Previous | Table of Contents | Next

Table 1 lists the various steels that were employed in this study. These steels are the same as those addressed in the initial interim report for this project, except that Type 304 and Type 2304SS were acquired in the meantime and added to the test matrix. (19)

Table 1. Listing of reinforcements that were investigated.

| Designation/Spec | Common Design | As-Rec'd Cond | Microstructure | PREN1 | Supplier | |

|---|---|---|---|---|---|---|

| UNS-S31603 | Type 316LSS | Pickled2 | Austenite | 26.43 | Slater Steels Corporation | |

| 25.14 | Dunkirk Specialty Steel | |||||

| UNS-S30400 | Type 304SS | Pickled2 | Austenite | 19.6 | Dunkirk Specialty Steel | |

| UNS-S32304 | Type 2304SS | Pickled | Duplex (Austenite plus Ferrite) | 24.9 | UGITECH | |

| ASTM A955-98 | Type 2101LDXSS | As-Rolled | Lean Duplex (Austenite plus Ferrite) | 25.1 | Gerdau AmeriSteel Corporation | |

| ASTM A1035 | MMFX 2 | As-Rolled | Microcomposite austenite-martensite | 9.4 | MMFX Corporation | |

| AASHTO MP 13M/MP 13-04 | Nouvinox | Pickled | 316 Clad/Carbon Steel Core | - | Stelax Industries, Ltd. | |

| SMI | Pickled | 316 Clad/Carbon Steel Core | - | CMC Steel Group | ||

| UNS-S41003 | Type 3Cr12SS | Pickled | Ferritic | 12 | American Utility Metals | |

| ASTM A615 | Black Bar | As-Rolled | Ferrite/Pearlite | 0.3 | Gerdau AmeriSteel Corporation | |

- indicates that the calculation is not applicable. 1 PREN (Pitting Resistance Equivalent Number) where PREN = %Cr + 3.3∙%Mo + 16∙%N 2 Pickled with HF and nitric acid per ASTM A380. 3 Subsequently designated as 316.16.4 Subsequently designated as 316.18. |

||||||

Composition for all of the bars is shown in table 2. Bar size in all cases was #5 (nominally 16 mm diameter) except for Type 304 SS, which was #4 (12.7 mm diameter). The two types of clad bars (designated as STAX and SMI) were fabricated by two distinct processes. The former were created by packing a stainless steel tube with steel scrap followed by rolling. The latter was created by applying a plasma spray of stainless steel to a carbon steel billet and then rolling it. Unless noted otherwise, bars were tested in the as-received surface condition.

Table 2. Composition of the reinforcements. [KF1]

| Alloy | C | Mn | P | S | Si | Cr | Ni | Mo | Cu | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type 316.16 | 0.03 | 1.55 | 0.025 | 0.001 | 0.59 | 18.43 | 10.06 | 2.08 | 0.42 | 0.068 | Bal |

| Type 316.18 | 0.03 | 1.66 | 0.026 | 0.005 | 0.42 | 16.97 | 10.07 | 2.15 | 0.85 | 0.065 | Bal |

| Type 304SS | 0.07 | 0.94 | 0.020 | 0.001 | 0.58 | 18.25 | 8.12 | 0.40 | 0.30 | - | Bal |

| Type 2205SS | 0.029 | 1.68 | 0.028 | 0.004 | 0.63 | 21.58 | 4.80 | 2.64 | - | 0.15 | Bal |

| Type 2304SS | 0.03 | 1.16 | 0.026 | 0.002 | 0.45 | 22.33 | 4.16 | 0.25 | 0.30 | 0.11 | Bal |

| Type 2101SS | 0.04 | 4.70 | 0.019 | 0.001 | 0.80 | 22.47 | 1.68 | 0.24 | 0.38 | 0.117 | Bal |

| A 1035 | 0.05 | 0.45 | 0.012 | 0.015 | 0.23 | 9.30 | 0.10 | 0.03 | 0.12 | - | Bal |

| Type 3Crl2SS | 0.04 | 0.38 | 0.018 | 0.024 | 0.71 | 11.69 | 0.50 | 0.09 | 0.02 | - | Bal |

| A 615 | 0.30 | 1.22 | 0.013 | 0.032 | 0.26 | 0.21 | 0.19 | 0.04 | - | - | Bal |

- indicates element not reported.

Three concrete test designs designated STD1 (five bags cement and 0.50 water-to-cement ratio (w/c)), which yields a high permeability concrete; STD2 (seven bags of cement and 0.41 w/c), which results in moderate permeability; and STD3 (seven bags of cement and 0.50 w/c), which is of improved permeability between that of STD1 and STD2, were employed. Target mix designs for each of these are listed in table 3. The various corrosion resistant alloy types, in addition to BB (table 1), were used as reinforcements.

Table 3. Concrete batch mix design.

| Material | STD1 | STD2 | STD3 |

|---|---|---|---|

| Cement (bags) | 5 | 7 | 7 |

| Cement, kg | 213 | 300 | 300 |

| Water, kg | 107 | 122 | 149 |

| Water/Cement | 0.50 | 0.41 | 0.50 |

| Fine aggregate (silica sand), kg | 652 | 540 | 489 |

| Coarse aggregate (limestone), kg | 753 | 753 | 747 |

Four different types of reinforced concrete specimens were fabricated by the Florida Department of Transportation State Materials Office (FDOT-SMO) in Gainesville, FL. The specimens include the following:

The first two specimen designs were intended to simulate a northern bridge deck or slab exposed to chlorides from either deicing salts or sea water, whereas the latter two specimens represent a marine substructure element. The SDS specimens underwent exposure at FAU, the MS and 3BTC specimen underwent exposure at the FDOT-SMO Corrosion Laboratory, and the FC underwent exposure at the Intracoastal Waterway site at Crescent Beach, FL. The STD consisted of all straight bars in the as-received condition in concrete compacted according to ASTM C192.(20) However, other specimens employed variations of this according to the description and nomenclature listed in table 4.

Table 4. Listing of the various specimen types, variables, and the nomenclature for each.

| Specimen Designation | Description | Specimen Type |

|---|---|---|

| STD1 | STD1 concrete mix. | SDS, FC |

| STD2 | STD2 concrete mix. | SDS, 3BTC |

| STD3 | STD3 concrete mix. | 3BTC |

| BCAT | STD1 concrete, bottom mat black steel. | SDS, MS |

| CCON | STD1 concrete mix, simulated concrete crack. | SDS, MS |

| CCNB | STD1 concrete mix, bottom mat (cathode) black bars, simulated concrete crack. | SDS, MS |

| CREV | STD1 concrete mix, top bar crevice. | SDS |

| CRV | STD1 concrete mix, simulated concrete crack, top bar crevice. | SDS |

| BENT | STD1 concrete mix, top bar bent. | MS |

| STD3 concrete mix, top bar bent. | 3BTC | |

| BNTB | STD1 concrete mix, top bar bent, bottom bars black steel. | MS |

| CBNT | STD1 concrete mix, simulated concrete crack, top bar bent. | MS |

| CBNB | STD1 concrete mix, simulated concrete crack, bottom bars black steel, top bar bent. | MS |

| ELEV | STD3 concrete mix, one bar elevated. | 3BTC |

| WB | STD1 concrete mix, top bars wire brushed. | SDS |

| ARWB | STD1 concrete mix, top bars as received. | MS |

| USDB | STD1 concrete mix, 3 mm diameter clad holes 25 mm apart on top bars. | SDS, MS |

| UBDB | STD1 concrete mix, 3 mm diameter clad holes 25 mm apart on top bars, top bar bent. | MS |

| CSDB | STD1 concrete mix, simulated concrete crack, 3 mm diameter clad holes 25 mm apart. | SDS, MS |

| CBDB | STD1 concrete, cracked concrete, 3 mm diameter clad holes 25 mm apart on top bars, top bar bent. | MS |

| BCCD | STD1 concrete mix, 3 mm diameter clad holes 25 mm apart on top bars, bottom bars black steel. | SDS. MS |

| ACID | STD1 concrete mix, top bars lab pickled, cathode as received. | SDS |

| ABRD | STD1 concrete mix, blasted/abraded top bars, bottom bars as received. | SDS |

| CVNC | STD1 concrete mix, top bar crevice, no end caps. | SDS |

Prior to casting, the reinforcement was degreased by cleaning it with hexane. Next, heat shrink tubing was applied at the bar ends to provide an electrical barrier at the concrete-reinforcement interface. This process left only the center portion of the reinforcement to within approximately 25 mm of the concrete surface exposed. The casting procedure was similar for all specimen types. This process involved placing freshly mixed concrete in the specimen molds in two lifts, followed by consolidating each lift for 20 s to 30 s on a vibration table. The first lift filled the specimen mold approximately half full, and the second lift filled the mold completely. The surface of the specimens was troweled smooth using a wooden or metal float. After 24 hours, the molds were dissembled. The specimens were removed, placed in sealed plastic bags, and stored for 6 months. The design of the four specimen types is provided below.

SDS specimens were fabricated with six bars, three of which comprised a top layer and three a bottom layer, as illustrated schematically in figure 5. The heat shrink tubing at the bar ends is not depicted in the figure.

Figure 5. Chart. Standard SDS specimens.

Concrete cover for all of the bars was 25 mm, and triplicate specimens were prepared for each bar type and specimen variable (described subsequently). Because of the large inventory of specimens, fabrication and delivery to FAU occurred at six different times. The interim report provides results for the exposure of the initial three specimen lots (lots 1-3), and data for these have been updated in this report.(19) In addition, data acquired from the final three lots (lots 4-6) are presented and discussed. Specimens in lots 4-6 are listed in table 5.

Table 5. Listing of SDS specimens in lots 4-6.

Lot 4 Specimens |

Lot 5 Specimens |

Lot 6 Specimens |

|---|---|---|

4-STD2-SMI-1 |

5-STD1-2304-1 |

6-CCRV-304-1 |

4-STD2-SMI-2 |

5-STD1-2304-2 |

6-CCRV-304-2 |

4-STD2-SMI-3 |

5-STD1-2304-3 |

6-CCRV-304-3 |

4-STD1-SMI-1 |

5-STD1-MMFX-1 |

6-CCON-304-1 |

4-STD1-SMI-2 |

5-STD1-MMFX-2 |

6-CCON-304-2 |

4-STD1-SMI-3 |

5-STD1-MMFX-3 |

6-CCON-304-3 |

4-CCON-SMI-1 |

5-STD1-BB-1 |

6-WB-304-1 |

4-CCON-SMI-2 |

5-STD1-BB-2 |

6-WB-304-2 |

4-CCON-SMI-3 |

5-STD1-BB-3 |

6-WB-304-3 |

4-CREV-SMI-1 |

5-STD1-2101-1 |

6-CVNC-SMI-1 |

4-CREV-SMI-2 |

5-STD1-2101-2 |

6-CVNC-SMI-2 |

4-CREV-SMI-3 |

5-STD1-2101-3 |

6-CVNC-SMI-3 |

4-BCCD-SMI-1 |

5-STD1-3Cr12-1 |

6-CCNB-304-1 |

4-BCCD-SMI-2 |

5-STD1-3Cr12-2 |

6-CCNB-304-2 |

4-BCCD-SMI-3 |

5-STD1-3Cr12-3 |

6-CCNB-304-3 |

4-CCRV-SMI-1 |

5-USDB-MMFX-1 |

6-CREV-304-1 |

4-CCRV-SMI-2 |

5-USDB-MMFX-2 |

6-CREV-304-2 |

4-CCRV-SMI-3 |

5-USDB-MMFX-3 |

6-CREV-304-3 |

4-USDB-SMI-1 |

- |

6-STD1-304-1 |

4-USDB-SMI-2 |

- |

6-STD1-304-2 |

4-USDB-SMI-3 |

- |

6-STD1-304-3 |

4-CCRV-3Cr12-1 |

- |

6-STD2-304-1 |

4-CCRV-3Cr12-2 |

- |

6-STD2-304-2 |

4-CCRV-3Cr12-3 |

- |

6-STD2-304-3 |

4-CSDB-SMI-1 |

- |

6-BCAT-304-1 |

4-CSDB-SMI-2 |

- |

6-BCAT-304-2 |

4-CSDB-SMI-3 |

- |

6-BCAT-304-3 |

- indicates that no specimen was fabricated.

A distinction between the initial and final three lots is that heat shrink end sleeves were not installed on bar ends of the specimens in lots 1-3. Because of the concern that the absence of sleeves on bars of the initial three lots may have resulted in premature corrosion initiation where rebars exited the concrete, replicates of BB, 3Cr12, MMFX-2, and 2101 reinforced specimens (these were the only STD type specimens that initiated corrosion) were included in lot 5. Otherwise, specimens in lots 4-6 consisted of reinforcement types/specimen configurations that were not present in lots 1-3. Figure 6 illustrates the nomenclature that was adapted to identify a standard specimen.

4-STD2-SMI-3

Figure 6. Chart. Example nomenclature for standard specimens.

There were six specimen lots, and these correspond to the order in which they were fabricated and delivered to FAU by FDOT. Likewise, designation of specimens that were non-standard (BCAT, CCON; see table 4) is illustrated in figure 7.

4-CCON-3Cr12-2

7. Chart. Example nomenclature for non-standard specimens.

Thus, the last digit identifies the above example as SDS specimen 2. The reinforcement is 3Cr12 with a simulated crack from lot 4. The default mix design (no indication) is STD1. Concrete mix designs STD1 and STD2 were employed for Type 304SS and SMI bars but with most specimens being prepared using the former. Eight different modifications to the above standard SDS specimen configuration were prepared and exposed, as listed and described below.

Figure 8 illustrates this specimen type schematically. Reinforcement types in lots 4-6 SDS specimens that employed this configuration were Type 304SS and SMI.

Figure 8. Chart. Schematic illustration of the CREV type simulated deck slab specimens.

Upon delivery to FAU, an electrical connection was established between bars in both layers of each slab using a stainless steel wire in conjunction with a drilled hole and connection screw at one end of each bar. Periodically, a 10![]() resistor, where

resistor, where ![]() designates the units for resistance, was temporarily inserted in the circuit between the two bar layers. Voltage drop across the resistor was then measured, and the macrocell current was calculated. The specimen sides were coated with an ultraviolet-resistant paint and inverted relative to their orientation at casting. A plastic bath with a vented lid was mounted on what was the bottom-formed face. Prior to ponding, the specimens were stored outdoors in a covered location for 2 months at the FAU Sea Tech Campus, which is approximately 300 m inland from the Atlantic Ocean southeast of Ft. Lauderdale, FL. The initial week of ponding occurred with potable water to promote saturation or a high humidity pore structure so that upon ponding, diffusion, not sorption, would be the primary Cl- ingress mechanism. This week was followed by cyclic 1 week wet/1 week dry ponding with 15.0 wt percent NaCl. The salt water pondings commenced for lots 4, 5, and 6 on July 26, 2005, August 10, 2005, and December 11, 2006, respectively. Figure 9 is a photograph of a mold with CREV-SMI reinforcement prior to concrete pouring. Figure 10 shows two specimens under test, and figure 11 is a perspective view of the test site.

designates the units for resistance, was temporarily inserted in the circuit between the two bar layers. Voltage drop across the resistor was then measured, and the macrocell current was calculated. The specimen sides were coated with an ultraviolet-resistant paint and inverted relative to their orientation at casting. A plastic bath with a vented lid was mounted on what was the bottom-formed face. Prior to ponding, the specimens were stored outdoors in a covered location for 2 months at the FAU Sea Tech Campus, which is approximately 300 m inland from the Atlantic Ocean southeast of Ft. Lauderdale, FL. The initial week of ponding occurred with potable water to promote saturation or a high humidity pore structure so that upon ponding, diffusion, not sorption, would be the primary Cl- ingress mechanism. This week was followed by cyclic 1 week wet/1 week dry ponding with 15.0 wt percent NaCl. The salt water pondings commenced for lots 4, 5, and 6 on July 26, 2005, August 10, 2005, and December 11, 2006, respectively. Figure 9 is a photograph of a mold with CREV-SMI reinforcement prior to concrete pouring. Figure 10 shows two specimens under test, and figure 11 is a perspective view of the test site.

Figure 9. Photo. View of a mold for a CCRV-SMI specimen prior to concrete pouring.

Figure 10. Photo. Two SDS specimens under exposure.

Figure 11. Photo. SDS specimens under exposure in the outdoor test yard.

Monitoring the potential of electrically connected bars of individual specimens and of voltage drop between bar layers was performed weekly. The onset of active corrosion was defined as having occurred if a measureable voltage drop was detected for two consecutive measurement periods. This detection limit corresponded to a current of 0.1 ![]() A. Subsequent to the BB specimens becoming active (the first specimens to do so), the potential and voltage drop measurement procedure was modified, as follows:

A. Subsequent to the BB specimens becoming active (the first specimens to do so), the potential and voltage drop measurement procedure was modified, as follows:

The design for the MS specimens is a modification of the standard G109 geometry and consisted of either a single straight or bent top bar and four straight bottom bars. The latter was positioned at two elevations beneath the top bar. This geometry is illustrated by figure 12. The standard condition was with the reinforcement wire brushed (ARWB), but one set was prepared with bars as received. The STD1 specimens were fabricated with and without a simulated crack, but specimens based upon the STD2 concrete mix were of the standard type only (no crack).

Figure 12. Chart. Geometry of the macrocell slab type specimen with both bent and straight bars.

The types of specimens that were fabricated are indicated in table 4 with individual specimens identified according to the same convention that was explained above for SDS specimens. However, "MS" is included in the nomenclature. Subsequent to curing, the specimens were inverted relative to the orientation at casting, and a 76 mm by 152 mm plastic container for ponding was attached to what had been the bottom cast face. The top bar was wired to the four lower bars through a 1 ![]() resistor via 16 gauge multi-strand wire and solder eyelet connectors. The latter was attached to bar ends using a stainless steel screw mounted into a hole drilled into the end of each bar. The specimens were subjected to a 14 days wet/14 days dry cyclic ponding with a 3.0 wt percent NaCl solution until corrosion-induced cracking occurred. Duplicate sets of three STD1 specimens were prepared with one set exposed in a screened covered outdoor location. The second set (designated STD1G) was prepared in a constant temperature (25 oC) and relative humidity (50 percent) room. In addition, a single set of three other reinforcement/ specimen types (see table 4) and STD2 specimens were prepared and exposed in the same outdoor location noted previously.

resistor via 16 gauge multi-strand wire and solder eyelet connectors. The latter was attached to bar ends using a stainless steel screw mounted into a hole drilled into the end of each bar. The specimens were subjected to a 14 days wet/14 days dry cyclic ponding with a 3.0 wt percent NaCl solution until corrosion-induced cracking occurred. Duplicate sets of three STD1 specimens were prepared with one set exposed in a screened covered outdoor location. The second set (designated STD1G) was prepared in a constant temperature (25 oC) and relative humidity (50 percent) room. In addition, a single set of three other reinforcement/ specimen types (see table 4) and STD2 specimens were prepared and exposed in the same outdoor location noted previously.

Figure 13 shows a photograph of three MS specimens, and figure 14 is a perspective view of the outdoor exposure. For both the controlled and ambient outdoor exposures, potential was recorded monthly, as was the current for the controlled temperature/relative humidity specimens. The current for the outdoor exposed specimens was recorded daily via an Agilent 34970A data acquisition system.

Figure 13. Photo. Three MS specimens under exposure.

Figure 14. Photo. MS slab specimens under exposure.

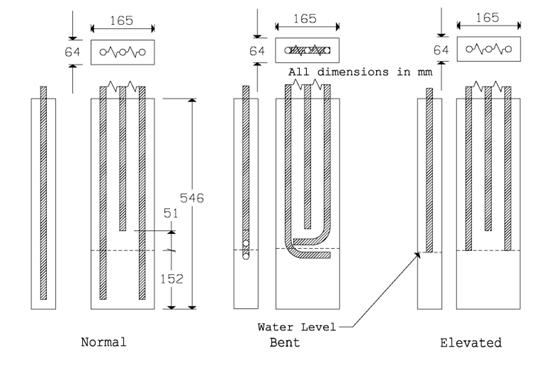

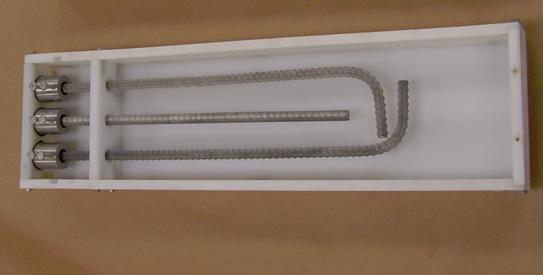

As noted previously, the 3BTC specimens were intended to simulate a marine bridge substructure element. Three bar configurations-normal (STD), bent (BENT), and elevated (ELEV)-were prepared, as illustrated in figure 15. Concrete mixes STD2 and STD3 (table 3) were employed.

Figure 15. Chart. 3BTC specimen for each of the three bar configurations.

Figure 16 shows a photograph of bars of the bent configuration in a mold prior to concrete placement. The bar clamping and alignment method that is illustrated in the figure serves to maintain the intended cover (24 mm) to within close tolerance. The normal reinforcement configuration has been employed by the FDOT for more than 10 years, and it is intended to provide baseline data that can be compared to results from previous studies. On the other hand, the bent bar configuration was considered particularly relevant in the case of stainless clad and possibly MMFX-2 reinforcements because of the possibility of clad or surface layer cracking. Reinforcements that were employed were BB, 3Cr12, MMFX-2, 2101, Type 316, Type 304 SS, and SMI. Six specimens with each rebar type were prepared for the STD2 and STD3 BB type specimens. Otherwise, the number of specimens was three.

Figure 16. Photo. Type 304 rebars of the bent configuration in a mold prior to concrete placement.

Figure 17 is a photograph of a specimen after casting. Prior to exposure, a 1 ![]() resistor was wired between each long bar and the other two bars using the procedure described previously for the MS specimens. Subsequent to curing, specimens were positioned vertically in a plastic tank and submerged in a 3.5 wt percent NaCl solution to a depth of 152 mm to facilitate formation of an electrochemical macrocell on each of the longer bars.

resistor was wired between each long bar and the other two bars using the procedure described previously for the MS specimens. Subsequent to curing, specimens were positioned vertically in a plastic tank and submerged in a 3.5 wt percent NaCl solution to a depth of 152 mm to facilitate formation of an electrochemical macrocell on each of the longer bars.

Figure 17. Photo. 3BTC specimen.

Figure 18 shows specimens under exposure in the outdoor screened room at the FDOT-SMO Corrosion Laboratory. Once exposure was initiated, potential of all three bars coupled, and voltage drop across the two resistors for each specimen was measured daily utilizing a pair of Agilent 34970A data acquisition systems. Exposure of individual specimens was terminated upon concrete cracking or appearance of visible corrosion product bleed-out.

Figure 18. Photo. 3BTC specimens under exposure.

FC specimens were based upon the STD1 concrete mix design with bars only in the as-received condition. Figure 19 illustrates the specimen geometry. The reinforcements that were employed were BB, 3Cr12, MMFX-2, 2101, Type 316.16 SS, Type 304 SS, and SMI with end caps. Each bar was electrically isolated from the others during exposure and potential measurements. The columns were exposed in the Intracoastal Waterway at Crescent Beach, FL by jetting the lower 1.2 m in sand such that mean high water was approximately 1.8 m from the specimen bottom. Placement was delayed because of environmental permitting issues, but it commenced in September 2005.

Figure 19. Chart. Geometry of the field column type specimen.

Figure 20 is a photograph of the specimens installed at the exposure site. A single potential was measured for each of the four bars by placing a copper-copper sulfate electrode in the moist sand near the base of the column. Polarization resistance (Rp) of one bar in each column was determined using an embedded Ti electrode as reference and one of the other three bars as a counter electrode. A cyclic polarization scan was performed to calculate total resistance (Rt), and solution resistance (Rs) was determined using a three-point resistance test. Finally, Rp was calculated as Rt − Rs. These measurements were performed at the time of initial exposure and at approximately 6-month intervals subsequently until corrosion-induced cracking or visible corrosion product bleed-out was observed.

Figure 20. Photo. Field column specimens under exposure at the Intracoastal Waterway site in Crescent Beach, FL.

Table 3.8 to table 3.13 of the interim report list all of the specimens of each of the four designs that had been deployed as of that submission.(19) Those tables are reproduced here as table 6 to table 11. Shaded cells in these tables indicate specimens that had not been fabricated at the time the earlier report was prepared, but these were included in the inventory for lots 4-6 (see table 1).

Table 6. Listing of specimens reinforced with 316.18 and 3Cr12.

Description |

SDS |

S3BC |

3BTC |

MS |

FC |

|---|---|---|---|---|---|

STD1 mix design, standard specimen |

3 |

6 |

- |

6 |

3 |

STD3 mix design, standard specimen |

3 |

3 |

3 |

3 |

- |

STD2 mix design, standard specimen |

- |

- |

6 |

- |

- |

STD1-BCAT |

3 |

- |

- |

3 |

- |

STD1-CCON |

3 |

- |

- |

3 |

- |

STD1-CCNB |

3 |

- |

- |

3 |

- |

STD1-CREV |

3 |

- |

- |

- |

- |

STD1-CCRV |

3 |

- |

- |

- |

- |

STD1-BENT |

- |

3 |

- |

3 |

- |

STD3-BENT |

- |

- |

3 |

- |

- |

STD1-BNTB |

- |

- |

- |

3 |

- |

STD1-CBNT |

- |

- |

- |

3 |

- |

STD1-CBNB |

- |

- |

- |

3 |

- |

STD1-ELEV |

- |

3 |

- |

- |

- |

STD3-ELEV |

- |

- |

3 |

- |

- |

STD1-WB |

3 |

- |

- |

- |

- |

STD1-ARWB |

- |

- |

- |

3 |

- |

Total |

24 |

15 |

15 |

33 |

3 |

TOTAL: 90 |

|||||

- indicates that no specimen of the indicated type was fabricated.

Table 7. Listing of specimens with 2101 rebar.

Description |

SDS |

S3BC |

3BTC |

MS |

FC |

|---|---|---|---|---|---|

STD1 mix design, standard specimen |

3 |

6 |

- |

6 |

3 |

STD3 mix design, standard specimen |

3 |

3 |

3 |

3 |

- |

STD2 mix design, standard specimen |

- |

- |

6 |

- |

- |

STD1-BCAT |

3 |

- |

- |

3 |

- |

STD1-CCON |

3 |

- |

- |

3 |

- |

STD1-CCNB |

3 |

- |

- |

3 |

- |

STD1-CREV |

3 |

- |

- |

- |

- |

STD1-CCRV |

3 |

- |

- |

- |

- |

STD1-BENT |

- |

3 |

3 |

3 |

- |

STD3-BENT |

- |

- |

3 |

- |

- |

STD1-BNTB |

- |

- |

- |

3 |

- |

STD1-CBNT |

- |

- |

- |

3 |

- |

STD1-CBNB |

- |

- |

- |

3 |

- |

STD1-ELEV |

- |

3 |

3 |

- |

- |

STD3-ELEV |

- |

- |

3 |

- |

- |

STD1-WB |

3 |

- |

- |

- |

- |

STD1-ARWB |

- |

- |

- |

3 |

- |

STD1-ACID |

3 |

- |

- |

- |

|

STD1-ABRD |

3 |

||||

Total |

30 |

15 |

15 |

33 |

3 |

TOTAL: 96 |

|||||

- indicates that no specimen of the indicated type was fabricated. Shaded cells indicate that specimens of his type had not been fabricated at the time of the earlier report.

Table 8. Listing of specimens reinforced with MMFX-2.

| Description | SDS | S3BC | 3BTC | MS | FC |

|---|---|---|---|---|---|

| STD1 mix design, standard specimen | 3 | 6 | - | 6 | 3 |

| STD2 mix design, standard specimen | 3 | 3 | 3 | 3 | - |

| STD3 mix design, standard specimen | - | - | 6 | - | - |

| STD1-BCAT | 3 | - | - | 3 | - |

| STD1-CCON | 3 | - | - | 3 | - |

| STD1-CCNB | 3 | - | - | 3 | - |

| STD1-CREV | 3 | - | - | - | - |

| STD1-CCRV | 3 | - | - | - | - |

| STD1-BENT | - | 3 | - | 3 | - |

| STD3-BENT | - | - | 3 | - | - |

| STD1-BNTB | - | - | - | 3 | - |

| STD1-CBNT | - | - | - | 3 | - |

| STD1-CBNB | - | - | - | 3 | - |

| STD1-ELEV | - | 3 | - | - | - |

| STD3-ELEV | - | - | 3 | - | - |

| STD1-WB | 3 | - | - | - | - |

| STD1-ARWB | - | - | - | 3 | - |

| STD1-USDB | 3 | - | - | 3 | - |

| STD1-ACID | 3 | - | - | - | - |

| STD1-ABRD | 3 | - | - | - | - |

| Total | 33 | 15 | 15 | 36 | 3 |

| TOTAL: 102 | |||||

- indicates that no specimen of the indicated type was fabricated.

Table 9. Listing of specimens reinforced with Stelax.

Description |

SDS |

S3BC |

3BTC |

MS |

FC |

|---|---|---|---|---|---|

STD1 mix design, standard specimen |

3 |

6 |

- |

6 |

3 |

STD2 mix design, standard specimen |

3 |

3 |

3 |

3 |

- |

STD3 mix design, standard specimen |

- |

- |

6 |

- |

- |

STD1-CCON |

3 |

- |

- |

3 |

- |

STD1-CREV |

3 |

- |

- |

- |

- |

STD1-CCRV |

3 |

- |

- |

- |

- |

STD1-BENT |

- |

3 |

3 |

3 |

- |

STD3-BENT |

- |

- |

3 |

- |

- |

STD1-CBNT |

- |

- |

- |

3 |

- |

STD1-ELEV |

- |

3 |

3 |

- |

- |

STD3-ELEV |

- |

- |

3 |

- |

- |

STD1-WB |

3 |

- |

- |

- |

- |

STD1-ARWB |

- |

- |

- |

3 |

- |

STD1-USDB |

3 |

- |

- |

3 |

- |

STD1-UBDB |

- |

- |

- |

3 |

- |

STD1-CSDB |

3 |

- |

- |

3 |

- |

STD1-CBDB |

- |

- |

- |

3 |

- |

STD1-BCCD |

3 |

- |

- |

3 |

- |

STD1-ACID |

3 |

- |

- |

- |

- |

STD1-ABRD |

3 |

- |

- |

- |

- |

STD1-CVNC |

3 |

- |

- |

- |

- |

Total |

36 |

15 |

15 |

36 |

3 |

TOTAL: 105 |

|||||

- indicates that no specimen of the indicated type was fabricated. Shaded cells indicate that specimens of this type had not been fabricated at the time of the earlier report.

Table 10. Listing of specimens reinforced with SMI.

Description |

SDS |

S3BC |

3BTC |

MS |

FC |

|---|---|---|---|---|---|

STD1 mix design, standard specimen |

3 |

- |

- |

6 |

3 |

STD2 mix design, standard specimen |

3 |

- |

3 |

3 |

- |

STD3 mix design, standard specimen |

- |

- |

6 |

- |

- |

STD1-CCON |

3 |

- |

- |

3 |

- |

STD1-CREV |

3 |

- |

- |

- |

- |

STD1-CCRV |

3 |

- |

- |

- |

- |

STD1-BENT |

- |

- |

- |

3 |

- |

STD3-BENT |

- |

- |

3 |

- |

- |

STD1-CBNT |

- |

- |

- |

3 |

- |

STD1-ELEV |

- |

- |

- |

- |

- |

STD3-ELEV |

- |

- |

3 |

- |

- |

STD1-WB |

3 |

- |

- |

- |

- |

STD1-ARWB |

- |

- |

- |

3 |

- |

STD1-USDB |

3 |

- |

- |

3 |

- |

STD1-UBDB |

- |

- |

- |

3 |

- |

STD1-CSDB |

3 |

- |

- |

3 |

- |

STD1-CBDB |

- |

- |

- |

3 |

- |

STD1-BCCD |

3 |

- |

- |

3 |

- |

STD1-ABRD |

3 |

- |

- |

- |

- |

STD1-CVNC |

3 |

- |

- |

- |

- |

Total |

33 |

0 |

15 |

36 |

3 |

TOTAL: 87 |

|||||

- indicates that no specimen of the indicated type was fabricated. Shaded cells indicate that specimens of this type had not been fabricated at the time of the earlier report.

Table 11. Listing of specimens reinforced with black bar.

| Description | SDS | S3BC | 3BTC | MS | FC |

|---|---|---|---|---|---|

| STD1 mix design, standard specimen | 3 | 6 | - | 9 | 3 |

| STD2 mix design, standard specimen | 3 | 6 | 6 | 3 | - |

| STD3 mix design, standard specimen | - | - | 6 | - | - |

| CCON-STD1, cracked concrete | 3 | - | - | 3 | - |

| Total | 9 | 12 | 12 | 15 | 3 |

| TOTAL: 51 | |||||

- indicates that no specimen of the indicated type was fabricated.

Figure 21. Chart. Concrete sectioning for SDS specimens.

SDS specimens that became active and were designated for dissection were opened and evaluated. First, testing and exposure were terminated, and the ponding bath was removed. Next, two saw cuts were made; each of them were perpendicular to the top surface and parallel to and at mid-spacing between the center and each of the two outer bars of each layer. For each of the three resultant specimen parts, a further saw cut was made on each of the previous saw cut faces and on what had been the two specimen side faces opposite and parallel to the top rebars to a depth approximately 10 mm from each rebar. In some cases where corrosion of bottom layer BB was thought to have occurred, this procedure was also performed at the level of these bars. Each specimen section was then split open by placing a chisel in one of the previous saw cuts and tapping gently with a hammer until a fracture occurred. This split created a fracture that exposed both the rebar and its trace, which were then examined for corrosion and photographed. Figure 21 schematically illustrates the location of concrete cuts, as listed above.

Dissection procedures for these specimens were essentially the same as for the SDS specimens, as described previously.

Figure 22. Chart. Concrete sectioning for 3BTC specimens.

Dissection of the 3BTC specimens was performed by making a saw cut to the steel depth on the front and back faces along both longer bars starting at the bottom of the specimens and extending up about 0.25 m or more if visual cracking was apparent beyond this. A cut to the steel depth was then made on the front and back faces perpendicular to the reinforcement bars at the 0.25 m elevation across the width of the specimens or just above the highest reaching crack. Once all of the cuts were made, a hammer and chisel were used to split off the cut portion of concrete and expose the reinforcement. Figure 22 provides a schematic illustration of these cuts on a specimen.

No dissections have been made on FC specimens due to a lack of an environmental permit to remove them from the test site.

Concrete samples for [Cl-] determinations were acquired from SDS specimens according to two methods. Both were performed as soon as possible once all of the top layer bars had initiated corrosion, as explained previously. The first method involved acquiring a 75-mm-diameter core from the top concrete surface at the mid-spacing between two adjacent top layer bars. This core was then dry sliced parallel to the top surface at 6.4 mm intervals, and the individual slices were separately ground to powder. The second method involved individually mounting the concrete sections from the top portion of each specimen on a mill and milling a cut approximately 0.6 mm deep along that portion of the rebar trace that was void of corrosion products using a 10-mm-diameter square end cutter. Figure 23 illustrates this process schematically. For both methods (coring and milling), the powder samples were analyzed for [Cl-] using the FDOT wet chemistry method.

Figure 23. Chart. SDS specimen milling along rebar trace to acquire powdered concrete for chloride analysis.

Previous | Table of Contents | Next

FHWA-HRT-09-020