U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| TECHBRIEF |

| This techbrief is an archived publication and may contain dated technical, contact, and link information |

| Publication Number: FHWA-HRT-15-037 Date: August 2015 |

Publication Number: FHWA-HRT-15-037 Date: August 2015 |

PDF Version (2.13 MB)

PDF files can be viewed with the Acrobat® Reader®

Publication No.: FHWA-HRT-15-037 FHWA Contact: Y. Jane Jiang, HRDI-30, 202-493-3149, jane.jiang@dot.gov |

This document is a technical summary of the Federal Highway Administration report, Long-Term Pavement Performance Program Determination of In-Place Elastic Layer Modulus: Backcalculation Methodology and Procedures (FHWA-HRT-15-036).

This TechBrief provides an overview of the methodology and procedures used to backcalculate the elastic layer modulus from deflection basins for all test sections included in the Long-Term Pavement Performance (LTPP) database.

Deflection data have been measured at periodic intervals with the falling weight deflectometer (FWD) on all rigid, flexible, and composite pavement test sections included in the LTPP program. These data are used to determine the load-response properties of the pavement structure and subgrade. Currently, there are 16,364 FWD testing days and more than 2,400 test sections in the LTPP database.

A common use of deflection data is to backcalculate in-place layered elastic modulus values. These modulus values, and how the values change over time, are inputs for estimating remaining life and determining an appropriate rehabilitation and design strategy. In addition, many agencies have used the LTPP deflection data for calibrating mechanistic-empirical distress transfer functions, including those in the Mechanistic-Empirical Pavement Design Guide (MEPDG).(1)

Several years ago, the Federal Highway Administration (FHWA) sponsored studies to backcalculate elastic layer modulus values from deflection basins and included the computed values in the LTPP database. (See references 2 through 5.) Since then, the amount of deflection data in the LTPP database has increased substantially, especially for the Specific Pavement Studies (SPS) sites. Therefore, FHWA sponsored a follow-up project to revisit the methods used in the first round of backcalculation and to calculate the elastic layer modulus values for the deflection data that did not exist during the first round of backcalculation.

The major goal of the backcalculation project was to determine the in-place elastic layer moduli from deflection basin measurements for the LTPP test sections and execute those methods for all flexible, rigid, and composite pavement sections included in the LTPP program. Another key goal was to automate the process and make it less dependent on the user so that others not directly involved in the development of the tools and procedures can recreate the results.

One of the difficulties in backcalculation is that it does not determine a unique solution or set of elastic layer moduli for a specific set of measured deflection basins. More importantly, the quality of the results depends greatly on the expertise of the user in setting up the problem. In other words, different users can obtain different results for the same set of deflection basins. The non-uniqueness of these solutions has been a major deterrent for some agencies to take full advantage of backcalculation methods for routine rehabilitation design. In addition, many agencies limit use of the deflection data to only determine the subgrade elastic modulus.

This TechBrief provides a general overview of the backcalculation process and summarizes the steps that were automated in calculating the elastic layer moduli from deflection basin data. It also describes the tools written to simplify the backcalculation process while taking full advantage of the entire deflection basin dataset for rehabilitation design in accordance with the MEPDG.(1) The automated process is specific to LTPP and the data tables included in the LTPP database. The activities presented here, however, can be used to improve the backcalculation of elastic layer moduli for any rehabilitation project.

The backcalculation project resulted in the development of two major products: (1) a set of computed parameter tables (CPT) stored in the LTPP database and (2) analytical tools for the pre-and post-processing of the deflection basin data. A user's guide is available for executing the automated backcalculation process, as well as for the utility and software tools for organizing the results included in the CPTs.

The backcalculated elastic layer modulus values, simulated pavement structures for each LTPP test section, and other related parameters were integrated into the CPTs of the LTPP database and are now available for use. Six CPTs were designed to store the results from the backcalculation process and assist in interpreting the results. One set of tables stores the EVERCALC or MODCOMP results, and a second set of tables stores the BEST FIT results. A third set of tables stores the non-backcalculated data and values for each test section. The backcalculated modulus values from EVERCALC or MODCOMP and the BEST FIT method are organized by agency in separate files. Table 1 includes a listing of the following CPTs:

| Tables for Backcalculated Modulus Values from Individual Basins | Tables for Summary of Results and Processed Data from a Test Day | Tables for Non-Backcalculated Values |

|---|---|---|

| Elastic layer moduli that are basin-specific from the EVERCALC or MODCOMP software packages for all test sections (rigid, flexible, and composite) included in the LTPP program. | Average and standard deviation of the elastic layer moduli for a test day (all rigid, flexible, and composite test sections), lane number, and drop height. This set of tables excludes the backcalculation results that were rejected from the acceptance criteria. | Backcalculation section information that identifies the number of basins used to calculate the elastic layer moduli and whether a rigid layer was included in the simulation. |

| Elastic layer moduli from the BEST FIT method for test sections with PCC surfaces for bonded and unbonded simulations that are basin-specific. | Average and standard deviation of the elastic layer moduli from the BEST FIT method for the bonded and unbonded simulations for a test day, lane number, and drop height for LTPP test sections with PCC surfaces. | Structure used in the backcalculation process using EVERCALC or MODCOMP for a specific test day (layer thickness and material type). |

| LTE for tests performed at transfer joints and crack locations that are basin-specific. | Average and standard deviation of the LTE for a test day, lane number, and drop height for LTPP test sections with PCC surfaces. | Structure used in the calculation process using the BEST FIT method for a specific test day (layer thickness and material type). |

CPT = Computed parameter table.

LTE = Load transfer efficiency.

LTPP = Long-Term Pavement Performance.

PCC = Portland cement concrete.

The following three software packages were used to calculate the elastic layer moduli from deflection basins measured on flexible, rigid, and composite pavements:

All three programs were executed in a batch mode process on a State-by-State basis to handle the computational effort needed for the large volume of deflection basins in the LTPP database. The BEST FIT method provides unique solutions for PCC-surfaced pavements using a three-layered structure. The EVERCALC and MODCOMP analyses were performed in four main analysis phases. Each phase progressively identified and filtered out those cases with poor quality results and made appropriate adjustments to the analysis parameters to improve the convergence in the subsequent phase. The first phase included all LTPP data, while the second phase used a subset from the first phase. The third and fourth analysis phases, if required, used a subset from the second phase. Phases 1 and 2 used EVERCALC, and phases 3 and 4 used MODCOMP.

The backcalculation methods and procedures, including the pre- and post-processing tools, were automated to minimize manual errors and enable independent users (those not directly involved in the development of the tools and procedures) to recreate the results. In addition, the automation process was designed to enable users to generate results for additional data collected by LTPP in the future.

A user's manual and source code were prepared for all software packages and tools that were modified, revised, or developed as a part of the backcalculation project. In addition, source codes were prepared for each of the pre- and post-processing utility tools used in the backcalculation process. Source codes were not prepared for any unchanged program that was already available in the public domain.

The computational tools utilize raw data in Microsoft® Access format from the LTPP database as the starting point to generate the backcalculation results. The results are merged back into Microsoft® Access tables with common reference fields with the original deflection tables. Therefore, Microsoft® Access-based macros, Microsoft® Windows-based utilities,

The macros were developed in Microsoft® Access primarily because the raw data resided in Microsoft® Access tables. The macros were used to perform the preliminary data checks and create supplementary data tables. Supplementary data include all data other than the raw FWD deflection data that are necessary to perform the backcalculation analyses, including sensor spacing; temperature data; backcalculation layer structure and layer thicknesses; layer material information, including specified ranges for EVERCALC analysis; and beta factors for the BEST FIT analysis methods.

A standalone software program, Back Calculator, was developed for bulk processing and filtering the deflection data, executing EVERCALC and BEST FIT programs, and processing the backcalculation results. Figure 1 shows a simplified flowchart of the Back Calculator program using the EVERCALC software package. MODCOMP analyses were not included in this program because only a limited number of sections were analyzed using MODCOMP. MODCOMP analyses were performed in a batch mode by executing the application file from an MS-DOS® prompt.

Figure 1. Chart. Simplified flowchart for the Back Calculator program using EVERCALC as the backcalculation software package.

Two criteria were used to establish a quantitative measurement for categorizing the validity of the backcalculated modulus values: the root mean squared error (RMSE) and a range of the elastic modulus values. The RMSE criterion was set at 3 percent (i.e., for the results to be valid, the RMSE needed to be at or below 3 percent). The range of backcalculated modulus values for each layer had to fall within an acceptable or atypical range for each layer type and layer category based on the default range of values included in the MEPDG.(1)

Another factor included in the automated process for evaluating the acceptability of the results was to determine whether the calculated elastic layer moduli are characteristic of a normal distribution. Nearly all volumetric and structural properties exhibited a normal distribution unless some type of bias was created during construction or a boundary condition. Thus, results from a single test day were evaluated to determine whether those results exhibited a normal distribution. The verification for normal distribution was performed using the Jarque-Bera test statistic, which asymptotically has a chi-squared distribution with 2 degrees of freedom.

The deflection data were extracted from LTPP Standard Data Release 27.0 and included specific data from all LTPP test sections for all days of deflection basin testing. The data needed for the backcalculation of layer modulus values were grouped into two categories: direct and indirect. The direct data were from those tables needed to establish the inputs for the backcalculation and forward calculation of layer moduli, and the indirect data included were from tables needed to evaluate the results from the backcalculation process. The direct data elements were extracted from the LTPP database for all test sections on an experimental basis. The indirect data elements were extracted for those test sections that had an appreciable number of results that were considered unacceptable to identify potential reasons for the unacceptable or poor results.

The number of sections by each LTPP experiment included 1,744 sections with an asphalt concrete (AC) surface and 1,008 sections with a PCC surface. There were a total of 7,771 test days, of which 4,534 sections had an AC surface and 2,237 sections had a PCC surface. The surface type changed in 381 of the test sections. For example, a jointed plain concrete pavement that was eventually overlaid with AC is counted in two categories or experiments. Therefore, there were a total of 3,133 unique sections in all States combined. The number of deflection basins considered acceptable and unacceptable for the backcalculation process is as follows:

Nearly 97 percent of all deflection basins were considered acceptable for backcalculation. This high percentage is a testament to the LTPP quality control procedures. Slightly fewer of the data were reported with backcalculated moduli because of a lack of convergence in the backcalculation analysis and missing critical data elements. In addition some of the acceptable basins were borderline.

Of the deflection basins included in the backcalculation process, 4,311,814 resulted in elastic layer moduli that met the acceptance criteria, for a slightly more than 76 percent success rate. More importantly, some 75 to 90 percent of the deflection basins measured along most of the LTPP test sections exceeded the acceptance criteria.

The following sections provide some examples of how the results can be used related to pavement design and rehabilitation, as well as research topics that can be tackled with this data.

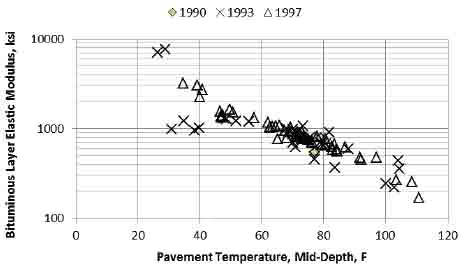

Figure 2 and figure 3 illustrate the change in the AC modulus over time for two LTPP test sections in Minnesota. These data can be used to determine the in-place damage for rehabilitation designs and forensic investigations, as defined by the MEPDG.(1) Figure 2 shows no damage for test section 27-1018, while figure 3 shows damage in the later years of testing for test section 27-6251. The backcalculated elastic moduli can be used to confirm or reject the concept included in the MEPDG for rehabilitation designs in determining the in-place damage of bound layers. In addition, the backcalculation results can be used to determine the temperature-modulus relationship of various hot mix asphalt (HMA) mixtures.

Figure 2. Graph. Minnesota section 27-1018.

Figure 3. Graph. Minnesota section 27-6251.

The backcalculated elastic modulus data can be used to determine the in-place layer modulus for different PCC repair techniques. Table 2 lists the average PCC elastic layer modulus values calculated from the deflection basins measured on two test sections from the Oklahoma SPS-6 project before and after using the two fractured slab concepts (crack and seat and rubblization). Significantly different modulus values were obtained above and below the reinforcing steel for the rubblization test sections. These data can be used to confirm or revise the default values included in the MEPDG.(1)

| Section | Fracture Method | Prior to Fracturing; Intact Slabs | After Fracturing Slabs | |

|---|---|---|---|---|

| 40-0606 | Crack and seat method | 4,799 ksi | 3,615 ksi | |

| 40-0608 | Rubblization method | Above reinforcing steel | 5,082 ksi | 284 ksi |

| Below reinforcing steel | 2,013 ksi | |||

Figure 4 shows the elastic modulus of the fractured PCC slabs from the crack and seat and rubblization methods used in rigid pavement rehabilitation in comparison with the intact PCC slabs for the Michigan SPS-6 test sections. The backcalculation data can be used to determine the default modulus values at the time of rehabilitation and define how those values change over time.

Figure 4. Graph. Michigan SPS-6 project.

More importantly, the current version of the MEPDG assumes that these modulus values remain constant over time. The backcalculation data can be used to confirm or recommend changes to that hypothesis.

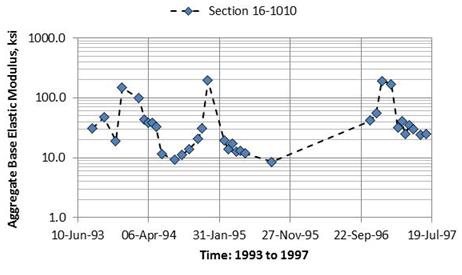

Figure 5 shows the change in elastic modulus over time from the Idaho Seasonal Monitoring Program (SMP) test section. The backcalculation data can be used to estimate the effect of seasonal factors on the response of different unbound aggregate base layers, as well as for the subgrade soils and embankments.

Another important application of the backcalculation data is to define characteristics of the deflection basin that can be used to identify subsurface features that could have a significant impact on the rehabilitation or reconstruction project.

Figure 5. Graph. Idaho SMP project.

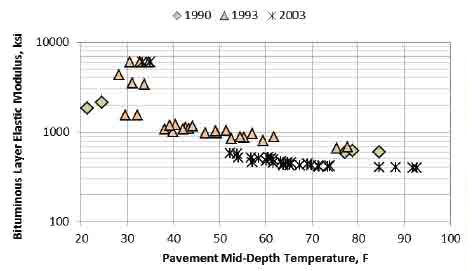

Figure 6 compares the elastic modulus of different HMA mixtures (with and without reclaimed asphalt pavement (RAP)) in the Minnesota SPS-5 project for flexible pavement rehabilitation. The backcalculation data can be used to compare the load-response characteristics between different mixtures, which can be compared with laboratory-measured dynamic values in determining whether there will be any significant difference in performance. Most of the SPS-5 projects exhibit no significant difference between the in-place elastic modulus values for mixtures with and without RAP.

Figure 6. Graph. Minnesota SPS-5 project.

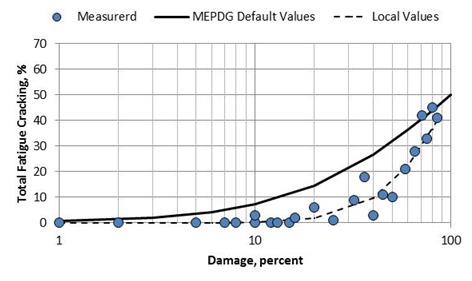

Figure 7 shows a relationship between the in-place damage and the amount of fatigue cracking for the Georgia LTPP test sections and other roadway segments that were used in their local calibration project.(6) The in-place damage is defined as the ratio of the backcalculated elastic modulus values and laboratory-measured dynamic modulus values in accordance with the MEPDG.(1)

The backcalculated elastic layer moduli and fatigue cracking data were used to determine the coefficients of the fatigue cracking transfer function independent of executing the MEPDG software. The coefficients from this relationship were found to result in no bias between the predicted and measured fatigue cracking. Confirmation of this concept and determination of the coefficients independent of the software reduces the amount of field work and materials testing required for local calibration. More importantly, confirmation of this damage concept permits agencies to make more use of their deflection basin data for rehabilitation design in day-to-day practice, as well as in selecting and planning preventive maintenance type projects.

Figure 7. Graph. Georgia LTPP test sections used in local calibration.

Backcalculation of elastic properties is not an exact science and requires user interaction in some cases. To reduce the impact of user interaction, bias, and/or inexperience, the process was automated through a series of utility functions and tools. Results from this automated procedure provide elastic layer load response properties that are consistent with previous experience and laboratory material studies related to the effect of temperature, stress state, and seasonal effects on the material load-response behavior. The following lists some of the important findings from this study:

|

Researchers—This study was performed by Applied Research Associates Inc., Contract No. DTFH61-11-C-00051. Distribution—his TechBrief is being distributed according to a standard distribution. Direct distribution is being made to the FHWA Divisions and Resource Center. Availability—The report will be available in 2015 and may be obtained from the FHWA Product Distribution Center by e-mail to report.center@fhwa.dot.gov, by fax to 301-577-1421, or by phone to 301-577-0818. Key Words—Backcalculation, deflection data, elastic modulus, Falling Weight Deflectometer, Long-Term Pavement Performance, MODCOMP, MODTAG, Mechanistic-Empirical Pavement Design Guide, EVERCALC. Notice—This document is disseminated under the sponsorship of the U.S. Department of Transportation in the interest of information exchange. The U.S. Government assumes no liability for the use of the information contained in this document. The U.S. Government does not endorse products or manufacturers. Trademarks or manufacturers' names appear in this report only because they are considered essential to the objective of the document. Quality Assurance Statement—The Federal Highway Administration (FHWA) provides high-quality information to serve Government, industry, and the public in a manner that promotes public understanding. Standards and policies are used to ensure and maximize the quality, objectivity, utility, and integrity of its information. FHWA periodically reviews quality issues and adjusts its programs and processes to ensure continuous quality improvement. |