Transportation Asset Management Case Studies

CMS Case Study

Background

Asset Management is presently a key focus area for many transportation agencies in the United States and abroad. Asset Management merges quality asset data with well-defined objectives to help improve a transportation department's business process for resource allocation and utilization. In short, Asset Management is a strategic approach to managing transportation infrastructure.

The American Association of State Highway and Transportation Officials (AASHTO) Subcommittee on Asset Management defines Asset Management as a strategic and systematic process of operating, maintaining, upgrading, and expanding physical assets effectively throughout their lifecycle. It focuses on business and engineering practices for resource allocation and utilization, with the objective of better decision making based upon quality information and well-defined objectives.1

Asset Management typically relies on data from the following management systems:

- Bridge management.

- Pavement management.

- Tunnel management.

- Ancillary structures management (i.e., sign structures, high-mast light poles, retaining walls, and roadway appurtenances).

- Information management.

This case study examines different types of CMSs used by State and county DOTs. The management systems include the Pontis BMS, the FHWA CMS, and a State-developed system.

In order to determine the characteristics of a well-functioning CMS, the study focuses on the following aspects:

- Inventory.

- Inspection.

- Management and documentation.

- Planning, budget, and decision-making methodology.

Using a CMS assists a DOT not only in keeping track of its assets but also helps with prioritization of rehabilitation, repair, and replacement of structures. Prioritization in turn helps to optimize the use of the limited amount of funds a DOT may have available for culverts.

Case Study

In reality, every DOT practices some form of Asset Management. However, the differences lie in the sophistication of data collection and management systems, and how they are employed in budgeting and decision-making processes.

Based on a questionnaire sent to FHWA division bridge engineers (see Figure 1), only 29 States have some sort of CMS, 8 report using Pontis, 13 are using an in-house program, and 8 are using some combination of systems for small structures and culverts under 20 ft in length. These combinations include using Pontis for some lengths and an in-house program for the remainder. Some in-house systems are quite sophisticated and include GIS capabilities, while some use simple spreadsheets and databases. Twenty-three of the States do not have a CMS. This case study highlights the use of different management systems in Maryland, Minnesota, Alabama, and Shelby County. The experiences of these transportation agencies are presented to encourage more States to implement culvert management.

FHWA Culvert Management System

(from the User's Manual)

The FHWA CMS was developed in 2001 under the Local Technical Assistance Program to assist road agencies in managing their programs of culvert inventory and condition assessment and improvement. The purpose of this program is to provide a tool to facilitate the coordination of maintenance and repair or replacement operations on a system-wide basis.

The CMS formalizes and automates functions already performed by many agencies responsible for culverts. The program assists DOTs with:

- Recording the number and location of culverts for which the agency is responsible.

- Tracking the condition of the culverts.

- Determining what repairs are necessary to fix the culverts.

- Developing a long-term plan for repairs over the next 5 years.

- Formulating a schedule of work to be performed during the next year.

The CMS consists of five modules to aid the user in managing the inventory of culverts:

- Inventory module.

- Condition module.

- Maintenance and Repair module.

- Work Funding module.

- Schedule module.

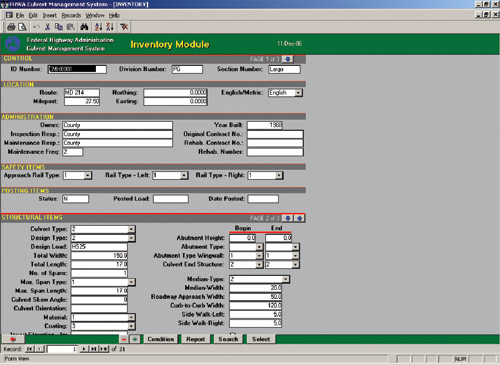

The Inventory module (see Figure 2) is a simple database storage and retrieval tool used primarily to supply information directly to users of the system and to other modules of the CMS. The inventory information is typically gathered from design and construction plans and from field verification and helps DOTs answer the question of "how many culverts do we have?" Information such as location, size, material type, and structure ID number is stored here. This module also allows users to enter new structures, delete structures that have been replaced, and obtain a detailed culvert description report. A search for culvert structure records can be performed in each module based on the culvert's unique structure ID.

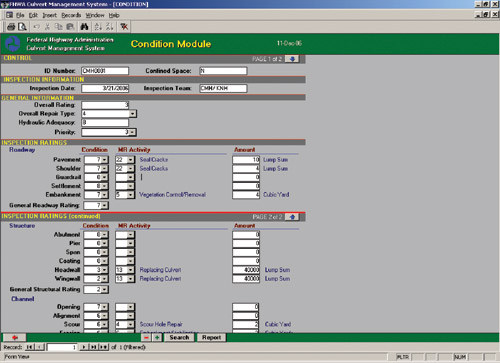

The Condition module (see Figure 3) is used to enter and store information related to the condition of the culverts based on visual inspections. This information is used to develop work needs, costs, budgets, and schedules. The condition is rated on 17 different items, including inspection dates, overall condition rating, hydraulic adequacy, proposed repair types, and roadway condition. The inspection identifies the maintenance and rehabilitation activity to be performed to correct the condition in addition to the quantity of work required.

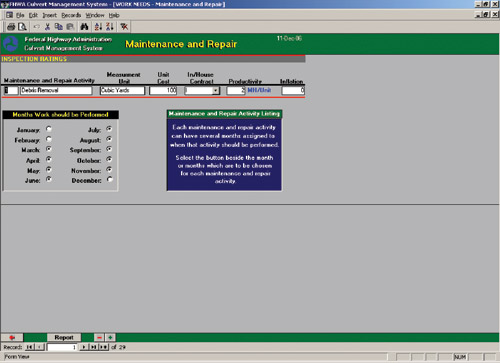

The Maintenance and Repair module (see Figure 4) develops the total work needs and costs for all work identified in the Condition module. This module has two parts:

- Defining the work to be performed.

- Developing the work needs and costs.

The work performed or maintenance and rehabilitation activities include items such as debris removal, scour hole repair, vegetation control, and joint sealing. The module then takes the work needs from the Condition module and applies unit costs to the work quantity.

The Work Funding module uses the work needs developed in the previous module to create a multi-year list of funded projects prioritized by repair type. The procedure uses a series of factors, defined by the user, that takes into account such items as priority, cost, remaining life, traffic, and hydraulic capacity to rank projects, and determines the projects that can be done that year using available funds. It also indicates the projects that cannot be undertaken due to lack of funding.

The Schedule module allows the user to schedule the programmed work for the year. The scheduling process takes the work programmed from the Work Funding module and, using the constraints of labor, dollars, and pre-scheduled projects input by the user, establishes when the various culvert projects can be performed. In the scheduling process, all of the activities within a project will be performed at the same time.

By using the FHWA CMS program to track culvert inventory, condition, and cost information, an agency can better manage its culvert program. This systematic process will help the agency to prioritize repair and replacement decisions and maximize the limited resources it has to expend on culverts.

1 http://www.transportation.org/sites/scoh/docs/Motion_Trans_Asset_Management.doc (.doc, 32 kb). Retrieved May 2, 2007.