U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-17-096 Date: October 2017 |

Publication Number: FHWA-HRT-17-096 Date: October 2017 |

Constructed in 1960s, the Laporte Road (County Road L) bridge over Mud Creek is a three-span reinforced concrete slab bridge located in Brandon, IA, approximately 35 mi (56.3 km) northwest of Cedar Rapids. A photo of the bridge is shown in figure 14. The bridge was originally designed using H20-44 loading, and although it has low average daily traffic (ADT), it carries large trucks with agricultural loads. The bridge is supported at the ends by reinforced concrete abutments that were cast over steel H-piles. The abutment-to-abutment length of the bridge is 100 ft (30.5 m). The width of the bridge is 28 ft (8.53 m) and services two lanes of traffic.

Figure 14. Photo. Laporte Road bridge.

The interior spans of the bridge are supported by H-piles that were permanently encased in concrete. The reinforced concrete slab superstructure of the bridge is composed of three spans that measure 30.5 ft (9.3 m), 39 ft (11.9 m), and 30.5 ft (9.3 m). The slab has a uniform thickness of 16.9 in (430 mm) and was reinforced in the longitudinal direction with bars ranging between #6 and #10 and was reinforced with #6 and #7 bars in the transverse direction. The original design drawings specified a 2-in (51-mm) clear cover between the top mat of steel and the bare ride surface of the concrete deck. The bridge deck has a five percent super elevation.

The bridge deck was beginning to exhibit delaminations and spalling along the northern (low elevation) curbline and at each end at the expansion joints. It is likely that the deterioration was related to chloride laden water ingress into the concrete and past the strip seal expansion joints, leading to reinforcement corrosion and freeze-thaw cycle-related distress. This deterioration had progressed to the point where maintenance actions were necessary. A UHPC overlay solution was selected to repair the deteriorated deck. This project was a demonstration project for UHPC overlays.

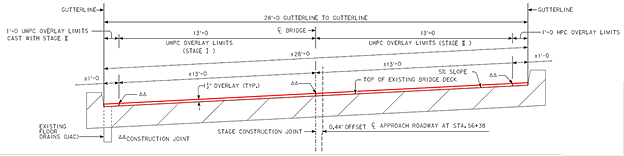

Figure 15 shows a typical section from the construction plans. The UHPC overlay material used on this project was proprietary, and the material supplier provided onsite technical support to the contractor during installation of the overlay. The overlay was constructed in two stages. The overlay was installed on the westbound lane first (Stage I) and the eastbound lane subsequently (Stage II). Design drawing notes stated that concrete was not to be removed below the top mat layer of deck reinforcing steel. Prior to installing the overlay, the surface of the deck was to be scarified and prewetted to promote bond between the substrate concrete and the UHPC overlay. As shown in figure 15, the UHPC overlay was to be 1.5 in (38 mm) thick.

Figure 15. Illustration. Typical section showing the UHPC overlay looking eastbound.

Key observations were made prior to installation of the UHPC overlay relevant to the field testing plan presented in chapter 4. These observations and the associated photos were taken after the surface of the deck was scarified. The primary observation was that a few locations along the surface of the deck exhibited distress. Distress was in the form of poor concrete, cover delamination, and corrosion of top mat reinforcing steel. Figure 16 and figure 17 show the two regions that exhibited the most distress: the westbound lane over pier 1 (figure 16) and the westbound lane near the west abutment (figure 17).

Figure 16. Photo. Distressed region observed on the westbound lane over the pier 1 prior to installing the UHPC overlay.

Figure 17. Photo. Distressed region observed on the westbound lane near west abutment prior to installing the UHPC overlay.

As noted above, the existing surface of the deck was ground to remove poor concrete and provide a roughened surface to promote bond between the concrete substrate and the UHPC overlay material. A photo of the deck surface after scarification is shown in figure 18. On completion of the grinding, all fines and debris were to be removed from the surface of the deck, and deck surface was premoistened a few hours prior to installing the overlay.

Figure 18. Photo. Deck surface after scarification.

The UHPC overlay material was mixed in large pan-style mixers. Two mixers were used to provide a constant supply of UHPC; one mixer was discharged while the other was being charged. The UHPC overlay material was then transported and placed using a motorized buggy (shown in figure 19). Workers using a hand tool assisted the placement of UHPC once discharged from the motorized buggy. As the desired overlay layer thickness was achieved, a lane-wide vibratory screed was progressively drawn down the lane. The placement of UHPC and the vibratory screed are shown in figure 19. Once screeded, a water-based, wax-based concrete curing compound was sprayed on the UHPC overlay surface to prevent dehydration. When the entire lane length was complete, the overlay was covered with a thin plastic sheet (shown in figure 20). The UHPC overlay surface was milled to obtain the desired ride surface (shown in figure 21).

Figure 19. Photo. Placement of the UHPC overlay on the westbound lane.

Figure 20. Photo. Curing of the overlay on the westbound lane.

Figure 21. Photo. Completed overlay after deck milling looking eastbound.