U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Focus

| Accelerating Infrastructure Innovations |

Publication Number: FHWA-HRT-04-028

Date: August 2004

Rich in historical, ecological, and archaeological significance, the Iowa River Greenbelt is a rare, remaining piece of old-growth woodland in Iowa. Less than a mile wide in most places, this haven for bald eagles is also home to the rare Northern Monkshood plant and three threatened species of freshwater mussel. To protect this environmentally sensitive river valley and habitat while constructing a much needed new bridge over the Iowa River on U.S. 20, the Iowa Department of Transportation (DOT) chose to employ a unique construction method known as incremental launching.

Using this method, the superstructure of the bridge is erected on one side of the waterway and then rolled across the water into its final position. When Iowa DOT initiated the project, it knew of only one other bridge project in the United States that had used launching techniques, although a number of steel bridges have been constructed in Europe using the method. Using the launching method minimized construction activity in, and potential disturbance from construction equipment to, the Greenbelt Valley, as the bulk of construction activity took place within the footprint of the bridge's permanent location. None of the bridge piers were built in the waterway, helping to protect the Iowa River also.

Construction of the bridge began in August 2000. The bridge was designed as a 460-m (1,510-ft) steel I-girder structure, with five 92-m (302-ft) spans supported by six piers. a launching pit (approximately 198-m long (650-ft), 36-m wide (120-ft), and 4.5-m deep (15 ft)) was excavated at the top of the river valley to serve as a work area where the steel bridge superstructure would be assembled. The superstructure was constructed on a series of six temporary steel pile bents in the launching pit. Bridge sections were built and attached to other sections, forming a girder "train." Four of the steel pile bents in the launching pit were equipped with vertical bearing rollers, while the remaining two were used as temporary support points during the steel girder assembly. Vertical rollers were also placed on the structure's six bridge piers. To minimize rolling friction, the vertical rollers were equipped with bronze and fiber linings.

|

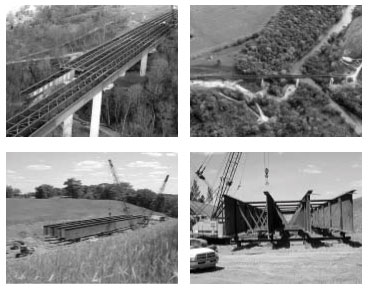

| Top left and right: Aerial views of the Iowa River Bridge under construction. Bottom left: The launching pit during assembly of the steel girders for the bridge's eastbound section. Bottom right: The steel girders during assembly. |

Horizontal guide rollers were installed at each pile bent and pier location to provide steering and alignment control. Guide rollers at several key locations were equipped with 50-ton hydraulic jacks that could be adjusted to provide an active steering force on the girders.

A temporary launching "nose" consisting of two tapered I-girders was then attached to the leading end of the girder train. Its primary purpose was to "touch down" on top of the landing pier rollers and lift the permanent girders upward into position as they continued to be launched forward. The trailing end of the girders was equipped with an 8.4-m long (27.5-ft) tapered tail section, which was designed to transfer the launch forces uniformly to the girders.

During the launch, the attached girders were hydraulically jacked forward 92 m (302 ft) from Pier 6 to Pier 5. The tail section was then removed and additional girder sections were spliced to the back end of the girder train. The tail section was reinstalled and the girders were hydraulically jacked to Pier 4. This sequence was repeated for all five of the spans. The eastbound portion of the bridge was launched first. The temporary pile bents were then removed and reinstalled for the launching of the westbound portion.

The bridge's substructure and superstructure were monitored to obtain Strain, deflection, tilt, and load data for the launches. The superstructure monitoring included assessing girder flexural behavior, girder contact stress at the temporary bridge roller bearings, and cross-frame force distribution and magnitude. The launching force was also monitored. One of the most significant observations was that the bottom flange of the superstructure was subjected to large stresses during the crossing of the launch rollers. Ahmad Abu-Hawash, Chief Structural Engineer in Iowa DOT's Office of Bridges and Structures, notes that the agency did a follow-up inspection and did not see any cracks or other problems that would have a long-term impact. The DOT's recommendations for addressing this problem when using the launching technique in the future include using wider rollers or multiple smaller rollers to spread the load over a larger area.

The Iowa River Bridge opened to traffic on August 22, 2003. According to Abu-Hawash, use of the launching method did not increase construction time. The total cost of the bridge was $19.6 million, which included $1.1 million for the launching of the superstructure steel and the construction of the launching pit. Since Iowa's bridge was built, a very similar launched I-girder bridge has been constructed near Moorefield, West Virginia.

"Although the launching technique on Iowa's project addressed ecosystem and habitat conservation, as well as archaeological issues, the technique may be suitable for addressing traffic congestion and safety as well," says Max Grogg of FHWA's Iowa Division office.

A detailed report and video on the Iowa River Bridge construction are available at no cost from Iowa DOT and FHWA. To obtain a copy, contact Max Grogg at FHWA, 515-233-7306 (email: max.grogg@fhwa.dot.gov). For more information about the project, contact Ahmad Abu-Hawash at Iowa DOT, 515-239-1393 (email: ahmad.abu-hawash@dot.iowa.gov).