June 13, 2019

Innovation of the Month:

A-GaME: Advanced Geotechnical Methods in Exploration

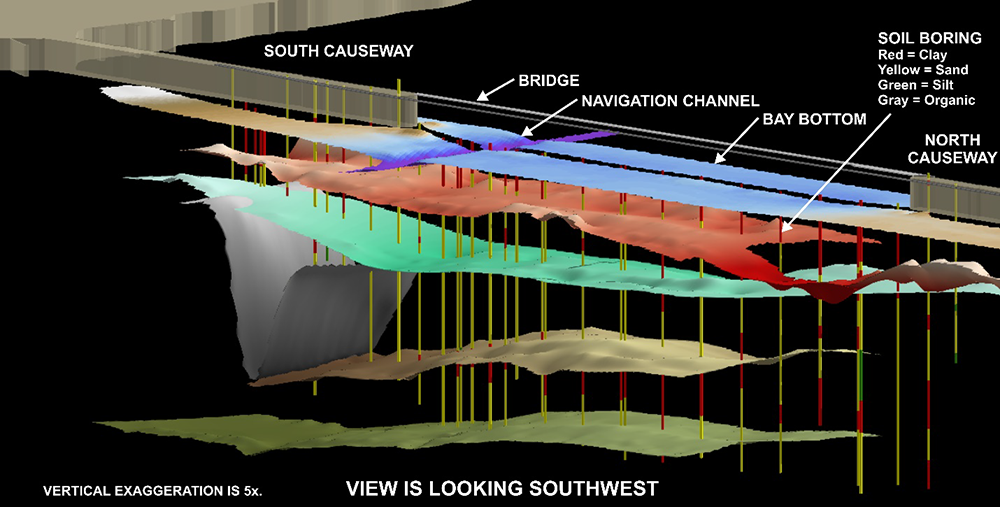

Last week, we introduced you to A-GaME, June's innovation of the month. A-GaME is an expanded toolbox approach to subsurface exploration that can reduce risk, optimize site characterization, enhance design reliability, and reduce geo-construction delays and cost escalations. Using these techniques, engineers can identify conditions that could otherwise present significant, unexpected problems for a project. Cone penetration testing (CPT) and seismic methods were successfully used during site characterization for the Choctawhatchee Bay Bridge project to avoid such issues.

Photo credit: Fugro

This project was a new, 2.5-mile crossing on US 331 in Florida over a sensitive marine environment with a history of frequent storm damage and erosion. When the original structure was built, the project encountered deep foundation construction challenges, and experienced ongoing settlement in its causeway after construction. Extensive site characterization was needed to understand the subsurface conditions and to provide recommendations for a new structure that was safe, long-lasting, and environmentally responsible.

A 200-foot deep subsurface model of the project site, shown in Figure 2, was built from seismic data, and was calibrated using historical borings. The model was used to strategically place CPT and dilatometer test (DMT) soundings to explore features of interest identified from the seismic marine survey. This helped develop information addressing areas of concern during preliminary design. The combined seismic and exploration data provided a refined ground model that could be used in analysis and design.

Photo credit: Fugro

The seismic reflection survey also identified multiple locations with soil layers containing gas beneath the existing causeway. This gas, caused by decaying organic material, was preventing the clays from consolidating. This helps explain the ongoing settlement issues experienced by the causeway.

Improved site characterization revealed why existing features of the project were behaving the way they were. This information and insight provided a good roadmap for how new structural pile foundations would need to be driven. Combining geophysics with existing information and the newly acquired CPT and DMT data helped engineers understand the subsurface conditions in water areas.

These techniques helped designers understand the behavior of existing features that had caused problems since before the mid-1980s and to develop effective solutions for foundation design and construction of the new structure.

To learn more about how to incorporate these proven, innovative geotechnical methods into your site characterization plans, contact Ben Rivers of the FHWA Resource Center or Silas Nichols of the FHWA Office of Infrastructure.

Case Studies Highlight Benefits of UHPC

Three recently published case studies illustrate examples of UHPC's successful application; a bridge replacement in South Carolina; a box girder connections and bridge deck overlay project in Delaware; and the Pulaski Skyway bridge deck replacement in New Jersey, the largest use of UHPC on a single project in North America to date.

To learn more about UHPC, watch the innovation spotlight video, view a UHPC webinar, or contact Benjamin Graybeal of the FHWA Turner-Fairbank Highway Research Center or Mark Leonard of the FHWA Resource Center.

Pavement Preservation Stretches Budget Dollars to Impact More Mileage

Pavement preservation techniques are cost-effective treatments that allow States to work on a significantly greater number of miles of roadway and allow for additional savings in both time and money. This is because pavement preservation projects tend to require less resources during preliminary engineering and construction engineering phases when compared to a rehabilitation and reconstruction (R&R) project.

In its newest plan, the Michigan Department of Transportation (MDOT), allocated $189 million to capital preventive maintenance (which includes pavement preservation projects), which yielded 110 projects addressing 1,988 miles of roadway. This illustrates the impact using pavement preservation projects can have on State roadway needs, when compared to the $226 million for R&R, which yielded 40 projects addressing 180.5 miles of roadway.

To learn more about how your State can use pavement preservation to address your State's roadway needs, contact Antonio Nieves, of the FHWA Office of Infrastructure.

About EDC

Every Day Counts, a State-based program of the Federal Highway Administration’s Center for Accelerating Innovation, works with State, local, and private sector partners to encourage the adoption of proven technologies and innovations to shorten and enhance project delivery.