U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

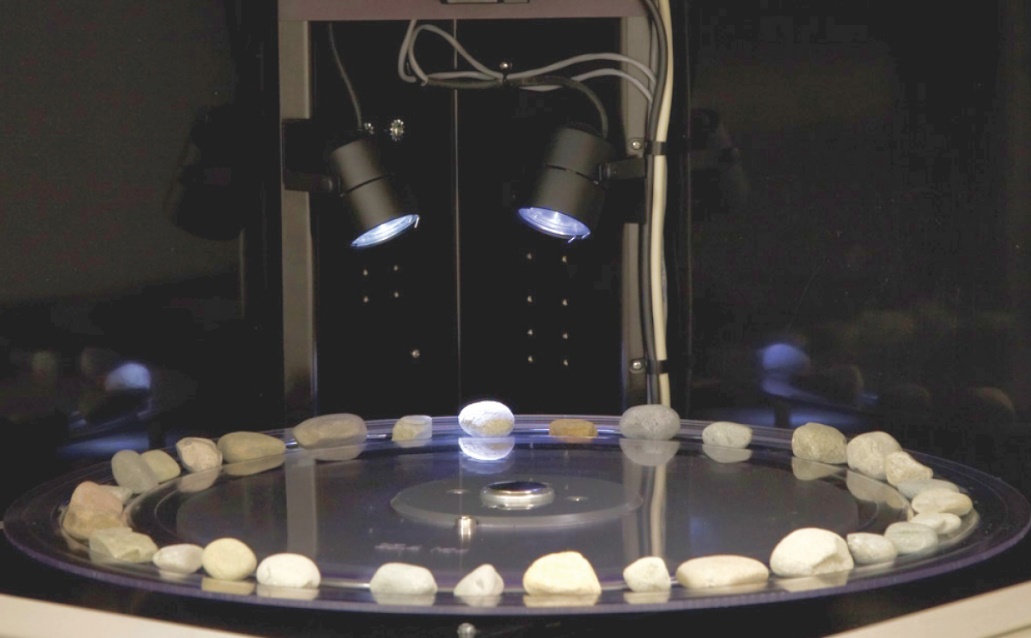

Need: The characteristics of aggregates used in hot-mix asphalt, hydraulic cement concrete, and aggregate pavement layers affect the structural integrity and durability of pavement systems and the skid resistance of pavement surfaces. Those characteristics include shape, (such as round or flat); angularity, (the sharpness of the corners of the aggregate particles); and texture, (the smoothness or roughness of the particle surface). Manual methods now used to measure aggregate characteristics can produce inconsistencies in measurement, quality assurance, and mix design.

Technology: The Aggregate Image Measurement System (AIMS2) to analyze aggregate properties using digital imaging technology. The AIMS2 combines hardware that captures real-time digital images of paving material samples and the proprietary software that analyzes aggregate characteristics that affect pavement quality and improves the speed and accuracy of testing.

Activities funded: The Pine Instrument Company refined the AIMS2 and conducted ruggedness testing and an inter-laboratory study. 32 university, commercial, and highway agency laboratories evaluated the reproducibility of the AIMS2 equipment and procedures. Two AASHTO provisional specifications were adopted as a result of this work.

Further Information: https://www.fhwa.dot.gov/hfl/partnerships/pavementtech.cfm

Contact:

Need: The way asphalt responds to low temperatures is critical to its performance. Low temperature thermal cracking (contraction of the pavement) is a major type of asphalt pavement failure. Millions of dollars are spent annually for pavement repair. To minimize premature failure due to thermal cracking, it is essential to properly grade asphalt binders for the expected climatic environment.

Technology: The ABCD system includes a computer to collect data and control the environmental chamber, which cools the asphalt binder samples at a controlled rate.

Activities funded: EZ Asphalt Technology refined the equipment and analysis software of the ABCD and conducted ruggedness testing and interlaboratory study with 28 labs. The interlaboratory study evaluated the binder cracking temperature and strength, ease of sample preparation and test procedures, and repeatability at other laboratories.

Further Information: https://www.fhwa.dot.gov/hfl/partnerships/pavementtech.cfm

Contact:

Need: Proper compaction of newly applied asphalt helps ensure a crack-free paved surface and longer lasting roadway. But if compaction levels do not meet the design requirements it can result in early degradation of the pavement. Currently, compaction is verified by testing core samples extracted from the hardened asphalt. Low compaction will result in either reduced payment or no payment for the sections.

Technology: The IACA is a device based on an artificial neural network technology that is mounted to vibratory compactors to provide real-time data so compaction inconsistencies can be remedied while asphalt is still pliable. Replacing the time-consuming manual process reduces construction time and make pavements last longer. Volvo is marketing the technology as DensityDirect.

Activities funded: Haskell Lemon Construction Company and the University of Oklahoma refined the technology, developed commercial prototypes, and conducted extensive field testing. Subsequent enhancements extend the ability of the IACA to estimate the stiffness of the pavement layer during its construction. Intelligent Compaction was promoted in round two of the Every Day Counts program.

Further Information:

Contact: