts its programs and processes to ensure continuous quality improvement. |