U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

In the past quarter century, roundabouts—circular intersections that can improve safety and mobility—have become as American as hot dogs and baseball.

Since 1990, when the first roundabout was built in the United States, between 3,500 and 4,000 of the innovative intersections have been constructed. By 2010, all 50 states and Washington, D.C., had a roundabout. Since 2014, when the Federal Highway Administration ended its promotion of roundabouts in round two of the Every Day Counts initiative, another 400-plus have been built.

In a roundabout, traffic travels counterclockwise around a central island and entering traffic must yield to circulating traffic. Roundabouts eliminate perpendicular crossings and opposing direction turns in favor of low-speed merging and diverging maneuvers.

Mini-roundabouts are essentially roundabouts that feature central and splitter islands that are fully traversable to accommodate large vehicles within constrained right-of-way.

“Well-designed modern roundabouts can provide local and state agencies with an intersection alternative that reduces fatal and injury crashes,” said Dr. Hillary Isebrands, safety engineer with FHWA’s Resource Center. “What’s more, roundabouts increase traffic flow, slow down speeds of all vehicles and reduce conflict points for pedestrians. Roundabouts can be a game-changing design alternative when safety and operational challenges are present or expected.”

Roundabouts have grown in popularity in large part because they create a safer intersection. Two National Cooperative Highway Research Program reports—Roundabouts in the United States and Roundabouts: An Informational Guide—point to a reduction of 35 percent and 76 percent in total and injury crashes, respectively, following conversion to a roundabout.

“The use of roundabouts is a proven strategy for improving intersection safety by eliminating or altering conflict types, reducing crash severity, and causing drivers to reduce speeds as they proceed into and through intersections,” according to Roundabouts: An Informational Guide. Simply stated, if conflicts occur, they are likely between slower-moving vehicles traveling in the same direction—not of the perpendicular type.

Isebrands points out that roundabouts are an efficient design. All traffic movements—left turn, through and right turn—have equal priority. Most roundabouts require little stopping during off-peak hours. They provide traffic with a flexibility of movement that may not have existed before.

Wisconsin has nearly 200 roundabouts on its state highway system. In 2011, the Wisconsin Department of Transportation did a before-and-after study on a sample of roundabouts that showed a 52 percent drop in fatal and injury crashes.

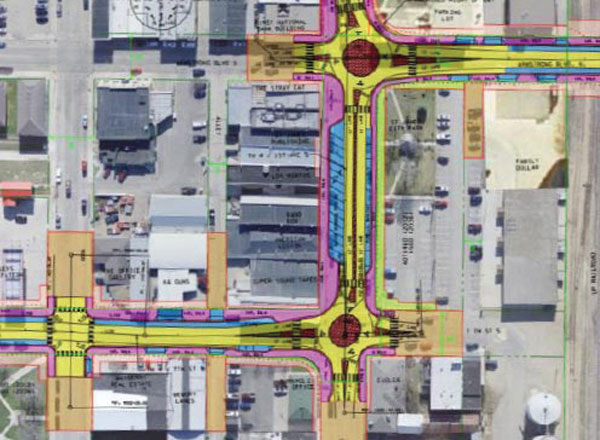

Mini-roundabouts in St. James, Minnesota, are part of an urban reconstruction project. Credit: Minnesota Department of Transportation.

In one of the state’s largest highway construction projects ever, the Wisconsin DOT is improving a total of 31 miles of U.S. 41 in Winnebago and Brown Counties. In addition to extensive widening and interchange work, the department is adding 40 roundabouts, 24 in Brown County and 16 in Winnebago County. Work began in 2009 and will be completed in 2017. The Wisconsin DOT aims to reduce fatal crashes by 90 percent, crashes with injuries by 76 percent and pedestrian crashes by 30 to 40 percent.

At least 15 mini-roundabouts, which offer the safety benefits of regular roundabouts in a smaller footprint, are in operation in the United States, and dozens more are planned. Among the states with mini-roundabouts are Colorado, Georgia, Maryland, New York, Texas and Washington.

The Minnesota Department of Transportation and city of St. James are using an Accelerated Innovation Deployment Demonstration award to build two mini-roundabouts—the first on the state’s highway system and the first in a constrained urban setting. The mini-roundabouts are part of the Highway 4 reconstruction project and will replace two signalized intersections on 1st Avenue South.

The Washington State Department of Transportation, FHWA, and local and state officials broke ground last December on a roundabout in Benton City. The project is one of many Connecting Washington projects throughout the state focused on safety, economic, environmental and mobility improvements. The roundabout, which will replace the intersection at State Routes 224 and 225, is designed to cut traffic congestion and improve access in Benton City.

Video: View a video on the safety benefits of roundabouts.

Video: Watch a video on how to drive on Minnesota’s mini-roundabouts.

See FHWA’s Roundabouts and Mini-Roundabouts webpage for case studies, reports and technical information.

See the Wisconsin DOT’s How Roundabouts Work webpage for driving tips, brochures and videos for road users.

Read Roundabout Practices for a summary of roundabout policies, guidance and procedures at state transportation departments.

Contact Hillary Isebrands of FHWA’s Resource Center for more information.

As part of its push to streamline project coordination, the Texas Department of Transportation sends construction and maintenance agreements to railroads electronically rather than on paper. This enables railroads to load documents into their agreement management systems more easily and get internal approvals faster.

As a result, agreement processing time dropped from more than 16 weeks to as little as four to six weeks.

“Our biggest success has been on our simple maintenance agreements, which represent two-thirds of our overall project load,” said Robert Travis, manager of the agency’s Rail Highway Safety Branch. “We’ve been able to reduce the turnaround time from two to three months to less than one month for review and acceptance by the railroad.”

Texas is one of nine states that have institutionalized the use of tools and practices to improve department of transportation and railroad coordination, a strategy the Federal Highway Administration is promoting in the third round of Every Day Counts. Another six states and Washington, D.C., are piloting the innovation or preparing for full deployment.

The EDC-3 effort uses a model agreement library, tools and training developed under the second Strategic Highway Research Program R16 project, which enables agencies and railroads to identify sources of conflict and develop memorandums of understanding for projects and programs.

“When you consider the hundreds of highway projects that cross or abut railroad rights-of-way each year, you get an idea of the magnitude of extended coordination needed between these organizations,” said Joseph Taylor of the FHWA Office of Infrastructure, who leads the EDC-3 Improving DOT and Railroad Coordination Innovation Deployment Team.

Enhancing collaboration and streamlining processes can save money and time for highway agencies and railroads and result in faster, smarter highway renewal, Taylor said.

“Although most projects go smoothly, delays during project development and construction do occur,” he said. “Coupling that with predictions that freight rail will increase 88 percent by the year 2035 and highway renewal projects will increase as the highway infrastructure continues to age, new approaches are needed to improve collaboration between the organizations.”

The approaches FHWA is encouraging in EDC-3 fall into two categories:

Alabama Department of Transportation staff meet with county engineers, railroad representatives and FHWA staff to coordinate on railroad-related issues, such as the railroad agreement and invoicing process. The Alabama DOT collaborated with railroads to write new railroad crossing guidance for developing Federal-Aid Highway Program projects that involve railroad property.

Enhancing collaboration between highway agencies and railroads can expedite transportation project delivery.

The Delaware Department of Transportation is using SHRP2 funds to develop master agreements with the seven railroad companies it works with to streamline the construction project process. The agency signed a maintenance agreement with Norfolk Southern Railway for railroad crossings in the pavement rehabilitation program.

The Idaho Transportation Department collaborated with the primary railroad companies operating in the state on a master agreement project. The department and BNSF Railway agreed to keep their existing agreement. The department approved and Union Pacific Railroad is reviewing a draft master agreement for the two organizations. Secondary railroads plan to follow the agreement between the department and Union Pacific Railroad.

The Iowa Department of Transportation developed an online railroad safety awareness course that inspection staff on railroad-related projects now use. The agency produced standard specifications for work on or near Union Pacific Railroad, Canadian Northern Railway and Canadian Pacific Railway property and is developing specifications for short-line railroads in the state.

The Tennessee Department of Transportation has master agreements with CSX, Illinois Central Railway and Norfolk Southern Railway. Benefits of coordination include early identification of issues railroads may have with project plans and time savings on project development processes. For example, the Tennessee DOT worked with Norfolk Southern to streamline the process for resurfacing projects, which reduced railroad approval time.

Watch Railroad-DOT Mitigation Strategies, a webinar on the SHRP2 R16 project and tools available to help agencies and railroads work together on projects.

Read Strategies for Improving the Project Agreement Process Between Highway Agencies and Railroads for recommended practices, streamlined permitting processes and model agreements.

Contact Joseph Taylor of the FHWA Office of Infrastructure for information and technical assistance.

With the addition of the Hawaii State Transportation Innovation Council, the national STIC network now includes all 50 states, Puerto Rico, the U.S. Virgin Islands, Washington, D.C., and Federal Lands Highway.

“The completion of the national STIC network is a significant milestone,” Federal Highway Administrator Gregory Nadeau said in remarks at the American Association of State Highway and Transportation Officials Spring Meeting in May. “But this isn’t the finish line. It’s the starting line.”

Since launching the Every Day Counts initiative in 2009, the Federal Highway Administration has encouraged the formation of STICs in each state to enable government agencies and the private sector to work together on innovation deployment. The councils meet regularly to evaluate innovations from a variety of sources, decide which to adopt, develop implementation plans and set the pace for implementation.

“We need to engage the national network more fully than ever, learning from each other’s successes and failures,” Nadeau said. “I look forward to continuing to nurture and develop this network because I think it has a still-untapped potential to identify and deploy innovations that could be advanced by Every Day Counts.”

Hawaii transportation leaders signed a STIC charter in April that calls for fostering “a collaborative culture for rapid implementation of meaningful innovations to efficiently deliver to the public a modern, high-quality highway system.”

STIC members include the Hawaii Department of Transportation, FHWA, local agencies, University of Hawaii, American Council of Engineering Companies of Hawaii, General Contractors Association of Hawaii, Cement and Concrete Products Industry of Hawaii, Hawaii Asphalt Pavement Industry and Local Technical Assistance Program.

Other additions to the STIC network in 2016 include California and Texas, which signed charters in March, and Nebraska, which joined in February:

FHWA Administrator Gregory Nadeau (left) was on hand when California Department of Transportation Director Malcolm Dougherty signed the state’s STIC charter.

FHWA offers resources through its STIC Incentive program to help STICs mainstream innovations. The program provides up to $100,000 per STIC per year to support the costs of standardizing innovative practices in a state transportation department or other public sector STIC stakeholder.

STIC Incentive projects funded in 2016 include an Idaho workshop to advance 3D modeling and automated machine guidance and a series of Ohio events for local agencies on e-Construction, road diets and data-driven safety analysis. Awards also will be used to procure an automated cylinder end grinder to test ultra-high performance concrete in Delaware and develop a mapping framework for data integration in Vermont.

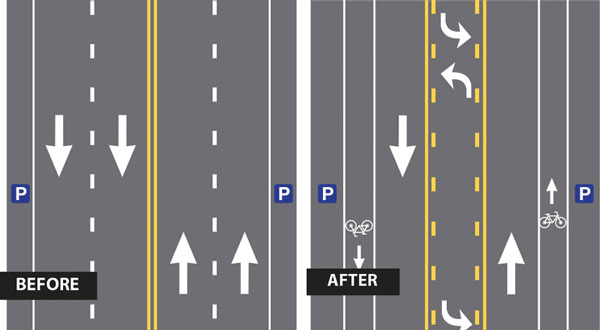

Santa Monica, California, installed a temporary road diet on a stretch of Ocean Park Boulevard with two schools after other safety measures had insufficient influence on a surge in crashes and speeding.

A Santa Monica, California, road diet decreased crashes and travel speeds near schools. Credit: Eric Windstrand

The city of Santa Monica converted part of four-lane Ocean Park Boulevard to one travel lane and bicycle lane in each direction with a two-way left-turn lane in the middle.

Road diets have been used to enhance safety and mobility in the United States for more than three decades, with one of the first installations in Billings, Montana. Over the years, they’ve become more popular as highway agencies and communities recognize their benefits:

Today, road diets are attracting widespread interest as part of the third round of the Federal Highway Administration’s Every Day Counts initiative. They are a standard practice in 11 states and Washington, D.C. Another 32 states are installing road diets and developing processes for identifying potential sites for roadway reconfiguration.

One of the cities that has institutionalized road diets is Phoenix, Arizona, which implemented a Comprehensive Bicycle Master Plan and complete streets ordinance. Both efforts rely on road diets to improve safety and add bike and pedestrian facilities.

Road diets are part of the Indiana Department of Transportation’s Common Paths approach to roadway planning and design that balances the needs of various travel modes to ensure safe, efficient and accessible transportation for all users. The agency introduced the road diet concept during Common Paths workshops for designers, engineers, planners and decision makers.

The Maine Department of Transportation routinely considers road diets to enhance safety and mobility. The agency temporarily reconfigured a section of Route 202 in Manchester using road diet concepts. The road was changed from two eastbound lanes and one westbound lane to one eastbound lane, one westbound lane and a center left-turn lane. If the trial run is successful, the reconfiguration will become permanent.

Road diet projects in Maryland are adding bike lanes on Maryland Route 170 and U.S. 1. The Maryland State Highway Administration plans to select additional road diet projects using criteria such as annual average daily traffic of more than 20,000 vehicles, road width of 48 or more feet, and proximity to transit facilities and bicycle destination points.

The New Jersey Department of Transportation promotes road diets to address high pedestrian crash rates. The agency is developing a checklist for analyzing highway sections to determine road diet feasibility. In addition to installing road diets on state roads, the New Jersey DOT works with metropolitan planning organizations to identify projects on local and county roads.

The Virginia Department of Transportation’s Reston road diets project won a National Roadway Safety Award from the Roadway Safety Foundation and FHWA. The road diets were designed to make travel safer by reducing the number of lanes on segments of Lawyers Road and Soapstone Drive that each carry 10,000 vehicles a day and were prone to speeding. After project completion, crashes dropped 69 percent on Lawyers Road and 67 percent on Soapstone Drive.

Read Road Diet Case Studies for more examples and advice on implementing road diets.

Watch the EDC Exchange: Road Diets webcast for a discussion of road diet applications and success stories.

Go to the Ohio Local Technical Assistance Program’s eLearning website for a free course on road diets, including why they’re an effective safety strategy and how to analyze their impact.

Read Road Diet Informational Guide for details on the decision-making process to determine if road diets are a good fit for a corridor.

See the FHWA Road Diets webpage for roadway reconfiguration resources, including the Michigan Department of Transportation road diet checklist and Oakland, California, complete streets/pavement project coordination checklist.

Contact Becky Crowe of the FHWA Office of Safety and Keith Harrison of the FHWA Resource Center for information and technical assistance.

Preliminary results from the Oklahoma Department of Transportation’s first two high-friction surface treatment projects on rural, low-traffic roads were promising. But the agency wanted to evaluate the technology on highways with high traffic volumes.

An Accelerated Innovation Deployment Demonstration award enabled the Oklahoma DOT to gain experience applying HFST—pavement overlay systems with exceptional skid resistance—on interstates.

The 2015 project, documented in a report, involved using HFST on three-lane curves at three locations on I-40 and I-44 in Oklahoma City. The project’s purpose was twofold:

The Oklahoma DOT chose the sites for HFST application based on crash experience and pavement condition. The entire application was done using an automated process. Because of the traffic volumes at the three locations, work was done at off-peak travel times and on weekends. Only one lane at a time was closed, except when crews applied HFST to the center lanes.

After the Oklahoma City project was finished, stakeholders met to review results and lessons learned:

The Oklahoma DOT plans to collect crash, friction and skid data at the project sites for at least three years to evaluate the safety impacts of applying HFST. Initial skid numbers for the completed project were high at 80 to 84, a substantial improvement over preconstruction skid numbers ranging from 31 to 36. Friction numbers also showed significant improvement.

“The Oklahoma DOT determined from the preliminary results of our data analysis that installation of HFST on multilane high-volume highways is practicable and that dramatically improved friction numbers can be achieved,” the agency said in its report.

Using experience gained on the project, the Oklahoma DOT is developing HFST standards and initiating a program to apply the technology to a number of selected curves each year.

The Delaware Department of Transportation started work on a project to build the state’s first diverging diamond interchange at Delaware Routes 1 and 72 in New Castle County. The agency is using the design-build delivery method on the project, which received an Accelerated Innovation Deployment Demonstration award. Using a diverging diamond interchange and design-build is expected to lower project costs while enhancing safety and mobility at the interchange.

The Kansas Department of Transportation continues to make progress on the Johnson County Gateway, the state’s first major design-build project. Two new flyover ramps opened in the spring to serve traffic on eastbound I-435 to northbound I-35 and westbound I-435 to southbound I-35. The project is designed to improve safety and relieve congestion on the I-435/I-35/K-10 interchange. It’s scheduled for completion by the end of 2016.

The Pueblo of Acoma is using the construction manager/general contractor method to accelerate construction on nine transportation improvement projects in Acomita Village, New Mexico, while delivering the projects under budget and enhancing quality. The projects include road stabilization, intersection safety improvements, bridge replacements, road maintenance plan development and a highway reconstruction that accommodates biking and walking paths.

The Rhode Island Department of Transportation is using accelerated bridge construction techniques to replace the East Shore Expressway and McCormick Quarry bridges in East Providence. The agency will cut project construction time and traffic delays by building geosynthetic reinforced soil abutments and using self-propelled modular transporters to install new superstructures. The bridges—a vital link in Rhode Island’s highway system—are expected to be completed a year earlier than possible using conventional construction methods.

Credit: Washington State Department of Transportation

A spring ceremony celebrated the grand opening of the Washington State Department of Transportation’s State Route 520 floating bridge. The 7,700-foot-long bridge—the world’s longest floating bridge—was built with the design-build project delivery method. The new bridge replaces one that opened in 1963 with a safer structure that offers more roadway and transit capacity.

Summer showcases offered two opportunities to observe geosynthetic reinforced soil-integrated bridge system construction in person. The Indiana Local Technical Assistance Program, Hamilton County Highway Department and FHWA hosted a Hamilton County Bridge 299 project showcase in Noblesville, Indiana. FHWA and Crook County, Wyoming, planned a Sand Creek bridge replacement project showcase in Spearfish, South Dakota. Both events featured presentations on implementing the technology and project site visits.

Innovator, published by the FHWA Center for Accelerating Innovation, advances implementation of innovative technologies and accelerated project delivery methods in the highway industry. Its audience is transportation professionals in highway agencies, trade and research groups, academia and the private sector, and the driving public.

Anthony R. Foxx, Secretary, U.S. DOT

Gregory F. Nadeau, Acting Administrator, FHWA

Thomas Harman, Director

Ewa Flom, Program Coordinator

Julie Zirlin, Technology Partnerships Coordinator

Ellen Schweppe, Managing Editor

James Cline, Jr., Designer

Rodney Walker, Designer

Rebecca Taylor, Designer

Email reprint requests to: Julie.Zirlin@dot.gov