U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

R&T NOW This newsletter is an archived publication and may contain dated technical, contact, and link information. |

|

| Publication Number: Date: March/April 2020 |

Publication Date: March/April 2020

|

PDF files can be viewed with the Acrobat® Reader®

In this issue…

Every year, taxpayer dollars fund research and development (R&D) at Federal laboratories. To improve the transition of innovations from the laboratory to the marketplace, the Federal Highway Administration (FHWA) formed the Technology Transfer (T2) program.

T2 strives to ensure that innovations developed for the U.S. transportation system are broadly available to all levels of the Government and the general public. FHWA's goal is to become a recognized leader in T2, accelerating the movement of innovations beyond labs and into the government and public marketplace to benefit society. It is because of this vision that the T2 program recognizes the FHWA Advanced Sensing Technology (FAST) Nondestructive Evaluation Laboratory (NDE Lab) at the Turner-Fairbank Highway Research Center (TFHRC) for its use of advanced, multidisciplinary technologies and its ability to share these technologies with external partners.

© Genex Systems.

Interview with the NDE Program Manager, Hoda Azari, in the NDE Lab.

The FAST NDE Lab is a world-class facility that conducts quality research, development, improvement, and implementation of FAST NDE systems and technologies to assist infrastructure owners.

T2 and the FAST NDE Lab, in a collaborative effort to communicate and market lab technologies, developed a video to demonstrate the work being done on FAST NDE Lab products, which include an extensive collection of commercial and customized FAST NDE equipment. In addition, the T2 program creates marketing collateral for dissemination to the public.

The T2 program is dedicated to assisting inventors and licensees through the entire T2 process. The program is focused on the commercialization of research products at FHWA by identifying new technologies and marketing them to the government and commercials sectors.

For more information about the program, contact Mary Huie at mary.huie@dot.gov.

Gridlock, poor signal timing, an inability to quickly identify incident types, and poor road conditions are just a few of the many issues transportation agencies struggle with to manage the traffic system. Addressing these needs is expensive and time intensive.

© Utah Department of Transportation.

Crowdsourcing addresses a need or problem by enlisting the services of a large number of people through technology.

Crowdsourcing has the potential to address these needs at very little cost. Crowdsourcing is a powerful tool that leverages the public to improve traveler information, traffic incident management, signal timing, weather-responsive management, work zone management, and more.

More than half of all States and many local transportation agencies already use some form of crowdsourcing. Agencies gather data from agency-operated and third party mobile applications, crowdsource data providers, and social media. These sources gather information that includes vehicle speeds, travel times, crashes, stalled vehicles, pothole or debris locations, adverse weather conditions, temperatures, and work zone locations.

Crowdsourcing overcomes gaps in geographic coverage of real-time monitoring systems, lags in timeliness of information, costs to build and maintain monitoring equipment, and jurisdictional data issues. Crowdsourced data are available wherever and whenever people travel, giving visibility into suburban and rural networks where roadway sensor technology is not available.

Agencies wanting to be more proactive in transportation systems management and operations (TSMO) may want to consider harnessing the power of crowdsourcing to monitor roads and manage existing monitoring systems. View the Innovation Spotlight video to learn more about how crowdsourcing may help your agency.

For more information, contact James Colyar at james.colyar@dot.gov or Paul Jodoin at paul.jodoin@dot.gov.

State DOTs are always looking for ways to ease congestion, improve roadway safety, and identify roadway interruptions and maintenance needs. The Vehicle-to-Everything (V2X) Hub enables cities and States to leverage real-time, location-specific data to accomplish these goals.

The V2X Hub uses software that facilitates the exchange of data in a format that can be understood by vehicles and infrastructure devices to incorporate infrastructure into the connected vehicle (CV) architecture. The V2X Hub can receive messages from CVs and road users in the Society of Automotive Engineers (SAE) J2735 standard and transcodes the data to a National Transportation Communications for ITS Protocol (NTCIP) that infrastructure components, such as signal controllers, can understand, and vice versa.

The V2X Hub can also translate Signal Phase and Timing (SPaT) data from NTCIP to SAE J2735 and send them to a roadside unit (RSU) to broadcast to vehicles. The V2X Hub is a message handler that acts as a translator and data aggregator/disseminator for infrastructure components of a CV deployment.

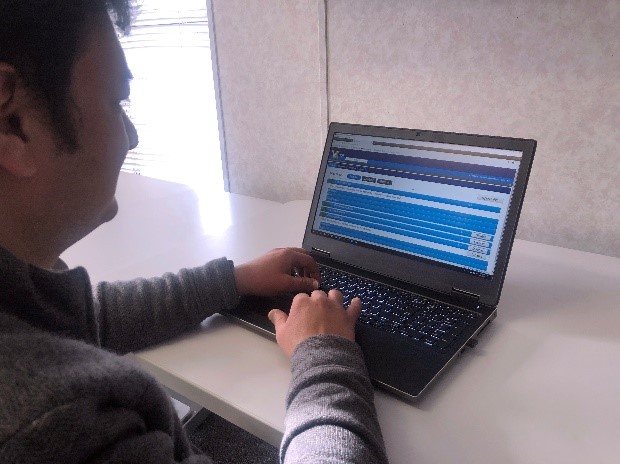

Source: FHWA

A Saxton Transportation Operations Laboratory researcher using the newest edition of V2X Hub.

V2X Hub 5.0 includes updates to improve performance, such as a performance-measures application to run traffic status, such as queue length and average delay, based on real-time vehicle data logged; a web API service that adds a new channel of data exchange between outside components and the V2X Hub and adds the possibility of remotely monitoring and configuring the V2X Hub and its plugins, therefore, adding capabilities to traffic management centers (TMC) for remote traffic management; a pedestrian plugin, which allows vehicles to receive messages from smartphones held by pedestrians who intend to cross a nearby intersection; a preemption plugin that allows emergency vehicles to request preemption calls to an approaching intersection if the vehicle has its siren and lights on and is in an emergency response situation; and work zone messages with data that can be updated from a remote TMC to make managing active work zones easier with multiple RSUs in the field.

For more information, contact Deborah Curtis at deborah.curtis@dot.gov.

Finding lower cost ways to increase highway capacity without financing major upgrades to existing road infrastructure is a challenge all State DOTs face.

FHWA's Human Factors Team at the TFHRC conducted research to examine the potential of cooperative-adaptive cruise control (CACC) to increase existing roadway capacity by reducing gaps between strings of CACC vehicles traveling together. The Human Factors Team recently published an article entitled, "Merging into strings of cooperative-adaptive cruise-control vehicles," in the Journal of Intelligent Transportation Systems: https://doi.org/10.1080/15472450.2020.1728264.

Source: FHWA

The FHWA highway driving simulator used in the first experiment.

The study centered on two experiments using a full-scale highway driving simulator at the TFHRC. In the first experiment, drivers attempted to merge into a continuous stream of simulated CACC vehicles using either a CACC vehicle with merge assist, a CACC vehicle without merge assist, or a manually driven vehicle. Experiment 2 assessed how drivers traveling in a CACC string respond to vehicles attempting to merge into the string and whether that response is dependent upon a driver's actual gap size or preferred following distance.

The researchers concluded that drivers seem willing to accept CACC technology and trust it to partially control the vehicle under certain circumstances. The findings highlight the value of providing drivers with CACC technology that can help them to safely manage merges.

For more Information, please contact Brian Philips, Team Leader, Human Factors, Office of Safety R&D at brian.philips@dot.gov.

Source: FHWA

In this test, a pickup truck weighing 2270 kg (5000 lbs) and traveling at 100 km/h (62 mp/h) impacted a short-radius bridge-end barrier at an angle of 15 degrees.

Crash tests are fundamental to ensuring safe design standards of roadway infrastructure. A full-scale crash test was conducted in March at the TFHRC's Federal Outdoor Impact Laboratory (FOIL) in McLean, Virginia.

In this test, a pickup truck weighing 5000 lbs and traveling 62 mp/h impacted a short-radius bridge-end barrier at an angle of 15 degrees. This test is one of a series of tests being conducted to assess the barrier's safety performance under different crash conditions. The objective of this research and test is to develop guidance and a barrier safety treatment to be placed near bridge ends with restricted rights of way in a format suitable for potential adoption and inclusion as an update to the American Association of State Highway and Transportation Officials Roadside Design Guide (RDG). The proposed design(s) shall meet minimum TL-3 MASH requirements by successfully meeting the criteria of the following tests with both the 2270P pick-up truck, and the 1100C small car.

A number of sensors, such as high-speed cameras, accelerometers, angular-rate transducers, and speed-measuring devices, were employed to capture and document the crash event. These measured data will be used as ground truth, confirming the accuracy of the simulated results.

For more information, contact Eduardo Arispe, Roadway Safety Research at eduardo.arispe@dot.gov.

A poorly constructed road leads to high costs and other problems "down the road." Knowing the best methods, materials, and mixtures can help roads last longer.

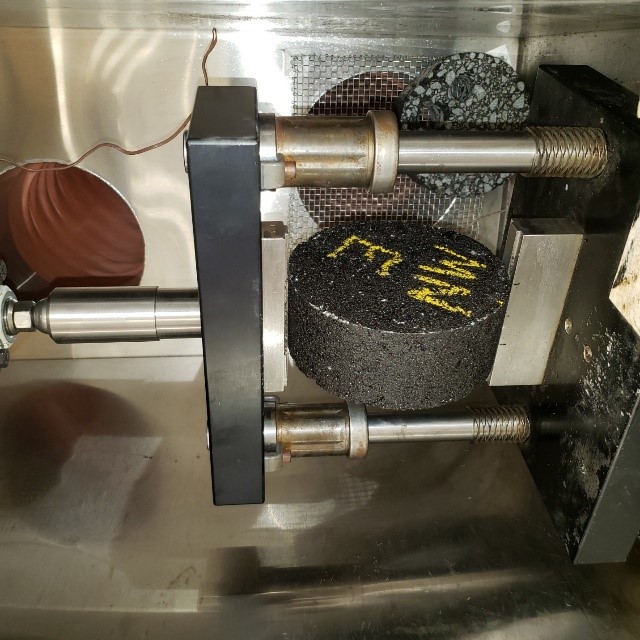

The Asphalt Materials Research program is undertaking a mixture-performance test-comparison study, relating intermediate temperature, index-based cracking tests to field performance.

The study consists of three phases: evaluation of six tests using reheated loose mixtures from FHWA's pavement test facility (PTF); evaluation of three tests using two long-term oven-aging procedures on loose mixtures from FHWA's PTF; and evaluation of three tests using mixtures from State DOT partners.

In the asphalt materials field, the premier topic of focus in mixture design and characterization relates to performance tests, especially those that can be conducted at intermediate (30°C or less) temperatures and are capable of assessing fatigue resistance. This study features collaboration with industry, academic, and agency partners to advance the community's knowledge of test variability and feasibility in a State quality-assurance program, and provide the ability to accurately align with known field performance.

Phase one of the study is finishing now. The six tests featured have been reduced to three for phase two, and the mixtures are being prepared in the asphalt binder and mixture laboratory. Phase three mixtures are being collected, and the anticipated end date for the study is early 2021. This experiment will be disseminated through technical briefs at the conclusion of each phase, and webinar opportunities are being explored.

For more information regarding this study, contact Dr. David Mensching at david.mensching@dot.gov.

Source: FHWA

Specimen prepared for the indirect tensile-cracking test in accordance with ASTM D8225–19.

Rehabilitation, retrofit, or reconstruction of alkali-silica reaction (ASR)-affected infrastructure is a multibillion-dollar challenge for highway agencies. First discovered in 1935, ASR is an insidious cause of concrete deterioration that may not become evident until the affected infrastructure has been in service for many years.

ASR occurs when the alkali in cement reacts with silica in the aggregate and forms a gel (called an ASR gel) that can absorb water, swell, and crack the concrete. Researchers have been devising test methods since 1947 that attempt to predict whether or not a given aggregate is likely to form ASR gels if used in concrete. There have been many variations of these tests, and almost all have been engineering tests that rely on measuring the physical expansion of concrete and mortar specimens.

Source: FHWA

Concrete deterioration caused by ASR.

The current best test is ASTM 1293, which takes a year and does not reliably predict field performance in all cases. After more than ten years of intensive research, the chemistry laboratory at the TFHRC has developed a very simple and economical test method that gives superior results to ASTM 1293 in just 21 days. It relies on purely chemical measurements; no concrete or mortar specimens are needed. The new test is called T-FAST (Turner-Fairbank ASR Susceptibility Test).

To disseminate this test method to industry partners, the TFHRC chemistry lab staff conducted a 2-day training class at the TFHRC in December and disseminated a webinar in February.

The director of the Pennsylvania Aggregate and Concrete Association said the suggestion that the test is a game changer is an understatement because the test is so different and easy. T-FAST remains a work in progress. Stakeholders are invited to join in pushing this research effort forward.

For more information, contact Terry Arnold at terry.arnold@dot.gov.

A multiyear research effort into LDOEP use is detailed in "Development of Guidelines for Bearing Resistance of Large Diameter Open-End Steel Piles" (FHWA-HRT-20-011). LDOEP foundations are often preferred over similar-size drilled shafts and/or pile groups in bridge projects requiring support from larger lateral, seismic, and axial loads because they are more cost effective and also address constructability and/or environmental concerns. However, current design guidance and codes are based on load tests for open-end piles with diameters less than 24 inches, casting doubt as to the reliability of existing methods to estimate the bearing resistance of LDOEPs.

This research evaluates static design methods using a new load-test dataset of steel LDOEPs in cohesive, cohesionless, and mixed soil conditions (see the FHWA Deep Foundation Load Test Database v.2). The analysis includes development of steel LDOEP-specific resistance factors for each of the design methods considering multiple load-test failure criteria, combinations of design methods, and combinations of side and base conditions, all leading to recommended design approaches for LDOEPs. This report is useful for geotechnical and bridge engineers, consultants, and contractors.

For more information, contact Dr. Jennifer Nicks at jennifer.nicks@dot.gov.

© Shannon & Wilson.

Installation of large diameter open-end steel pipe piles.

How can a road agency minimize risk in project delivery and increase the likelihood that the project will be of high quality and on track? Construction specifications provide the requirements for construction on a project to help achieve a higher level of confidence in accepting quality materials with higher performance, longer life, and reduced lifecycle costs.

FHWA has released a series of three animated whiteboard videos focused on specifications for highway construction to help improve quality. The first video, Types and Uses of Construction Specifications, introduces viewers to various types of specifications, including quality assurance specifications, warranty specifications, performance-based specifications, and performance-related specifications. The second video, Quality Assurance Specifications, covers how quality assurance specifications work, and highlights key aspects of a well-written quality assurance specification. The third video, Performance Related Specifications, covers how performance related specifications work, and includes steps involved in their development.

The videos, which can also be shared via social media, are available on the FHWA YouTube channel.

Video 1: Types and Uses of Construction Specifications

https://youtu.be/-FfOUfIbfF4

Video 2: Quality Assurance Specifications

https://youtu.be/VeicnhCzn2A

Video 3: Performance Related Specifications

https://youtu.be/Lpu3ye1URrs

For more information, contact Matthew Corrigan, FHWA Office of Infrastructure R&D, at matthew.corrigan@dot.gov.

Increased demand for transportation infrastructure causes congestion and forces cities and States to develop alternative solutions to manage congestion.

The Exploratory Advanced Research (EAR) Program is supporting a second study, "Using Behavioral Economics to Better Understand Managed Lane Choice," which could improve the accuracy of travel demand models. Researchers at the Texas A&M Transportation Institute are examining the choices drivers make between priced managed lanes and general-purpose lanes and the factors behind these choices. The research team has identified behavioral traits at different price points that may help predict habitual, compared to deliberative, decisions.

For more information about the managed lane choice project, contact Bingxin Yu, FHWA Office of Transportation Policy Studies, at bingxin.yu@dot.gov.

© Texas A&M Transportation Institute.

Models that predict the use of priced managed lanes help gauge the demands placed on tolled highways and aid in planning future infrastructure.

Cell phones are the number one distraction on roads today. As of 2019, more than 25 percent of accidents are caused by texting while driving.

FHWA's EAR Program supports a behavioral economics project that can result in more accurate models for predicting the choices travelers make while on the road and inform policy and transportation planning decisions.

Researchers from the University of Pennsylvania and the Children's Hospital of Philadelphia are examining the influence of technology-based nudges and tiered incentives in a study called "Comparative Effectiveness of Alternative Smartphone-Based Nudges to Reduce Cellphone Use While Driving" that may help develop public safety programs for reducing distracted driving.

For more information about the EAR Program's project on cellphone use, contact James Pol, FHWA Office of Safety R&D, at james.pol@dot.gov.

In this issue: Public Involvement Communication Tools for a 21st Century Audience, Unmanned Aerial Systems Take Flight in Highway Transportation, Innovation Synergy: UAS Videos Enhance Virtual Public Involvement Techniques, The Pathway to Innovation, Safety Awards Highlight Every Day Counts Innovations, States Innovate, EDC Outtakes: Weather-Responsive Management Strategies.

The issue is available online.

The Spring 2020 issue of Public Roads magazine is now available on the FHWA website. This issue recognizes the role that women play in the transportation industry and demonstrates FHWA's commitment to inspiring the next generation of women in transportation. In this special thematic issue, get to know women—including USDOT's top leaders Elaine L. Chao, Nicole R. Nason, K. Jane Williams, and Mala K. Parker—who are making a difference and advancing key USDOT initiatives. By maintaining our diverse workforce, FHWA can leverage a range perspectives when solving the Nation's transportation challenges.

The spring issue is available at: https://www.fhwa.dot.gov/publications/publicroads/20spring/index.cfm.

For more information or to submit an article, contact Maria Romstedt at maria.romstedt@dot.gov.

Please forward this newsletter to others you think might find it interesting and/or useful.

Suggestions may be submitted to FHWA_Now@fhwa.dot.gov.

FHWA R&T Now is a newsletter containing information and updates about research, technology, and development from the U.S. Department of Transportation, Federal Highway Administration. The newsletter is an electronic newsletter and is updated approximately every other month.

Send your comments, questions, and feedback to FHWA_Now@dot.gov.

Online access:

https://www.fhwa.dot.gov/publications/rtnow/.

Mail:

Federal Highway Administration

FHWA Office of Research, Development, and Technology

Attention: Dawn Vanlandingham

6300 Georgetown Pike

McLean, VA 22101

Distribution–FHWA R&T Now is being distributed according to a standard distribution. Direct distribution is being made to the FHWA Divisions and Resource Center.

Key Words–Infrastructure, Operations, Safety, EAR, exploratory advanced research, research, V2X Hub, technology transfer, T2, nondestructive evaluation, NDE lab, crowdsourcing, CACC, cooperative adaptive cruise control, vehicle string, crash test, cell phone, managed lanes, alkali-silica reaction, ASR, simulator, asphalt, pavement test facility, indirect tensile-cracking test.

Notice–This document is disseminated under the sponsorship of the USDOT in the interest of information exchange. The U.S. Government assumes no liability for the use of the information contained in this document.

The U.S. Government does not endorse products or manufacturers. Trademarks or manufacturers' names appear in this report only because they are considered essential to the objective of the document.

Quality Assurance Statement–The Federal Highway Administration (FHWA) provides high-quality information to serve Government, industry, and the public in a manner that promotes public understanding. Standards and policies are used to ensure and maximize the quality, objectivity, utility, and integrity of its information. FHWA periodically reviews quality issues and adjusts its programs and processes to ensure continuous quality improvement.