U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

| This report is an archived publication and may contain dated technical, contact, and link information |

|

Federal Highway Administration > Publications > Research > Structures > Covered Bridge Manual |

Publication Number: FHWA-HRT-04-098 |

Previous | Table of Contents | Next

Figure 77. Thetford Center Bridge, exterior view, Thetford, VT.

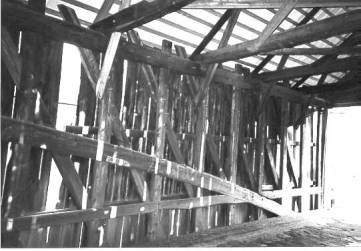

Figure 78. Thetford Center Bridge, interior view, Thetford, VT.

This section (chapters 8 through 14) is devoted to the technical issues and challenges related to engineering of covered bridges. Chapter 8 sets the stage for the technical difficulties related to this work, which are substantially complex and quite unlike work on other bridges. Chapter 9 deals with the codes and specifications that govern work on covered bridges. Chapter 10 presents the issues related to the timber itself-availability, seasoning, and sawing of members. Chapter 11 discusses the analytical evaluation of covered bridges (determining the forces in the members from various loading and combinations of loads). Issues related to the actual sizing of members to satisfy stress requirements follow. Chapter 12 deals with analysis, and chapter 13 deals with specific nuances of allowable stresses. Finally, chapter 14 presents a discussion of connections of covered bridges-one of the most complex issues confronting covered bridge engineers.

One of the most basic issues is the weight of the bridge. Timber, unlike steel or concrete, varies considerably in density and unit weight, depending on its species and moisture content. Some common covered bridge materials may weigh as little as 400 kilograms per cubic meter (kg/m3) (25 pounds per cubic foot (pcf)) (dry spruce) or may weigh up to 640-800 kg/m3 (40-50 pcf) (pressure treated). Such variation creates much uncertainty in predicting the actual weight of the bridge. For covered bridges, the weight of the bridge is often larger in comparison with vehicular loading than for conventional bridges, and its accurate prediction is important. In special cases, use of jacking equipment may be appropriate to allow an actual weighing of the bridge. Unnecessarily conservative estimates of weight can lead to decisions to replace members that might not need to be replaced. More specifically, while the AASHTO Standard Specifications specify use of 800 kg/m3 (50 pcf) for timber structures, that specification is an appropriate guideline for open-decked modern timber bridges; it is not necessarily appropriate for covered bridges.

The trusses are important in determining bridge capacity (assuming the floor system is easily analyzed). The process of determining forces in the myriad truss configurations is often very challenging (see more in chapter 12, "Force Analysis Methodology"). The strength of the individual members is often very difficult to assess, and member characteristics often change from member to member in the bridge because of variation in the original construction or random member replacement during subsequent rehabilitation of the bridge. Therefore, it is difficult to accurately isolate the controlling member and its controlling stress parameter.

Determining the species of the timber and its grade is also a technical challenge. Few individuals are sufficiently skilled to identify the variety of timber components confronting covered bridge engineers. Douglas Fir and Southern Pine are common materials used in more recent rehabilitation projects, yet the original members may be of local hemlock, pine, spruce, or may even be a mixture of species. It is always safest to obtain samples and have a trained timber materials specialist identify them. Grade is a function of a number of features of the timber, including the alignment of the grain with respect to the axis of the member, the spacing of the annular rings of the wood, and defects (knots, shakes, splits). Accurately determining the grade of a timber, therefore, requires evaluation by a trained specialist. This topic is explored in more depth in a later section of this manual.

Given the preceding discussion of the various challenges confronting covered bridge engineers, it seems straightforward to develop a systematic method to address each of the questions or topics to identify a solution for the covered bridge in question. Unfortunately, any standard approach based on conventional bridge engineering often indicates serious distress of a covered bridge, which may not correlate with the physical behavior. Routine analysis often indicates that some bridges should have failed long ago, yet they remain standing.

This is because the bridge can withstand more load and/or stress than the analyses suggest. Alternatively, it may be that the actual safety factor is smaller than the desired one. In some instances, the bridge may not have experienced the full loading used in the design review.

The issue of bridges having more capacity than analysis suggests is not unique to covered bridges, and refinements to analysis techniques constantly are being developed to help engineers more accurately predict the true load carrying capacity of bridges.

It is important that the evaluation and ultimate rehabilitation of covered bridges be entrusted to engineers and contractors highly experienced with the nuances of covered bridges and timber structures. There is no substitute for sound judgment based on experience.