U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-12-031 Date: August 2012 |

Publication Number: FHWA-HRT-12-031 Date: August 2012 |

PDF files can be viewed with the Acrobat® Reader®

CTE tests of the PCC specimens from LTPP sections were performed by FHWA’s Turner-Fairbank Highway Research Center (TFHRC) using the AASHTO TP 60 protocol.(11) TFHRC initiated an inter-laboratory study during which an error was discovered with the protocol and procedure used to measure concrete CTE. The source of the error was in the assumption of a single CTE value for the calibration specimen. Testing performed at independent laboratories revealed that a CTE value must be determined for each calibration specimen, and the calibration specimen should be tested over the same range of temperature over which the concrete CTE is determined—50 to 122 °F. Not meeting these two conditions caused an overestimation of the reported CTE by approximately 0.83 inch/inch/°F. Since all of the initial LTPP testing for CTE had been done in one laboratory with one calibration specimen, the calibration offset can be corrected in the database, and it has been corrected in Long-Term Pavement Performance Standard Data Release 24.0.(12)

This overestimation of the CTE has significant ramifications, especially in light of the fact that the TFHRC has tested over 2,100 specimens for the LTPP program and the fact that the LTPP database was the primary source for the national calibration of the AASHTO MEPDG rigid pavement performance models. The national calibration coefficients for all JPCP and CRCP performance models may be invalid, and the models may need to be recalibrated. As a result, local implementation efforts may be delayed.

The impact of this error in the CTE values on the current study was described in an internal status report submitted to LTPP. LTPP Standard Data Release Version 23.0 contained the uncorrected CTE values; therefore, the CTE models developed in this study are not applicable for the corrected data.(10) However, the models demonstrate the ability to develop correlations, and the procedures herein may be repeated for the corrected data.

CTE test data were averaged for each aggregate type, which constitutes level 3 inputs for MEPDG. Table 25 lists the average PCC CTE for each aggregate type as found in the literature. The data are in general agreement, providing a degree of confidence in the level 3 MEPDG input recommendations. The average CTE values determined from the data subset are recommended by this study.

Table 25. Prediction model 13 for PCC CTE based on aggregate type, x 10-6 inch/inch/°F.

|

Aggregate Type |

Average From Literature |

Average From All LTPP Data |

Average From Data Used in Model (Recommended) |

|

Basalt |

4.85 |

5.11 |

4.86 |

|

Chert |

6.55 |

6.24 |

6.90 |

|

Diabase |

4.85 |

5.33 |

5.13 |

|

Dolomite |

5.75 |

5.79 |

5.79 |

|

Gabbro |

4.85 |

5.28 |

5.28* |

|

Granite |

4.55 |

5.62 |

5.71 |

|

Limestone |

4.25 |

5.35 |

5.25 |

|

Quartzite |

6.85 |

6.07 |

6.18 |

|

Andesite |

4.85 |

4.99 |

5.33 |

|

Sandstone |

6.05 |

5.98 |

6.33 |

|

N |

228

|

91

|

|

*There were no samples with a Gabbro aggregate type in the data used in the model. Hence, the average from the entire dataset is recommended.

Figure 72 shows a plot of recommended CTE

values versus average CTE values obtained

from other sources. While they are in fairly good agreement, the

values recommended from this study are slightly higher for most

cases. This can be explained by the overestimation of CTE during

testing.

Figure 72. Graph. Comparison of average values from other sources and recommended CTE values based on aggregate type from LTPP data.

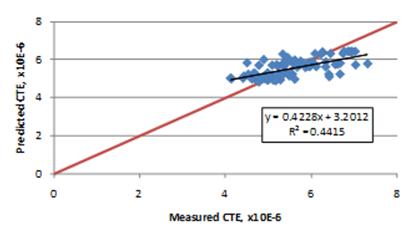

The PCC CTE model based on mix volumetrics was established as follows:

Figure 73. Equation. Prediction model 14 for CTEPCC.

Where:

CTECA = Constant determined for each aggregate type as shown in table 26.

The model statistics are presented in table 26, and details of the range of data used to develop the model are presented in table 27. The model has 89 data points, an R2 value of 44.15 percent, and an RMSE of 0.35006 psi.

Table 26. Statistical analysis results for CTE model based on mix volumetrics.

|

Parameter |

Comment |

Estimate |

Standard Error |

95 Percent Confidence Limits |

|

|

c |

N/A |

6.4514

|

0.1889

|

6.0758

|

6.827

|

|

d |

CTECA for basalt |

3

|

0

|

3

|

3

|

|

e |

CTECA for chert |

6.4

|

0

|

6.4

|

6.4

|

|

f |

CTECA for diabase |

3.4835

|

1.2824

|

0.9337

|

6.0333

|

|

g |

CTECA for dolomite |

5.1184

|

0.408

|

4.3071

|

5.9297

|

|

h |

CTECA for gabbro |

3.75

|

N/A

|

N/A

|

N/A

|

|

i |

CTECA for granite |

4.7423

|

0.4188

|

3.9096

|

5.5749

|

|

j |

CTECA for limestone |

3.2886

|

0.3579

|

2.5771

|

4.0001

|

|

k |

CTECA for quartzite |

6.1

|

0

|

6.1

|

6.1

|

|

l |

CTECA for andesite |

3.6243

|

1.4539

|

0.7336

|

6.515

|

|

m |

CTECA for sandstone |

4.5

|

0

|

4.5

|

4.5

|

Table 27. Range of data used for CTE model based on mix volumetrics.

|

Parameter |

Minimum |

Maximum |

Average |

|

Coarse aggregate content |

582

|

2,730

|

1,811

|

|

Coarse aggregate specific gravity |

2.42

|

2.86

|

2.65

|

|

w/c ratio |

0

|

0.71

|

0.45

|

|

Coarse aggregate volume fraction |

0.13

|

0.62

|

0.41

|

|

Mortar volume |

0.38

|

0.87

|

0.59

|

The predicted versus measured plot and the residual error plots are presented in figure 74 and figure 75, respectively.

Figure 74. Graph. Predicted versus measured for CTE model based on mix volumetrics.

Figure 75. Graph. Residual errors for CTE model based on mix volumetrics.

The constant, C, determined as 6.4514, is equivalent to the CTE of the mortar. (At TFHRC, using the AASHTO TP 60 uncorrected values, a CTE value of 6.2 for mortar containing silica sand was determined, validating this equation.(12)) Since the mortar (all components of the mix design except the coarse aggregate) occupies a large volume of the matrix, it was necessary for the model to predict higher CTE for increased mortar proportions (or decreasing coarse aggregate proportions). In optimizing the model and selecting the representative CTE for each aggregate type, it was ensured that the CTE of the aggregate was not above 6.4514.

Figure 76 and figure 77 show a comparison of the predicted CTE values with average values reported in literature for each aggregate type. Figure 78 shows the sensitivity of the model to coarse aggregate content. As expected, CTE decreases as the coarse aggregate content increases (or mortar volume decreases). While this is true for most cases, it was also observed that for aggregates with high CTE values, such as chert and quartzite, the CTE of the aggregate approaches the CTE of the mortar, thereby showing little or no sensitivity to coarse aggregate content. As with all other models, the user is advised to verify model predictions with other sources of information. If possible, both CTE models should be evaluated simultaneously to obtain a range.

Figure 76. Graph. Comparison of CTE model prediction with average values reported in literature for each aggregate rock type.

Figure 77. Graph. CTE model prediction versus average values reported in literature for each aggregate rock type.

Figure 78. Graph. Sensitivity of the CTE model to coarse aggregate content.