U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-088 Date: March 2015 |

Publication Number: FHWA-HRT-14-088 Date: March 2015 |

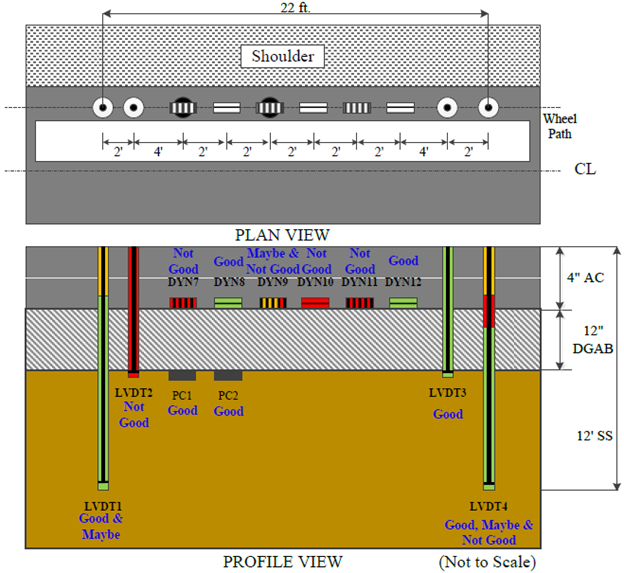

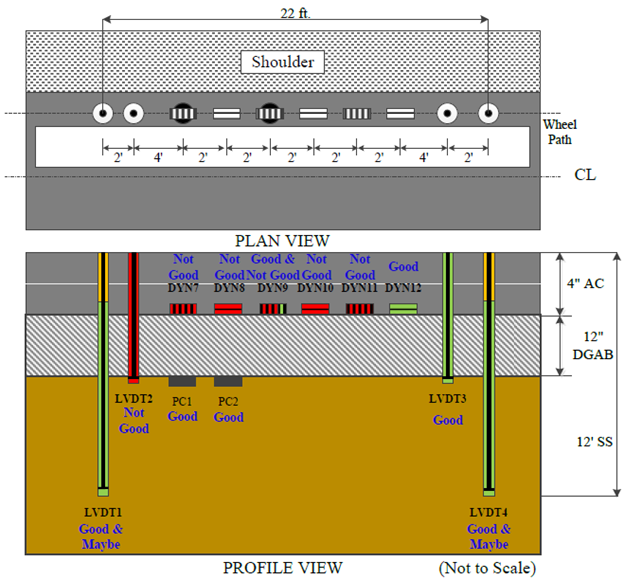

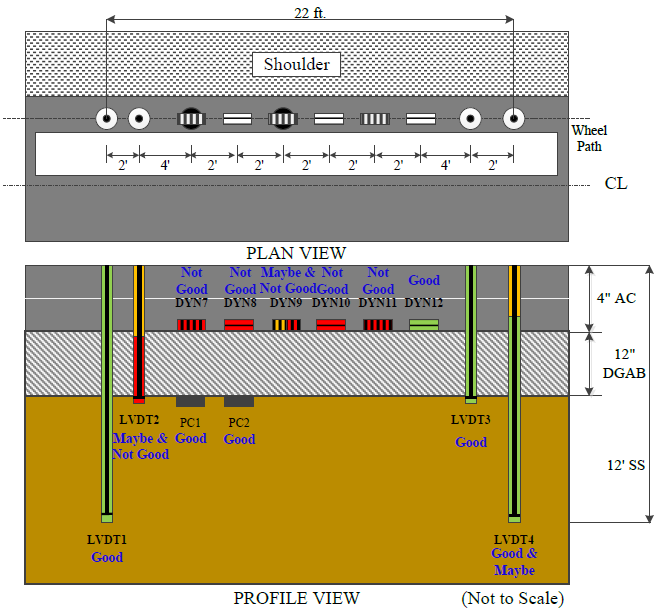

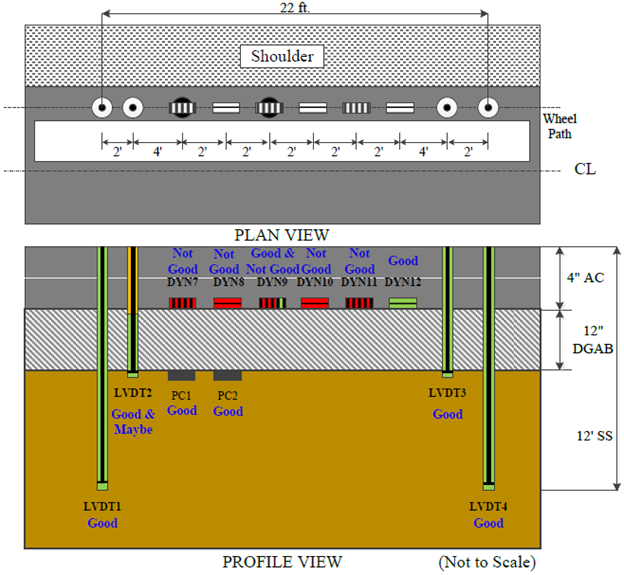

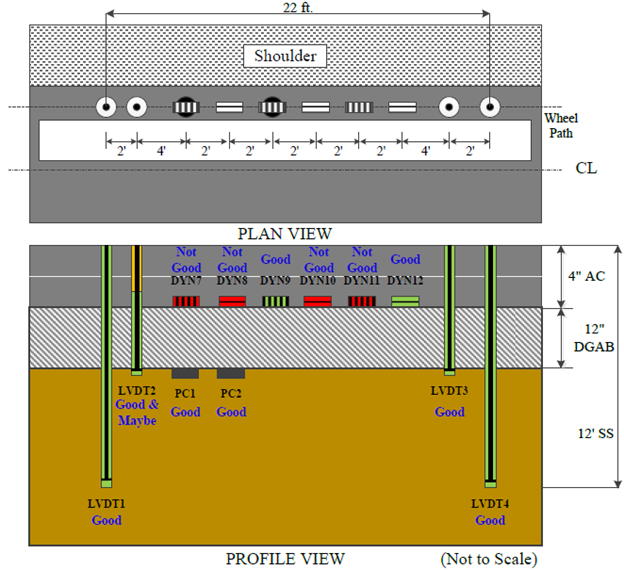

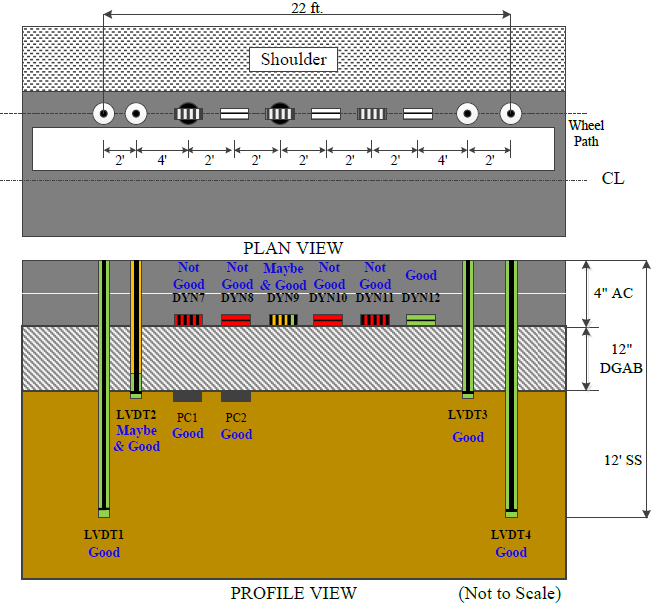

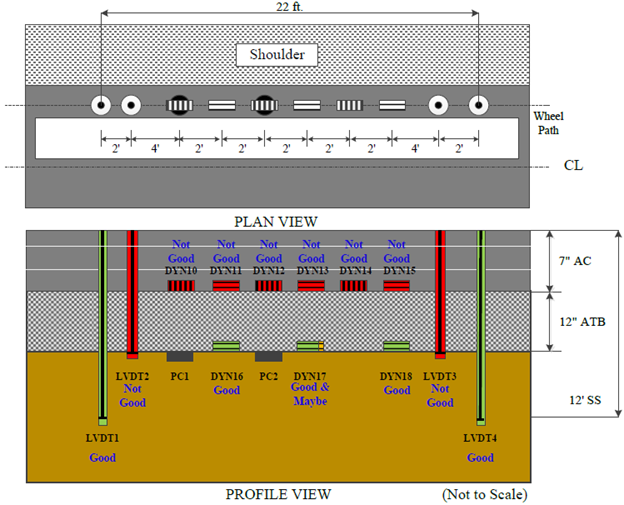

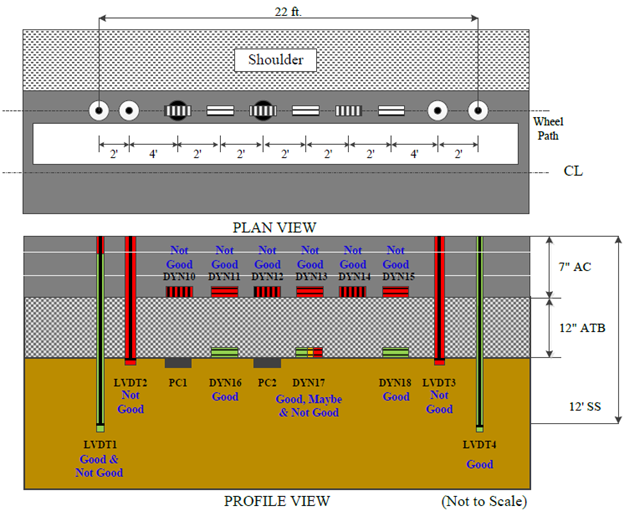

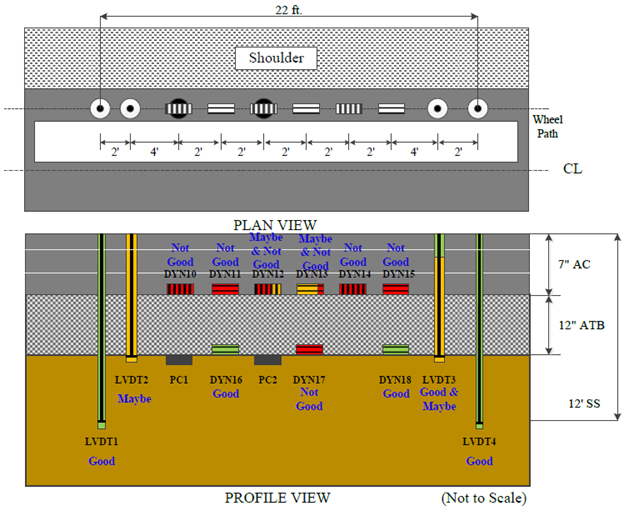

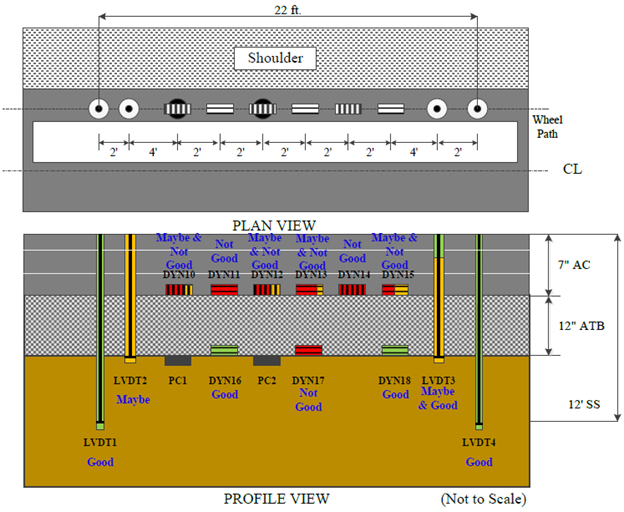

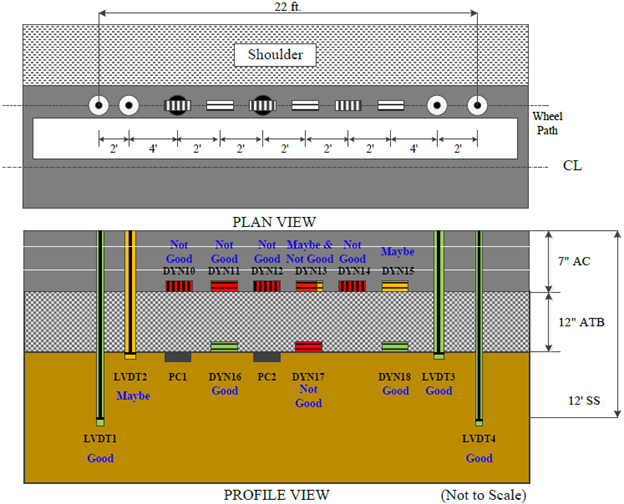

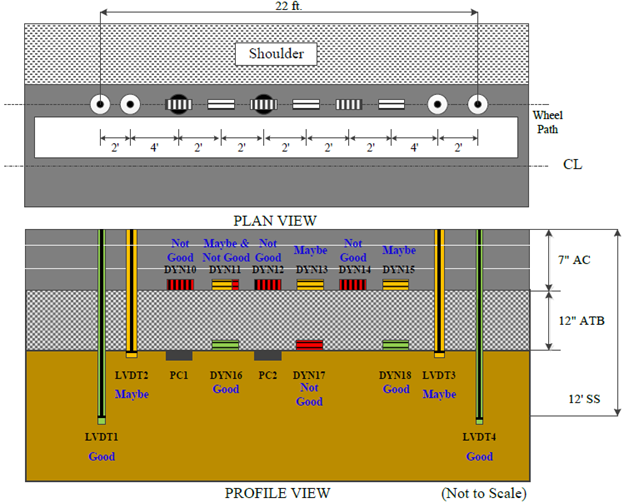

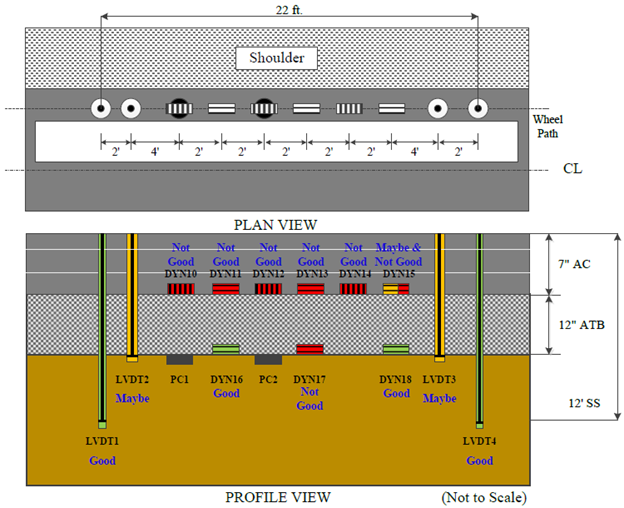

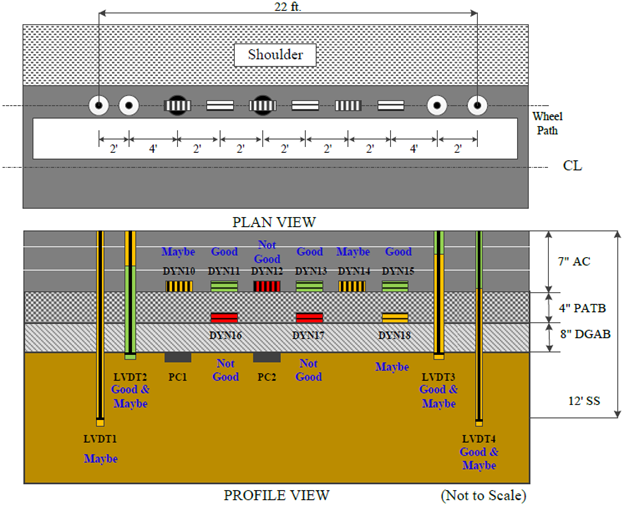

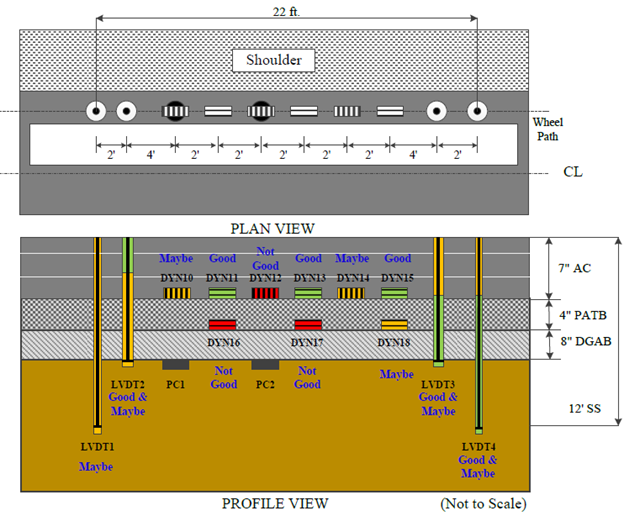

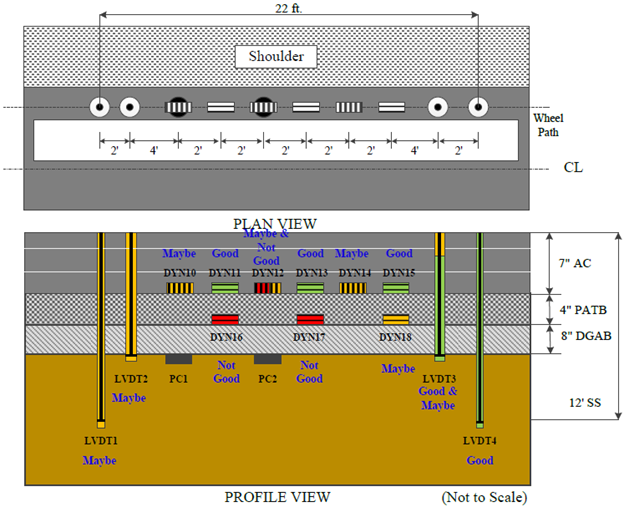

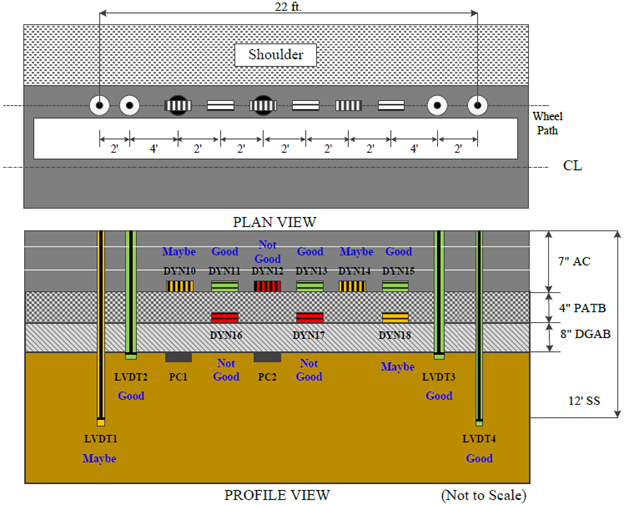

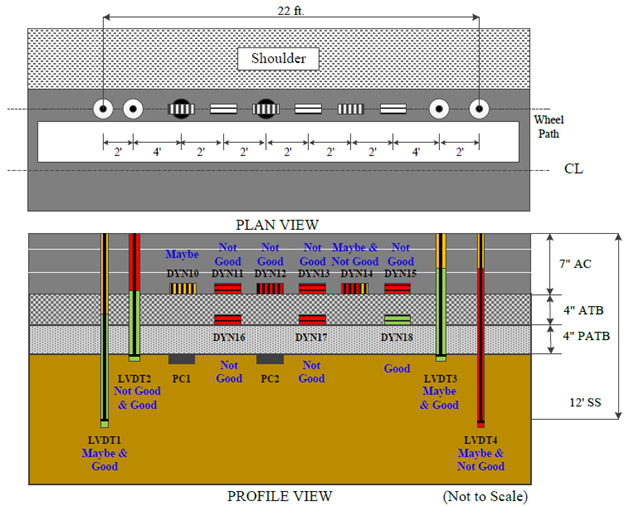

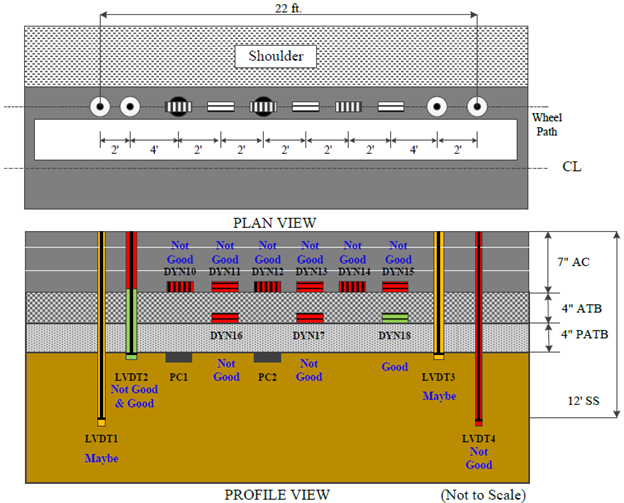

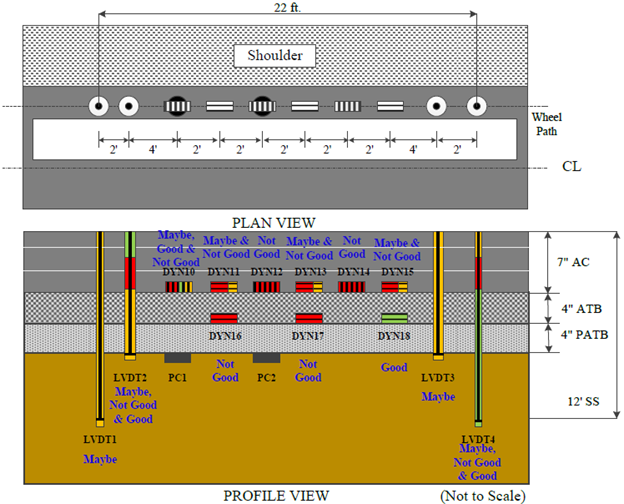

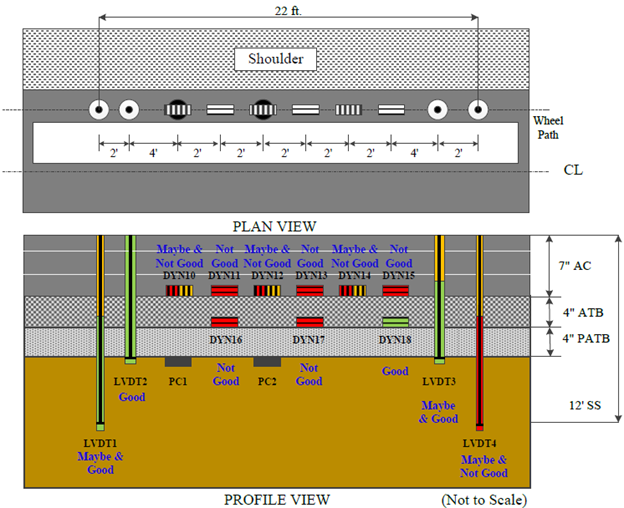

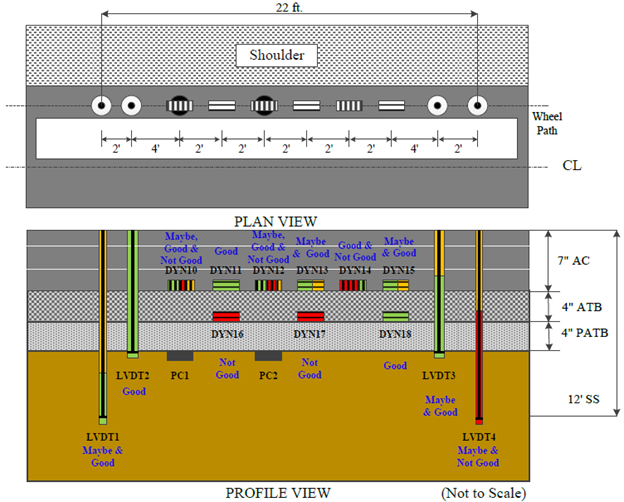

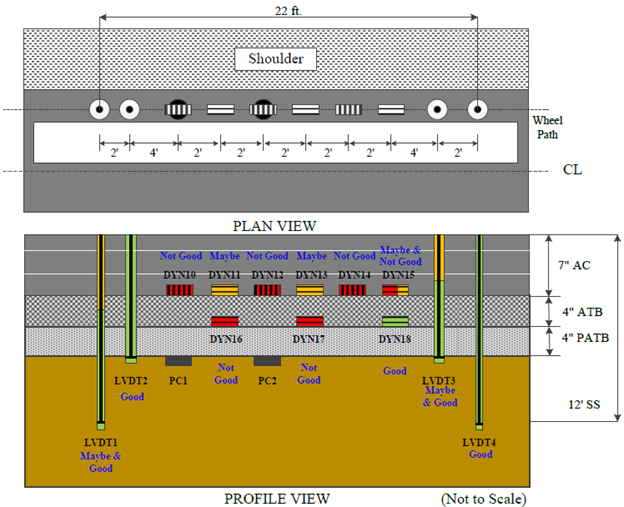

Appendix B shows the instrumentation layout in plan and profile view as well as the pavement layer structure in profile view with sensor status (good, maybe, and not good) for the 23 Ohio SPS-1 DLR test sections.

For figure 27 through 49, sensor colors represent the status of a sensor based on QC results, where green represents good, orange represents maybe, and red represents not good. The sensors with color combinations of more than one color represent status in combination. For example, if a sensor color is in a combination of green and orange, the status of the sensor is a combination of good and maybe.

Figure 27. Illustration. QC results by sensor type for test section 390102 test J2A

Figure 28. Illustration. QC results by sensor type for test section 390102 test J2C

Figure 29. Illustration. QC results by sensor type for test section 390102 test J2D

Figure 30. Illustration. QC results by sensor type for test section 390102 test J2E

Figure 31. Illustration. QC results by sensor type for test section 390102 test J2F

Figure 32. Illustration. QC results by sensor type for test section 390102 test J2G

Figure 33. Illustration. QC results by sensor type for test section 390104 test J4A

Figure 34. Illustration. QC results by sensor type for test section 390104 test J4B

Figure 35. Illustration. QC results by sensor type for test section 390104 test J4C

Figure 36. Illustration. QC results by sensor type for test section 390104 test J4D

Figure 37. Illustration. QC results by sensor type for test section 390104 test J4E

Figure 38. Illustration. QC results by sensor type for test section 390104 test J4F

Figure 39. Illustration. QC results by sensor type for test section 390104 test J4G

Figure 40. Illustration. QC results by sensor type for test section 390108 test J8A

Figure 41. Illustration. QC results by sensor type for test section 390108 test J8D

Figure 42. Illustration. QC results by sensor type for test section 390108 test J8E

Figure 43. Illustration. QC results by sensor type for test section 390108 test J8G

Figure 44. Illustration. QC results by sensor type for test section 390110 test J10A

Figure 45. Illustration. QC results by sensor type for test section 390110 test J10C

Figure 46. Illustration. QC results by sensor type for test section 390110 test J10D

Figure 47. Illustration. QC results by sensor type for test section 390110 test J10E

Figure 48. Illustration. QC results by sensor type for test section 390110 test J10F

Figure 49. Illustration. QC results by sensor type for test section 390110 test J10G