U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Focus

| Accelerating Infrastructure Innovations |

Publication Number: FHWA-RD-00-055

Date: January 2000

What do you get when you mix a city of more than a half million people with 227 bridges and tunnels and a thriving economy? Traffic--and lots of it. The people who live, work, visit, or do business in Washington, DC, rely heavily on the District's roadway system. Although many components of the roadway infrastructure--which includes a bridge built in 1836--are in need of rehabilitation, the incessant travel demand makes it difficult to close a bridge to conduct a conventional rehabilitation project.

|

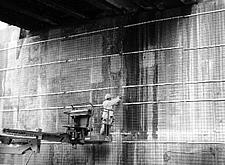

| The ECE process is used to rehabilitate the Eastern Avenue bridge in Washington, DC. |

The District's Department of Public Works (DCDPW), working in partnership with the Federal Highway Administration (FHWA), investigated bridge rehabilitation alternatives and found the electrochemical chloride extraction (ECE) process to be a promising new technology for rehabilitating and protecting concrete components of bridges. The ECE process is fast and economical, and because it reduces the time it would take to replace structural components by conventional methods, there are fewer traffic delays to snarl commuters, residents, and businesses. "In the past 5 years, the ECE process has become nationally recognized as a promising technology that can benefit the owners of thousands of reinforced concrete structures," says Donald Jackson of FHWA.

DCDPW expects to save approximately $250,000 and 6 months of construction time on its first ECE project, which involves rehabilitating the abutments on the Eastern Avenue bridge. The bridge was built in 1934. The bridge deck is currently being replaced using conventional construction methods, but since the bridge abutments showed signs of only minor corrosion, they were suitable for treatment with ECE. The ECE process (see sidebar) will mitigate the effects of the corrosion and eliminate the need to totally reconstruct the damaged sections.

|

| By using ECE, the DC Department of Public Works expects to save $250,000 on its Eastern Avenue bridge project. |

Gary Burch of DCDPW says, "Any rehabilitation technique that allows us to keep a bridge open and minimize congestion is worth studying." To showcase this new technology, DCDPW and FHWA held an "open house" in November, inviting State transportation agencies and consultants to take a firsthand look at the Eastern Avenue project, which is jointly funded by DCDPW and FHWA.

Larry Lundy from the Virginia Department of Transportation (DOT) was glad he drove up from Richmond to attend the open house. "I had never seen an ECE system in place, although I had read about the technology and was very interested in it. The open house helped me understand the process, particularly how it is applied on vertical surfaces, and gave me a chance to see the magnitude of the equipment needed."

James Cheatham of FHWA's DC Division says, "ECE offers benefits over conventional means of bridge rehabilitation or replacement because this technology requires less disruptive and expensive rehabilitation work, can extend the service life of the structure by as much as 12 to 15 years or more, and can save construction time. The District, as the Nation's capital and a major urban area, should be a laboratory for testing new technologies such as the ECE process."

For more information on the ECE process or the open house, contact Donald Jackson at FHWA (telephone: 202-366-9481; fax: 202-366-7495; email: donald.jackson@fhwa.dot.gov).

What is ECE?

When chloride ions, either from deicing chemicals or seawater, penetrate portland cement concrete, they cause the reinforcing steel to corrode. As the steel corrodes, it expands to several times its normal size, which causes the concrete to spall and crack. With the ECE process, an electrical current is applied to the reinforcing steel, causing the chloride ions to be drawn away from the steel and repassivating the steel.

The ECE process requires three basic components--a cathode, a temporary anode, and a temporary electrolyte. The reinforcing steel serves as the cathode, and a titanium or steel mesh covering placed over the area to be treated serves as the anode. The electrolyte (typically, a sodium borate or lithium borate solution) is constantly circulated around the anode, keeping it wet. The system is left in place for several weeks. Once the process is complete, the bridge is usually sprayed with a sealant to impede the penetration of chloride ions in the future.