Volume 1: Practical Guide, Final Report and Appendix A

After the agency makes all of the decisions required to

develop a project-specific PRS, the final step required before actually using the

specification is the generation of the appropriate preconstruction output. This

chapter is provided as a step-by-step guide to generating preconstruction output for both

Level 1 and Level 2 specifications.

Identifying Required Inputs |

A number of steps are the same whether the agency chooses a

Level 1 or Level 2 pay adjustment procedure. These steps require the collection of

much project-specific information required to conduct LCC simulations. The specific

steps for identifying the required inputs are detailed below.

Step 1—Define the General Project Information. The general

project information should be identified as a first step. This information includes

items such as project location, lane configuration, starting and ending stations, and lane

widths. These are selected in accordance with the guidelines presented in the

section titled

Design-Related

Variables, in chapter 5 of this volume.

Step 2—Define Pavement Performance. The agency must select the

distress indicators that will be used to define pavement performance. These are

selected in accordance with the guidelines presented in the section titled

Defining Pavement Performance,

in chapter 5 of this volume.

Step 3—Select the AQC's to be Included in the Specification.

The agency must select the AQC's that are to be sampled and tested for

acceptance. These are selected in accordance with the guidelines presented in the

section titled

Selection of

Included AQC's, in chapter 5 of this volume.

Step 4—Define the Required Constant Values. A number of

design-, climatic-, and traffic- related variables must be defined for use in the chosen

distress indicator models. These are selected in accordance with the guidelines

presented in the section titled

Identification of

Constant Variable Values, in chapter 5 of this volume.

Step 5—Define the AQC Acceptance Sampling and Testing Plan.

The agency must define the sampling and testing procedures to be used in measuring the

AQC's in the field. This plan not only defines the actual required sampling and

testing methods to be used, but also defines the number of samples per sublot, the methods

for determining random sampling locations, and some general information on

retesting. The defined acceptance sampling and testing plan is determined in

accordance with the guidelines presented in the section titled

Selecting

an AQC Acceptance Sampling and Testing Plan, in chapter 5 of this volume.

Step 6—Define the Required As-Designed AQC Target Values. The

agency must select as-designed target means and standard deviations for each of the

included AQC's. (Note: The selected means and standard deviations are dependent

on the selected sampling and testing plan—defined in step 5.) Guidelines for

selecting appropriate target values (interpreting existing specifications or from

historical AQC construction data) are presented in the section titled

Selection of AQC Target Values,

in chapter 5 of this volume.

Step 7—Define Lots and Sublots. Lots and sublots must be

clearly defined for the project. This primarily consists of defining the target

lengths of each. The definitions for both lots and sublots are determined in

accordance with the guidelines presented in the section titled

Definition of Lots and Sublots,

in chapter 5 of this volume.

Step 8—Define the Maintenance and Rehabilitation Plan. The

agency must select an appropriate M & R plan to be used for the specific project.

This involves selecting the type and frequency of application for maintenance,

localized rehabilitation, and global rehabilitation activities. The defined M &

R plan is determined in accordance with the guidelines presented in the section titled

Selecting a

Maintenance and Rehabilitation Plan, in chapter 5 of this volume.

Step 9—Define the Included Costs. The agency must identify the

particular costs to be included in the overall lot LCC. These decisions include

identifying the M & R unit costs associated with the chosen M & R activities,

deciding on an appropriate percentage of user costs to be included, and determining an

appropriate discount rate. All of these cost-related decisions are made in

accordance with the guidelines presented in the section titled

Cost-Related Decisions, in

chapter 5 of this volume.

Step 10—Define the Simulation Parameters. In order to conduct

any LCC simulations for the as-designed or as-constructed pavement, the agency must define

the required simulation parameters, such as the number of simulation lots required to

simulate a lot LCC and the appropriate range of number of sublots per lot. These

simulation-related parameters are determined in accordance with the guidelines presented

in the section titled

Selecting

Simulation Parameters, in chapter 5 of this volume.

Step 11—Choose the Appropriate Pay Adjustment Procedure. The

agency must select one of two pay adjustment methods available in the prototype

PRS—Level 1 or Level 2. Level 1 should be selected for initial implementation

of PRS. This decision is made in accordance with the guidelines presented in the section

titled

Selecting

a Pay Adjustment Procedure (Level 1 or Level 2), in chapter 6 of this

volume. The details for each of these pay adjustment methods are explained

separately in the following sections.

Level 1—Generating Individual AQC Pay Factor Curves |

|

|

For the Level 1 specification, the preconstruction output

involves simulating data points making up the individual AQC pay factor charts. Each

AQC pay factor chart is made up of a series of pay factor curves (each specific to a

different AQC standard deviation) plotted over a chosen AQC mean range. Pay factor

regression equations are fit through the data making up each pay factor curve.

Individual AQC pay factors may then be determined using the developed regression equations

(or read directly from these charts) by knowing the as-constructed AQC lot means and

standard deviations. If the measured AQC standard deviation does not exactly match

that of one of the simulated pay factor curves, the pay factor is determined by

interpolating between the appropriate pay factor equations. An explanation of the

development of the Level 1 pay factor curves (and corresponding pay factor regression

equations) is contained in more detail in this section.

Level 1, Step 12—Simulate the As-Designed LCC. In order to

calculate pay factors for different hypothetical levels of as-constructed AQC quality, the

representative target as-designed LCC must first be simulated. The PaveSpec 2.0 specification

simulation software is used to estimate representative target as-designed LCC's for

the different numbers of sublots per lot chosen by the agency (see the section titled

Selecting Simulation Parameters,

in chapter 5 of this volume). For example, the agency may decide to simulate

as-designed LCC's for three different scenarios where the number of sublots per lot

would equal 3, 4, and 5. Each of these simulated LCC's (representing a specific

number of sublots per lot) is a function of many different agency-defined variables,

including the number of simulation lots, acceptance and sampling plan, M & R plan, AQC

target values, analysis life, and chosen costs. Individual Level 1 pay factor charts

will be developed independently for each scenario chosen by the agency.

Level 1, Step 13—Choose a Range of As-Constructed Means for Each AQC.

Reasonable ranges of AQC means are selected that will define the values used in the

simulation of the Level 1 AQC pay factor curves. These chosen ranges of AQC

simulation means are based on the chosen AQC target values. The agency is required

to define the range of the AQC means and the number of simulation points within the range.

The agency-chosen values will be used to define the x-axis range of the developed

Level 1 pay factor charts. It is recommended that the boundary conditions of this range be

defined as the agency-defined AQC RQL's and MQL's (see the section titled

Retesting Procedures in chapter 5

of this volume).

Level 1, Step 14—Choose a Range of As-Constructed Standard Deviation Levels

for Each AQC. The pay factor curves (contained in the Level 1 pay factor

charts) depend not only on the as-constructed AQC mean, but also on the as-constructed AQC

standard deviation. Therefore, it is important to choose a range of as-constructed

standard deviation levels that will show the influence of the AQC variability. Three

to five different levels of standard deviation are typically chosen for each AQC. (One of

the chosen standard deviation levels should always be the AQC target standard deviation.)

Level 1, Step 15—Simulate As-Constructed LCC's and Calculate an

Independent AQC Pay Factor for Each Hypothetical As-Constructed Mean/ Standard Deviation

Pair. The hypothetical as-constructed mean/standard deviation pair values

(coming from combinations of means and standard deviations defined in Level 1, steps 13

and 14, respectively) are used to define individual simulation sessions in PaveSpec.

Each AQC is investigated independently for each simulation session (e.g., if

strength is being investigated, all of the other AQC as-constructed means and standard

deviations are set equal to the target values). Each mean/standard deviation pair is

used in PaveSpec to simulate a corresponding representative as-constructed LCC mean

(AC-LCC

MEAN). A pay factor is calculated for each

hypothetical pair using equation 3

in chapter 3 of this

volume. (Note: Pay factors are calculated using an agency-selected appropriate bid

price determined in accordance with the guidelines set forth in the section titled

Selecting

an Appropriate Bid Price for Developing Level 1 Preconstruction Output in chapter

5.)

Level 1, Step 16—Determine Individual AQC Pay Factor Regression Equations.

Best fit regression equations are defined for each set of simulated pay factors

related to each as-constructed AQC standard deviation (chosen in Level 1, step 14).

These individual pay factor equations are generated using the PaveSpec 2.0 software.

Level 1, Step 17—Plot Pay-Factor Equations vs. AQC Mean. The

defined pay factor regression equations (determined in Level 1, step 16) can be graphed

easily as a function of the AQC mean. Pay factor charts (containing plots of all of

the regression equations defined in Level 1, step 16) are then plotted for each AQC

independently. These charts are created for each number of sublots per lot chosen by

the agency (see the section titled

Selecting Simulation Parameters

in chapter 5 of this volume).

Level 1, Step 18—Define the CPF Equation. The agency must

define a governing CPF equation in accordance with the guidelines presented in the section

titled

Defining

a Level 1 Composite Pay Factor Equation, in chapter 6 of this volume.

Level 1, Step 19—Define Pay Factor Limits. The agency must

define pay factor limits that are applied to the computed individual AQC pay factors, or

the lot CPF, or both. Any chosen pay factor limits are determined in accordance with

the guidelines presented in the section titled

Selecting Pay Factor Limits,

in chapter 6 of this volume.

Level 2—Simulating the As-Designed LCC |

|

|

For a Level 2 specification, the preconstruction output only

involves the simulation of the target as-designed life-cycle cost (LCCDES).

Overall lot pay factors are calculated directly as a function of this LCCDES,

the determined as-constructed LCC (LCCCON), and the contract bid

price (using equation 3 in chapter 3 of this

volume). This Level 2 LCCDES is determined using the same

procedure described in Level 1, Step 12.

Developing Operating Characteristic Curves |

|

|

Under the Level 1 PRS, operating characteristic (OC) curves

are generated for each AQC using the PaveSpec 2.0 computer software. Each set of OC

curves is developed specific to a defined sampling plan (i.e., number of sublots, number

of samples per sublot, and sample and test types). The following steps outline the

general procedure used within the software to generate these charts:

For each AQC, the following applies:

- Distributions of pay factors for different AQC mean values (over the chosen range of AQC

means) are simulated by setting the as-constructed AQC standard deviation equal to the

target value. Each distribution is the result of a minimum of 500 simulated lot pay

factors.

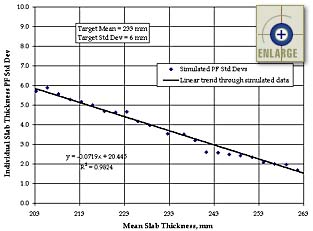

- Pay factor means and standard deviations (computed at each hypothetically

chosen AQC mean) are plotted over the chosen range of AQC means. Relationships of

pay factor mean and pay factor standard deviation versus AQC mean are determined.

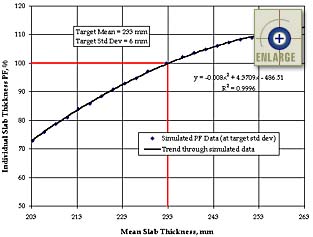

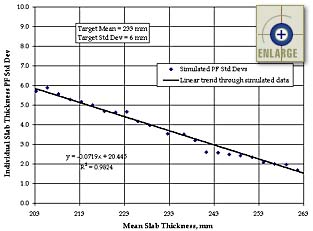

Figures 20 and 21 illustrate these respective relationships for slab thickness on an

example project. Figure 20 is commonly referred to as an expected pay (EP) curve.

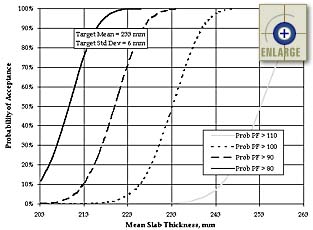

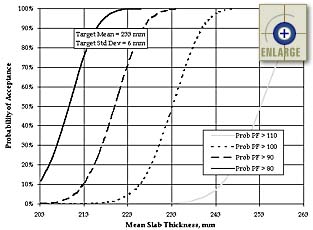

- The user must define the different pay factor acceptance levels for which the

probability of acceptance will be investigated (e.g., PF ³

80%, PF ³ 100%, PF ³ 110%).

- Finally, OC curves for each of the chosen pay factor acceptance levels are

plotted using the results of steps 1 through 3. Figure 22 contains the example OC

chart plotted using the relationships determined for the slab thickness example

(determined in step 2).

|

| Figure 20. Example of a simulated pay factor mean versus AQC mean

relationship used to develop OC curves for a Level 1 PRS. |

|

| Figure 21. Example of a simulated pay factor standard deviation

versus AQC mean relationship used to develop OC curves for a Level 1 PRS. |

|

| Figure 22. Example of an OC curve constructed for a Level 1

PRS—case of four sublots and two samples per sublot (for each AQC). This chart

reflects the relationships presented in figures 20 and 21. |

Different examples of interpreting figure 22 are given as

the following:

- If the contractor wishes to have a 50-percent probability that he/she will obtain a PF ³ 100 percent, then a mean slab thickness of 233 mm must be

constructed.

- If the contractor wishes to have a 90-percent probability that he/she will obtain a PF ³ 100 percent, then a mean slab thickness of 240 mm must be

constructed.

- If the contractor wishes to have a 90-percent probability that he/she will obtain a PF ³ 110 percent, then a mean slab thickness of 260 mm must be

constructed.

- f the contractor actually builds a mean slab thickness of 223 mm (the

target was 233 mm), the probability that he/she will receive a PF ³ 100

percent is approximately 5 percent. The probability that he/she will receive a PF ³ 90 percent is 70 percent.