U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-021 Date: January 2014 |

Publication Number: FHWA-HRT-14-021 Date: January 2014 |

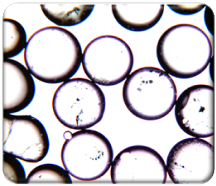

Samples of AASHTO M247 glass beads were requested from State transportation department inventories in current use in pavement-marking operations. These samples of glass beads (see figure 1) were shipped directly to Texas A&M University Transportation Institute (TTI) in quart- to gallon-size resealable plastic bags packaged in boxes. After all the glass beads were received and cataloged, 15 of the received Type I samples were randomly selected for analysis. Subsamples weighing 100 g of each sample were collected into new resealable, zipper bags and renamed by a technician to blind the laboratory staff running the sample extractions and analysis from the identity and location of the provided samples.

Figure 1. Photo. Magnified light table image of AASHTO M247 Type I bead sample included in this study.

Three subsamples from each of the 15 randomly selected bead samples were used to determine the total, extractable, and bioaccessible fractions of arsenic and lead in the beads. The total metals digestion was performed following the Pacific Northwest National Laboratory (PNNL) Potassium Hydroxide (KOH) Fusion digestion method, extractable metals extraction was performed following Environmental Protection Agency (EPA) Method 3050B, and the bioaccessible extraction was performed according to the in-vitro oral bioaccessibilty method.([1]) The resulting digestion and extraction solutions were analyzed by inductively coupled plasma-mass spectrometry (ICP-MS) according to EPA Method 6020A.

Additional studies were performed to determine the comparability of four methods used to assess total arsenic and lead contents in the glass beads. These four methods were: 1) the PNNL KOH fusion digestion followed by ICP-MS analysis, 2) EPA Method 3052 (microwave assisted hydrofluoric acid digestion) followed by ICP or atomic absorption spectroscopy (AAS) analysis to evaluate metals in siliceous solids, 3) bench-top XRF (X-ray fluorescence), and 4) Field-Portable XRF (FP-XRF).([2], [3]) A National Institute of Standards and Technology (NIST) standard for metals in glass, Standard Reference Material (SRM) 612, was also analyzed for total metals using KOH fusion and EPA Method 3052.

Table 1 provides the mean total, extractable, and bioaccessible arsenic and lead content measured in the 15 samples of glass beads. Lead and arsenic were measured in all 15 samples of glass beads following total digestion of the beads at a mean concentration of 71 and 54 ppm, respectively. The mean arsenic and lead content observed in the beads were below the currently proposed limit of 200 ppm. However, large variability in total arsenic and lead content was observed between replicates of the same bead sample. Repeat analysis of both the replicates and of additional subsamples within the batch reproduced the variability. Analysis of NIST SRM 612, however, resulted in mean measured concentrations of arsenic and lead at 94 percent and 86 percent of the expected value with minimal variability between replicates. Therefore, the observed variability of arsenic and lead in the beads was determined to be caused by actual variability of metals content within the supplied samples.

Table 1. Mean ± standard deviation of arsenic and lead content (ppm) in glass beads provided by State transportation department participants.

|

Bead |

Total (ppm) |

Extractable (ppm) |

Bioaccessible (ppm) |

|||

|

Arsenic |

Lead |

Arsenic |

Lead |

Arsenic |

Lead |

|

|

AA |

75 ± 27 |

79 ± 50 |

BDL |

0.38 ± 0.1 |

BDL |

BQL |

|

AC |

11 ± 8 |

22 ± 19 |

BDL |

0.74 ± 0.5 |

BDL |

3.6 ± 5.4 |

|

BD |

65 ± 36 |

67 ± 58 |

BDL |

0.21 ± 0.1 |

BDL |

BQL |

|

BE |

55 ± 24 |

89 ± 62 |

BDL |

0.70 ± 0.3 |

BDL |

BQL |

|

BI |

53 ± 25 |

100 ± 71 |

BDL |

3.29 ± 1.0 |

BDL |

1.7 ± 2.4 |

|

DA |

62 ± 31 |

176 ± 154 |

BDL |

0.25±2x10-3 |

BDL |

BQL |

|

DB |

70 ± 40 |

161 ± 186 |

BDL |

BDL |

BDL |

BDL |

|

DC |

82 ± 65 |

199 ± 246 |

BDL |

BQL |

BDL |

BQL |

|

DD |

61 ± 27 |

3 ± 7 |

BDL |

BDL |

BDL |

BDL |

|

EA |

51 ± 30 |

13 ± 13 |

BDL |

BDL |

BDL |

BDL |

|

FH |

50 ± 20 |

72 ± 36 |

BDL |

0.31 ± 0.1 |

BDL |

0.19±0.01 |

|

GA |

49 ± 34 |

10 ± 9 |

BDL |

BDL |

BDL |

BDL |

|

GB |

52 ± 22 |

38 ± 33 |

BDL |

BDL |

BDL |

BDL |

|

GC |

45 ± 15 |

15 ± 6 |

BDL |

BDL |

BDL |

BDL |

|

GD |

35 ± 37 |

28 ± 26 |

BDL |

BDL |

BDL |

BDL |

ppm = parts per million

BDL = below detection limit (< 0.07 µg/g for arsenic, < 0.004 µg/g for lead)

BQL = below quantification limit (< 0.1 µg/g for arsenic and lead)

The extractable and bioaccessible arsenic and lead contents were significantly lower than the total arsenic and lead content of the beads. Reportable levels of arsenic were not observed in either the extractable metal or bioaccessible metal extraction solutions in any of the samples. When observed, mean concentrations of 0.8 ppm for extractable lead and 1.8 ppm for bioaccessible lead were measured. However, lead was only present in 7 of the 15 extractable metal solutions and in 3 of the bioaccessible metal solutions. The results of the arsenic and lead analysis indicate that while both metals are present in the glass matrix within the sampled beads (total metal digestions), the levels of arsenic and lead that leave the matrix under environmental (extractable metals by Method 3050B) or intestinal (oral bioaccessibility method) exposures are significantly lower.

The mean arsenic and lead content returned by each of the four evaluated methods across the 15 bead samples are shown in table 2. Although results of the intra-method comparison for analysis of total arsenic and lead in the glass bead samples were not in agreement for the samples, agreement was achieved between the results of KOH fusion and EPA Method 3052 for the NIST SRM 612 standard. While a systematic approach was used to evaluate the cause of the observed difference in the samples but not in the control, method or instrumental errors that could explain the observed difference were not identified. Therefore, because KOH fusion gave the overall most conservative (highest) estimate of arsenic and lead content observed in the beads, the authors report KOH fusion results in this technical report to represent a conservative (upper value) estimate of the total arsenic and lead content in the bead samples.

Table 2. Intra-method comparison for total arsenic and lead in the 15 glass bead samples.

|

Method |

Arsenic |

Lead |

||

|

No. of Samples with Measurable Arsenic |

Mean Content When Present (ppm) |

No. of Samples with Measurable Arsenic |

Mean Content When Present (ppm) |

|

|

Portable XRF |

2 of 15 |

8.5 |

3 of 15 |

15 |

|

Bench-top XRF |

6 of 15 |

1.0 |

10 of 15 |

15 |

|

EPA Method 3052 |

15 of 15 |

1.3 |

15 of 15 |

8.2 |

|

KOH Fusion |

15 of 15 |

51 |

15 of 15 |

68 |

XRF = X-ray fluorescence

EPA = Environmental Protection Agency

KOH = potassium hydroxide

Speciation of arsenic in water has a significant impact on the toxicity of arsenic in aqueous systems. Because the beads are used and stored in locations where they could come into contact with rainfall, there was interest in determining the resulting speciation of arsenic within bead leachate for future risk assessments.

Subsamples of three glass bead samples (AA, DC, and EA) were placed in an up-flow cartridge reactor, and laboratory-prepared water (pH of 7) was passed through the cartridges at a flow rate of 30 mL/h. Cartridge effluents were sampled after 1 h, preserved with 1 percent hydrochloric acid, and refrigerated until they were analyzed. Speciation was achieved using a high-performance chromatograph with a reversed phase column operating within a binary mobile phase coupled to an ICP-MS. A complete description of the analytical method for speciation can be found in Section 1 of this report.

The speciation analysis of arsenic revealed the presence of both arsenite (As3+) and arsenate (As5+) as the two predominant species of arsenic in solution. Table 3 presents the results for the analysis. While total arsenic levels (As3+ + As5+) in the pure leachate exceeded the 10 µg/L drinking water maximum contaminant level for arsenic, under environmental conditions, the impact of leachate on existing groundwater or surface water reserves would be minimal for these samples because of dilution.

Table 3. Arsenic speciation in leachate water in contact with beads.

|

Sample |

As3+ |

As5+ |

|

AA |

3.02 |

8.92 |

|

DC |

ND |

14.7 |

|

EA |

1.42 |

10.6 |

ND = Non-detectable

The relationship between arsenic content and retroreflective performance was evaluated because of historical use of arsenic within glass production as a high-temperature oxidant for removing imperfections in glass. The researchers were curious to evaluate whether higher arsenic levels would correlate to higher retroreflectivity measurements.

Retroreflective performance measurements were conducted by creating pavement markings containing glass beads on metal sheets. Immediately following paint application, glass beads were applied on the surface using a bead dispenser for even, but random and dispersed, application on the paint. After curing, a Delta LTL-X retroreflectometer was used to measure the retroreflectivity of the pavement-marking samples. Pearson’s product moment correlation coefficient (r) was determined to assess the direction and the strength of the correlation between the arsenic content of the beads and their retroreflective performance.

Figure 2 shows the relationship between retroreflectivity and total mean arsenic content within the glass beads for all 15 samples. The correlation r for the dataset was determined to be 0.564, suggesting a positive moderate correlation may exist between the arsenic content and retroreflective performance. However, additional samples should be analyzed to determine whether a correlation actually exists. In this study, the range of mean arsenic contents was limited to between 15 and 88 ppm. The retroreflectivity data, however, demonstrate that suitable performance can be achieved at low arsenic levels within the beads.

Figure 2. Graph. Relationship between mean arsenic content and mean retroreflectivity of each sample of glass beads evaluated within this research.