U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Accelerated Bridge Construction

Advancing ABC Across the Transportation Community

New Jersey, Pennsylvania, and Washington Win STIC Excellence Awards

Innovations Help States Deliver Outstanding Transportation Projects

Visualize Rural Roadway Departure Countermeasures With Training Cards

The Arizona Department of Transportation used geosynthetic reinforced soil-integrated bridge system technology to accelerate replacement of an Interstate 40 bridge.

Credit: Arizona Department of Transportation

Accelerated bridge construction (ABC) is now a widespread concept in the United States, where a majority of State transportation departments use ABC on projects and about a third have made it a standard practice.

Incorporating innovative technology in planning, design, materials, and construction methods, ABC minimizes traffic disruption, enhances motorist and worker safety, and reduces onsite construction time when building new and rehabilitating existing bridges. "We have come a long way since ABC's inception," said Jamal Elkaissi, structural engineer at the Federal Highway Administration Resource Center. "ABC is here to stay because it makes sense to build bridges faster, better, and safer."

Reducing the impact of construction projects on the traveling public is a key reason for the growing use of ABC, which in many cases enables agencies to7 limit traffic disruption to days rather than weeks or months. "ABC translates into mobility," said Elkaissi. "Agencies learned that there's an alternative method of building bridges than closing lanes or detouring traffic for a long period of time. Now the public expects it."

Agencies also choose ABC because reduced onsite construction time improves safety for travelers and workers in work zones, where 799 people died in 2017. "Less time spent in work zones means fewer fatalities will occur during construction," said Elkaissi.

Another driver is enhanced quality. Today's most widely used ABC technology is prefabricated bridge elements (PBEs), fabricated offsite in a controlled environment and moved to the project location for rapid installation. PBEs not only shorten onsite construction time, they also offer superior durability and a longer service life. "Many State DOTs are attracted to ABC technologies such as PBEs that increase quality because of the potential to stretch taxpayer dollars," said Elkaissi.

A pioneer in embracing ABC, the Utah Department of Transportation (UDOT) institutionalized construction strategies to minimize traffic disruption, improve public and worker safety by getting construction done faster and away from travelers, and enhance quality.

"For us, ABC is just part of doing business," said Carmen Swanwick, Region Two deputy director for UDOT, which incorporated ABC design documents and drawings into its Structures Design and Detailing Manual and stopped counting how many agency bridge projects use ABC when the number topped 200 a few years ago. "We don't evaluate a project for ABC when it gets to design. We're already thinking about it in concept."

New Jersey's Pulaski Skyway deck replacement featured precast deck panels connected with UHPC, stainless steel rebar, and a polyester concrete overlay to maximize durability.

Credit: WSP USA

A new generation of cementitious composite materials, ultra-high performance concrete (UHPC) gets credit for expanding use of PBEs to accelerate bridge projects. Field-cast UHPC creates connections between PBEs that use less concrete and provide better long-term performance than typical connections. Promotion through FHWA's Every Day Counts program helped quadruple UHPC use to more than 200 bridge projects nationwide, in most cases to provide strong, long-lasting connections for PBEs.

"Using UHPC to cast simpler, more durable connections between prefabricated bridge elements is the 'killer app' that has emerged as the entry point for owners, consultants, and contractors to begin using this new class of concrete," said Benjamin Graybeal, bridge engineering research team leader in FHWA's Office of Infrastructure Research and Development.

New Jersey's Pulaski Skyway deck replacement is the largest application of UHPC to date. The project featured precast deck panels connected with UHPC, stainless steel rebar, and a polyester concrete overlay to maximize durability. The New Jersey Department of Transportation chose this system to minimize future repairs and traffic disruption on the heavily traveled bridge.

To reduce traffic disruption, crews in Glenwood Springs, CO, built a bridge on temporary supports before sliding it into place.

Credit: FHWA

Another ABC technique many agencies use successfully is slide-in bridge construction, in which crews construct a bridge on temporary supports next to the existing structure and move the new bridge into position during a road closure. Glenwood Springs, CO, used the technique on its 27th Street Bridge project to reduce traffic and economic impacts while replacing this vital downtown link over the Roaring Fork River.

Crews built the replacement bridge near the existing bridge while it remained open to traffic, then demolished the old bridge and slid the new one into place during a week-long road closure in September. "The Glenwood Springs project is an exciting example of ABC moving from implementation at the State level to local and county agencies," said Elkaissi.

Also growing in popularity is geosynthetic reinforced soil-integrated bridge system (GRS-IBS) technology, a cost-effective, rapid-construction, high-quality method of bridge support that blends the roadway into the superstructure. GRS-IBS can be built with simple and readily available materials, equipment, and labor. "Time and cost savings result from the simplicity of the design and construction procedures as well as the materials selected for construction," said Daniel Alzamora, senior technical engineer at the FHWA Resource Center.

An Arizona Department of Transportation (ADOT) project to replace the Interstate 40 bridge at Meteor City Road used GRS-IBS to get the work done faster, limit inconvenience for motorists, and reduce long-term maintenance costs. The 2019 project, ADOT's first use of this technique, made it possible for a bridge replacement that ordinarily would take about 6 months to wrap up in a third of the time. State Transportation Innovation Council Incentive funds enabled ADOT to develop GRS-IBS specifications for use on this and future projects.

The Arizona Department of Transportation chose GRS-IBS to minimize motorist impact and expedite the replacement of an Interstate 40 bridge.

Credit: Arizona Department of Transportation

Many transportation departments now use a programmatic approach to ABC, developing standard practices and evaluating potential ABC use early in project processes. UDOT created an ABC Decision-Making Process template to evaluate every bridge project at the concept stage. "Our matrix is very simple," said Swanwick. "Other States have adapted it to the way they do business and added different criteria, which is great."

Using the UDOT matrix as a starting point, the Connecticut Department of Transportation (CTDOT) developed its own ABC Decision Matrix and adopted it as a bridge design standard practice. The matrix helps CTDOT assess the viability of ABC during the preliminary design phase of projects to replace bridge decks, superstructure spans, or entire bridges.

CTDOT's methodology determines the effect of ABC on the overall cost of the bridge, including bid price, project management costs, and road user impacts. Preliminary road user impacts are assessed by estimating and comparing road user delay time for conventional construction to a proposed ABC construction method.

"What drove the decision methodology was the need for more uniformity in how we analyzed the ABC potential for a bridge project," said Timothy Fields, CTDOT transportation principal engineer. "It was to create a more objective way of assessing ABC."

The Federal Highway Administration promoted various aspects of accelerated bridge construction (ABC) in the first four rounds of Every Day Counts (EDC), including prefabricated bridge elements and systems, ultra-high performance concrete connections, slide-in bridge construction, and geosynthetic reinforced soil-integrated bridge system technology. Outreach and technical assistance from EDC deployment teams, peer exchanges with States experienced in ABC use, and demonstration projects encouraged many transportation agencies to adopt ABC.

In 2018, the American Association of State Highway and Transportation Officials (AASHTO) published the LRFD Guide Specifications for Accelerated Bridge Construction, which compiles recommended design and construction specifications for ABC technologies. "The fact that AASHTO pushed guidance forward gives ABC a lot of credibility and could make States more willing to use it," said Carmen Swanwick, Utah Department of Transportation Region Two deputy director.

The second Strategic Highway Research Program (SHRP2)—a collaborative effort of FHWA, AASHTO, and the Transportation Research Board—yielded several ABC resources. They include a widely distributed ABC toolkit that features a guidebook, standard design details, and specifications and a SHRP2 training class that reached more than 850 people in the past year.

As a result of these efforts, ongoing research, and agencies' sharing of best practices and lessons learned, ABC implementation continues to accelerate. "Today, ABC technologies are widely used across the country," said Romeo Garcia, bridge construction engineer in the FHWA Office of Infrastructure. Agencies are changing the way they do business, moving from project to programmatic deployment of ABC and using game-changing technologies to produce safer, more durable bridges than those built conventionally.

State Transportation Innovation Councils (STIC) in New Jersey, Pennsylvania, and Washington received 2019 STIC Excellence Awards for demonstrating success in fostering a strong culture of innovation.

The American Association of State Highway and Transportation Officials and Federal Highway Administration collaborate on the annual award, which was presented to the winning STICs at AASHTO's annual meeting in St. Louis, MO.

The New Jersey STIC is developing a culture of innovation with broad stakeholder participation, shared metrics, and an engaged leadership. The STIC established processes to identify and move new technologies into practice, including an online portal to solicit potential ideas. The STIC also created three teams—Infrastructure Preservation, Safety, and Mobility and Operations—to champion innovations.

The STIC includes New Jersey Department of Transportation (NJDOT) communications, Local Technical Assistance Program, and research staff to promote innovations through social media, with local partners, and with the university community. A new web page features information on the STIC's innovation initiatives and a searchable innovation database.

New Jersey's STIC is advancing unmanned aerial systems for bridge inspection and traffic incident monitoring, including developing guidance and specifications. To improve motorist and responder safety, the STIC is promoting the use of crowdsourcing applications to notify the public where NJDOT Safety Service Patrol vehicles are working on roadsides.

The Pennsylvania STIC fosters an innovative culture at all levels of government and throughout the private and nonprofit sectors to ensure smart investments in Pennsylvania's highway infrastructure. The Moving Forward strategic plan, unveiled in 2018, provided the framework to reorganize and rightsize the STIC organization.

The STIC consolidated its Technical Advisory Groups (TAGs) from 10 to four—Design, Construction and Materials, Maintenance, and Safety and Traffic Operations—to improve efficiency and enhance collaboration between groups on overlapping innovations. The streamlined structure also provides flexibility to engage a variety of subject matter experts to support a wider range of innovations.

The STIC added Innovation Owners and Development Teams to expand participation opportunities, particularly for Pennsylvania Department of Transportation engineering district staff members responsible for deploying innovations. To enhance stakeholder communication, the STIC revamped its website, which features innovation deployment information and an interactive Year-End Report.

The Washington STIC is building a culture of innovation through collaboration to update the Washington State Department of Transportation (WSDOT) Hydraulics Manual and to develop a programmatic biological assessment with the U.S. Fish and Wildlife Service (USFWS). These efforts brought local, Federal, and private sector partners to the table to look at how to institutionalize innovations statewide.

With STIC Incentive funds, WSDOT revised its Hydraulics Manual to incorporate two-dimensional (2D) hydraulic modeling, fish passage and stream restoration design guidance, and bridge scour methodology to assist State and local hydraulic and design engineers. When erosion occurred around the foundations of the U.S. 101–Elwha River Bridge, for example, WSDOT engineers used 2D modeling to develop scour repair and monitoring strategies until a new bridge is designed and built.

WSDOT collaborated with USFWS on a programmatic biological assessment that allows local agencies to streamline Endangered Species Act (ESA) consultations. This approach reduces the ESA consultation timeline on local agency projects from a year to a few months and is expected to be used on at least seven projects in the next year.

For information on the STIC Excellence Awards, contact Sara Lowry of the FHWA Center for Accelerating Innovation.

The Minnesota Department of Transportation (MnDOT) integrated data-driven safety analysis into its routine business practices. MnDOT updated its district safety plans using systemic data analysis, which identifies locations at high risk for serious crashes across a road network so agencies can install cost-effective safety countermeasures. MnDOT is working with Minnesota counties to include systemic analysis in local roadway safety plans. Focusing on predictive analysis, MnDOT published a Performance-Based Practical Design guidance document, which emphasizes use of the American Association of State Highway and Transportation Officials Highway Safety Manual to inform decisions. The agency made crash modification factors—which calculate expected crash numbers after applying safety countermeasures—standard practice to quantify benefits of spot location safety projects.

Transportation utility fees (TUFs) are a value capture technique that can provide an effective way to fund road repair and maintenance projects. Under TUF programs, residents and businesses pay monthly fees based on formulas developed by the Institute of Transportation Engineers linking road maintenance costs to transportation system benefits. The city of Newberg, OR, adopted a TUF to generate about $1.2 million a year. In one project, the city rehabilitated four blocks of East Fifth Street rated in poor condition. The TUF covered nearly two-thirds of the cost to reconstruct the street and bring sidewalks and ramps up to Americans With Disabilities Act standards.

A review of Pennsylvania Department of Transportation (PennDOT) data found that fatalities, injuries, and crashes decreased overall at 19 roundabouts built at 16 locations that were previously stop or signal controlled. The agency evaluated roundabouts that had at least 3 years of crash data available before and after construction. The data show that fatalities declined from two to none, suspected serious injuries dropped 90 percent, and total number of crashes decreased 34 percent. In addition to the 19 roundabouts reviewed, PennDOT has built 29 other roundabouts and has 40 more in design. To educate road users, the agency created a video on how to use roundabouts whether in a vehicle, on a bicycle, or on foot.

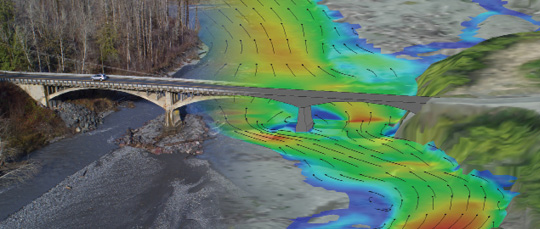

More than half a million U.S. bridges—80 percent of the total—span water. Two-dimensional (2D) hydraulic modeling tools in the Every Day Counts (EDC) initiative on collaborative hydraulics: advancing to the next generation of engineering (CHANGE) illustrate the complex interactions between these transportation assets and waterways.

"Flood flows are the primary cause of damage to bridges and other infrastructure, such as embankments and culverts," said Laura Girard, Federal Highway Administration hydraulic engineer and CHANGE team co-leader. "Without 2D hydraulic modeling, many design teams would have difficulty designing projects for complex flow scenarios."

Using 2D modeling eliminates the need for many assumptions applied in traditional one-dimensional (1D) models that can lead to inaccurate results. As a result, 2D tools improve the design and ultimately the safety and resilience of infrastructure. These new tools include graphics and visualization software that enable engineers to more effectively communicate the results of complex hydraulic analysis to a broad audience. This can enhance collaboration and streamline project development, including regulatory activities.

The CHANGE team's outreach goes beyond State transportation departments to include resource agencies, floodplain administrators, and local agencies. In addition to providing technical support and training, the team hosts bimonthly 2D Hydraulic Modeling User's Forum webinars that attract more than 500 participants. "We're working with practitioners at a wide range of experience levels," said Scott Hogan, FHWA senior hydraulic engineer and CHANGE team co-leader. "We want to see everybody move forward."

The number of States at the demonstration, assessment, or institutionalized stages of CHANGE implementation is expected to reach 46 in EDC-5. "This is not just a tool to use here and there. This is a fundamental change in how hydraulic engineering design will be done," said J.R. Taylor, Montana Department of Transportation district hydraulics engineer and CHANGE team member.

In the past 3 years, the Colorado Department of Transportation (CDOT) saved more than $14 million using 2D hydraulic modeling to develop more detailed analyses of bridges, culverts, and roadways than with 1D modeling. The return on investment for four demonstration projects alone was $4.4 million in savings during design, said Brian Varrella, CDOT resident engineer and CHANGE team member.

On a demonstration project to retrofit structures at six river crossings, 2D modeling helped CDOT optimize the structures for scour protection while saving $500,000 on materials. A 2D model created for a U.S. Highway 287 project allowed CDOT to save $300,000 in material costs by reducing the size of riprap originally proposed. On a State Highway 55 project, 2D modeling helped the agency more accurately calculate how the river pushed against an abutment and develop a protection solution that cut construction costs by $1.8 million. On a State Highway 144 project, using 2D modeling accelerated the scoping process by months and saved $2 million.

CDOT is expanding 2D modeling through an initiative to value-engineer projects at the planning and scoping stage to save an estimated $20 million a year. "If we invest 20 to 40 hours in 2D modeling—less than a week of work—we can refine our scope," said Varrella. "This is turning into a project management tool."

Two-dimensional hydraulic modeling provides a more accurate representation of design conditions and the graphical visualization tools offer a more effective means of collaborating with project partners.

Credit: FHWA

The Arizona Department of Transportation (ADOT) used cutting-edge data collection and 2D hydraulic modeling for a U.S. 160 bridge project that created a sustainable solution to erosion from a creek on the Navajo Nation Reservation. The project addressed scouring of the Laguna Creek Bridge's abutments, protected the creek banks, and reduced the channel's meandering at the bridge. To accomplish this, engineers installed gabion baskets, metal cages filled with rocks.

While engineers designing similar improvements often have limited data on stream flows, ADOT coordinated with the U.S. Geological Survey to make the Laguna Creek Bridge a pilot site to test 2D hydraulic modeling tools. The project used sensors and gauges to provide real-time surface flow data during and after storms, drones, video cameras, laser-aided surveying, and three-dimensional surface modeling.

Collecting this data for a year before construction provided a comprehensive view of the creek's flow and velocity, allowing engineers to compare the current channel with a time-lapse view of how it changed over time and anticipate what will happen in the future. The instruments continue to provide data that will help engineers assess the effectiveness of work to stabilize the banks where U.S. 160 crosses Laguna Creek and determine whether more improvements are needed.

Visit FHWA's hydraulic engineering web page for guidance, reports, software downloads and tutorials, and training information.

Contact Scott Hogan or Laura Girard of the FHWA Resource Center for information and technical assistance and to join the 2D Hydraulic Modeling User's Forum.

A new interchange concept, technology to improve winter maintenance, accelerated bridge construction (ABC), and unmanned aerial systems (UAS) are among the innovations States used in projects recognized in the 2019 America's Transportation Awards competition.

Sponsored by the American Association of State Highway and Transportation Officials (AASHTO), AAA, and U.S. Chamber of Commerce, the annual competition showcases projects State transportation departments deliver to better serve their customers.

The Missouri Department of Transportation (MoDOT) deployed an innovative interchange concept called a "divergabout" at Interstate 49 and 155th Street in the Kansas City area. The concept combines the benefits of a diverging diamond interchange (DDI) and a roundabout, reducing the number of left-turn conflict points and enhancing safety. MoDOT design engineers tailored the divergabout for interchanges with high traffic volumes and increased risk of serious crashes.

The Missouri Department of Transportation built the world's first divergabout to improve safety and traffic flow at Interstate 49 and 155th Street in the Kansas City area

Credit: Missouri Department of Transportation

The first of its kind, the divergabout project reconstructed the interchange to replace the bridge over I-49 with a solution to handle future traffic increases while accommodating current traffic. The project features a DDI that switches 155th Street traffic onto the left side of the bridge to allow for better traffic flow and a roundabout coupled to the DDI that enables motorists to access the outer roads and 155th Street smoothly in all directions. The project added a shared-use path to the interchange to increase safety for pedestrians and bicyclists. MoDOT reports reduced congestion at the divergabout location and plans to conduct a future safety analysis. The agency built a second divergabout at U.S. 50 and Missouri Route 291 South in the Kansas City area.

Using a weather-responsive management strategies approach, the Nebraska Department of Transportation (NDOT) leveraged technology to manage highway clearance operations and help motorists make safer travel decisions during winter weather. The project installed maintenance decision support system (MDSS) and automatic vehicle location technology on NDOT's 633 snowplow trucks. With this system, NDOT maintenance managers can access weather and pavement models, plow truck locations, dashboard camera views of roadway conditions, and information on the amount of salt and other materials spread.

Snowplow operators receive roadway treatment recommendations, weather forecasts, weather radar maps, and instant messages from NDOT managers via the system. Recommendations are updated hourly to reflect changing road and weather conditions, optimizing resource use and ensuring that trucks spread materials efficiently across the State's highways. An online Plow Tracker shows the location of active snowplow trucks and their camera images, providing a tool to help motorists make informed travel decisions.

The New Hampshire Department of Transportation (NHDOT) and town of East Kingston chose ABC technologies to rehabilitate a structurally deficient bridge in an accelerated timeframe without disrupting train service underneath it. Originally built in 1937 and last rehabilitated in 1969, the bridge carries 2,200 vehicles a day over a commuter rail line. NHDOT and East Kingston received Accelerated Innovation Deployment Demonstration funds to deploy prefabricated bridge elements (PBEs) and ultra-high performance concrete (UHPC), technologies they had not used before.

Senior Highway Designer Ryan Hale explains the divergabout concept in a Missouri Department of Transportation video.

Credit: Missouri Department of Transportation

The project reconstructed the bridge superstructure and repaired the piers and abutments. The bridge deck used PBEs constructed offsite and transported to the bridge site for rapid installation. Crews poured UHPC between the deck panels to create strong, long-lasting connections. The bridge was closed to vehicle traffic while the project was underway to expedite construction. The project was finished in 25 days—3 days ahead of schedule—instead of an entire season for conventional construction.

The North Carolina Department of Transportation (NCDOT) deployed UAS technology to monitor and document flooding, road conditions, and traffic impacts after Hurricane Florence struck in 2018. More than a dozen NCDOT drone teams flew more than 260 missions and captured more than 8,000 photos and videos of the damage and flooding left behind by the storm.

NCDOT provided the drone-collected data, images, and video to Federal, State, and local agencies through a custom-designed online dashboard, a portal that also allowed the department to share information with the public via traditional and social media. The project helped agencies make real-time decisions on providing emergency response, planning detour routes, assessing repair needs, expanding disaster declarations, and warning the public of potential dangers on roadways. This was the first time drones had been used to monitor a disaster in North Carolina and the first time they were used at such a scale in the United States.

Contact Maggie Kasperski of AASHTO for information on America's Transportation Awards.

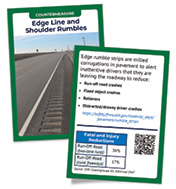

The focus on reducing rural roadway departures (FoRRRwD) team published a set of 18 trading cards that illustrate rural roadway departure crash types, countermeasures, and tools. Transportation agencies can use the cards to educate staff on approaches to reduce crashes and save lives. The cards are available in three print-ready versions on the FoRRRwD website. For information, contact Cate Satterfield of the Federal Highway Administration Office of Safety or Dick Albin of the FHWA Resource Center.

Innovator, published by the FHWA Center for Accelerating Innovation, advances implementation of innovative technologies and accelerated project delivery methods in the highway industry. Its audience is transportation professionals in highway agencies, trade and research groups, academia and the private sector, and the driving public.

Elaine L. Chao, Secretary, U.S. DOT

Nicole R. Nason, Administrator, FHWA

Thomas Harman, Director

Jeffrey Zaharewicz, Senior Advisor

Sara Lowry, Program Coordinator

Fawn Thompson, Program Coordinator

Julie Zirlin, Program Manager

Nichole Causey, Marketing Specialist

Ellen Schweppe, Managing Editor

James Cline, Jr., Designer

Pat Holcombe, Designer

Rodney Walker, Designer

Email reprint requests to Nichole Causey

View Innovator archive.