EDC Legacy: Collaborating to Solve Road Data Challenges

For more than a decade, FHWA’s Every Day Counts (EDC) program has promoted proven but underused innovations that enhance roadway safety, improve project delivery, and reduce traffic congestion. From 2013 to 2014, EDC round two (EDC-2) encouraged agencies to use geospatial data collaboration tools to increase information sharing that could improve the quality and speed of decision-making.

Brian Gardner, of FHWA’s Office of Planning, Environment, and Realty, said EDC-2 focused mostly on applications for environmental products, then in EDC-3, regional models of cooperation expanded the emphasis to include more types of planning data.

“Those early rounds of EDC raised awareness among agencies of the value of collaborative data tools and approaches by demonstrating what peer agencies were doing and the benefits they were seeing,” said Gardner. “This helped lay the groundwork for current, much broader efforts to develop a consistent means of collecting, maintaining, and publishing all road network data.”

Sharing Road Network Information

Imagine navigating a city without a map or attempting to repair a road without knowing its condition. This is the challenge that transportation agencies confront daily, and the solution lies in road data collaboration—local agencies working together with State departments of transportation (DOTs) to share essential information about road networks. This collaborative approach ensures improved planning, safer roads, and more efficient use of resources for everyone.

Road data collaboration is akin to a team effort where each government entity contributes expertise and data. Local agencies manage their road networks, collecting details such as road type, width, pavement condition, and traffic patterns. State DOTs oversee the broader highway system and need local data for effective planning. Collaboration enables agencies to gain a comprehensive understanding of the entire road network, which is crucial for informed resource allocation, project prioritization, and improved transportation decision-making.

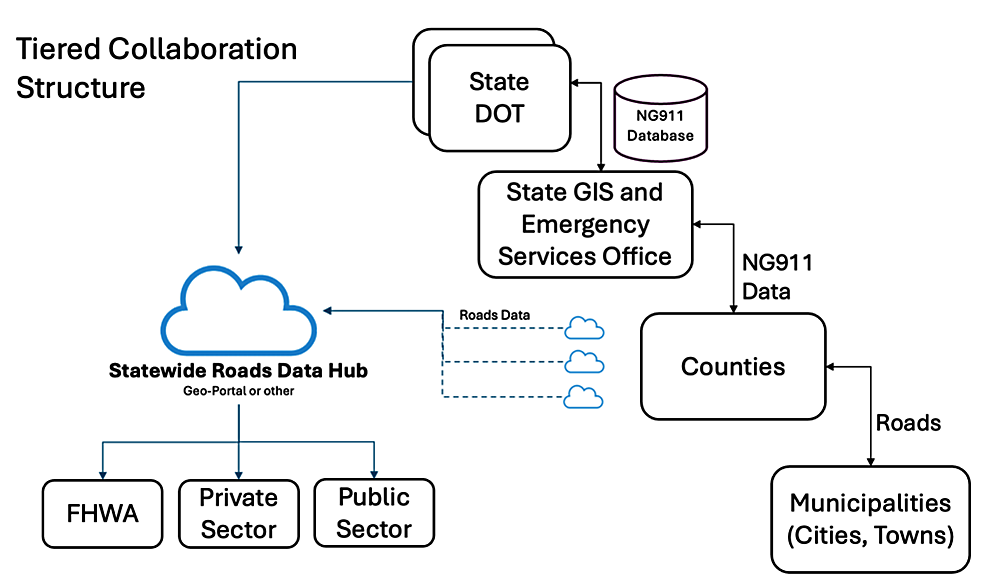

In road data collaborations, cloud-based data portals let local agencies upload data for sharing with the State DOT and State GIS and emergency management offices.

Credit: FHWAThe types of data shared include road classifications, characteristics, mileage, lane configurations, pavement conditions, traffic counts, and work zones, as well as structural assets in the right-of-way.

Most State DOTs use Geographic Information Systems (GIS) to manage and exchange this road data. GIS allows for both data integration and visualization. Cloud-based data portals can let local agencies upload data for sharing with State agencies. These portals may include data validation tools to ensure quality and accuracy. State DOTs incorporate this data into their State Roads management system to prepare a statewide roads dataset with contributions from local agencies. The data flow on these centralized GIS platforms is governed by digital processes that develop a unified data model by integrating various information sources, combining road geometry and relevant attributes data.

Establishing a Framework for Collaboration

In 2018, FHWA launched the Applications of Enterprise GIS in Transportation (AEGIST) initiative to address challenges in road data management and governance. The associated pooled fund study involved 18 State DOTs focused on establishing a framework for collaboration, including guidelines for road data modeling, exchange, integration, publication, and use.

Phase 1 of the study produced the AEGIST Guidebook to help agencies migrate to the enterprise level for creating, maintaining, and governing roadway data. FHWA is currently updating the guidebook to document the best practices and implementation approaches developed by the AEGIST States during phase 2 of the pooled fund study.

One of these approaches is the California Road Sharing (CaRS) program. CaRS is a current effort by the California DOT (Caltrans), the California Office of Emergency Services, and local agencies to work together to develop a reliable road data source in the State.

The CaRS program aims to standardize road data, enhance quality, and ensure accessibility. It establishes a supply chain for local agencies to submit road data for validation and integration into Caltrans’ records. The CaRS framework in California follows practices from AEGIST States like Georgia, Arizona, and Pennsylvania, where DOTs utilize local road data to create a statewide dataset.

Benefitting from Robust Datasets

The benefits of road data collaboration are significant for all stakeholders, from government agencies to the general public. Access to comprehensive road data allows State DOTs and local agencies to create effective transportation plans, from identifying upgrade and expansion areas to formulating emergency response strategies. Analyzing shared data can also help ensure agency funding targets critical projects, such as prioritizing maintenance for deteriorating roads based on pavement condition data.

Having comprehensive road data will enable agencies to more effectively manage assets, such as bridges and culverts, leading to improved maintenance and extended asset lifespans. A unified view of the road network also empowers agencies to make informed, data-driven decisions to support enhanced safety analysis.

Looking ahead, robust road datasets will likely facilitate new technologies such as connected and autonomous vehicles and artificial intelligence or machine learning applications.

Joseph Hausman in FHWA’s Office of Planning, Environment, and Realty said the benefits of road data collaboration will go beyond simple information sharing—they are establishing a foundational framework designed to enhance transportation accessibility for everyone.

“These cooperative efforts are allowing local transportation agencies and State DOTs to create a road network dataset that is more accurate, reliable, and accessible,” said Hausman. “The datasets will lead to more effective planning, increased roadway safety, and optimized resource use, ultimately benefiting all communities along with the road network.”

—MORE INFORMATION

Visit FHWA’s GIS in Transportation webpage for links to program resources.

Visit the Applications of Enterprise GIS in Transportation (AEGIST) webpage for information on pooled fund State activities.

Contact Joseph Hausman or Brian Gardner, FHWA Office of Planning, Environment, and Realty, for details and technical assistance.

Disclaimer: The U.S. Government does not endorse products or manufacturers. Trademarks or manufacturers’ names appear in this document only because they are considered essential to the objective of the document. They are included for informational purposes only and are not intended to reflect a preference, approval, or endorsement of any one product or entity.

Except for the statutes and regulations cited, the contents of this document do not have the force and effect of law and are not meant to bind the States or the public in any way. This document is intended only to provide information regarding existing requirements under the law or agency policies.

Recommended Citation: U.S. Department of Transportation, Federal Highway Administration - Washington, DC (2025) Innovator Newsletter, March/April 2025, Volume 18 (103). https://doi.org/10.21949/xj4k-9v21

- Cover

- From Simulation to Reality: Puerto Rico’s First Diverging Diamond Interchange

- Concrete Innovation: ODOT’s Strategic Approach to Internal Curing

- EDC Legacy: Collaborating to Solve Road Data Challenges

- Systemic Safety Analysis: The Power of Prevention

- States Innovate

- Enhance Concrete Performance with Internal Curing

- About Innovator