Reactive Solutions - An FHWA Technical Update on Alkali-Silica Reactivity

Volume 3, Issue 4

Inside this Issue:

- FHWA Releases Second ASR Report

- Additional Information on AASHTO ASR Recommended Practice Presented at Annual Meeting

- Icelandic Volcano Ash Shows Promise in Mitigating AAR

- Ask the Experts

- Schedule of Events

- This Issue's Photos

FHWA Releases Second ASR Report

New Report Assists Engineers in Diagnosing and Mitigating ASR

The Federal Highway Administration (FHWA) recently published Report on the Diagnosis, Prognosis, and Mitigation of Alkali-Silica Reaction (ASR) in Transportation Structures (Publication No. FHWA -HIF-09-004). The report details the process necessary to confirm the presence of ASR in a pavement, bridge, or other highway structure. First, a Level 1 investigation is performed, which consists of performing a condition survey to evaluate distresses. If further investigation of distresses is desired, a Level 2 investigation is conducted. A Level 2 investigation consists of documenting information, measuring the Cracking Index (CI), obtaining samples, and conducting a petrographic examination. The report discusses each step of the investigation in detail and provides information on how to interpret results. If an additional investigation is desired or warranted a Level 3 investigation is conducted. The Level 3 investigation is a detailed study of the diagnosis or prognosis of ASR. When conducting a Level 3 investigation, the expansion reached to date, the current rate of expansion, and the potential for future expansion is determined. It is necessary to conduct in-situ testing of the structure as well as a laboratory testing to gather all information necessary to determine how expansion is progressing with time.

Report Cover

The report also includes information about mitigation measures for structures affected by ASR and also alkali-carbonate reaction (ACR). Mitigation can either treat the cause of the reaction or treat the symptoms of the reaction. As shown in the table on Page 2, there are various methods used to mitigate the effects of ASR of existing structures. The report discusses various mitigation measures and also highlights limitations and gaps of the methods.

Table 1. Potential Options for Mitigating ASR - Treating the Cause vs. Treating the Symptom (Taken from FHWA-HIF-09-004).

The appendices of the report will be very useful to engineers and practitioners. Step by step processes are outlined for determining the CI, how to conduct in-situ testing, determining the internal damage and expansion to date using the Modified Stiffness Damage Test (SDT), procedures for expansion tests on cores, determining the current rate of expansion, and evaluation of future expansion. Photographs are also provided to aid in the condition survey and petrographic analysis.

The report is available at https://www.fhwa.dot.gov/pavement/concrete/asrprotocols.cfm. For hard copies please contact Gina Ahlstrom at Gina.Ahlstrom@dot.gov. or Bebe Resendez at bebe@thetranstecgroup.com.

Additional Information on AASHTO ASR Recommended Practice Presented at Annual Meeting

Last year the American Association of State Highway and Transportation Officials (AASHTO) approved Recommended Practice PP 65-10, "Standard Practice for Determining the Reactivity of Concrete Aggregates and Selecting Appropriate Measures for Preventing Deleterious Expansion in New Concrete Construction". During the August 2010 Subcommittee on Materials Meeting the AASHTO Alkali-Silica Reactivity (ASR) Task Force presented a commentary section for inclusion in the recommended practice. The purpose of the commentary section is to provide additional background to the recommended practice and an explanation of the approach adopted in the practice. Inclusion of the commentary section in the recommended practice will be balloted this year. If approved, it will be included in the next publication of the AASHTO guide specifications.

For additional information on the proposed commentary section or for a copy of the presentation discussing the commentary please contact Jim Pappas at james.pappas@state.de.us.

Icelandic Volcano Ash Shows Promise in Mitigating AAR

April Eruption of Eyjafjallajökull Volcano Results in Useful Ash for AAR

In April 2010, the Eyajafjallajökull volcano in Iceland erupted. As a result, a large plume of volcanic ash was thrown into the atmosphere. Although this eruption is better known for freezing air travel in the area, engineers have discovered that the ash from the volcano actually possesses promising alkali-aggregate reaction (AAR) mitigative properties.

Engineers at the International Centre of Research and Applied Technology for Alkali-Aggregate Reactions conducted Accelerated Mortar Bar Tests (American Society of Testing and Materials ASTM C 1260) prepared without the ash and using a 5% cement replacement. After 14 days, the specimens with the ash showed considerably lower expansion (0.02%) than the control specimens (0.45%).

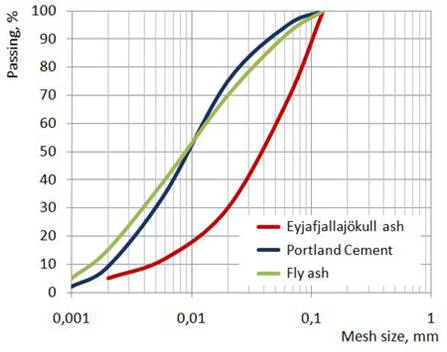

Engineers also evaluated the chemical composition of the ash, which appeared to be similar to fly ash, with approximately 60% of the ash containing SiO2. Further testing included an examination of the particle size distribution of the ash compared to Portland cement and fly ash (see Figure 1).

Figure 1. Particle size distribution of the volcanic ash compared to Portland cement and fly ash. (Source: Concrete Products)

Additional testing results of the ash's effects on the properties of fresh and hardened mortar indicate that this ash may show promise as an additive to mitigate AAR if it is feasible to quarry. For more information, please visit http://www.concreteconstruction.net/industry-news.asp?sectionID=1419&articleID=1298530.

Ask The Experts

"In regard to lithium nitrate, when the lithium replaces the alkaline metals or combines first with silica, what happens to the nitrate portion of the original formula? Does it then combine with sodium or potassium or something else?"

Submitted by Tom Collins, Bridge Engineer, Caltrans

In general, much of the nitrate anion from the admixture simply stays free in the pore solution. In contrast, other compounds, such as lithium carbonate, essentially all of the carbonate ions precipitate out with calcium (from the calcium hydroxide produced from the cement hydration that dissolves into the pore solution). Thus, the pore solution becomes more basic as a result of hydroxide ions replacing the carbonate ions in the pore solution (that is, the later is the case for lithium carbonate, not lithium nitrate). In addition, lithium fluoride essentially behaves just like lithium carbonate in this manner, as calcium fluoride falls out of solution and the concentrations of hydroxide ion increases in the pore solution. Moreover, lithium hydroxide simply increases the hydroxide in the pore solution. As a result, lithium hydroxide, lithium carbonate, and lithium fluoride all behave the same way in regard to their effect on the pore solution. However, the nitrate in lithium nitrate remains free as a "spectator ion" and does not significantly increase the hydroxide concentration in the pore solution-this is actually the key to the greater effectiveness of lithium nitrate. Remember, of course, that it is actually the hydroxide ion that is attacking the susceptible silica in the first place when it comes to ASR.

Got a question? Finding it difficult to get a clear-cut answer?

This section of the newsletter is dedicated to answering your ASR-related questions. In each issue, our editorial committee selects and answers one question submitted by you, the reader. Ask one of our experts-we're here to listen.

Email your question to asrnewsletter@transtec.us.

Schedule of Events

November

October 28-2 2010 AASHTO Annual Meeting, Biloxi, Mississippi

29-December 3 ACPA's 47th Annual Meeting, Bonita Springs, Florida

December

1-3 7th TRB International Bridge Conference, San Antonio, Texas

5-8 ASTM Committee Meeting on Concrete and Concrete Aggregates, New Orleans, LA

January

17-21 World of Concrete, Las Vegas, NV

23-27 90th Transportation Research Board Annual Meeting, Washington, D.C.

This Issue's Photo

Instrumentation of an ASR-affected bridge wall near Montpelier, Vermont.

Have a picture you'd like to send us of an ASR-affected structure in your state? Send us what you like - a bridge, a core, a snapshot of your lab, etc. - our editorial committee will select one picture and post it here for all to see. Email your pictures to asrnewsletter@transtec.us.

Technical Editor: Dr. Michael Thomas

Managing Editor: Bebe Resendez

FHWA Contact: Gina Ahlstrom, Concrete Pavement Engineer (Gina.Ahlstrom@dot.gov.) FHWA-Office of Pavement Technology

Editorial Committee: Lizanne Davis (FMC Corporation), Steve Lane (Virginia DOT), Colin Lobo (National Ready Mix Concrete Association), Brian Merrill (Texas DOT), Peter Taylor (CP Tech Center), Paul Tennis (Portland Cement Association), Leif Wathne (American Concrete Pavement Association)

Get On the Reactive Solutions Mailing List

Want to subscribe to future issues? Email us at asrnewsletter@transtec.us. - Subscriptions are free.