Lab & Field Testing of AUT Systems for Steel Highway Bridges

6. RESULTS (cont'd)

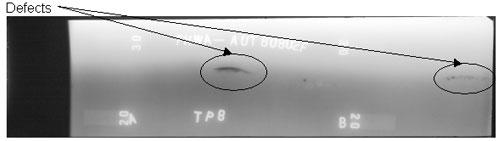

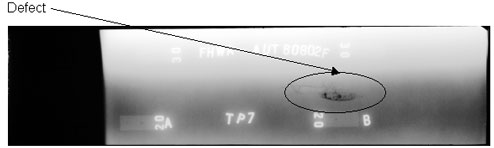

Figure 58. Laboratory specimen S135: Radiographic image showing discontinuities in the weld between markers A and B. |

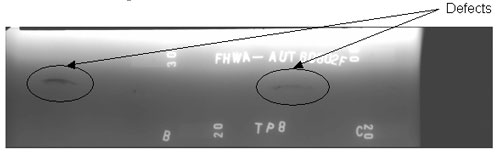

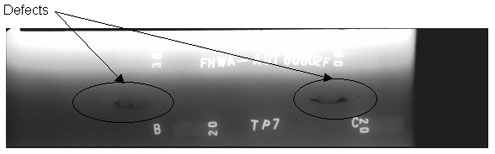

Figure 59. Laboratory specimen S135: Radiographic image showing discontinuities in the weld between markers B and C. |

Figure 60. P-scan images of laboratory specimen S135: From TSC side of centerline between 0 and 203.2 mm (0 and 8 inches).

|

Figure 61. P-scan images of laboratory specimen S135: From BSC side of centerline between 0 and 203.2 mm (0 and 8 inches). |

Figure 62. P-scan images of laboratory specimen S135: From TSC side of centerline between 203.2 and 454 mm (8 and 17.875 inches). |

Figure 63. P-scan images of laboratory specimen S135: From BSC side of centerline between 203.2 and 454 mm (8 and 17.875 inches). |

Figure

64. Laboratory specimen S136: Side view of joint. Figure

64. Laboratory specimen S136: Side view of joint.

|

Figure

65. Laboratory specimen S136: Top

view of joint.

|

Figure

66. Laboratory specimen S136:

Radiographic image showing discontinuities in the weld between markers A

and B.

|

Figure

67. Laboratory specimen S136:

Radiographic image showing discontinuities in the weld between markers B

and C.

|

Figure 68. P-scan images of laboratory specimen S136: From TSC side of centerline between 0 and 203.2 mm (0 and 8 inches).

|

Figure

69. P-scan images of laboratory

specimen S136: From BSC side of centerline between 0 and 203.2 mm (0 and 8

inches).

|

Figure

70. P-scan images of laboratory

specimen S136: From TSC side of

centerline between 203.2 and 454 mm (8 and 17.875 inches).

|

Figure

71. P-scan images of laboratory

specimen S136: From BSC side of centerline

between 203.2 and 454 mm (8 and 17.875 inches).

|

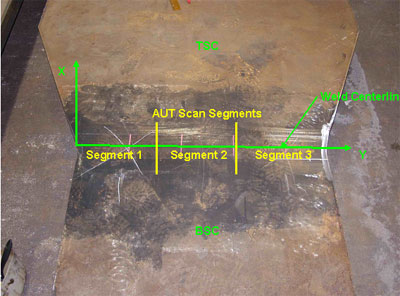

Figure 72. Field specimen FG38k-TF2-TopF-FCM used in blind testing: Top view of joint. |

Figure 73. Field specimen FG38K-TF2-TopF-FCM used in blind testing: Side view of joint. |

Figure 74. P-scan images of field specimen FG38K-TF2-TopF-FCM using 45-degree probe: From TSC side of certerline between 0 and 279.4 mm (0 and 11 inches). |

Figure 75. P-scan images of field specimen FG38K-TF2TopF-FCM using 45-degree probe: From BSC side of centerline between 0 and 270.4mm (0 and 11 inches). |

Figure 76. P-scan image of field specimen FG38K-TF2-TopF-FCM using 45-degree probe: From TSC side of centerline between 279.4 and 558.8 mm (11 and 22 inches). |

Figure 77. P-scan iamges of field specimen FG38K-TF2-TopF-FCM using 45-degree probe: From BSC side of centerline between 279.4 and 558.8 mm (11 and 22 inches). |

Figure 78. P-scan iamges of field specimen FG38K-TF2-TopF-FCM using 45-degree probe: From TSC side of centerline between 558.8 and 857.25 mm (22 and 33.75 inches). |

Figure 79. P-scan iamges of field specimen FG38K-TF2-TopF-FCM using 45-degree probe: From BSC side of centerline between 558.8 and 857.25 mm (22 and 33.75 inches). |

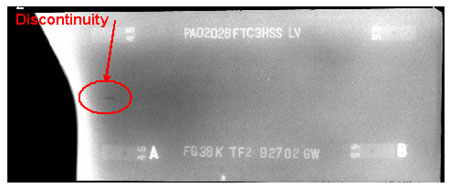

Figure 80. Radiographic image of field specimen FG38K-TF2-TopF-TCM: Section A-B. |

Figure 81. Radiographic image of field specimen FG38K-TF2-TopF-FCM: Section B-C. |

Figure 82. Radiographic image of field specimen FG38K-TF2-TopF-FCM: Section C-D. |

BLIND FIELD-TESTING RESULTS

During the course of the AUT field study, it was not convenient to

conduct blind testing because of fabrication plant logistics and scheduling. However,

one blind test was conducted successfully. The purpose of blind testing was to

eliminate bias by performing AUT inspection before RT and manual UT inspection.

The specimen (selected at random) for blind testing was FG38K-TopF-FCM.

Specimen FG38K-TopF-FCM was composed of two welded butt joints designated as

FG38K-TF1-TopF-FCM and FG38K-TF2-TopF-FCM, each having a width transition.

Specimen FG38K-TopF-FCM was 76.2 mm (3 inches) thick, 857.25 mm (33.75 inches)

wide, and was designated as a fracture-critical member (FCM). Plates designed as

FCMs must be inspected by both RT and manual UT according to section 6.7.1.2 of

the AASHTO/AWS D1.5M/D1.5: 2002 Bridge Welding Code.(1) Table 6.2 in

the AASHTO/AWS D1.5M/D1.5: 2002 Bridge Welding Code(1) indicates that

plates with thicknesses ranging from greater than 60 to 90 mm (2.5 to 3.5

inches) must be inspected by UT using 45-degree and 70-degree probes. The

45-degree probe inspects the top quarter of the weld thickness, while the

70-degree probe inspects the remainder of the weld thickness. Unfortunately,

the AUT inspection was only performed using a 45-degree probe because of time

constraints.

For convenience, the width of each butt joint was divided into three

segments: 280 mm (11 inches), 280 mm (11 inches), and 300 mm (11.75 inches)

long. The P-scan results indicated that specimen FG38K-TF1-TopF-FCM passed the

AUT inspection with no rejectable defects in the weld. However, specimen

FG38K-TF2-TopF-FCM (figures 72 and 73) was diagnosed with defects and was rejected.

The P-scan images of specimen FG38K-TF2-TopF-FCM are shown in figures 74

through 79. Figures 74 and 75 show the P-scan images of the first segment of

the weld. At location Y = 27.686 mm (1.09 inches) from the datum, a 20.32-mm-

(0.8-inch-) long indication was found. In addition, subsurface indications were

detected along face A (i.e., the top surface) and face B (i.e., the

bottom surface) of the plate. Figures 76 and 77 show the second segment of the

weld with rejectable subsurface indications. Figures 78 and 79 show rejectable

subsurface indications in the third segment of the weld. Figures 80 through 82

show the RT results for specimen FG38K-TF2-TopF-FCM in three segments. The

first section extends from the left edge of the plate to approximately 304.8 mm

(12 inches) from the left edge (figure 80). Fiducial marker B,

indicated in figure 80, corresponds to the same marker in figure 81

(the second segment of the radiograph). Fiducial marker C, in figure 81,

corresponds to the same marker in figure 82 (the third segment of the

radiograph). The radiographic image for specimen FG38K-TF2-TopF-FCM (shown in figure

80) indicates a slag inclusion at location Y = 19.05 mm (0.75 inch)

from the left edge. No subsurface defects were observed in the other radiographs.

Table 7 summarizes the blind field-testing results.

Table 7. Inspection results of blind field testing.

Specimen ID |

RT |

Manual UT |

AUT |

FG38K-TF2-TopF-FCM |

Rejected

Ind. 1: A-B, Slag 0.75" From A Edge

(i.e., Y = 0.75") |

Rejected

Ind. 1:  = 45° = 45°

L = 0.80"

Y = 1.00"

Ind. 2: Subsurface Indications |

Rejected*Ind. 1A: BSC,  = 45° = 45°

d = -2 dB

L = 0.55", Z = 1.72"

X = -0.40", Y = 1.09"

Ind. 1B: TSC,  = 45° = 45°

d = +3 dB

L = 0.25", Z = 1.82"

X = -0.08", Y = 1.79"

Ind. 2A: TSC,  = 45° = 45°

d = +9 dB

L = 1.86", Z = 0.08"

X = -2.06", Y = 4.68"

Ind. 2B: BSC,  = 45° = 45°

d = +10 dB

L = 0.15", Z = 0.05"

X = -0.04", Y = 6.45"

Ind. 3: BSC,  = 45° = 45°

d = +8 dB

L = 1.10", Z = 2.82"

X = -0.49", Y = 6.68"

Ind. 4: BSC,  = 45° = 45°

d = +9 dB

L = 4.44", Z = 2.883"

X = +0.56", Y = 11"

Ind. 5: BSC,  = 45° = 45°

d = +7 dB

L = 1.45", Z = 2.85"

X = -1.08", Y = 16.41"

Ind. 6: BSC,  = 45° = 45°

d = +8 dB

L = 0.31", Z = 0.07"

X = -0.56", Y = 20.01"

Ind. 7: BSC,  = 45° = 45°

d = +9 dB

L = 1.19", Z = 2.88"

X = +0.69", Y = 22.86"

Ind. 8: BSC,  = 45° = 45°

d = +10 dB

L = 2.42", Z = 2.9"

X = +0.84", Y = 27" |

FG38K-TF1-TopF-FCM |

Accepted |

Accepted |

Accepted |

*Under the

provisions of table 6.3 in the AASHTO/AWS D1.5: 2002 Bridge Welding Code (i.e.,

class B and class C flaws shall be separated by at least 2L), Ind. 1A,

Ind. 1B, ... are considered as a single defect, Ind. 2A, Ind. 2B, ... are

considered as a single defect, etc.

1

inch = 25.4 mm

FIELD-TESTING RESULTS

The field testing

results are summarized in tables 8 through 12. The first column of tables 8

through 12 indicates the specimen identification code. The second, third, and fourth

columns indicate the inspection method performed on each specimen. "Rejected"

or "Accepted" indicates that the specimen was either rejected or accepted,

respectively, by the employed inspection method. "Not Required" indicates that

the owners did not prescribe the particular inspection method for the specimen.

In the cases where the specimens were rejected by RT and the owners did not

require manual UT inspection, the fabricators used manual UT to determine the

defect depth so that efficient repairs could be performed. In tables 8

through 12, "Ind." stands for indication, and the angle (q)

indicates the transducer's refracted angle. The indication characteristics in

the fourth column (i.e., indication rating (d), length (L), depth (Z),

x-position, and y‑position) are obtained from P-scan images. These

characteristics are compared with the UT acceptance-rejection criteria in tables

6.3 and 6.4 from the AASHTO/AWS D1.5M/D1.5: 2002 Bridge Welding Code(1)

to determine whether the indications are accepted or rejected.

Tables 8

through 12 show that RT was performed on the remaining 44 field specimens

according to the owner's requirements. Note that section 6.7.1.2 of the

AASHTO/AWS D1.5M/D1.5: 2002 Bridge Welding Code(1) indicates that

100 percent of each joint subjected to calculated tension or stress reversal

and 25 percent of each joint subjected to compression or shear should be

inspected by manual UT or RT. The P-scan and radiographic images of the rejected

field specimens are provided in figures 83 through 96.

The results from

the first field test set at HSS are summarized in table 8. Only two specimens were tested in the first set using RT and AUT. Manual UT

was not required. RT and AUT accepted both specimens with no rejectable

defects.

Table 8. Inspection results of the first field testing at HSS.

Specimen ID |

RT |

Manual UT |

AUT |

G20A-TF2-BottF |

Accepted |

Not Required |

Accepted |

G21A-TF2-BottF |

Accepted |

Not Required |

Accepted |

Table 9. Inspection results of the second field testing at HSS.

Specimen ID |

RT |

Manual UT |

AUT |

G3F-CF1-BottF |

Accepted |

Not Required |

Accepted |

G3F-CF2-BottF |

Accepted |

Not Required |

Accepted |

G3F-TF1-TopF |

Accepted |

Not Required |

Accepted |

G3F-TF2-TopF |

Accepted |

Not Required |

Accepted |

G4F-TF1-TopF |

Accepted |

Not Required |

Accepted |

G4F-TF2-TopF |

Accepted |

Not Required |

Accepted |

G3J-TF1-TopF |

Accepted |

Not Required |

Accepted |

G3J-CF1-BottF |

Accepted |

Not Required |

Accepted |

G2A-CF1-TopF |

Accepted |

Not Required |

Accepted |

G2A-CF2-TopF |

Accepted |

Not Required |

Accepted |

G2A-CF3-TopF |

Accepted |

Not Required |

Accepted |

G2A-CF4-TopF |

Accepted |

Not Required |

Accepted |

G5G-TF1-TopF |

Rejected

Ind. 1: A-B,

0.13" Slag 0.94" From Edge

(i.e., L = 0.13", Y = 0.94")

Ind. 2: B-C,

0.25" Slag 0.82" From Edge

(i.e., L = 0.25", Y = 19.19")

|

Not Required

(Accepted Within Code

Ind.1:

L = 0.5", Z = 0.56"

X = 0, Y = 0

Ind. 2:

L = 0.5",

X = 0, Y = 19.0")

|

Accepted Within Code

Ind. 1: TSC,  = 70° = 70°

d = +14 dB

L = 0.52", Z = 0.81"

X = -0.05", Y = 0"

Ind. 2: BSC,  = 70° = 70°

d = +14 dB

L = 1.12", Z = 0.11"

X = -0.22", Y = 18.4"

|

G2G-CF1-BottF-FCM |

Accepted |

Rejected |

Rejected*Ind. 1A: TSC,  = 45° = 45°

d = +5 dB

L = 0.58", Z = 1.12"

X = -0.06", Y = 26.21"

Ind. 1B: TSC,  = 45° = 45°

d = 0 dB

L = 1.50", Z = 1.12"

X = +0.01", Y = 26.93"

|

*Under the

provisions of table 6.3 in the AASHTO/AWS D1.5: 2002 Bridge Welding Code (i.e.,

class B and class C flaws shall be separated by at least 2L), Ind. 1A,

Ind. 1B, ... are considered as a single defect, Ind. 2A, Ind. 2B, ... are

considered as a single defect, etc.

1 inch = 25.4 mm

Table 10. Inspection results of the third field

testing at HSS.

Specimen ID |

RT |

Manual UT |

AUT |

FG4A-TF1-BottF-FCM |

Accepted |

Accepted |

Accepted |

FG1A-TF1-BottF-FCM |

Accepted |

Accepted |

Accepted |

FG2A-TF1-BottF-FCM |

Accepted |

Accepted |

Accepted |

FG3A-TF1-BottF-FCM |

Accepted |

Accepted |

Accepted |

FG37K-TF2-TopF-FCM |

Accepted |

Accepted |

Accepted |

FG38K-TF3-BottF-FCM |

Accepted |

Accepted |

Accepted |

FG26G-TF2-BottF-FCM |

Rejected

Ind. 1: A-B,

0.12" Slag 0.59"

From B Edge

(i.e., L = 0.12", Y = 11.29") |

Accepted Within Code |

Accepted Within Code

Ind. 1: BSC,  = 70° = 70°

d = +7 dB

L = 0.39", Z = 0.76"

X = 0.45", Y = 9.97" |

FG16D-TF1-BottF-FCM |

Rejected

Ind. 1: A-B, Within Code

0.04" Slag at A

(i.e., L = 0.04", Y = 0")

Ind. 2: A-B,

0.12" Slag 0.98" From B Edge

(i.e., L = 0.12", Y = 11.02") |

Accepted Within Code |

Accepted Within Code

Ind. 1: BSC,  = 70° = 70°

d = +14 dB

L = 1.74", Z = 0.69"

X = -0.24", Y = 0.61"

Ind. 2: BSC,  = 70° = 70°

d = +9 dB

L = 0.72", Z = 0.32"

X = -0.14", Y = 9.56" |

FG36K-TF2-TopF-FCM |

Rejected

Ind. 1: C-D,

Edge of Plate

(i.e.,

Y = 33.75") |

Rejected

Ind. 1:  = 70° = 70°

L = 2", Z = 0.5"

X = -0.75", Y = 33.5"

Ind. 2: Subsurface Indications |

Rejected*Ind. 1: BSC,  = 45° = 45°

d = +7 dB

L = 0.83", Z = 0.04"

X = +1.2", Y = 22.55"

Ind. 2A: TSC,  = 45°d = +9 dB = 45°d = +9 dB

L = 1.31", Z = 0"

X = -0.85", Y = 25.55"

Ind. 2B: TSC,  = 45° = 45°

d = +3 dB

L = 0.70", Z = 0.04"

X = -0.53", Y = 27.60"

Ind. 3A: BSC,  = 45° = 45°

d = -2 dB

L = 1.31", Z = 0.02"

X = -0.67", Y = 31.18"

Ind. 3B: TSC,  = 45° = 45°

d = -3 dB

L = 1.43", Z = 0.02"

X = -0.58", Y = 31.78" |

|

FG37K-TF3-BottF-FCM |

Accepted |

Rejected

Ind. 1:  = 45° = 45°

L = 1.0", Z = 2.0"

X = +0.50", Y = 26" |

Rejected

Ind. 1: BSC,  = 45° = 45°

d = +6 dB

L = 0.41", Z = 1.85"

X = +0.54", Y = 26.67" |

|

TP2 |

Rejected

Slags

Ind. 1:

L = 0.50", Y = 0.25"

Ind. 2: L = 0.75", Y = 3.50"

Ind. 3: L = 1.13", Y = 7.0"

Ind. 4: L = 1", Y = 10.5"

|

Rejected

Ind. 1:

d = +5 dB

L = 0.38", Z = 0.92"

X = -0.50", Y = 0"

Ind. 2:

d = +2 dB

L = 0.50", Z = 0.18"

X = +0.31", Y = 3.63"

Ind. 3:

d = -1 dB

L = 0.75", Z = 0.95"

X = -0.13", Y = 7.13"

Ind. 4:

d = +1 dB

L = 0.50", Z = 0.09"

X = -0.38", Y = 10.5"

|

Rejected

Ind. 1:

d = +4 dB

L = 0.46", Z = 0.97"

X = -0.53", Y = 0"

Ind. 2:

d = +2 dB

L = 0.88", Z = 0.01"

X = +22", Y = 3.17"

Ind. 3:

d = -3 dB

L = 1.12", Z = 0.93"

X = -0.19", Y = 7.0"

Ind. 4:

d = +1 dB

L = 0.89", Z = 0"

X = -0.30", Y = 10.19"

|

|

AWS-FCM-02-6A |

Rejected |

Rejected |

Rejected |

*Under

the provisions of table 6.3 in the AASHTO/AWS D1.5: 2002 Bridge Welding Code

(i.e., class B and class C flaws shall be separated by at least 2L), Ind.

1A, Ind. 1B, ... are considered as a single defect, Ind. 2A, Ind. 2B, ...

are considered as a single defect, etc.

1 inch = 25.4 mm

Table 11. Inspection results of the fourth field

testing at HSS.

| Specimen ID |

RT |

Manual UT |

AUT |

FBG80-TF1-BottF-FCM |

Accepted |

Accepted |

Accepted |

FG1E-TF2-TopF- FCM |

Accepted |

Accepted |

Accepted |

FG2E-TF2-TopF-FCM |

Accepted |

Accepted |

Accepted |

G11THW-CF1-BottF |

Accepted |

Not Required |

Accepted |

G11THW-CF2-BottF |

Accepted |

Not Required |

Accepted |

G7UHW-CF1-TopF |

Accepted Within Code

Ind. 1: B-C,

Indication 1.31" Right of A

(i.e., Y = 1.31")

Ind. 2: B-C,

Indication 0.5" Left of B (i.e., Y = 17.5") |

Not Required |

Accepted |

FG40M-TF1- Curved-FCM |

Accepted |

Rejected

Ind. 1:  = 45° = 45°

d = +1 dB

L = 1.75", Z = 2"

X = +0.38", Y = 12"

Ind. 2:  = 45° = 45°

d = +5 dB

L = 0.75", Z = 1.38"

X = +0.63", Y = 16" |

Rejected*Ind. 1A: BSC,  = 45° = 45°

d = +8 dB

L = 1.29", Z = 2"

X = +0.49", Y = 10.68"

Ind. 1B: TSC,  = 45° = 45°

d = +1 dB

L = 1.02", Z = 1.37"

X = +1.10", Y = 11.17" |

|

FG1A-TF2-BottF- FCM |

Rejected

Ind. 1: A-B, Slag |

Rejected |

Rejected*Ind. 1A: TSC,  = 60° = 60°

d = -1 dB

L = 0.97", Z = 0.49"

X = -1.40", Y = 3.0"

Ind. 1B: TSC,  = 70° = 70°

d = +6 dB

L = 1.11", Z = 0.72"

X = -1.50", Y = 3.08" |

G3VHW-CF1-BottF |

Rejected

Ind. 1: A-B,

Indication 3.25" Left of B (i.e., Y = 9.88") |

Not Required

(Accepted Within Code) |

Accepted Within Code

Ind. 1: TSC,  = 70° = 70°

d = +4 dB

L = 0.66", Z = 1.52"

X = +1.46", Y = 8.76" |

G5VHW-CF1-BottF |

Rejected

Ind. 1: B-C,

0.25" Slag 1.06 From C Edge

(i.e., L = 0.25", Y = 25.19") |

Not Required

(Accepted Within Code) |

Accepted Within Code

Ind. 1: TSC,  = 45° = 45°

d = +9 dB

L = 0.40", Z = 1.70"

X = +0.71", Y = 24.76" |

*Under the provisions of table 6.3 in the AASHTO/AWS D1.5: 2002 Bridge Welding Code (i.e.,

class B and class C flaws shall be separated by at least 2L), Ind. 1A,

Ind. 1B, ... are considered as a single defect, Ind. 2A, Ind. 2B, ... are

considered as a single defect, etc.

1 inch = 25.4 mm

Table 12. Inspection results of field testing at Stupp.

Specimen ID |

RT |

Manual UT |

AUT |

FS32B1&2-BottF Joint B015 |

Accepted |

Accepted |

Accepted |

FS45A1&2 Joint T019 |

Accepted |

Accepted |

Accepted |

FS46A1&2 Joint T021 |

Accepted |

Accepted |

Accepted |

FS31B1&2 Joint B011 |

Accepted Within Code |

Accepted |

Accepted |

|