U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

Research & Technology Transporter This newsletter is an archived publication and may contain dated technical, contact, and link information. |

|

| Publication Number: N/A Date: October 1999 |

Publication Date: October 1999

|

|

| A new bridge design course introduces modal testing as experimental dynamic testing and modal analysis. |

FHWA's Office of Infrastructure R&D, the National Highway Institute, and the Society for Experimental Mechanics Inc., are offering a course on bridge dynamics and testing at the 18th International Modal Analysis Conference in San Antonio, TX, on Feb. 5 and 6, 2000.

The course will provide theoretical and practical aspects of bridge responses to various dynamic loadings, such as wind, earthquakes, traffic, and ship collisions.

The course will provide an introduction to modal testing as experimental dynamic testing and modal analysis. The course is designed for bridge engineers. Space for the course is limited. For more information or reservations please contact Dr. Hamid Ghasemi, (202) 493-3042, hamid.ghasemi@fhwa.dot.gov; or Dr. Philip Yen, (202) 493-3056, wen-huei.yen@fhwa.dot.gov.

Dawn Vanlandingham (202) 493-3198 dawn.vanlandingham@fhwa.dot.gov

|

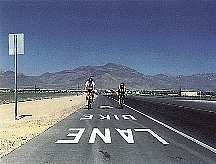

| The Pedestrian and Bicycle Information Center offers technical information and resources for transportation professionals. |

If you've ever had a technical question about bicycling or walking facilities, wanted to know what the latest research says about bicycle and pedestrian safety, or needed examples of how different communities have solved a problem involving bicycling or walking, you can now call (877) WALKBIKE or visit the Web site at www.walkinginfo.org or www.bicyclinginfo.org to find the answer.

In both instances you'll be dealing with the new Pedestrian and Bicycle Information Center established by U.S. DOT to serve as a clearinghouse and technical resource for professionals in the field. Managed by the University of North Carolina's (UNC) Highway Safety Research Center, with the expert assistance of the Association of Pedestrian and Bicycle Professionals, the center provides a unique resource, which is accessible by mail, phone, fax, and online.

Call the toll-free number and talk with the on-site technical resource person, Andy Clarke, or one of UNC's knowledgeable staff members.

Carol Tan Esse (202) 493-3315 carol.tan.esse@fhwa.dot.gov

The goals of U.S. DOT's National Bicycling and Walking Study are to double the percentage of trips made on foot and by bicycle and to reduce the number of crashes that involve bicyclists and pedestrians by 10 percent.

In an effort to meet those goals, bicycle and pedestrian coordinators from more than 30 State DOTs visited the extensive bicycling and walking facilities in Madison, WI, on Sept. 15 and 16. State coordinators were joined by staff from nine FHWA division offices, DOT headquarters, the National Highway Traffic Safety Administration, and the Federal Railroad Administration.

Meeting participants discussed the importance of making bicycling and walking a routine part of Federal and State transportation agencies. To do this, coordinators must encourage and educate the State DOTs on bike/ped issues, enforce regulations, and encourage engineering that is geared toward bicyclists and pedestrians. Participants discussed the following topics at the meetings:

Al Eisenberg, deputy assistant secretary for transportation policy, asked the coordinators to work with liveable-community coalitions to promote the message of bicycle and pedestrian safety to a larger audience and to better document bicycling and walking activity. A new Pedestrian and Bicycle Information Center was launched to assist in these and other bicycling and walking programs.

Bicycle and pedestrian coordinators viewed on- and off-street bicycling facilities in Madison, which included trails, bike lanes (counter-flow, left-side, and shared-bus and bike lanes), traffic calming measures, and a network of bicycle-friendly streets.

John Fegan

|

| Dowel-bars are retrofit and monolithic, bonded 7.5 cm concrete overlay is placed in an innovative one pass process |

The Oklahoma Department of Transportation (DOT) is demonstrating that two rehabilitation techniques can be combined into one productive pavement rehabilitation approach. In October 1998, the Oklahoma DOT combined the two rehabilitation techniques of dowel-bar retrofit and bonded concrete overlay in an innovative, one-pass approach on Interstate 40 in Oklahoma City. The new pavement rehabilitation technique repairs existing distress (faulting) with dowel bar retrofitting and reestablishes smoothness, adds structural capacity, and provides a new riding surface with the bonded overlay at a cost that compares favorably with more traditional approaches.

Prior to the rehabilitation, the existing pavement in the 300-m (1000-ft) test section was 30 years old; 23-cm- (9-in-) thick; and made with jointed plain concrete on bituminous base with joints at a spacing of 4.5 m (15 ft). The pavement was moderately faulted but exhibited no other distresses. For the rehabilitation, a modified roto-mill head was used so that three slots could be quickly milled in each wheel path. The surface was cleaned and dowels were placed in the slots. The pre-overlay surface was given a final cleaning and a 7.5-cm (3-in) overlay of fiber-reinforced concrete was placed with a standard paver. The slots for the dowels were monolithically backfilled with the same concrete as the overlay.

|

| Slots for the dowel-bar retrofit are milled into existing concrete with the modified roto mill head |

Dowel-bar retrofitting is a technique several States have successfully used to address faulting in older jointed plain concrete pavements. The typical approach is to saw cut and jackhammer out the slots for the dowels. Following dowel placement, the slots are then typically backfilled with a non-shrink concrete mixture, and the pavement is diamond-ground to restore smoothness.

Oklahoma's approach in this experiment was innovative in several ways: Using modified roto-mill heads to mill the slots is a much quicker method for milling the pavement than the traditional saw-and-jackhammer approach, which is very labor intensive. The backfilling of the slots monolithically with the bonded concrete overlay is also a new approach, as is the simultaneous construction of both dowel bar retrofit and bonded concrete overlay.

|

| The modified roto-mill head mills slot for the dowel-bar retrofit |

The test section has been carrying interstate traffic (75,000, avarage daily traffic,11 percent of those were trucks) for one year now and has not exhibited any distresses. Oklahoma plans to continue to monitor the performance of the test section and hopes that this might be another useful approach to rehabilitating their faulted jointed plain concrete pavements.

Dean Mentjes (405) 605-6166, ext. 326 dean.mentjes@fhwa.dot.gov

The Long-Term Pavement Performance (LTPP) program recently released DataPave 2.0, an updated version of its DataPave software package. DataPave 2.0 holds nearly three times as much data as the earlier version and includes new LTPP database tables. Other new features include enhanced program functions, such as customized printout and export capabilities for individual section reports, in addition to tutorials that walk users through the program and provide data set examples.

DataPave is a simple, user-friendly software package on CD-ROM and contains most of the data currently available from LTPP experiments.

The CD-ROM contains an inventory; information on material testing, pavement-performance monitoring, climatic factors, traffic, road maintenance and rehabilitation; and seasonal testing data from approximately 2,400 pavement test sections at 900 locations on in-service highways throughout North America. All of the data on the CD-ROM have gone through LTPP's quality-control procedures and the package has been extensively tested to ensure that it will work on all computers using the Microsoft Windows™ 95 or Windows NT operating systems.

Charlie Churilla (202) 493-3333 charlie.churilla@fhwa.dot.gov

To advise FHWA and assist the Office of Highway Policy Information, the Motor-Fuel Reporting Committee held a meeting, on September 23 and 24 to discuss key reporting issues including international fuel tax, the use of diesel fuel by the public, Highway Trust Fund distribution, loss allowances, the use of fuel by Native Americans, and the use of alternative fuels.

The committee is sponsored by FHWA, AASHTO, and the Federal Tax Administrators.

TEA-21 uses motor-fuel and Highway Trust Fund receipts attributed on motor-fuel reporting as a formula factor in the apportionment of Federal funds. This winter the committee will meet again to continue its work and to revise FHWA's Guide to Reporting Highway Statistics. The minutes of the meetings will be available on the Office of Highway Policy Information's Web site in early November (www.fhwa.dot.gov/ohim).

Tom Howard (202) 366-0170 tom.howard@fhwa.dot.gov

|

| Surveys are showing that unanticipated trip delays are the biggest cause of fatigue and stress |

FHWA's Office of Motor Carrier and Highway Safety (OMCHS) is evaluating how the scheduling practices of interstate commercial motor carriers can be a factor in the occurrence of driver fatigue. Understanding operational scheduling requirements and practices of motor carriers will help improve government safety policies and regulations pertaining to driver fatigue. The research began in September 1997 and will be complete by the summer of 2000.

Researchers have already completed an extensive review of driver fatigue literature, conducted carrier-firm site visits and interviews, and held discussions with focus groups comprised of carrier personnel involved in driver scheduling, i.e., drivers, dispatchers, safety directors, and management. Based on the discussions of the focus groups, major scheduling concerns of drivers include:

Driver's say that unanticipated trip delays, particularly those occurring at shipper and receiver facilities, are the biggest cause of fatigue and stress.

Survey instruments have been developed by Iowa State University and approved by the Office of Management and Budget. Surveys are being mailed to truck and motorcoach drivers, dispatchers, safety directors, and top-level executives asking about their operations and scheduling.

After survey results have been received and analyzed, the project team will prepare a draft final report and convene a symposium of experts to review the findings and develop recommendations for scheduling practices that enhance safety.

The study's final report is expected to be available by fall 2000. A technical brief providing an interim update of the study is available from the Office of Motor Carrier Research and Standards. For more information, please contact:

Phil Roke (202) 366-5884 phil.roke@fhwa.dot.gov

|

| Exhibits showcase valuable FHWA programs and offer the opportunity to reach both niche and broad audiences alike. |

During September 19th through the 22nd, FHWA attended the 1999 International Public Works Congress and Exposition, at the Denver Convention Center in Denver, CO.

More than 6,800 attendees from around the country and the world attended the American Public Works Association's (APWA) annual congress and exhibition. FHWA was one of about 400 exhibitors. FHWA exhibited informative displays highlighting FHWA activities in work-zone safety, rumble strips, motor carrier programs, innovative bridge designs, LTAP, international programs, training, real estate relocation issues in highway construction, and FHWA/DOT Web sites.

The two and a half day exhibition was well attended, and a steady flow of customers visited FHWA's display booths.

These exhibits showcased valuable FHWA programs and offered the opportunity to reach both niche and broad audiences alike. For more information on how you can use exhibiting to reach your FHWA customers, contact:

Kevin Connor (202) 493-3187 kevin.connor@fhwa.dot.gov

|

| There are 26 ADHS corridors under construction in the 13-state Appalachian Region. |

Completed portions of the Appalachian Development Highway System (ADHS) in 13 Appalachian States are creating thousands of new jobs and generating economic benefits that will exceed highway construction and maintenance costs by more than $1 billion, according to a new study.

Conducted for the Appalachian Regional Commission (ARC), the study evaluated the extent to which 1,400 completed miles of the proposed 3,025-mile highway system have attained their economic development objective. In 1965 Congress created ARC and authorized construction of the system to support economic development in the Appalachian Region. About 80 percent of the modern highway system is completed or under construction at a cost of about $4.3 billion in Federal funds.

U.S. Transportation Secretary Rodney E. Slater said, "This study confirms once again that transportation is about more than concrete, asphalt and steel. The ADHS is providing opportunity for people in the Region, especially the rural areas, to get to jobs, to schools, and to market so that they can share fully in the economic and social benefits of this nation."

The study looked at completed portions of 12 ADHS highway corridors. The study examined the impact of construction on 165 counties served by the completed segments, which total about 1,400 miles. The counties involved in the study represent about 40 percent of the 406 counties within the entire Region. The ADHS is a major Federal-aid highway program administered by FHWA in conjunction with the Appalachian Regional Commission.

Claretta Duren(202) 366-4636 claretta.duren@fhwa.dot.gov