Collaborative hydraulic modeling tools yield safer, more resilient structures on waterways

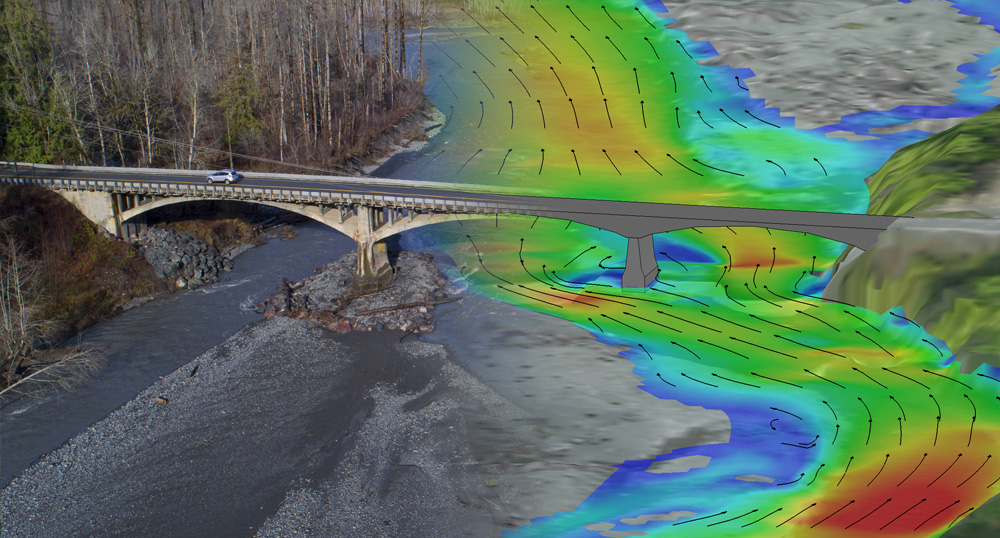

More than half a million U.S. bridges—80 percent of the total—span water. Two-dimensional (2D) hydraulic modeling tools in the Every Day Counts (EDC) initiative on collaborative hydraulics: advancing to the next generation of engineering (CHANGE) illustrate the complex interactions between these transportation assets and waterways.

“Flood flows are the primary cause of damage to bridges and other infrastructure, such as embankments and culverts,” said Laura Girard, Federal Highway Administration hydraulic engineer and CHANGE team co-leader. “Without 2D hydraulic modeling, many design teams would have difficulty designing projects for complex flow scenarios.”

Using 2D modeling eliminates the need for many assumptions applied in traditional one-dimensional (1D) models that can lead to inaccurate results. As a result, 2D tools improve the design and ultimately the safety and resilience of infrastructure. These new tools include graphics and visualization software that enable engineers to more effectively communicate the results of complex hydraulic analysis to a broad audience. This can enhance collaboration and streamline project development, including regulatory activities.

The CHANGE team’s outreach goes beyond State transportation departments to include resource agencies, floodplain administrators, and local agencies. In addition to providing technical support and training, the team hosts bimonthly 2D Hydraulic Modeling User’s Forum webinars that attract more than 500 participants. “We’re working with practitioners at a wide range of experience levels,” said Scott Hogan, FHWA senior hydraulic engineer and CHANGE team co-leader. “We want to see everybody move forward.”

The number of States at the demonstration, assessment, or institutionalized stages of CHANGE implementation is expected to reach 46 in EDC-5. “This is not just a tool to use here and there. This is a fundamental change in how hydraulic engineering design will be done,” said J.R. Taylor, Montana Department of Transportation district hydraulics engineer and CHANGE team member.

In the past 3 years, the Colorado Department of Transportation (CDOT) saved more than $14 million using 2D hydraulic modeling to develop more detailed analyses of bridges, culverts, and roadways than with 1D modeling. The return on investment for four demonstration projects alone was $4.4 million in savings during design, said Brian Varrella, CDOT resident engineer and CHANGE team member.

On a demonstration project to retrofit structures at six river crossings, 2D modeling helped CDOT optimize the structures for scour protection while saving $500,000 on materials. A 2D model created for a U.S. Highway 287 project allowed CDOT to save $300,000 in material costs by reducing the size of riprap originally proposed. On a State Highway 55 project, 2D modeling helped the agency more accurately calculate how the river pushed against an abutment and develop a protection solution that cut construction costs by $1.8 million. On a State Highway 144 project, using 2D modeling accelerated the scoping process by months and saved $2 million.

CDOT is expanding 2D modeling through an initiative to value-engineer projects at the planning and scoping stage to save an estimated $20 million a year. “If we invest 20 to 40 hours in 2D modeling—less than a week of work—we can refine our scope,” said Varrella. “This is turning into a project management tool.”

Two-dimensional hydraulic modeling provides a more accurate representation of design conditions and the graphical visualization tools offer a more effective means of collaborating with project partners.

Two-dimensional hydraulic modeling provides a more accurate representation of design conditions and the graphical visualization tools offer a more effective means of collaborating with project partners. The Arizona Department of Transportation (ADOT) used cutting-edge data collection and 2D hydraulic modeling for a U.S. 160 bridge project that created a sustainable solution to erosion from a creek on the Navajo Nation Reservation. The project addressed scouring of the Laguna Creek Bridge’s abutments, protected the creek banks, and reduced the channel’s meandering at the bridge. To accomplish this, engineers installed gabion baskets, metal cages filled with rocks.

While engineers designing similar improvements often have limited data on stream flows, ADOT coordinated with the U.S. Geological Survey to make the Laguna Creek Bridge a pilot site to test 2D hydraulic modeling tools. The project used sensors and gauges to provide real-time surface flow data during and after storms, drones, video cameras, laser-aided surveying, and three-dimensional surface modeling.

Collecting this data for a year before construction provided a comprehensive view of the creek’s flow and velocity, allowing engineers to compare the current channel with a time-lapse view of how it changed over time and anticipate what will happen in the future. The instruments continue to provide data that will help engineers assess the effectiveness of work to stabilize the banks where U.S. 160 crosses Laguna Creek and determine whether more improvements

are needed.

—MORE INFORMATION

Visit FHWA’s hydraulic engineering web page for guidance, reports, software downloads and tutorials, and training information. Contact Scott Hogan or Laura Girard of the FHWA Resource Center for information and technical assistance and to join the 2D Hydraulic Modeling User’s Forum.

- Cover

- Accelerated Bridge Construction Changes How Transportation Agencies Do Business

- New Jersey, Pennsylvania, and Washington Win STIC Excellence Awards

- States Innovate

- Agents for CHANGE

- Innovations Help States Deliver Outstanding Transportation Projects

- Visualize Rural Roadway Departure Countermeasures With Trading Cards

- About Innovator