Reactive Solutions - An FHWA Technical Update on Alkali-Silica Reactivity

Volume 4, Issue 2

Welcome to the newest edition of Reactive Solutions, a Technical Update on Alkali-Silica Reactivity (ASR) issues. This periodical disseminates important ASR subject matter from a variety of sources, including the Federal Highway Administration's ASR Program. The program's goal is to deploy methods that state highway agencies can use to prevent and mitigate ASR. This goal is being achieved through technology transfer, including real-world field trials, demonstration projects, and tools for practitioners to address ASR in their state. This periodical helps achieve the program's goal by providing readers with the tools and information needed to address this complex concrete distress problem.

Inside this Issue:

An Update on Ongoing Field Trials

Part 1 of 2

The Federal Highway Administration's (FHWA) ASR activities include a multi-year program termed the ASR Development and Deployment Program. The program includes field trials of real-world ASR prevention and mitigation. To date, there are a total of eight field trials. This issue of Reactive Solutions is the first of a two-part update on the progress of the field trials.

Georgetown, Delaware

In May 2009, a section of pavement along State Route 113 in Georgetown, Delaware was evaluated as a candidate for treatment under the FHWA ASR Development and Deployment Program. After the results of a petrographic analysis confirmed ASR distress in the pavement, the test section, totaling 16 lane miles, was treated with a topical application of lithium nitrate. The objective of this field trial was to determine the efficacy of using topical applications of lithium nitrate in mitigating the ongoing ASR distress in the pavement. Sections of the pavement were instrumented for future monitoring activities to capture the efficacy of the treatment.

Figure 1. Treatment of concrete pavement in Georgetown Delaware. Water application (first vehicle) followed by lithium application (second vehicle). Third vehicle with second pass of water not shown.

In June 2009, the pavement was prepared for the topical lithium treatment. The topical treatment consisted of a water pass (at 1 gal/1000 ft2) to pre-wet the concrete surface (as per the manufacturer's recommendation), followed by the lithium treatment (at 1.5 gal/1000 ft2), and ended with a final water pass (at 1 gal/1000 ft2), as shown in Figure 1. This treatment regimen was repeated the following day to complete the total lithium application of 3 gal/1000 ft2.

Monitoring activities, which included collecting expansion measurements and crack mapping data, were conducted on the site a year later in June 2010. However, in December 2010, the project team was informed that several areas of the test section had deteriorated badly, and the Delaware Department of Transportation (DelDOT) decided to construct a single layer of Novachip over the entire treatment section.

With this new information, arrangements were made with DelDOT to conduct one final monitoring visit to capture expansion and crack mapping data prior to the overlay. During the last monitoring visit in April 2011, a few cores were extracted from select test panels for final petrographic and lithium profiling testing.

New Braunfels, Texas

In 2010, the Texas Department of Transportation (TxDOT) contacted FHWA about a number of precast concrete girders that showed signs of ASR. After a series of communications between TxDOT and FHWA's project team, it was decided to treat a section of the girders with a silane in order to determine the efficacy of using this type of coating in an attempt to reduce the internal humidity in the structures and mitigate the ongoing distress.

Figure 2. View of precast girders in New Braunfels, Texas prior to treatment. Only two out of four girders are shown.

Four girders, located in New Braunfels, Texas, were set aside for treatment and evaluation. It was decided to treat half of each girder topically with silane, leaving the untreated half as a control.

Figure 3. Topical application of silane using a handheld garden sprayer (left); view of girder after treatment (right). Only half of each girder was treated with silane.

Figure 4. TxDOT worker extracting cores for further testing.

In December 2010, the girders were treated and instrumented with humidity sleeves and tubes for future internal humidity measurements. Since TxDOT had already instrumented the girders with steel pins for expansion measurements, no additional pins were drilled into the girders.

The first monitoring visit was conducted in April 2011, and expansion and humidity measurements were collected for all girders. Expansion measurements were collected using the FHWA comparator device, as well as TxDOT's comparator. In addition, the team requested additional cores be extracted from the control section for further petrographic testing.

Figure 5. Humidity probes enclosed in plastic covers.

The next monitoring visit for this site is scheduled for October 2011.

Houston, Texas

In March 2006, a series of columns in Houston, Texas was treated with various methods under FHWA's Lithium Implementation Program, a previous effort performed to evaluate the use of lithium nitrate as a preventative and mitigative method for ASR. The treatment site, located near the intersection of Interstate 10 and Interstate 45 (shown in Figure 6), had been monitored during the length of the Lithium Implementation Program contract, which ended in 2009. However, FHWA felt it would be beneficial to continue monitoring the columns under their ASR Development and Deployment Program.

Figure 6. Location of columns in Houston treated under the FHWA Lithium Implementation Program.

Two sets of five columns each were selected for treatment under the Lithium Implementation Program. A total of eight columns (four columns from each set) were treated using the following methods: 1) electrochemical lithium treatment on media-blasted concrete surface; 2) vacuum treatment with lithium; 3) topical silane on media-blasted concrete surface; and 4) topical silane on painted concrete surface. Two columns, one from each set, were left untreated as controls. All treatments were completed in May 2006. The objective of this field trial was to evaluate the efficacy of lithium nitrate in mitigating ASR when applied in a vacuum setting and electrochemically, and then compare its efficacy to silane materials.

Figure 7. Conducting humidity measurements on a treated column (left); view of a column treated electrochemically with lithium nitrate (right).

In March of 2011, a visit was arranged to conduct monitoring activities in Houston. The columns were instrumented prior to the treatments with expansion pins, humidity tubes and sleeves. Therefore, no additional instrumentation was needed. However, the grids marked for crack mapping measurements had weathered and were redrawn. Expansion, humidity, and crack mapping data were collected.

The next monitoring visit is expected in September 2011.

Montpelier, Vermont

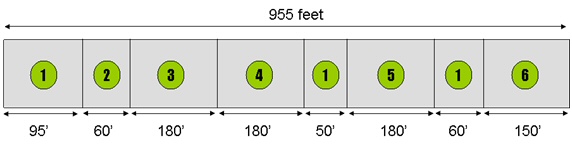

In early 2010, a site visit was conducted to visually survey a stretch of bridge walls along the I-89/Dog River Bridge located near Montpelier, Vermont. As a result of the visit, cores were extracted in May 2010 and a petrographic report was performed in July 2010; the results of the petrographic report confirmed the presence of ASR in the bridge walls. It was decided, along with the Vermont DOT representatives, to treat the bridge walls with a series of sealers and coatings to determine the efficacy of each material in mitigating the ASR. Both the northbound and southbound bridge walls would be treated with three different sealers (as determined by the research team) and one additional sealer generally used by the Vermont DOT. Figure 8 and Table 1 below show a schematic of the treatment sections and materials used.

Figure 8. Schematic of treatment plan (southbound, showing one side). However, the northbound side is scheduled to receive "mirror" treatments.

| Treatment Number | Treatment Type |

|---|---|

| 1 | 100% silane, followed by elastomeric paint |

| 2 | Control |

| 3 | 40% silane |

| 4 | 100% silane |

| 5 | Elastomeric paint |

| 6 | Contractor's treatment (silane) |

The elastomeric paint is an acrylic coating material that bridges cracks and has shown promise in suppressing ASR expansion in jersey barriers in Illinois. Therefore, FHWA's project team was interested in trying this material to compare its efficacy against the two silane materials used in this field trial. In August 2010, the bridge was instrumented for expansion, crack mapping, and humidity readings. Due to ongoing construction on the bridge, only the northbound section was instrumented in early August; however, the southbound section was instrumented later that month for expansion, crack mapping, and humidity measurements as well.

Figure 9. Worker labeling the treatment on the bridge wall (left); Instrumentation site with crack mapping, expansion, and humidity sites for data collection (right).

The treatment of the bridge walls was scheduled for May 2011. However, due to weather constraints and scheduling conflicts, only the northbound part of the bridge was treated. The remaining treatments are scheduled to be completed by the end of summer 2011.

Figure 10. Overview of treatment site.

Schedule of Events

July

24-27 10th International Conference on Low-Volume Roads, Lake Buena Vista, Florida

31-August 5 2011 AASHTO Subcommittee on Materials Meeting, Burlington, Vermont

August

2 Australian Society for Concrete Pavements (ASCP) First National Conference, West Ryde, New South Wales, Australia

5-8 7th International Conference on Road and Airfield Pavement Technology, Bangkok, Thailand

9-11 2011 International Concrete Sustainability Conference, Boston, Massachusetts

16 MnROAD Research Conference, Twin Cities area, Minnesota

September

13-15 Technology Transfer Concrete Consortium (TTCC) and National Concrete Consortium (NCC) Meeting, Rapid City, South Dakota

21-23 12th International Exhibition Roads Bridges Tunnels, St. Petersburg, Russia

26-30 24th World Road Congress, Mexico City, Mexico

Technical Editor: Dr. Michael Thomas

Managing Editor: Bebe Resendez

FHWA Contact: Gina Ahlstrom, Concrete Pavement Engineer (Gina.Ahlstrom@dot.gov.) FHWA'Office of Pavement Technology

Editorial Committee: Lizanne Davis (FMC Corporation), Steve Lane (Virginia DOT), Colin Lobo (National Ready Mix Concrete Association), Brian Merrill (Texas DOT), Peter Taylor (CP Tech Center), Paul Tennis (Portland Cement Association), Leif Wathne (American Concrete Pavement Association)

Get On the Reactive Solutions Mailing List

Want to subscribe to future issues? Email us at asrnewsletter@transtec.us. - Subscriptions are free.