Key Findings from LTPP Analysis: 1990-1999

Introduction

The Long-Term Pavement Performance (LTPP) analysis program has addressed a broad array of topics-from field validation of pavement design procedures, to the study of variability in traffic and materials data, to investigating pothole repair techniques. Findings from these efforts illustrate not only the immediate value of the LTPP database, but also its future potential for the improvement of pavement technology.

The purpose of this document is to highlight some of the key findings from LTPP analysis studies between 1990 and 1999. These findings have been organized into the following areas: Site Conditions, Structural Features, Materials, Initial Roughness, Pavement Maintenance, Pavement Rehabilitation, American Association of State Highway and Transportation Officials (AASHTO) Design Validation, and Performance Modeling.

In all, approximately 50 documents (including LTPP research reports, TechBriefs, and Product Briefs) were reviewed to develop this summary. Our goal is to provide LTPP partners with information that can help them in their quest to design, build, and maintain cost-effective and long-lived roads.

Site Conditions

Pavement projects start out with a given set of site conditions. These include traffic, climate, subgrade, and geometrics. LTPP data analyses have shown that each of these site conditions affects pavement performance. While they cannot be controlled by the designer, they should always be considered, and in critical situations, the pavement design features should be selected to mitigate the adverse effects of site conditions on performance. The following are key findings from several LTPP site condition analyses. They are grouped into three areas: Traffic, Climate, and Subgrade/Foundation.

Traffic

Highly accurate estimates of annual load can only be achieved by continuous monitoring of traffic conditions at specific sites. This level of accuracy is needed to develop new pavement design procedures and other similar analyses. At the same time, smaller data samples can be used to provide annual load estimates that are acceptable for analyses that are less sensitive to traffic data accuracy.

Report No. FHWA-RD-98-124

The most common finding regarding the variation of truck volumes and loads was that weekend truck volumes tend to be much lower than weekday truck volumes. This leads to a significant reduction in the pavement loading rate on the weekend. In fact, weekend loadings in many locations are only 20 percent of the average weekday load.

Report No. FHWA-RD-98-124

Weights per truck (by class) did not differ by weekday/weekend at the majority of the locations. Therefore, it is not necessary at the majority of the sites to weigh vehicles during weekends to accurately estimate annual loads. However, at sites where significant weekday/weekend differences in the average weight per vehicle by classification exist, these differences must be measured directly to accurately estimate annual conditions.

Report No. FHWA-RD-98-124

Seasonal changes in loading patterns are not as consistent from site to site as the weekday/weekend patterns mentioned above, although some regional patterns do exist. Many sites experience relatively little change in trucking activity over the year. Other sites show extremely large changes in truck volumes, truck mix, or truck weights by class (or some combination of these) during parts of the year. These changes occur because of seasonal changes in the level of commercial activity.

Report No. FHWA-RD-98-124

General Traffic Pattern Findings

Report No. FHWA-RD-98-117:

Business-Day Trucking: Most truck traffic starts and ends during the normal business day.

Sunday traffic volumes are the lowest of the week for trucks at most sites, but average car volumes on Sundays can be fairly high at many rural sites.

Tuesday-through-Thursday volumes are similar for all truck classes.

Friday is the highest volume day of the week for cars.

Saturday volumes tend to be low for trucks, but like Sundays, they can be either high or low for cars, depending on the location.

There are many exceptions to these general findings. The most significant exception is that many sites in the Great Plains and some Rocky Mountain States have different day-of-the-week patterns.

Generally, car and truck volumes are lower in the winter than in the summer and fall. In addition, seasonal differences in truck volumes tend to be smaller in urban areas than in rural areas. However, the size and timing of truck volume changes are normally different from those of cars. In some States, truck classifications have unusual seasonal increases or decreases that relate to specific commodity movements (e.g., harvest hauls). In other States, truck movements show almost no seasonal change.

Report No. FHWA-RD-98-117

Weigh-in-Motion

Report No. FHWA-RD-98-104

A study on weigh-in-motion (WIM) scale calibration showed that every 1 percent error that a scale is under-calibrated results in slightly more than a 3-percent underestimation of the true ESAL value. Every 1-percent overestimation in axle weight represents a 4.5 percent overestimation of equivalent single-axle load (ESAL) values. Thus, even an overcalibration of only 10 percent would result in a 45 percent error in estimated damage.

For short-duration counts, calibration should be performed immediately before the start of data collection. Calibration of a WIM scale after it has been installed at a site ensures that it is measuring axle weights correctly. Calibration should include a comparison of static axle weights with axle weights that are estimated from multiple vehicle passes with more than one vehicle.

For longer duration counts, the WIM scale should be calibrated initially, the traffic characteristics at that site should be recorded, and the scale's performance should be monitored over time. The Agency should also perform additional, periodic on-site calibration checks (at least two per year). These steps will ensure that the data being collected are accurate and reliable.

Traffic Loading Effects on Rigid Pavement Performance

An increased International Roughness Index (IRI) was associated with a higher level of traffic for undoweled jointed plain concrete pavement (JPCP). This was not found with doweled JPCP or jointed reinforced concrete pavements (JRCP). An increased IRI was associated with higher levels of traffic for continuously reinforced concrete pavements (CRCP).

Report No. FHWA-RD-98-113

Traffic Loading Effects on FlexiblePavement Performance

Traffic loading is the strongest contributor to the occurrence of flexible pavement rutting and roughness. Pavement age was the strongest contributor for the occurrence of transverse cracking.

Report No. SHRP-P-393

The amount of traffic on an asphalt concrete overlay clearly affects the growth of roughness or increasing IRI values. It is, however, quite possible to construct asphalt concrete overlays for heavy traffic that will remain smooth for 15 years or more.

Report No. FHWA-RD-00-029

Data showed that traffic levels are not particularly critical to the occurrence of transverse cracks in asphalt concrete overlays.

Report No. FHWA-RD-00-029

Climate

In wet-freeze climates it is especially important to design JPCP to resist transverse joint faulting (doweled joints seem to minimize the adverse effect of climate on faulting). In the drier climates (western United States) where high thermal gradients exist, it is more important to design for resistance to transverse cracking (shorter joint spacing minimizes the adverse effect of climate). JPCP in colder and wetter climates was rougher.

Report No. FHWA-RD-97-131

The effect of joint spacing on pavement performance varies significantly with climate. Colder and wetter climates could allow longer joint spacing, whereas warmer and drier climates require shorter joint spacing.

Report Nos. SHRP-P-393 and FHWA-RD-96-198

Climate affects undoweled JPCP more than doweled JPCP in terms of faulting performance.

Report No. FHWA-RD-00-076

Climatic conditions and subgrade conditions showed a strong relationship with IRI (asphalt concrete (AC) pavement on granular base/subbase). The performance of these sections over fine-grained soils was strongly related to the Atterberg limits and the percentage of subgrade passing the No. 200 sieve. Generally, more roughness is found where sections are located in areas of greater precipitation. In freezing environments, pavements in areas that have a high freeze index or a large number of freeze-thaw cycles had higher IRI values. Thus, adequate frost protection is an important factor for good performance. In hot climates, the IRI value of the pavements was strongly related to days above 32°F.

Report No. FHWA-RD-97-147

Subgrade/Foundation

Existence of increased subgrade support (as indicated by the backcalculated k-value) results in a lower IRI over time for JPCP, JRCP, and CRCP.

Report No. SHRP-P-393

Fine-grained soil subgrades showed more joint faulting than coarse-grained subgrades, probably due to increased erosion and reduced bottom seepage of water. JPCP constructed on coarse-grained subgrades were smoother than those constructed on fine-grained subgrades. Thus, placement of a thick layer of granular material beneath the base course may contribute to improved drainage and reduced faulting, especially for nondoweled pavements.

Report No. FHWA-RD-97-131

One design feature that can help achieve the goal of building an initially smooth JPCP, JRCP, or CRCP is a good foundation on which to build. The LTPP data showed that a good working platform (specifically, stabilized base and granular subgrade or embankment) contributed to a smoother pavement construction.

Report No. FHWA-RD-97-131

Structural Features

Contrary to popular belief, good pavement design is a complex problem. The obvious decisions-asphalt or concrete, and how thick-are, in many respects, less important than decisions regarding other structural features. The following are key findings from several LTPP analyses on the effects of structural features on pavement performance. They are grouped into two areas: Rigid and Flexible Pavements.

Rigid Pavements

Jointed Plain Concrete Pavements

Given a JPCP that has been constructed to be very smooth, LTPP analyses have shown that several design features are associated with keeping it smooth. Obviously, this means minimizing joint faulting, slab cracking, and other modes of failure. The following are findings that are relative to design features that are significant in minimizing roughness, faulting, and cracking for JPCP.

Joint Load Transfer

A strong relationship between rate of increase in IRI and increased joint faulting was found. Many LTPP analyses showed that the use of dowels had a strong impact on controlling joint faulting. LTPP JPCP sections with dowels showed 50 percent less joint faulting than those without dowels. In critical climates (i.e., wet or freeze climates), the use of dowels appeared to negate the effects of cold temperatures and increased moisture that lead to erosion and pumping of fines.

Report Nos. FHWA-RD-97-131, FHWA-RD-00-076 and SHRP-P-393;

Subdrainage

(longitudinal edge drains only, not permeable bases)

The effect of subdrainage is critical for both IRI and joint faulting for undoweled JPCP. Undoweled JPCP with higher AASHTO drainage coefficients (edge drains and/or improved climatic conditions) had a lower IRI.

Report Nos. FHWA-RD-97-131 and SHRP-P-393

Base Type and Modulus

JPCP with a stabilized base had less faulting and were smoother than those with an untreated aggregate base. This was especially true for undoweled JPCP. JPCP with an asphalt-stabilized base or lean concrete base had a significantly lower IRI when compared to other bases. On the other hand, JPCP sections with granular bases and asphalt-stabilized bases had a significantly lower percentage of cracked sections than JPCP with cement-treated or lean concrete bases. However, this cracking was not associated with an increased IRI.

Report Nos. FHWA-RD-97-131 and FHWA-RD-98-113

Slab Widening

Widened (by 0.6 m) portland cement concrete (PCC) slabs reduce faulting of concrete pavements by reducing the critical deflections at the corner of the slab caused by heavy truck axles. The mean faulting data for undoweled sections (10 years old or less) show about 50 percent less faulting with a widened slab. This agrees with previous non-LTPP field performance data. There was no difference between the faulting of doweled widened slab sections and doweled conventional-width JPCP. JPCP sections with widened lanes did not show any transverse cracking. The LTPP database contains information on only a few JPCP sections (GPS-31) with widened slabs. Considerable results will be obtained from the SPS-22 sections, where direct comparisons between conventional and widened slabs will be made.

Report Nos. FHWA-RD-00-076 and FHWA-RD-97-131

1GPS-3 - General Pavement Studies (GPS) use existing pavement sections that were nominated by the States. GPS-3 focuses on jointed plain concrete. Like all GPS test sections, the GPS-3 sections were in service prior to the initiation of LTPP monitoring. Thus, the sections yield data on performance in the later stages of pavement life.

2SPS-2 - Specific Pavement Studies (SPS) use either specified sets of new pavement structures constructed for the study of high-priority effects or selected sets of existing pavements to which maintenance and rehabilitation treatments are applied. SPS-2 focuses on the Strategic Study of Structural Factors for Rigid Pavements. SPS-2 projects were specially constructed in the late 1980s with multiple pavement designs at a given site. Thus, they yield data that will enable direct comparison of the design features constructed, including widened lanes and different slab thicknesses.

Joint Spacing

Previous studies have shown that increased JPCP joint spacing increases transverse cracking greatly and increases joint faulting to a lesser extent. Where randomly spaced joints were used, longer slabs cracked far more often. The mechanistically based early analysis transverse cracking prediction model, a more recent mechanistic model, and the AASHTO 1998 supplemental rigid pavement structural design model all show very significant effects of JPCP joint spacing on the percentage of slabs with transverse cracking. These studies all show that increased joint spacing results in an increase in expected transverse cracking.

Report Nos. FHWA-RD-96-198, FHWA-RD-98-113 and SHRP-P-393

Joint Type

The use of skewed joints was not significant in transverse joint faulting for doweled JPCP. For undoweled joints, the LTPP data show that skewing joints is helpful in reducing faulting; whereas for doweled joints (with reasonable drainage), skewing joints is not necessary.

Report No. FHWA-RD-97-101

Slab Thickness

LTPP-based mechanistic transverse cracking models show a strong effect of slab thickness on transverse cracking. The AASHTO 1998 supplemental rigid pavement design procedure also shows a strong effect of slab thickness on serviceability over time. While adequate thickness is important, the data show that it is not possible to solve a poor joint load transfer problem with increased slab thickness. Considerable results related to slab thickness will be obtained from the SPS-2 studies.

Report Nos. FHWA-RD-96-198, FHWA-RD-98-113, and SHRP-P-393

Continuously Reinforced Concrete Pavements

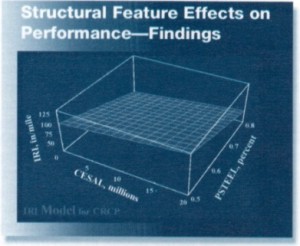

CRCP have the potential to provide long-term low-maintenance service life, as evidenced by the many well-performing sections in the GPS-5 experiment. The key CRCP distress types considered in the LTPP data analyses are roughness (IRI) and localized failures. The LTPP findings show that steel content is among the most significant parameters that can improve performance and minimize the possibility of poor performance of CRCP.

- Steel Content

- It is well known that the greater the percentage of reinforcing steel, the shorter the crack spacing and the tighter the crack width. Conventional wisdom is to set the reinforcing steel content in an attempt to keep crack spacing at about 0.91 m. However, the model from the LTPP early analysis for IRI and a more recent model both show that the percent of steel was a very significant design feature and that the greater the percentage of steel, the lower the IRI (smoother pavement). The LTPP study on good and poorly performing PCC pavements also showed the same result. Note that other studies, such as the Illinois CRCP analyses, showed that the greater the percentage of steel, the fewer the number of localized failures (punchouts). These findings lead to questioning of the conventional recommendations for limiting steel content. Pavements that performed well had steel contents ranging from 0.51 to 0.75 percent. Further work is needed to develop specific guidelines.

Report Nos. FHWA-RD-97-147, FHWA-RD-98-052, FHWA-RD-98-113 and SHRP-P-393

Flexible Pavements

The "depth of cover" concept has long been used in flexible pavement design to ensure that the load-carrying capacity of the surface was sufficient to prevent load-induced failure of the base, and that the combined bearing capacity of the surface and base provided adequate protection for the subgrade. Similarly, in areas with soils prone to volume change effects, additional thicknesses of granular material or stabilized layers have been used to minimize the magnitude and impact of volume changes. Findings from LTPP analyses support these practices.

Base Type

Full-depth asphalt concrete pavements built directly on expansive soils appear to have inferior performance characteristics, as opposed to those pavements where the asphalt concrete material was placed on a granular base/subbase or stabilized material. Also, the use of a stabilized subgrade on expansive clay soils appears to help maintain the moisture content in the clay subgrade at a near optimum condition, resulting in slightly lower rates of change in the IRI over time.

Report No. FHWA-RD-97-085

Pavements with a cement-treated base and full-depth asphalt concrete pavements generally have lower rut depths than those on unbound granular bases. This suggests that some of the measured rut depths at the surface of the thinner or conventional asphalt concrete pavements may be related to, or occurring in the granular base/subbase materials.

Report No. FHWA-RD-99-193

Layer Thickness

Full-depth asphalt concrete pavements appear to perform better or have less fatigue cracking than those pavements with thinner asphalt concrete layers placed over granular base materials.

Report No. FHWA-RD-97-085

Materials

Accurate characterization of the materials is critical to the design of durable and cost-effective pavements. The following are key findings from several LTPP materials studies. They are grouped into two areas: Material Characterization and Superpave Binder Selection

Material Characterization

Rigid Pavement Design

The elastic modulus of subgrade reaction (elastic k-value) of the underlying subgrade can be determined by three methods:

Procedures for each method were verified using LTPP data. A practical, easy-to-use table for estimating the k-value is provided in Phase I: Validation of Guidelines for k-Value Selection and Concrete Pavement Performance Prediction

Report No. FHWA-RD-96-198.

The k-values backcalculated from FWD measurement exceeded plate-load elastic k-values by a factor of approximately 2.0.

Report No. FHWA-RD-96-198

Flexible Pavement Design

Correlation with the physical properties of the subgrade soil should not be used to estimate the design resilient modulus for the design of high-volume roadways. The design resilient modulus should be determined from laboratory resilient modulus tests or backcalculated from deflection basins. The possibility of large errors is simply too high when using gross correlations between physical properties or strength values (such as the California Bearing Ratio [CBR]) and resilient modulus.

Report No. FHWA-RD-97-091

For asphalt concrete mixtures, the backcalculated moduli are significantly greater than the laboratory measured values due to the difference in the response time to the two different loading situations. The ratios of backcalculated to laboratory-measured are dependent on pavement and testing temperatures. These resulting ratios range from 1.0 at 5° C to 4.0 at 40° C. When designing asphalt concrete pavement using the AASHTO Design Guide, all backcalculated in-situ elastic moduli must be adjusted to equivalent laboratory-measured values.

Report No. FHWA-RD-97-085

Superpave Binder Selection

The LTPP Seasonal Monitoring Program temperature data indicate that low pavement temperatures were up to -10.6° C higher than the prevailing low air temperature. Thus, the low-temperature asphalt binder performance grade determined by the Superpave procedure is too conservative, since it assumes that low pavement temperature equals low air temperature. The high-temperature performance grades determined using the Superpave and LTPP models agreed up to a performance grade of 52. At higher temperatures, the LTPP model required performance grades that were sometimes one performance grade lower.

Report No. FHWA-RD-97-104 and FHWA-RD-99-082

Initial Roughness

Roughness is widely regarded as the most important measure of pavement performance because it is the measure most evident to the traveling public. It greatly affects ride quality, safety, and vehicle operating costs. The following are key findings from several LTPP studies to enhance understanding of how and why roughness occurs in pavements.

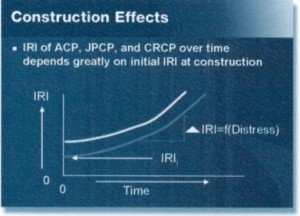

Analysis of IRI data indicated that flexible pavements generally start off with a lower initial IRI, but develop roughness more quickly and at lower traffic volumes than rigid pavements.

Report No. FHWA-RD-97-147

Data analysis showed that the average IRI of a JPCP over time depends greatly on its initial IRI. Thus, smoother construction results in smoother JPCP over time and traffic.

Report No. FHWA-RD-97-131

The results from LTPP Analysis clearly show the value of achieving a very smooth CRCP right from the beginning. The initial smoothness appears to remain over many years for CRCP, as long as the pavement does not show excessive localized failure.

Report No. FHWA-RD-97-131

Ride, as measured by the IRI, was generally smooth (IRI less than 1.5 m/km) for most of the GPS-5 test sections.

Report No. FHWA-RD-99-086

Plots of IRI over time showed that IRI stayed very constant over several years of monitoring, even for older CRCP.

Report No. FHWA-RD-94-147

Pavement Maintenance

Timely maintenance of pavements is critical to achieving long pavement life at minimum cost. Accomplishing necessary maintenance with minimal disruption to traffic is equally critical from the standpoint of customer satisfaction, the safety of both those doing the work and the travelling public, and the overall productivity. The following are key findings from several LTPP pavement maintenance studies. They are grouped into two areas: Maintenance of JPCP and Maintenance of Flexible Pavements.

Maintenance of JPCP

Treatment Performance

SPS-43 sealed joint sections performed better than unsealed sections. Unsealed joints in the control sections contain significantly more debris than sealed joint sections. Unsealed joints also have significantly more joint spalling than the sealed joint sections.

Report No. FHWA-RD-96-208

3SPS-4 - SPS-4 focuses on the Preventive Maintenance Effectiveness of Rigid Pavements.

Maintenance of Flexible Pavements

Treatment Performance

There was consensus among those evaluating the SPS-34 sites that the thin asphalt concrete overlay treatments performed best after 5 years.

Report No. FHWA-RD-96-208

In general, chip seal treatments also performed well. Chip seal performance was best in the southern region (predominantly wet-no freeze environment).

Report No. FHWA-RD-96-208

The crack seal treatment performed very well in wet-freeze environments where the wide shallow sealant reservoir was routed (38.1 mm wide and 9.5 mm deep). Crack seal performance in the other two regions was not as successful.

Report No. FHWA-RD-96-208

4SPS-3 - SPS-3 focuses on the Preventive Maintenance Effectiveness of Flexible Pavements.

Treatment Timing

The question of timing cannot be totally resolved from the visual observation of the SPS-3 sites, but indications are that earlier applications of the preventative maintenance treatments provides greater benefits than later application.

Report No. FHWA-RD-96-208

Pothole Repair Treatment Performance, Repair Methods

The throw-and-roll technique proved to be just as effective as the cut, fill, and compact method. The added labor and equipment-along with lowers productivity-contributed to poorer cost-effectiveness for the cut, fill, and compact method.

Report No. FHWA-RD-98-073

Spray-injection repairs performed as well as throw-and-roll, and cut, fill, and compact repairs at most sites. Problems with material compatibility (asphalt concrete binder and aggregates) and equipment performance (damp aggregate freezing in the hopper) served as reminders that operators need to be familiar with the equipment and materials being used to ensure good performance.

Report No. FHWA-RD-98-073

Pavement Rehabilitation

With much of the national highway system at or beyond its original design life, pavement rehabilitation has come to the forefront as a (if not the) key activity of highway agencies. The magnitude of the challenges faced by agencies as they pursue the rehabilitation of our highway system is tremendous. LTPP analysis has begun to provide some of the many answers agencies need as they address this challenge. The following are key findings from several LTPP analyses of pavement rehabilitation.

General Findings

Report No. FHWA-RD-00-029:

Early performance data from SPS-55 indicated the following:

Thick overlays are not superior to thin overlays (approximately 50 mm) in resisting rutting.

Virgin and recycled mixtures offer similar resistance to rutting.

The unmilled test sections rutted about the same as the milled test sections.

Test sections that were milled prior to the application of overlays generally performed better than the unmilled test sections for transverse cracking. Milling prior to overlay had little or no advantage in resisting both types of longitudinal cracking, fatigue cracking, rutting, or roughness. The thicker overlays consistently have less load-related cracking than the thin overlays. Based on the SPS-5 data, virgin mixes have lesser amounts of longitudinal cracking in the wheelpaths than the recycled mixes.

These observations are based on only the first few years of overlay life and may change as time goes on.

5SPS-5 - SPS-5 focuses on the Rehabilitation of Asphalt Concrete Pavements. At each SPS-5 test site, multiple test sections were constructed with different rehabilitation treatments. Data were collected to document the condition of the original pavements prior to rehabilitation and the performance of the rehabilitated pavements.

The GPS-6A6 data offer insight concerning long-term performance of overlays in rutting. In general, the data indicate:

The great majority of overlays may be expected to resist rutting for 10 years or more.

The majority of overlays should serve 15 or more years before rutting becomes sufficient to require rehabilitation.

Traffic levels are important in predicting rutting, but other factors (e.g., material properties, construction techniques, and quality control) are more important.

As long as the overlay thickness is reasonable (approximately 50 mm), it does not have a major effect on the occurrence of rutting (assuming adequate mix design and placement).

6SPS-6A - SPS-6A focuses on AC overlays of AC pavements. In GPS-6A projects, overlays were constructed prior to the start of LTPP monitoring. Therefore, there is no pre-overlay condition data and only one test section exists at a given site.

AASHTO DESIGN VALIDATION STUDIES

The predictive capability of the National Cooperative Highway Research Program (NCHRP) rigid pavement design model was evaluated using the LTPP data from GPS-3 (JPCP), GPS-4 (JRCP), and GPS-5 (CRCP) experiments. The following are additional findings contributed by the LTPP data analysis.

Subgrade Support Findings

A summary table was developed that lists soils by AASHTO soil classification, unified soil classification, and descriptive name, and identifies corresponding reasonable ranges for dry density, CBR, and static elastic k-value. Dry density of the soil appears to be a good predictor of the static elastic k-value.

Report No. FHWA-RD-96-198

The k-values backcalculated from FWD deflections exceeded plate load elastic k-values for those LTPP sections for which plate-load data were available, by factors averaging very close to 2 for all of the backcalculation algorithms. Thus, the conventional simple rule for dividing the backcalculated k-value by 2 to estimate the plate-load k-value is considered valid.

Report No. FHWA-RD-96-198

1998 Supplement to the AASHTO Design of Rigid Pavements

Analysis using LTPP data showed that the modified AASHTO structural design procedure developed under NCHRP Project 1-30 can be used with confidence. As a result of this verification, the procedure was balloted by AASHTO and adopted as the 1998 Supplement to the AASHTO Design of Rigid Pavements.

Report Nos. FHWA-RD-96-198 and FHWA-RD-99-129

Performance Modeling

Performance prediction models serve several important functions in pavement engineering. At the design stage they can be used to help select the structural section and design features to meet key performance criteria. After construction, they can be used in pavement management systems to help agencies predict future performance. Finally, they can be used to provide insight into the relative importance of different design features or the impact of design changes that might be considered. The following are key findings from several LTPP performance modeling studies.

Rigid Pavements

Sensitivity analyses of the joint faulting equations for both doweled joints and aggregate-interlock joints revealed that faulting will increase with increased erosion, precipitation, or joint spacing. The use of edge drains and crushed stone coarse aggregate will reduce faulting.

Report No. FHWA-RD-98-094

The models developed for JPCP based on LTPP data include joint faulting, slab transverse cracking, transverse joint spalling, and roughness. Based on these models, the following conclusions can be drawn.

Report Nos. FHWA-RD-96-198, FHWA-RD-98-113 and SHRP-P-393

The use of sufficiently large dowels for the traffic loadings will ensure that faulting will not become significant and cause roughness. Dowel use is particularly important for heavy traffic in cold and wet climates.

Thicker slabs by themselves do not reduce faulting significantly.

Longitudinal subdrainage will help reduce faulting of non-doweled joints.

A tied concrete shoulder will reduce doweled joint faulting.

Increased slab thickness has a strong effect on reducing transverse slab cracking and providing a smoother JPCP over time.

Provision of increased subgrade support, as indicated by the backcalculated k-value, results in a smoother pavement. Increased support over an existing soft subgrade would probably require either treatment of the soil or a thick granular layer over the subgrade.

The use of shorter slabs for JPCP will reduce the amount of joint faulting and transverse cracking and will result in a smoother pavement over time.

Specification of durable concrete in freeze climates is essential so that freezing/thawing and other climatic factors do not result in significant joint spalling.

Widened traffic lanes significantly reduce joint faulting and transverse cracking.

Publication No. FHWA-RD-00-085

|