Knowing what lies beneath the surface is critical to ensuring safe and cost-effective highway projects. Conventional subsurface exploration methods yield limited data for project design, which can result in constructability issues and increased costs. The Every Day Counts round five (EDC-5) initiative on advanced geotechnical methods in exploration (A-GaME) showcases proven but underused techniques to gather more detailed information on site conditions.

Combined with conventional boring data, A-GaME solutions can boost confidence in geotechnical site characterization. This can improve design and construction, leading to shorter project delivery times and lowering the risks associated with limited data on subsurface conditions. “Reducing uncertainties is the focus of the A-GaME,” said Ben Rivers, Federal Highway Administration geotechnical engineer and EDC-5 team co-leader.

A-GaME features five geotechnical exploration methods: cone penetration testing (CPT), electrical geophysical techniques, measurement while drilling, seismic geophysical methods, and optical and acoustic televiewers. “But we don’t want to exclude other geotechnical methods or use one method alone,” Rivers said. “We want to determine what methods to use together to provide us with the best understanding of subsurface site characteristics.”

More than 45 State and Federal agencies are using A-GaME strategies to reduce geotechnical project risks and improve reliability, including 27 agencies that are at the demonstration, assessment, or institutionalized stages of deployment. This fall and winter, the EDC-5 team will offer new web-based resources, such as virtual peer exchanges, training sessions, and demonstrations, to replace in-person events originally planned for 2020.

Across the country, agencies are using A-GaME solutions to identify subsurface conditions that could present challenges for projects. The Alaska Department of Transportation and Public Facilities (DOT&PF) has found that acquiring geophysical data while crews are in the field drilling traditional core samples adds little time to a project, but it provides data to fill in the blanks between holes and target holes more efficiently. Alaska DOT&PF has used ground-penetrating radar (GPR) to pinpoint utility locations when conducting drilling investigations in urban areas.

Alaska DOT&PF has also found it advantageous to use A-GaME techniques on projects in remote areas, where flying in people and equipment to conduct geophysical exploration is simpler and faster than mobilizing a drilling rig, which requires many days of work to justify the expense. In one example, the agency had enough recent drilling data to calibrate the geophysics data, and the continuous lines of new data were useful in identifying subsurface drainage patterns responsible for distress on a runway.

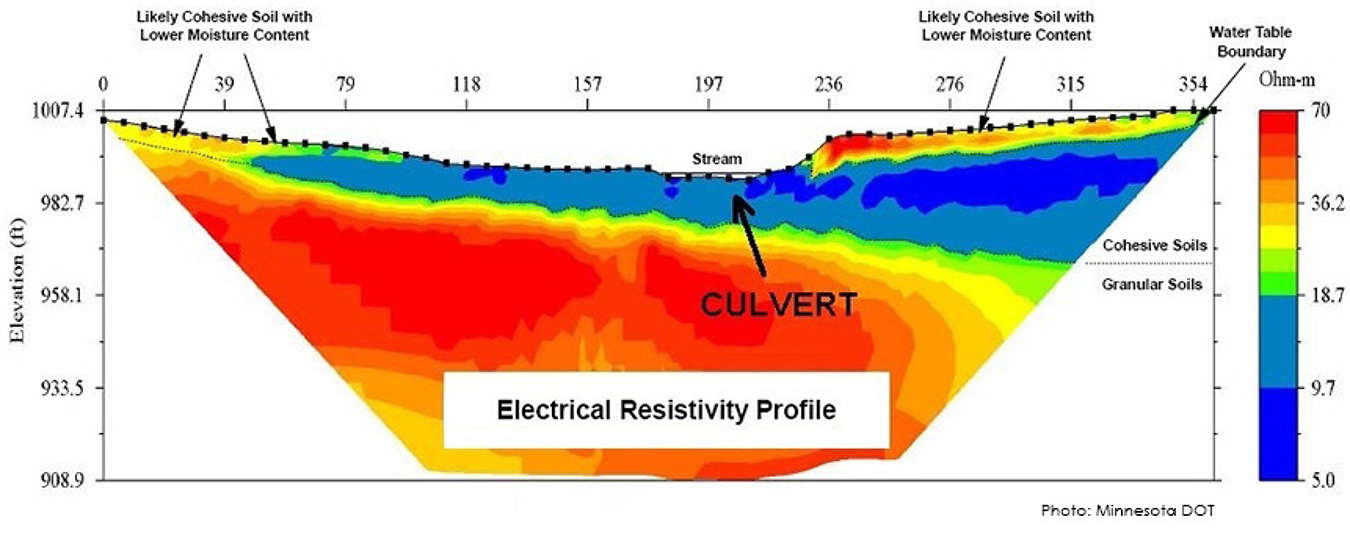

Geophysical imaging can distinguish material and groundwater variations across a site.

Geophysical imaging can distinguish material and groundwater variations across a site.The Indiana Department of Transportation (INDOT) has used electrical resistivity tomography, a method to image the subsurface using differences in measured electrical resistivity, on several projects. This method helped INDOT design a bridge project on U.S. 50 in an area of Lawrence County with karst, a type of landscape where dissolving bedrock has created hazards such as sinkholes, sinking streams, and caves. The data showed designers the location of problematic rock stratus and aided in the design of a stable slope.

INDOT combined electrical resistivity tomography with multichannel analysis of surface waves on an exploration for an Interstate 69 project in Marion County. During their investigation, crews discovered a large concrete boulder hidden underneath a reclaimed landfill, which will be part of the I-69 alignment. Locating this feature ahead of the project will reduce construction change orders later.

The Michigan Department of Transportation (MDOT) has completed about 30 CPT soundings at eight locations, most near traditional borings. On a culvert replacement project on M-66 near East Jordan, MDOT conducted CPTs before traditional drilling and sampling. The CPT data indicated a weak layer beneath the surface, which was targeted for additional sampling during soil borings. The additional testing and CPT data added valuable information to the decision-making process, leading MDOT to change the culvert type and construction process from part width to detour, which reduced risk to the traveling public and the project.

The Wisconsin Department of Transportation (WisDOT) conducted GPR investigations on two projects this year. These investigations included assessing if underground storage tanks were present on WisDOT right-of-way on U.S. 14 in Mazomanie and determining the location and extent of clay sewer pipe beneath an urban section of State Trunk Highway 96 in Kaukauna. In both cases, GPR provided information on subsurface conditions the project design and construction teams needed at a significant cost savings over conventional investigation methods.