U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-088 Date: March 2015 |

Publication Number: FHWA-HRT-14-088 Date: March 2015 |

Several DLR data inconsistencies were identified by the data analysis/operations feedback reports (DAOFRs) Ecompex-75-77 and the technical memorandum, Investigation of Ohio DLR data in LTPP Database. (See references 2-5.) The inconsistencies were between SPS-1 DLR raw data and SPS-1 DLR data in LTPP Standard Data Release (SDR) 22.0 and concerned differences in strain gauge trace peaks and related time stamps, sensor locations, and wheelpath offsets.(6) Similar inconsistencies were also found between SPS-2 DLR raw data and SPS-2 DLR data in SDR 22.0.

Ecompex-75 and 76 and the technical memorandum indicated that the SPS-1 DLR data in SDR 22.0 had time lag shifts in pavement deflection peak strains when compared to the DLR raw data (i.e., the test control software (TCS) data in American Standard Code for Information Interchange (ASCII) format). (See references 2, 3, 5, and 6.) A time lag shift is defined as the difference in time stamps between two peak strains.

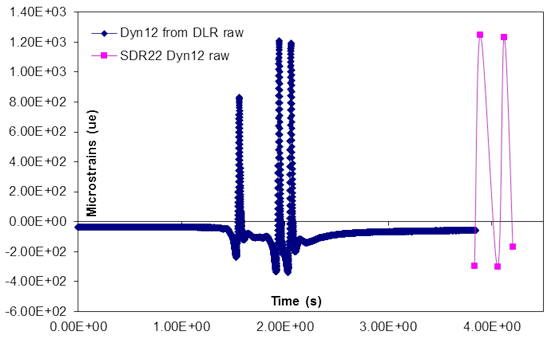

For test section 390102, figure 4 and table 1 compare the Dyn12 strain gauge peaks for a tandem-axle truck between SPS-1 DLR data in SDR 22.0 and raw DLR data. The data are from test J2C run 1. In figure 4, the Dyn12 raw data trace has three peaks. The first peak on the left was generated by the front axle, and the next two peaks were generated by the two rear axles. The SDR 22.0 Dyn12 trace has only two rear-axles peaks; the trace does not contain the front-axle peak.

Figure 4. Graph. Dyn12 strain gauge traces for test section 390102 test J2C run 1 with 2,000.579 Hz

Table 1 . Dyn12 strain gauge data for test section 390102.

Test Name |

Run |

Test Date |

Truck ID |

Dyn12 Peak No. |

TCS Raw |

SDR 22.0 Raw |

TCS Raw Versus |

|||

|---|---|---|---|---|---|---|---|---|---|---|

TCS |

SDR 22.0 |

Dyn12 |

Time |

Dyn12 |

Time |

|||||

J2C |

1 |

8/5/1996 |

2B |

2 |

1 |

1,210.00 |

1.94 |

1,245.20 |

3.89 |

1.92 |

J2C |

1 |

8/5/1996 |

2B |

2 |

2 |

1,180.00 |

2.06 |

1,232.70 |

4.12 |

|

J2C |

2 |

8/5/1996 |

2B |

2 |

1 |

1,180.00 |

1.83 |

1,282.70 |

3.81 |

N/A |

J2C |

2 |

8/5/1996 |

2B |

2 |

2 |

1,300.00 |

1.94 |

1,315.20 |

N/A |

|

J2E |

2 |

8/6/1996 |

2C |

1 |

1 |

1,270.00 |

1.43 |

1,282.70 |

2.85 |

2.01 |

J2E |

2 |

8/6/1996 |

2C |

1 |

2 |

1,540.00 |

1.70 |

1,537.70 |

3.39 |

|

J2E |

3 |

8/6/1996 |

2C |

1 |

1 |

999.00 |

0.87 |

1,015.20 |

1.74 |

1.97 |

J2E |

3 |

8/6/1996 |

2C |

1 |

2 |

1,440.00 |

1.15 |

1,455.20 |

2.29 |

|

J2E |

10 |

8/6/1996 |

2C |

1 |

1 |

472.00 |

1.24 |

480.10 |

2.49 |

2.01 |

J2E |

10 |

8/6/1996 |

2C |

1 |

2 |

1,650.00 |

1.40 |

1,650.30 |

2.81 |

|

J2G |

1 |

8/9/1996 |

2D |

1 |

1 |

736.00 |

1.13 |

740.10 |

2.25 |

2.00 |

J2G |

1 |

8/9/1996 |

2D |

1 |

2 |

1,110.00 |

1.41 |

1,117.70 |

2.81 |

|

N/A = Data not available.

Note: For SDR 22.0 Truck ID, 1 refers to a single rear axle truck, and 2 refers to a tandem rear axle truck.

The time lag shift factor was computed by comparing strain gauge Dyn12 peak value time stamps between the TCS raw data and SDR 22.0 raw data. For example, for test J2C run 1, the time lag shift factor of 1.92 was computed as follows: (4.12 - 3.89)/(2.06 - 1.95) = 1.92.

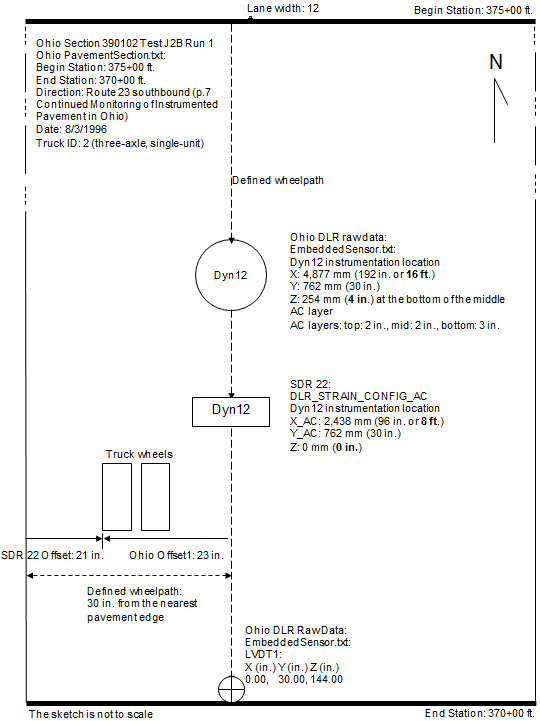

The inconsistencies involving strain gauge locations and wheelpath offset values between the SPS-1 raw DLR data and DLR data in SDR 22.0 were reported in Ecompex-77.(4) Figure 5 shows a sample sketch of Dyn12 strain gauge locations using data from table 2. The strain gauge location of Dyn12 in the raw data was 16 ft from the end station of test section 390102; the Dyn12 strain gauge in SDR 22.0 was 8 ft from the end station of the section.

Inconsistent wheelpath offsets between the raw DLR data and DLR data in SDR 22.0 are shown in figure 5 and listed in table 2. The wheelpath offset data were measured from the defined wheelpath, which was 30 inches from the right pavement edge. The SDR 22.0 wheelpath offset data were measured from the right pavement edge. Figure 5 shows the wheelpath offset data (the raw data) as 23 inches and the SDR 22.0 wheelpath offset data as 21 inches. Thus, the total of the two offsets is 44 inches, which is inconsistent with 30 inches, the width of the defined wheelpath.

In the table, X_AC is the distance along the direction of traffic as referenced from the start of the first LVDT gauge in the section; Y_AC is the distance from the shoulder joint as referenced from the start of the first LVDT gauge in the section; and Z is the distance from the pavement surface to measurement point of sensor. For the Ohio raw data, X is the X-coordinate measured from southernmost joint of first instrumented slab in PCC sections or from southernmost deep LVDT in AC sections and increases to the north; Y is the y-coordinate measured from the right edge of pavement and increases to the left; and Z is the z-coordinate measured from surface of pavement and increases downward, which makes a left-handed coordinate system in the northbound lane.

Figure 5. Illustration. Dyn12 strain gauge locations and wheelpath offsets for test section 390102

Table 2 . Strain gauge locations for SDR 22.0 and Ohio raw data

Test Section ID |

Test Name |

Tag ID |

DLR AC Strain Configuration for SDR 22.0 |

Ohio Raw Data |

||||

|---|---|---|---|---|---|---|---|---|

X_AC (inches) |

Y_AC (inches) |

Z |

X (inches) |

Y (inches) |

Z (inches) |

|||

390102 |

J2B |

Dyn1 |

216 |

30 |

0 |

72 |

30 |

2 |

390102 |

J2B |

Dyn2 |

192 |

30 |

0 |

96 |

30 |

2 |

390102 |

J2B |

Dyn3 |

168 |

30 |

0 |

120 |

30 |

2 |

390102 |

J2B |

Dyn4 |

144 |

30 |

0 |

144 |

30 |

2 |

390102 |

J2B |

Dyn5 |

120 |

30 |

0 |

168 |

30 |

2 |

390102 |

J2B |

Dyn6 |

96 |

30 |

0 |

192 |

30 |

2 |

390102 |

J2B |

Dyn7 |

96 |

30 |

0 |

72 |

30 |

4 |

390102 |

J2B |

Dyn8 |

96 |

30 |

0 |

96 |

30 |

4 |

390102 |

J2B |

Dyn9 |

96 |

30 |

0 |

120 |

30 |

4 |

390102 |

J2B |

Dyn10 |

96 |

30 |

0 |

144 |

30 |

4 |

390102 |

J2B |

Dyn11 |

96 |

30 |

0 |

168 |

30 |

4 |

390102* |

J2B |

Dyn12 |

96 |

30 |

0 |

192 |

30 |

4 |

390102 |

J2B |

Dyn13 |

96 |

72 |

0 |

72 |

72 |

4 |

390102 |

J2C |

Dyn12 |

96 |

30 |

0 |

192 |

30 |

4 |

390102 |

J2C |

Dyn13 |

96 |

72 |

0 |

72 |

72 |

4 |

390102 |

J2E |

Dyn12 |

96 |

30 |

0 |

192 |

30 |

4 |

390102 |

J2E |

Dyn13 |

96 |

72 |

0 |

72 |

72 |

4 |

390102 |

J2G |

Dyn12 |

96 |

30 |

0 |

192 |

30 |

4 |

390102 |

J2G |

Dyn13 |

96 |

72 |

0 |

72 |

72 |

4 |

390104 |

J4B |

Dyn1 |

216 |

30 |

0 |

72 |

30 |

2 |

390104 |

J4B |

Dyn2 |

192 |

30 |

0 |

96 |

30 |

2 |

390104 |

J4B |

Dyn10 |

96 |

30 |

0 |

72 |

30 |

7 |

390104 |

J4B |

Dyn11 |

96 |

30 |

0 |

96 |

30 |

7 |

390104 |

J4B |

Dyn12 |

96 |

30 |

0 |

120 |

30 |

7 |

390104 |

J4B |

Dyn13 |

96 |

30 |

0 |

144 |

30 |

7 |

390104 |

J4B |

Dyn14 |

96 |

30 |

0 |

168 |

30 |

7 |

390104 |

J4B |

Dyn15 |

96 |

30 |

0 |

192 |

30 |

7 |

*Indicates this scenario was plotted in figure 5.

Note: Bold text indicates inconsistent strain gauge locations.

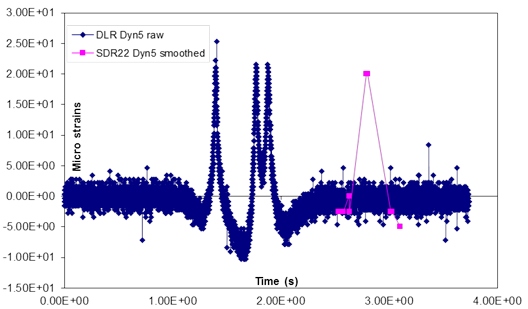

Similar to the data for SPS-1, the SPS-2 (PCC) DLR data in SDR 22.0 had time lag shifts in pavement deflection peak strains when compared to raw DLR data and also had inconsistent sensor locations and wheelpath offset values. Figure 6 compares the Dyn5 strain gauge peaks for a tandem-axle truck between SPS-2 DLR data in SDR 22.0 and SPS-2 raw DLR data for Ohio test section 390201.

Figure 6. Graph. Dyn5 strain gauge traces for test section 390201 test J1A run 2