U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-13-092 Date: May 2014 |

Publication Number: FHWA-HRT-13-092 Date: May 2014 |

CHAPTER 1. DISTRESSES FOR PAVEMENTS WITH ASPHALT CONCRETE SURFACES

This section covers asphalt concrete-surfaced pavements (ACP), including ACP overlays on either asphalt concrete (AC) or portland cement concrete (PCC) pavements. Each of the distresses has been grouped into one of the following categories:

Table 1 summarizes the various types of distress and unit of measurement. Some distresses also have defined severity levels.

Distress Type |

Unit of Measure |

Defined Severity Levels? |

|---|---|---|

A. Cracking / 2 |

||

1. Fatigue cracking |

Square meters |

Yes |

2. Block cracking |

Square meters |

Yes |

3. Edge cracking |

Meters |

Yes |

4. Longitudinal cracking |

|

|

4a. Wheel path longitudinal cracking |

Meters |

Yes |

4b. Non-wheel path longitudinal cracking |

Meters |

Yes |

5. Reflection cracking at joints |

Not measured |

N/A |

6. Transverse cracking |

Number, meters |

Yes |

B. Patching and Potholes / 15 |

||

7. Patch/patch deterioration |

Number, square meters |

Yes |

8. Potholes |

Number, square meters |

Yes |

C. Surface Deformation / 19 |

||

9. Rutting |

Millimeters |

No |

10. Shoving |

Number, square meters |

No |

D. Surface Defects / 21 |

|

|

11. Bleeding |

Square meters |

No |

12. Polished aggregate |

Square meters |

No |

13. Raveling |

Square meters |

No |

E. Miscellaneous Distresses / 25 |

||

14. Lane-to-shoulder dropoff |

Not measured |

N/A |

15. Water bleeding and pumping |

Number, meters |

No |

This section includes the following distresses:

1. Fatigue cracking.

2. Block cracking.

3. Edge cracking.

4. Longitudinal cracking.

4a. Wheel path longitudinal cracking.

4b. Non-wheel path longitudinal cracking.

5. Reflection cracking at joints.

6. Transverse cracking.

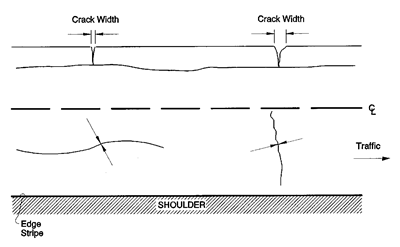

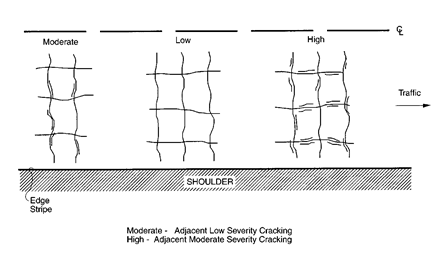

Measurement of crack width is illustrated in figure 1. Figure 2 depicts the effect on severity level of a crack, in this case block cracking, due to associated random cracking.

Figure 1. Measuring Crack Width in ACPs

Figure 2. Effect on Severity Level of Block Cracking due to Associated Random Cracking

Description

Occurs in areas subjected to repeated traffic loadings (wheel paths). Can be a series of interconnected cracks in early stages of development. Develops into many-sided, sharp-angled pieces, usually less than 0.3 m on the longest side, characteristically with a chicken wire/alligator pattern in later stages.

Must have a quantifiable area.

Severity Levels

Low:

An area of cracks with no or only a few connecting cracks; cracks are not spalled or sealed; and pumping is not evident.

Moderate:

An area of interconnected cracks forming a complete pattern; cracks may be slightly spalled; cracks may be sealed; and pumping is not evident.

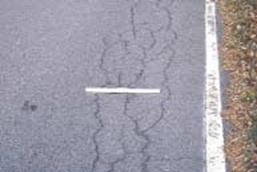

High:

An area of moderately or severely spalled interconnected cracks forming a complete pattern; pieces may move when subjected to traffic; cracks may be sealed; and pumping may be evident.

How to Measure

Record affected area at each severity level in square meters. If different severity levels existing within an area cannot be distinguished, rate the entire area at the highest severity present. Where fatigue and edge cracking exist and overlap in the same area, both should be rated.

Note: An area of short closely spaced (< 0.3 m) transverse cracks in the wheel path should be recorded as fatigue cracking.

Figure 3. Distress Type ACP 1-Fatigue Cracking

Figure 4. Distress Type ACP 1-Chicken Wire/Alligator Pattern Cracking Typical in Fatigue Cracking

Figure 5. Distress Type ACP 1-Low Severity Fatigue Cracking

Figure 6. Distress Type ACP 1-Moderate Severity Fatigue Cracking

Figure 7. Distress Type ACP 1-High Severity Fatigue Cracking with Spalled Interconnected Cracks

Description

A pattern of cracks that divides the pavement into approximately rectangular pieces. Rectangular blocks range in size from approximately 0.1 to 10 m2.

Severity Levels

Low:

Cracks with a mean width ≤ 6 mm or sealed cracks with sealant material in good condition and with a width that cannot be determined.

Moderate:

Cracks with a mean width > 6 mm and ≤ 19 mm or any crack with a mean width ≤ 19 mm and adjacent low severity random cracking. Random cracking should be considered adjacent when it is within 0.3 m of the primary distress.

High:

Cracks with a mean width > 19 mm or any crack with a mean width ≤ 19 mm and adjacent moderate to high severity random cracking. Random cracking should be considered adjacent when it is within 0.3 m of the primary distress.

How to Measure

Record the affected area at each severity level in square meters. If fatigue cracking exists within the block cracking area, the area of block cracking is reduced by the area of fatigue cracking. Longitudinal boundary cracks in a block cracking area are not rated separately. An occurrence should be at least 15 m long before rating as block cracking. Where block and edge cracking exist and overlap, both should be rated.

Figure 8. Distress Type ACP 2-Block Cracking

Figure 9. Distress Type ACP 2-Block Cracking with Fatigue Cracking in the Wheel Paths

Figure 10. Distress Type ACP 2-High Severity Block Cracking

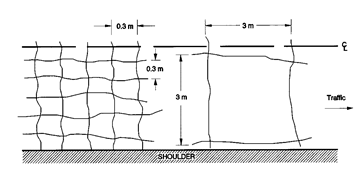

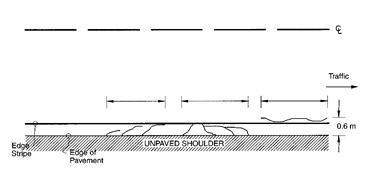

Description

Applies only to pavements with unpaved shoulders. Crescent-shaped cracks or fairly continuous cracks which intersect the pavement edge and are located within 0.6 m of the pavement edge adjacent to the shoulder. Includes longitudinal cracks outside of the wheel path and within 0.6 m of the pavement edge.

Severity Levels

Low:

Cracks with no breakup or loss of material.

Moderate:

Cracks with some breakup and loss of material for up to 10 percent of the length of the affected portion of the pavement.

High:

Cracks with considerable breakup and loss of material for more than 10 percent of the length of the affected portion of the pavement.

How to Measure

Record length in meters of pavement edge affected at each severity level. The combined quantity of edge cracking cannot exceed the length of the section. Where edge cracking and fatigue or block cracking exist and overlap in the same area, both should be rated.

Figure 11. Distress Type ACP 3-Edge Cracking

Figure 12. Distress Type ACP 3-Low Severity Edge Cracking

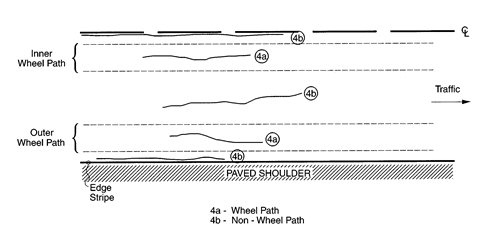

Description

Cracks predominantly parallel to pavement centerline. Location within the lane (wheel path versus non-wheel path) is significant.

Severity Levels

Low:

A crack with a mean width ≤ 6 mm or a sealed crack with sealant material in good condition and with a width that cannot be determined.

Moderate:

Any crack with a mean width > 6 mm and ≤ 19 mm or any crack with a mean width ≤ 19 mm and adjacent low severity random cracking. Random cracking should be considered adjacent when it is within 0.3 m of the primary distress.

High:

Any crack with a mean width > 19 mm or any crack with a mean width ≤ 19 mm and adjacent moderate to high severity random cracking. Random cracking should be considered adjacent when it is within 0.3 m of the primary distress.

Figure 13. Distress Type ACP 4-Longitudinal Cracking

How to Measure

Record separately.

4a. Wheel Path Longitudinal Cracking

Record the length in meters of longitudinal cracking within the defined wheel paths at each severity level.

Record the length in meters of longitudinal cracking with sealant in good condition at each severity level. Sealant is not considered to be in good condition unless at least 1 m of continuous sealant in good condition is present. In cases where a crack is less than 1 m in length, the sealant must be present and in good condition over the entire length of the crack. Any wheel path longitudinal crack that has associated random cracking or meanders and has a quantifiable area is rated as fatigue cracking.

4b. Non-Wheel Path Longitudinal Cracking

Record the length in meters of longitudinal cracking not located in the defined wheel paths at each severity level.

Record the length in meters of longitudinal cracking with sealant in good condition at each severity level. Sealant is not considered to be in good condition unless at least 1 m of continuous sealant in good condition is present.

Figure 14. Distress Type ACP 4a-Moderate Severity Longitudinal Cracking in the Wheel Path

Figure 15. Distress Type ACP 4b-High Severity Longitudinal Cracking not in the Wheel Path

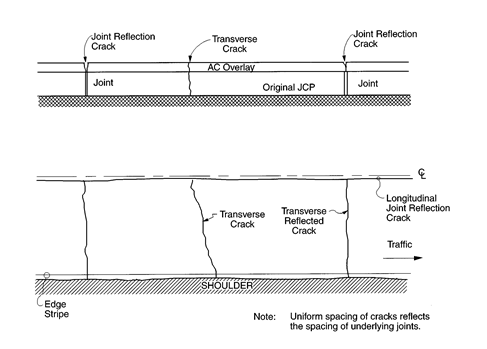

5. Reflection Cracking at Joints

Description

Cracks in AC overlay surfaces that occur over joints in concrete pavements.

Note: The slab dimensions beneath the AC surface must be known to identify reflection cracks at joints.

Severity Levels

Low:

An unsealed crack with a mean width ≤ 6 mm or a sealed crack with sealant material in good condition and with a width that cannot be determined.

Moderate:

Any crack with a mean width > 6 mm and ≤ 19 mm or any crack with a mean width ≤19 mm and adjacent low severity random cracking.

High:

Any crack with a mean width > 19 mm or any crack with a mean width ≤ 19 mm and adjacent moderate to high severity random cracking.

Figure 16. Distress Type ACP 5-Reflection Cracking at Joints

How to Measure

Recorded as longitudinal cracking (ACP 4) or transverse cracking (ACP 6) on LTPP surveys.

Figure 17. Distress Type ACP 5-High Severity Reflection Cracking at Joints

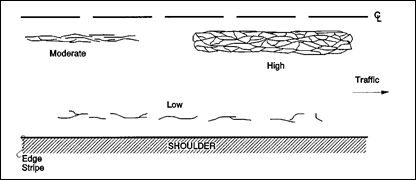

Description

Cracks that are predominantly perpendicular to pavement centerline.

Severity Levels

Low:

An unsealed crack with a mean width ≤ 6 mm or a sealed crack with sealant material in good condition and with a width that cannot be determined.

Moderate:

Any crack with a mean width > 6 mm and ≤ 19 mm or any crack with a mean width ≤ 19 mm and adjacent low severity random cracking. Random cracking should be considered adjacent when it is within 0.3 m of the primary distress.

High:

Any crack with a mean width > 19 mm or any crack with a mean width ≤ 19 mm and adjacent moderate to high severity random cracking. Random cracking should be considered adjacent when it is within 0.3 m of the primary distress.

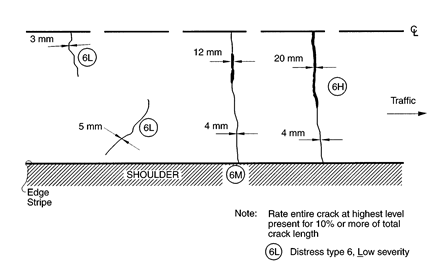

Figure 18. Distress Type ACP 6-Transverse Cracking ACPs

How to Measure

Record the number and length (in meters) of transverse cracks at each severity level. Rate the entire transverse crack at the highest severity level present for at least 10 percent of the total length of the crack.

Also record length (in meters) of transverse cracks with sealant in good condition at each severity level.

Note: The length recorded is the total length of the well-sealed crack and is assigned to the severity level of the crack. Record only when the sealant is in good condition for at least 90 percent of the length of the crack.

If the transverse crack extends through an area of fatigue cracking, the length of the crack within the fatigue area is not counted. The crack is treated as a single transverse crack but at a reduced length. Transverse saw cuts on a "saw and seal" treated AC test section are rated as transverse cracks.

Cracks less than 0.3 m in length are not recorded.

Figure 19. Distress Type ACP 6-Low Severity Transverse Cracking

Figure 20. Distress Type ACP 6-Moderate Severity Transverse Cracking

Figure 21. Distress Type ACP 6-High Severity Transverse Cracking

This section includes the following distresses:

7. Patch/patch deterioration.

8. Potholes.

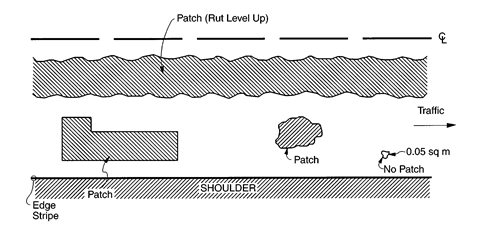

Description

Portion of pavement surface greater than or equal to 0.1 m2 that has been removed and replaced or additional material applied to the pavement after original construction.

Severity Levels

Low:

Patch has, at most, low severity distress of any type including rutting < 6 mm. Pumping is not evident, and there is no loss of patching material.

Moderate:

Patch has moderate severity distress of any type or rutting from 6 to 12 mm; pumping is not evident.

High:

Patch has high severity distress of any type including rutting > 12 mm, or the patch has additional different patch material within it. Pumping may be evident.

How to Measure

Record the number of patches and square meters of affected surface area at each severity level. Surface patches are limited to those with patching material that contain aggregate. If a surface patch has worn away, revealing an underlying distress, or if the underlying distress has reflected through the surface patch and the distress’ existence can be verified on prior surveys, then also rate the distress. Any new distress in the original pavement layer in the patched area should also be rated. Distresses in the patched area affect the severity level of the patch. Patches with no distress are rated low severity. Applications of sealant without aggregate are not to be recorded as patches. These should be drawn on the map sheets and recorded on the distress survey sheets as distress type 16 Other provided that they exceed 0.1 m2.

Note: Any distress in the boundary of the patch is included in rating the patch. Rutting (settlement) may be at the perimeter or interior of the patch.

Figure 22. Distress Type ACP 7-Patch/Patch Deterioration

Figure 23. Distress Type ACP 7-Low Severity Patch

Figure 24. Distress Type ACP 7-Low Severity Patch

Figure 25. Distress Type ACP 7-High Severity Patch

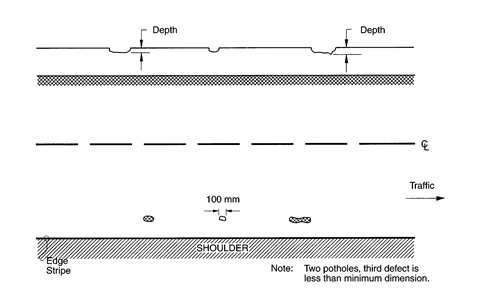

Description

Bowl-shaped holes of various sizes in the pavement surface. Minimum plan dimension is 150 mm. Circular potholes should have a minimum diameter of 150 mm. A 150-mm-diameter circle should fit inside irregular-shaped potholes.

Severity Levels

Low:

< 25 mm deep.

Moderate:

25 to 50 mm deep.

High:

> 50 mm deep.

How to Measure

Record the number of potholes and square meters of affected area at each severity level. Pothole depth is the maximum depth below pavement surface. If a pothole occurs within an area of fatigue cracking, the area of fatigue cracking is reduced by the area of the pothole. The minimum area for a pothole is about 0.02 m2. The actual plan dimensions and the actual area of the pothole shall be recorded on the distress map sheets. Potholes not meeting minimum plan dimension are to be drawn on the distress map sheets and commented on but not included in the measurement summaries.

Figure 26. Distress Type ACP 8-Potholes

Figure 27. Distress Type ACP 8-Low Severity Pothole

Figure 28. Distress Type ACP 8-Moderate Severity Pothole

Figure 29. Distress Type ACP 8-Moderate Severity Pothole, Close-up View

Figure 30. Distress Type ACP 8-High Severity Pothole, Close-up View

This section includes the following types of surface deformations:

9. Rutting.

10. Shoving.

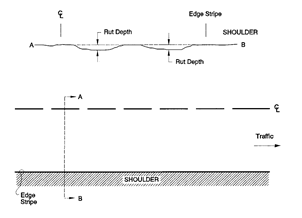

Description

A longitudinal surface depression in the wheel path. It may have associated transverse displacement.

Severity Levels

Not applicable. Severity levels could be defined by categorizing the measurements taken. A record of the measurements taken is much more desirable because it is more accurate and repeatable than are severity levels.

How to Measure

Specific Pavement Studies (SPS)-3 only. Record the maximum rut depth to the nearest millimeter at 15.25-m intervals for each wheel path, as measured with a 1.2-m straight edge.

All other LTPP sections: Transverse profile is measured with a Dipstick® profiler at 15.25-m intervals.

Figure 31. Distress Type ACP 9-Rutting

Figure 32. Distress Type ACP 9-Rutting

Figure 33. Distress Type ACP 9-Standing Water in Ruts

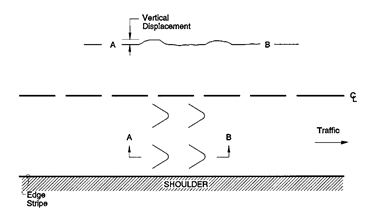

Description

A longitudinal displacement of a localized area of the pavement surface. It is generally caused by braking or accelerating vehicles and is usually located on hills or curves or at intersections. It may have associated vertical displacement.

Severity Levels

Not applicable. However, severity levels can be defined by the relative effect of shoving on ride quality.

How to Measure

Record the number of occurrences and square meters of affected surface area.

Figure 34. Distress Type ACP 10-Shoving

Figure 35. Distress Type ACP 10-Shoving in Pavement Surface

This section includes the following types of surface defects:

11. Bleeding.

12. Polished aggregate.

13. Raveling.

Note: Surface defects can coexist with cracking distresses.

Description

Excess bituminous binder occurring on the pavement surface, usually found in the wheel paths. May range from a surface discolored relative to the remainder of the pavement, to a surface that is losing surface texture because of excess asphalt, to a condition where the aggregate may be obscured by excess asphalt possibly with a shiny, glass-like, reflective surface that may be tacky to the touch.

Severity Levels

Not applicable. The presence of bleeding indicates potential mixture-related performance problems. Extent is sufficient to monitor any progression.

How to Measure

Record square meters of surface area that are affected.

Note: Preventative maintenance treatments (i.e., slurry seals, chip seals, fog seals, etc.) exhibit bleeding characteristics at times. These occurrences should be noted but not rated as bleeding.

Figure 36. Distress Type ACP 11-Discoloration

Figure 37. Distress Type ACP 11-Loss of Texture

Figure 38. Distress Type ACP 11- Aggregate Obscured

Description

Surface binder worn away to expose coarse aggregate.

Severity Levels

Not applicable. However, the degree of polishing may be reflected in a reduction of surface friction.

How to Measure

Record square meters of the affected surface area. Polished aggregate should not be rated on test sections that have received a preventive maintenance treatment that has covered the original pavement surface.

Figure 39. Distress Type ACP 12-Polished Aggregate

Description

Wearing away of the pavement surface caused by the dislodging of aggregate particles and loss of asphalt binder. Raveling ranges from loss of fines to loss of some coarse aggregate and ultimately to a very rough and pitted surface with obvious loss of aggregate.

Severity Levels

Not applicable. The presence of raveling indicates potential mixture-related performance problems. Extent is sufficient to monitor any progression.

How to Measure

Record square meters of the affected surface. Raveling should not be rated on chip seals.

Figure 40. Distress Type ACP 13-Loss of Fine Aggregate

Figure 41. Distress Type ACP 13-Loss of Fine and Some Coarse Aggregate

Figure 42. Distress Type ACP 13-Loss of Coarse Aggregate

This section includes the following distresses:

14. Lane-to-shoulder dropoff.

15. Water bleeding and pumping.

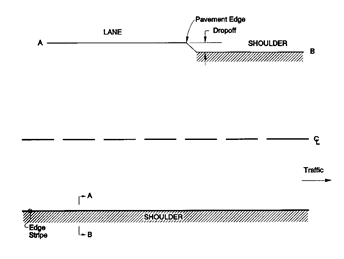

Description

Difference in elevation between the traveled surface and the outside shoulder. Typically occurs when the outside shoulder settles as a result of pavement layer material differences.

Severity Level

Not applicable. Severity levels could be defined by categorizing the measurements taken. A record of the measurements taken is much more desirable, however, because it is more accurate and repeatable than severity levels.

How to Measure

Not recorded in LTPP surveys, but should be noted.

Figure 43. Distress Type ACP 14-Lane-to-Shoulder Dropoff

Figure 44. Distress Type ACP 14-Lane-to-Shoulder Dropoff

15. Water Bleeding and Pumping

Description

Seeping or ejection of water from beneath the pavement through cracks.

In some cases, it is detectable by deposits of fine material left on the pavement surface, which were eroded (pumped) from the support layers and have stained the surface.

Severity Levels

Not applicable. Severity levels are not used because the amount and degree of water bleeding and pumping changes with varying moisture conditions.

How to Measure

Record the number of occurrences of water bleeding and pumping and the length of affected pavement, with a minimum length of 1 m.

Note: Water bleeding and pumping is measured longitudinally along the length of the test section. The combined length of water bleeding and pumping cannot exceed the length of the test section.

Figure 45. Distress Type ACP 15-Water Bleeding and Pumping

Figure 46. Distress Type ACP 15-Fine Material Left on Surface by Water Bleeding and Pumping