U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

| This report is an archived publication and may contain dated technical, contact, and link information |

|

Publication Number: FHWA-RD-02-082 Date: August 2006 |

Previous | Table of Contents | Next

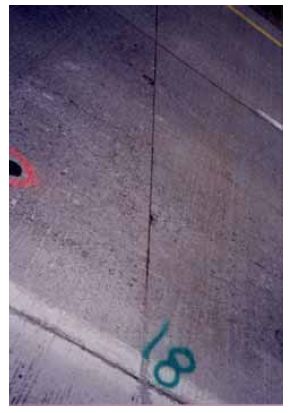

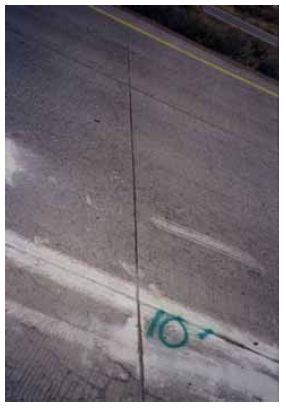

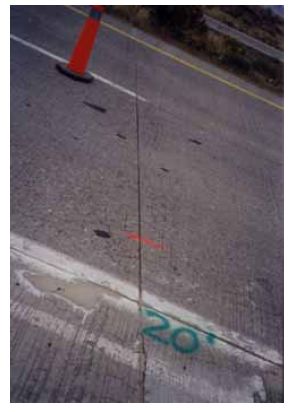

Figure A1. Photographs of typical joint sections for each test section (Winnemucca, NV).

(a) Control section 3 (C3)

(b) Lithium Hydroxide section 2 (L2)

(c) Silane section 2 (S2)

(d) Methacrylate section 2 (M2)

(e) Silane #2 section 1 (SA1)

(f) Linseed oil section 1 (LO1)

(g) Control section 2 (C2)

(h) Silane section 1 (S1)

(i) Lithium hydroxide section 1 (L1)

(j) Control section 1 (C1)

(k) Methacrylate section 1 (M1)

Petrographic Report for Winnemucca, NV, 1997

Two sections from each of the cores were cut and lapped. These sections were then soaked overnight and dried, and the entire lapped surface was traversed under a stereo microscope. The lapped surface was divided into five or more traverses and examined at magnifications of 10 to 30 times. All instances of cracks, alkali-silica gel, and deteriorated or reacted aggregate particles were counted.

Core 97-C1-B: The core is classed as slightly to moderately distressed. The wearing surface is severely worn, exposing coarse and fine aggregate particles. Popouts are occasionally identifiable. Sixty-one cracks (chiefly microscopic) and 54 instances of alkali-silica gel were counted. Eight coarse and 22 fine aggregate particles were distressed or had reacted. The core is marginally air-entrained with an estimated air content of 5 percent.

Core 97-C2-A: The core is classed as slightly distressed. The wearing surface is severely worn, exposing coarse and fine aggregate particles. Popouts are occasionally identifiable. Thirty-four cracks and 58 instances of alkali-silica gel were counted. Nine coarse and 42 fine aggregate particles were distressed or had reacted. The core is well air-entrained with an estimated air content of 6.5 percent.

Core 97-C3-A: The core is classified as slightly distressed. The wearing surface is severely worn, exposing coarse and fine aggregate particles. Popouts are occasionally identifiable. Eleven cracks and 50 instances of alkali-silica gel were counted. Three coarse and 27 aggregate particles show evidence of distress or reaction. The core is air-entrained with an estimated air content of 5.5 percent.

Core 97-L1-C: The core is classified as moderately distressed. The wearing surface is severely worn, exposing coarse and fine aggregate particles. Popouts are frequently identifiable. Sixtyfive cracks and 39 instances of alkali-silica gel were counted. One coarse and 21 fine aggregate particles show evidence of distress or reaction. The core is air-entrained with an estimated air content of 6 percent.

Core 97-L2-B: The core is classified as slightly distressed. The wearing surface is worn, exposing aggregate particles. Twenty cracks and 32 instances of alkali-silica gel were counted. Twenty-two fine aggregate particles showed evidence of distress or reaction. The core is airentrained with an estimated air content of 6 percent.

Core 97-LO1-B: The core is classified as moderately severely distressed. The wearing surface is worn, exposing numerous fine and coarse aggregate particles. Popouts are occasionally evident. Seventy-three cracks and 62 instances of alkali-silica gel were counted. Five coarse and 32 fine aggregate particles showed evidence of distress or reaction. The core is marginally to poorly airentrained with an estimated air content that varies between 4 and 5 percent.

Core 97-M1-C: The core is classed as severely distressed. The wearing surface is worn, exposing coarse and fine aggregate particles. Popouts are occasionally evident. One hundred eighty-five cracks and 81 instances of alkali-silica gel were counted. Several of the cracks are macroscopic. Thirteen coarse and 42 fine aggregate particles showed evidence of distress or reaction. The core is poorly air-entrained with an estimated air content of 4 percent.

Core 97-M2-B: The core is classified as slightly to moderately distressed. The wearing surface is worn, revealing fine and occasionally coarse aggregate particles; 48 cracks and 75 instances of alkali-silica gel were counted. Five coarse and 27 fine aggregate particles showed evidence of distress or reaction. The core is poorly air-entrained with an estimated air content of 4 percent.

Core 97-S1-C: The core is classified as moderately severely distressed. The wearing surface is moderately worn, exposing fine and occasionally coarse aggregate particles. Ninety-seven cracks and 85 instances of alkali-silica gel were counted. Thirteen coarse and 23 fine aggregate particles showed evidence of distress or reaction. The core is air-entrained with an estimated air content of 5.5 percent.

Core 97-SA1-C: The core is classified as moderately distressed. The wearing surface is worn, and popouts over aggregate particles are present. Seventy-seven cracks and 41 instances of alkali-silica gel were counted. Ten coarse and 64 fine aggregate particles showed evidence of reaction or distress. The core is air-entrained with an estimated air content of 6 percent.

Core 97-S2-A: The core is classified as slightly distressed. The wearing surface is worn; shallow popouts over coarse and fine aggregate particles are frequent; 29 cracks and 40 instances of alkali-silica gel were counted. Fourteen coarse and 53 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 6 percent.

Petrographic report for Winnemucca, NV, 1998

Sections from each of the cores were cut and lapped. These sections were then soaked overnight and dried, and the entire lapped surface was traversed under a stereo microscope. Each lapped surface was divided into five or more traverse areas and examined at magnifications of 10 to 30 times. All instances of cracks, alkali-silica gel, and deteriorated or reacted aggregate particles were counted.

98-C1-2: The wearing surface appears to be a worn, mechanically ground surface. The core contains abundant evidence of reaction but little distress. Forty microcracks and 129 instances of alkali-silica gel were counted. Seventeen coarse and 115 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 7 percent.

98-C2-1: The wearing surface is severely worn with very frequently exposed and polished aggregate particles. The core is severely distressed. Three large cracks, 139 microcracks, and 104 instances of alkali-silica gel were counted; 35 coarse and 129 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 6.5 percent.

98-C3-2: The wearing surface is very severely worn with frequently exposed and polished aggregate particles. The core is severely distressed. One large crack, 72 microcracks, and 84 instances of alkali-silica gel were counted. Sixteen coarse and 134 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 7.5 percent.

98-LI-1: The wearing surface is severely worn with frequently exposed and polished aggregate particles, and three prominent but tightly closed cracks. The core is moderately to severely distressed. One large crack, 121 microcracks, and 69 instances of alkali-silica gel were counted. Thirty-one coarse and 81 fine aggregate particles show evidence of distress or reaction. The core is air-entrained with an estimated air content of 5 percent.

98-L2-1: The wearing surface is moderately severely worn with frequent exposed and polished aggregate particles. The core is slightly distressed. Twenty-three microcracks and 88 instances of alkali-silica gel were counted. Sixteen coarse and 126 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 5 percent.

98-LOI-2: The wearing surface is moderately to severely worn with frequently exposed and polished aggregate particles. The core is slightly to moderately distressed. Forty-six microcracks and 84 instances of alkali-silica gel were counted. Twenty-seven coarse and 69 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 4.5 percent.

98-M1-1: The wearing surface is severely worn or possibly worn and mechanically ground, with frequently exposed and polished aggregate particles. The core is very severely distressed. Seven major cracks, 196 microcracks, and 105 occurrences of alkali-silica gel were counted. Fortyseven coarse and 102 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 5.5 percent.

98-M2-2: The wearing surface is severely worn with frequent exposed and polished aggregate particles. The core is moderately distressed. Seventy-five microcracks and 73 instances of alkalisilica gel were counted. Thirty-five coarse and 65 fine aggregate particles show evidence of distress or reaction. The core is air-entrained with an estimated air content of 5.5 percent.

98-S1-2: The wearing surface is severely worn with frequent exposed aggregate particles and occasional popouts. The core is very severely distressed. Two major cracks, 113 microcracks, and 90 occurrences of alkali-silica gel were counted. Fifty-eight coarse and 173 fine aggregate particles show evidence of reaction or distress. The core is air-entrained with an estimated air content of 5.5 percent.

98-S2-2: The wearing surface is worn with frequent exposed and polished aggregate particles. The surface appears to have been machine grooved at one time. One crack and a popout are apparent on the wearing surface. The core is very severely distressed. Three major and 153 microcracks, and 116 occurrences of alkali-silica gel were counted. Forty-five coarse and 102 fine aggregate particles showed evidence of reaction or distress. The core is poorly to marginally air-entrained with an estimated air content of 5 percent.

98-SA1-2: The wearing surface is severely worn with frequent exposed aggregate particles and occasional popouts. The core is severely distressed. One major crack, 114 microcracks, and 78 occurrences of alkali-silica gel were counted; 43 coarse and 156 fine aggregate particles showed evidence of reaction or distress. The core is air-entrained with an estimated air content of 6 percent.

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | – | 6.5 | 8 | 9 | 5.5 |

| 3L(sealed) | m | – | 0 | 0 | 0 | 0 | |

| 3M | m | 16 | 8.5 | 12.5 | 12.5 | 18.1 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 6 | 6 | 7 | 7 | 5 |

| 4L | m | 6.5 | 6.8 | 8 | 8 | 5.6 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 8.8 | 9.7 | 4.8 | 0 | 3.3 | |

| 4M | m | 0 | 0 | 0 | 0 | 0 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 10.54 | |

| 4H | no. | 0 | 0 | 2 | 4 | 4 | |

| 4H | m | 0 | 0 | 5.1 | 9.9 | 10.54 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 5 | 4 | 3 | 1 | 0 |

| 7L(length) | m | 13.6 | 12.8 | 9.2 | 2 | 0 | |

| 7M | no. | 1 | 2 | 2 | 4 | 0 | |

| 7M(length) | m | 2 | 2.6 | 3.7 | 11.2 | 0 | |

| 7H | no. | 0 | 0 | 1 | 1 | 6 | |

| 7H(length) | m | 0 | 0 | 2.6 | 3 | 18.9 | |

| Map cracking | 8a | no. | – | 3 | 5 | 8 | 11 |

| 8a | m2 | – | 1.2 | 1.5 | 2.02 | 5.9 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 1.2 | 0 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 2 | – | – | 0 |

| WP-M | no. | – | 3 | – | – | 4 | |

| WP-H | no. | – | 0 | – | – | 1 | |

| CL-L | no. | – | 4 | – | – | 1 | |

| CL-M | no. | – | 1 | – | – | 4 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 16 | 15 | 20.5 | 21.5 | 23.6 |

| Percent L | – | 0 | 43 | 39 | 42 | 23 | |

| Percent M | – | 100 | 57 | 61 | 58 | 77 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 11 | 10 | 11 | 11 | 11 |

| Total | m | 15.3 | 16.5 | 17.9 | 17.9 | 19.44 | |

| Percent L | 42 | 41 | 45 | 45 | 29 | ||

| Percent M | 58 | 59 | 27 | 0 | 17 | ||

| Percent H | 0 | 0 | 28 | 55 | 54 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 11 | 11 |

| Total | m | 15.6 | 15.6 | 15.4 | 16.2 | 18.9 | |

| Percent L | – | 87 | 83 | 59 | 12 | 0 | |

| Percent M | – | 13 | 17 | 24 | 69 | 0 | |

| Percent H | – | 0 | 0 | 17 | 19 | 100 | |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 6 | 5 | 5 | 11.5 | 1 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 16 | 13 | 6.5 | 7 | 17 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 9 | 3.5 | 3.5 | |

| 3H(sealed) | m | 0 | 0 | 0 | 1 | 0 | |

| Transverse cracking | 4L | no. | 0 | 0 | 0 | 1 | 5 |

| 4L | m | 0 | 0 | 0 | 1 | 0 | |

| 4L(sealed) | m | 0 | 0 | 0 | 1 | 0 | |

| 4M | no. | 3 | 2 | 1 | 2 | 1 | |

| 4M | m | 4.8 | 5.4 | 3.6 | 5.6 | 1.5 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 1 | 0 | 2 | |

| 4H | m | 0 | 0 | 2 | 0 | 5.1 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 6 | 4 | 2 | 2 | 0 |

| 7L(length) | m | 9.2 | 7 | 5.6 | 5.6 | 0 | |

| 7M | no. | 0 | 2 | 2 | 2 | 3 | |

| 7M(length) | m | 0 | 4.7 | 6.1 | 6.1 | 10.8 | |

| 7H | no. | 0 | 0 | 2 | 2 | 3 | |

| 7H(length) | m | 0 | 0 | 5.6 | 5.6 | 10.2 | |

| Map cracking | 8a | no. | – | 3 | 7 | 7 | 8 |

| 8a | m2 | 85 | 0.6 | 3.5 | 3.5 | 4 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 1.4 | 0.4 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 3 | – | – | 1 |

| WP-M | no. | – | 2 | – | – | 4 | |

| WP-H | no. | – | 0 | – | – | 0 | |

| CL-L | no. | – | 5 | – | – | 3 | |

| CL-M | no. | – | 0 | – | – | 2 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 22 | 18 | 20.5 | 22 | 21.5 |

| Percent L | – | 27 | 28 | 24 | 52 | 5 | |

| Percent M | – | 73 | 72 | 32 | 32 | 79 | |

| Percent H | – | 0 | 0 | 44 | 16 | 16 | |

| Transverse cracking | Total | no. | 3 | 2 | 2 | 3 | 3 |

| Total | m | 4.8 | 5.4 | 5.6 | 6.6 | 6.6 | |

| Percent L | 0 | 0 | 0 | 15 | 0 | ||

| Percent M | 100 | 100 | 64 | 85 | 23 | ||

| Percent H | 0 | 0 | 36 | 0 | 77 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 9.2 | 11.7 | 17.3 | 17.3 | 21 | |

| Percent L | – | 100 | 60 | 32 | 32 | 0 | |

| Percent M | – | 0 | 40 | 35 | 35 | 51 | |

| Percent H | – | 0 | 0 | 32 | 32 | 49 | |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 17 | 9.5 | 11 | 11.5 | 6.5 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 17 | 12.5 | 12.5 | 8 | 17.5 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 1 | 0 | 0 | 1 | 5 |

| 4L | m | 1 | 0 | 0 | 1 | 0 | |

| 4L(sealed) | m | 0 | 0 | 0 | 1 | 0 | |

| 4M | no. | 2 | 2 | 0 | 0 | 0 | |

| 4M | m | 5.3 | 7.2 | 0 | 0 | 0 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 2 | 2 | 2 | |

| 4H | m | 0 | 0 | 7.2 | 7.2 | 7.2 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 6 | 6 | 6 | 6 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 6 | 6 | 3 | 3 | 1 |

| 7L(length) | m | 14 | 9 | 6.1 | 6.4 | 1.8 | |

| 7M | no. | 0 | 0 | 2 | 2 | 1 | |

| 7M(length) | m | 0 | 0 | 5.6 | 5.6 | 3 | |

| 7H | no. | 0 | 0 | 1 | 1 | 4 | |

| 7H(length) | m | 0 | 0 | 3.6 | 3.6 | 12 | |

| Map cracking | 8a | no. | 3 | 4 | 5 | 9 | |

| 8a | m2 | 84.1 | 1.4 | 1.8 | 3.9 | 6 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 0.9 | 0 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 3 | – | – | 1 |

| WP-M | no. | – | 2 | – | – | 2 | |

| WP-H | no. | – | 0 | – | – | 2 | |

| CL-L | no. | – | 5 | – | – | 0 | |

| CL-M | no. | – | 0 | – | – | 5 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 34 | 22 | 23.5 | 19.5 | 24 |

| Percent L | – | 50 | 43 | 47 | 59 | 27 | |

| Percent M | – | 50 | 57 | 53 | 41 | 73 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 3 | 2 | 2 | 2 | 2 |

| Total | m | 6.3 | 7.2 | 7.2 | 7.2 | 7.2 | |

| Percent L | 16 | 0 | 0 | 15 | 0 | ||

| Percent M | 84 | 100 | 0 | 0 | 0 | ||

| Percent H | 0 | 0 | 100 | 100 | 100 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 14 | 9 | 15.3 | 15.6 | 16.8 | |

| Percent L | – | 100 | 100 | 40 | 41 | 11 | |

| Percent M | – | 0 | 0 | 37 | 36 | 18 | |

| Percent H | – | 0 | 0 | 24 | 23 | 71 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 11 | 11 | 11 | 15 | 5 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 8 | 9 | 7 | 6 | 15.9 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 4 | 6.5 | 8 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 5 | 3 | 1 | 2 | 2 |

| 4L | m | 6 | 5.4 | 1 | 2.5 | 3 | |

| 4L(sealed) | m | 0 | 0 | 0 | 2 | 2 | |

| 4M | no. | 0 | 1 | 3 | 3 | 3 | |

| 4M | m | 0 | 1 | 5.9 | 6.1 | 6.3 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 1 | 1 | |

| 4H | m | 0 | 0 | 0 | 1.5 | 2.1 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 5 | 5 | 5 | 5 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 4 | 1 | 1 | 1 | 0 |

| 7L(length) | m | 6.2 | 1.8 | 1.8 | 1.8 | 0 | |

| 7M | no. | 1 | 3 | 3 | 1 | 2 | |

| 7M(length) | m | 1.5 | 5.8 | 10.2 | 3 | 7.2 | |

| 7H | no. | 0 | 1 | 1 | 3 | 3 | |

| 7H(length) | m | 0 | 1.5 | 3.5 | 10.7 | 10.8 | |

| Map cracking | 8a | no. | 5 | 8 | 9 | 9 | |

| 8a | m2 | 93 | 2.1 | 3.75 | 5.5 | 7.3 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 0.3 | 0 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 4 | – | – | 1 |

| WP-M | no. | – | 1 | – | – | 4 | |

| WP-H | no. | – | 0 | – | – | 0 | |

| CL-L | no. | – | 5 | – | – | 5 | |

| CL-M | no. | – | 0 | – | – | 0 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 19 | 20 | 22 | 27.5 | 28.9 |

| Percent L | – | 58 | 55 | 50 | 55 | 17 | |

| Percent M | – | 42 | 45 | 32 | 22 | 55 | |

| Percent H | – | 0 | 0 | 18 | 24 | 0 | |

| Transverse cracking | Total | no. | 5 | 4 | 4 | 5 | 5 |

| Total | m | 6 | 6.4 | 6.9 | 8.6 | 9.3 | |

| Percent L | 100 | 84 | 14 | 29 | 32 | ||

| Percent M | 0 | 16 | 86 | 71 | 68 | ||

| Percent H | 0 | 0 | 0 | 0 | 0 | ||

| Spalling of transverse joints | Total | no. | 5 | 5 | 5 | 5 | 5 |

| Total | m | 7.7 | 19.1 | 15.5 | 15.5 | 18 | |

| Percent L | – | 81 | 20 | 12 | 12 | 0 | |

| Percent M | – | 19 | 64 | 66 | 19 | 40 | |

| Percent H | – | 0 | 16 | 23 | 69 | 60 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 4 | 5.5 | 8 | 7 | 7.4 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 11 | 9.5 | 9.5 | 11 | 21.2 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 8 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 6 | 7 | 6 | 4 | 4 |

| 4L | m | 5 | 9.4 | 7.5 | 4 | 4.5 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | ||

| 4M | no. | 2 | 1 | 2 | 4 | 3 | |

| 4M | m | 3 | 1.5 | 2.5 | 4.5 | 5.2 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 1 | 1 | |

| 4H | m | 0 | 0 | 0 | 1.5 | 2.1 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 6 | 6 | 6 | 6 | |

| 5aM | no. | 0 | 2 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 5 | 2 | 1 | 0 | 0 |

| 7L(length) | m | 16.2 | 6.1 | 2.5 | 0 | 0 | |

| 7M | no. | 1 | 4 | 4 | 6 | 5 | |

| 7M(length) | m | 3.8 | 13.6 | 14.4 | 21.6 | 18 | |

| 7H | no. | 0 | 0 | 1 | 0 | 1 | |

| 7H(length) | m | 0 | 0 | 3.6 | 0 | 3.6 | |

| Map cracking | 8a | no. | 6 | 8 | 9 | 10 | |

| 8a | m2 | 87.8 | 4.6 | 4.7 | 4.8 | 7 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 1 | 0.3 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 3 | – | – | 0 |

| WP-M | no. | – | 2 | – | – | 5 | |

| WP-H | no. | – | 0 | – | – | 0 | |

| CL-L | no. | – | 3 | – | – | 0 | |

| CL-M | no. | – | 2 | – | – | 5 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 15 | 15 | 17.5 | 18 | 28.6 |

| Percent L | – | 27 | 37 | 46 | 39 | 26 | |

| Percent M | – | 73 | 63 | 54 | 61 | 74 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 8 | 8 | 8 | 9 | 8 |

| Total | m | 8 | 10.9 | 10 | 10 | 11.8 | |

| Percent L | 63 | 86 | 75 | 40 | 38 | ||

| Percent M | 38 | 14 | 25 | 45 | 44 | ||

| Percent H | 0 | 0 | 0 | 15 | 18 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 20 | 19.7 | 20.5 | 21.6 | 21.6 | |

| Percent L | – | 81 | 31 | 12 | 0 | 0 | |

| Percent M | – | 19 | 69 | 70 | 100 | 83 | |

| Percent H | – | 0 | 0 | 18 | 0 | 17 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 1 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 15 | 13 | 15.5 | 8 | 5.5 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 1.5 | 4.2 | 4.2 | 12 | 25.1 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 2 | 3 | 3 | 1 | 1 |

| 4L | m | 2 | 3.5 | 3.3 | 0.8 | 0.8 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 0 | 0 | 0 | 2 | 2 | |

| 4M | m | 0 | 0 | 0 | 2.7 | 5.1 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 0 | |

| 4H | m | 0 | 0 | 0 | 0 | 0 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 6 | 6 | 6 | 6 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 5 | 0 | 0 | 0 | 0 |

| 7L(length) | m | 17.7 | 0 | 0 | 0 | 0 | |

| 7M | no. | 1 | 6 | 2 | 2 | 1 | |

| 7M(length) | m | 3.8 | 19.8 | 6.2 | 7.2 | 3.6 | |

| 7H | no. | 0 | 0 | 4 | 4 | 5 | |

| 7H(length) | m | 0 | 0 | 14.4 | 14.4 | 18 | |

| Map cracking | 8a | no. | 8 | 10 | 13 | 13 | |

| 8a | m2 | 81 | 2.9 | 4.3 | 11.4 | 11.4 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 0.4 | 0 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 1 | – | – | 0 |

| WP-M | no. | – | 4 | – | – | 5 | |

| WP-H | no. | – | 0 | – | – | 0 | |

| CL-L | no. | – | 3 | – | – | 1 | |

| CL-M | no. | – | 2 | – | – | 4 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 16.5 | 17.2 | 19.7 | 20 | 30.6 |

| Percent L | – | 91 | 76 | 79 | 40 | 18 | |

| Percent M | – | 9 | 24 | 21 | 60 | 82 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 2 | 3 | 3 | 3 | 3 |

| Total | m | 2 | 3.5 | 3.3 | 3.5 | 5.9 | |

| Percent L | 100 | 100 | 100 | 23 | 14 | ||

| Percent M | 0 | 0 | 0 | 77 | 86 | ||

| Percent H | 0 | 0 | 0 | 0 | 0 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 21.5 | 19.8 | 20.6 | 21.6 | 21.6 | |

| Percent L | – | 82 | 0 | 0 | 0 | 0 | |

| Percent M | – | 18 | 100 | 30 | 33 | 17 | |

| Percent H | – | 0 | 0 | 70 | 67 | 83 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 4.5 | 8 | 10.5 | 8.5 | 12.4 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 0 | 1.5 | 1.5 | 15.5 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 3 | 1 | 1 | 1 | 1 |

| 4L | m | 4 | 1 | 1.3 | 1.3 | 1.3 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 0 | 1 | 1 | 1 | 0 | |

| 4M | m | 0 | 3.6 | 3.6 | 3.6 | 0 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 1 | |

| 4H | m | 0 | 0 | 0 | 0 | 3.6 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 6 | 6 | 6 | 6 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 6 | 2 | 1 | 0 | 0 |

| 7L(length) | m | 21 | 4.5 | 2.9 | 0 | 0 | |

| 7M | no. | 0 | 4 | 2 | 2 | 0 | |

| 7M(length) | m | 0 | 10.2 | 5.6 | 7.2 | 0 | |

| 7H | no. | 0 | 0 | 3 | 4 | 6 | |

| 7H(length) | m | 0 | 0 | 10.6 | 14.4 | 21.6 | |

| Map cracking | 8a | no. | 4 | 3 | 11 | 13 | 13 |

| 8a | m2 | 3 | 1.5 | 3.4 | 8.8 | 8.9 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 0.6 | 1 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 2 | – | – | 0 |

| WP-M | no. | – | 3 | – | – | 3 | |

| WP-H | no. | – | 0 | – | – | 2 | |

| CL-L | no. | – | 5 | – | – | 0 | |

| CL-M | no. | – | 0 | – | – | 5 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 4.5 | 8 | 12 | 10 | 27.9 |

| Percent L | – | 100 | 100 | 88 | 85 | 44 | |

| Percent M | – | 0 | 0 | 13 | 15 | 56 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 3 | 2 | 2 | 2 | 2 |

| Total | m | 4 | 4.6 | 4.9 | 4.9 | 4.9 | |

| Percent L | 100 | 22 | 27 | 27 | 27 | ||

| Percent M | 0 | 78 | 73 | 73 | 0 | ||

| Percent H | 0 | 0 | 0 | 0 | 73 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 21 | 14.7 | 19.1 | 21.6 | 21.6 | |

| Percent L | – | 100 | 31 | 15 | 0 | 0 | |

| Percent M | – | 0 | 69 | 29 | 33 | 0 | |

| Percent H | – | 0 | 0 | 55 | 67 | 100 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 10 | 12.5 | 13 | 0 | 7.7 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 0 | 0 | 13.5 | 21 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 1 | 2 | 2 | 2 | 0 |

| 4L | m | 1 | 1.3 | 2.3 | 2.3 | 0 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 6 | 5 | 6 | 6 | 4 | |

| 4M | m | 6 | 6 | 6.3 | 6.3 | 6.3 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 1 | |

| 4H | m | 0 | 0 | 0 | 0 | 3.6 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 6 | 6 | 6 | 6 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 6 | 0 | 0 | 0 | 0 |

| 7L(length) | m | 21.6 | 0 | 0 | 0 | 0 | |

| 7M | no. | 0 | 5 | 1 | 1 | 0 | |

| 7M(length) | m | 0 | 14.7 | 2.5 | 3.6 | 0 | |

| 7H | no. | 0 | 1 | 5 | 5 | 6 | |

| 7H(length) | m | 0 | 3.6 | 18 | 18 | 21.6 | |

| Map cracking | 8a | no. | 7 | 14 | 15 | 16 | 18 |

| 8a | m2 | 6 | 11.8 | 7.8 | 15.2 | 16.1 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 0.8 | 1 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 0 | – | – | 0 |

| WP-M | no. | – | 5 | – | – | 3 | |

| WP-H | no. | – | 0 | – | – | 2 | |

| CL-L | no. | – | 3 | – | – | 0 | |

| CL-M | no. | – | 2 | – | – | 5 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 10 | 12.5 | 13 | 13.5 | 28.7 |

| Percent L | – | 100 | 100 | 100 | 0 | 27 | |

| Percent M | – | 0 | 0 | 0 | 100 | 73 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 7 | 7 | 8 | 8 | 4 |

| Total | m | 7 | 7.3 | 8.6 | 8.6 | 5.3 | |

| Percent L | 14 | 18 | 27 | 27 | 0 | ||

| Percent M | 86 | 82 | 73 | 73 | 100 | ||

| Percent H | 0 | 0 | 0 | 0 | 0 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 21.6 | 18.3 | 21.6 | 21.6 | 21.6 | |

| Percent L | – | 100 | 0 | 0 | 0 | 0 | |

| Percent M | – | 0 | 80 | 17 | 17 | 0 | |

| Percent H | – | 0 | 20 | 83 | 83 | 100 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 5.5 | 7.8 | 10 | 3.5 | 10.7 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 1.5 | 1.5 | 7 | 20 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 7 | 5 | 5 | 4 | 4 |

| 4L | m | 8 | 6 | 6.6 | 5 | 4.7 | |

| 4L(sealed) | m | 0 | 2 | 0 | 0 | 0 | |

| 4M | no. | 0 | 2.5 | 2 | 3 | 4 | |

| 4M | m | 0 | 0 | 3.5 | 5.1 | 7.5 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 1 | |

| 4H | m | 0 | 0 | 0 | 0 | 3.6 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 6 | 6 | 6 | 6 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 6 | 0 | 0 | 0 | 0 |

| 7L(length) | m | 21.6 | 0 | 0 | 0 | 0 | |

| 7M | no. | 0 | 5 | 3 | 3 | 0 | |

| 7M(length) | m | 0 | 17.7 | 10.6 | 10.8 | 7.2 | |

| 7H | no. | 0 | 1 | 3 | 3 | 6 | |

| 7H(length) | m | 0 | 3.6 | 9.2 | 10.8 | 21.6 | |

| Map cracking | 8a | no. | 3 | 6 | 9 | 9 | 13 |

| 8a | m2 | 2 | 3.5 | 4.5 | 4.2 | 6.2 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 1 | 0 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 0 | – | – | 0 |

| WP-M | no. | – | 5 | – | – | 5 | |

| WP-H | no. | – | 0 | – | – | 0 | |

| CL-L | no. | – | 4 | – | – | 2 | |

| CL-M | no. | – | 1 | – | – | 3 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 5.5 | 9.3 | 11.5 | 10.5 | 30.7 |

| Percent L | – | 100 | 84 | 87 | 33 | 35 | |

| Percent M | – | 0 | 16 | 13 | 67 | 65 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 7 | 7.5 | 7 | 7 | 8 |

| Total | m | 8 | 6 | 10.1 | 10.1 | 12.2 | |

| Percent L | 100 | 100 | 65 | 50 | 39 | ||

| Percent M | 0 | 0 | 35 | 50 | 61 | ||

| Percent H | 0 | 0 | 0 | 0 | 0 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 21.6 | 21.3 | 19.8 | 21.6 | 21.6 | |

| Percent L | – | 100 | 0 | 0 | 0 | 0 | |

| Percent M | – | 0 | 83 | 54 | 50 | 0 | |

| Percent H | – | 0 | 17 | 46 | 50 | 100 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 14 | 19 | 11 | 4 | 13 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 0 | 3 | 10 | 18.8 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0.8 | 0.8 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 5 | 4 | 3 | 3 | 3 |

| 4L | m | 2.9 | 3.5 | 2.7 | 2.7 | 2.7 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 2 | 2 | 1 | 1 | 1 | |

| 4M | m | 7.3 | 7.2 | 1 | 1 | 1.5 | |

| 4M(sealed) | m | 0 | 0 | 2 | 2 | 2 | |

| 4H | no. | 0 | 0 | 7.2 | 7.2 | 7.2 | |

| 4H | m | 0 | 0 | 0 | 0 | 3.6 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 6 | 6 | 6 | 6 | 6 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 6 | 0 | 0 | 0 | 0 |

| 7L(length) | m | 21.2 | 0 | 0 | 0 | 0 | |

| 7M | no. | 0 | 6 | 6 | 6 | 1 | |

| 7M(length) | m | 0 | 19.2 | 19.8 | 21.6 | 3.6 | |

| 7H | no. | 0 | 0 | 0 | 0 | 5 | |

| 7H(length) | m | 0 | 0 | 0 | 0 | 18 | |

| Map cracking | 8a | no. | 5 | 3 | 4 | 9 | 11 |

| 8a | m2 | 4 | 1 | 1.5 | 4.9 | 6 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 1 | 0.8 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 0 | – | – | 0 |

| WP-M | no. | – | 5 | – | – | 4 | |

| WP-H | no. | – | 0 | – | – | 1 | |

| CL-L | no. | – | 4 | – | – | 1 | |

| CL-M | no. | – | 1 | – | – | 4 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 14 | 19 | 14.8 | 14.8 | 31.8 |

| Percent L | – | 100 | 100 | 74 | 27 | 41 | |

| Percent M | – | 0 | 0 | 20 | 68 | 59 | |

| Percent H | – | 0 | 0 | 5 | 5 | 0 | |

| Transverse cracking | Total | no. | 7 | 6 | 6 | 6 | 6 |

| Total | m | 10.2 | 10.7 | 10.9 | 10.9 | 11.5 | |

| Percent L | 28 | 33 | 25 | 25 | 23 | ||

| Percent M | 72 | 67 | 9 | 9 | 13 | ||

| Percent H | 0 | 0 | 66 | 66 | 63 | ||

| Spalling of transverse joints | Total | no. | 6 | 6 | 6 | 6 | 6 |

| Total | m | 21.2 | 19.2 | 19.8 | 21.6 | 21.6 | |

| Percent L | – | 100 | 0 | 0 | 0 | 0 | |

| Percent M | – | 0 | 100 | 100 | 100 | 17 | |

| Percent H | – | 0 | 0 | 0 | 0 | 83 |

| Type | Identification code | Unit | 10/18/94 | 12/12/95 | 12/5/96 | 10/9/97 | 10/28/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 6 | 13 | 13 | 4 | 11 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 0 | 0 | 14 | 24.7 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 3 | 1 | 4 | 2 | 2 |

| 4L | m | 4.5 | 1.5 | 3.4 | 1.6 | 1.6 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 1 | 3 | 3 | 2 | 3 | |

| 4M | m | 1.5 | 4 | 4.5 | 3 | 4 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 0 | |

| 4H | m | 0 | 0 | 0 | 0 | 3.6 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | Y | Y | Y | Y | Y |

| 5aL | no. | 5 | 5 | 5 | 5 | 5 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 2 | 2 | 2 | 2 | 2 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 0 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 5 | 3 | 0 | 0 | 0 |

| 7L(length) | m | 17 | 5.5 | 0 | 0 | 0 | |

| 7M | no. | 0 | 1 | 4 | 3 | 1 | |

| 7M(length) | m | 0 | 2 | 10.6 | 10.8 | 3.6 | |

| 7H | no. | 0 | 1 | 1 | 2 | 5 | |

| 7H(length) | m | 0 | 2.7 | 3.5 | 7.2 | 18 | |

| Map cracking | 8a | no. | 9 | 12 | 13 | 15 | 16 |

| 8a | m2 | 7.5 | 8.7 | 7.8 | 13.3 | 14.9 | |

| Scaling | 8b | no. | 0 | 0 | 0 | 0 | 0 |

| 8b | m2 | 0 | 0 | 0 | 0 | 0 | |

| Polished aggregate | 9 | m2 | 0 | 0 | 0 | 0 | 0 |

| Popouts | 10 | no./m2 | 0.4 | 0.07 | 0 | 0 | 0 |

| Blowups | 11 | no. | 0 | 0 | 0 | 0 | 0 |

| Faulting | 12 | – | – | – | – | – | – |

| Lane-shoulder dropoff | 13 | – | – | – | – | – | – |

| Lane-shoulder separation | 14 | – | – | – | – | – | – |

| Other | WP-L | no. | – | 5 | – | – | 0 |

| WP-M | no. | – | 0 | – | – | 3 | |

| WP-H | no. | – | 0 | – | – | 2 | |

| CL-L | no. | – | 5 | – | – | 4 | |

| CL-M | no. | – | 0 | – | – | 1 | |

| CL-H | no. | – | 0 | – | – | 0 | |

| Longitudinal cracking | Total | m | 6 | 13 | 13 | 18 | 35.7 |

| Percent L | – | 100 | 100 | 100 | 22 | 31 | |

| Percent M | – | 0 | 0 | 0 | 78 | 69 | |

| Percent H | – | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | Total | no. | 4 | 4 | 7 | 4 | 5 |

| Total | m | 6 | 5.5 | 7.9 | 4.6 | 5.6 | |

| Percent L | 75 | 27 | 43 | 35 | 29 | ||

| Percent M | 25 | 73 | 57 | 65 | 71 | ||

| Percent H | 0 | 0 | 0 | 0 | 0 | ||

| Spalling of transverse joints | Total | no. | 5 | 5 | 5 | 5 | 6 |

| Total | m | 17 | 10.2 | 14.1 | 18 | 21.6 | |

| Percent L | – | 100 | 54 | 0 | 0 | 0 | |

| Percent M | – | 0 | 20 | 75 | 60 | 17 | |

| Percent H | – | 0 | 26 | 25 | 40 | 83 |