U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-14-065 Date: February 2015 |

Publication Number: FHWA-HRT-14-065 Date: February 2015 |

The pavement treatment types considered in this study were identified in the original proposal by FHWA and the project team. This list was further refined based on the treatment types that were provided by the various volunteer States.

Table 2 lists the treatment types considered in the study, with the treatments that were included in the final analysis highlighted in bold.

Table 2 . Flexible and concrete pavement treatment strategies considered in Phase VI.

FLEXIBLE PAVEMENT TREATMENT STRATEGIES |

CONCRETE PAVEMENT STRATEGIES |

|---|---|

Thin HMA Overlay |

Thin HMA Overlay |

Open Graded Friction Course (OGFC) |

Open Graded Friction Course (OGFC) |

Ultra-Thin Bonded Wearing Course (UTBWC) |

Ultra-Thin Bonded Wearing Course (UTBWC) |

Microsurfacing |

Microsurfacing |

Shotblasting/Abrading |

Shotblasting/Abrading |

High Friction Surfacing (HFS) |

High Friction Surfacing (HFS) |

Chip Seal (various binder types) |

Diamond Grinding |

Cape Seal |

Grooving |

Scrub Seal |

Next Generation Concrete Surface |

Slurry Seal |

|

Micro-Milling |

The decision was made early in the data collection effort to focus primarily on the most common treatments that are used throughout the United States, while also considering experimental-type treatments, if appropriate. As discussed previously, the majority of these treatments are typically used for pavement preservation purposes to extend the life of an existing pavement while also potentially improving skid resistance and ride quality. The notable exception is HFS, which is almost exclusively used for safety improvement purposes. The following sections summarize each of these treatment types.

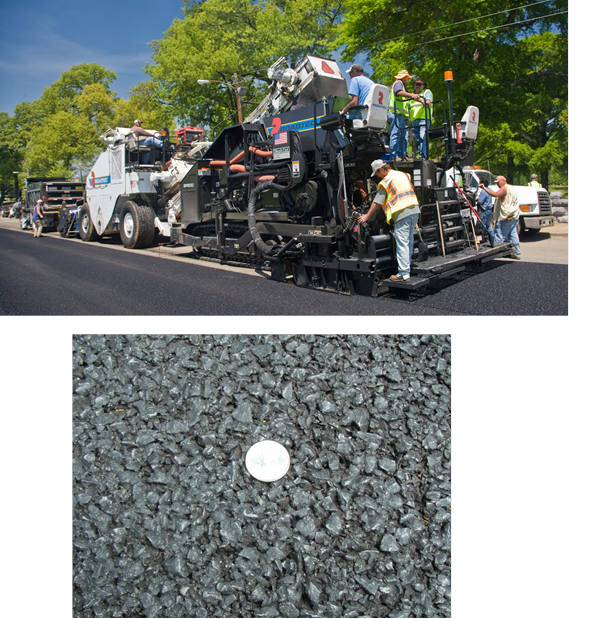

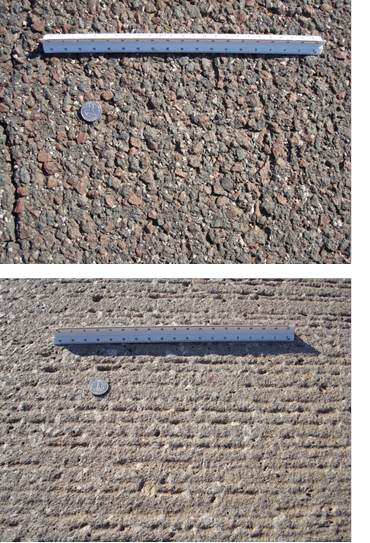

Thin HMA overlays (figure 5) are commonly used to correct minor to moderate pavement surface defects to restore ride quality and improve friction while protecting the underlying pavement structure. Thin overlays may be applied to either concrete or asphalt pavements, or over existing surface treatments, and are typically not considered a structural layer. Industry convention generally defines thin overlays as no more than 1.5 to 2 inches thick, typically constructed as a single lift, and therefore was the criterion used by the project team under this effort. In the list of thin HMA overlay candidate sites, the team included "mill and fill" projects, which included milling off the existing surface before applying the new overlay. Although the milling operation adds to the cost of the treatment, best practice generally dictates that the existing surface be milled off for best performance of the overlay. While thin overlays are not typically constructed explicitly to improve friction, mixtures are still designed to standards that will ensure appropriate friction levels.

Source: The Transtec Group, Inc.

Figure 5. Photo. Placement of thin asphalt overlay (top) and surface texture of new (bottom left) and worn (bottom right) dense graded asphalt surfaces.

An OGFC treatment (figure 6) is a type of thin HMA overlay, but uses an open graded or porous asphalt mixture that allows water to quickly drain away from the surface by flowing through the mixture itself. This helps to minimize sheeting or standing water on the surface and the potential for hydroplaning. The porosity of an OGFC can also significantly reduce tire-pavement noise and splash and spray potential of the pavement surface. Similar to conventional thin HMA overlays, OGFCs are not typically considered a structural layer and are typically used to renew the functional performance of a pavement, including ride quality, friction, and tire-pavement noise. They can be placed over pavement with minor to moderate surface defects, but not those with substantial distresses caused by subsurface issues. OGFCs are beneficial for locations with high amounts of rainfall, but generally are not used in colder climates because of their poor performance during freeze-thaw cycles. Because a specialty asphalt mixture is used to achieve the open graded texture, they are typically more expensive than conventional dense-graded asphalt. However, superior functional performance makes this treatment desirable for high-priority urban areas.

Source: The Transtec Group, Inc.

Figure 6. Photo. Surface texture of OGFC.

Ultra-Thin Bonded Wearing Course

UTBWC is a specialty ultra-thin asphalt overlay used to restore ride quality while sealing and protecting the underlying pavement. It can also be used to mitigate shallow (less than 0.5-inch) rutting and can help retard fatigue cracking.(32) UTBWC is a non-structural layer, typically only 0.5- to 0.75-inch thick and generally uses a gap-graded aggregate and polymer-modified asphalt. One of the primary differences between UTBWC and conventional ultra-thin asphalt overlays is how the treatment is placed. An emulsion layer is applied to the pavement surface immediately in front of the paving screed using a self-priming paver (figure 7). The emulsion helps to seal the underlying pavement surface while also immediately bonding it to the new asphalt surface. UTBWC was originally developed as a proprietary product called NovaChip, but since the patent expired, several State transportation departments have developed their own specification for this treatment. UTBWC can be applied to existing asphalt or concrete pavement or over other surface treatments. The underlying pavement must be structurally sound with only minor rutting, minor to moderate cracking, and minor to moderate bleeding and raveling.(33)

Sources: top: Roadtec; bottom: The Transtec Group, Inc.

Figure 7. Photo. Placement of an UTBWC using a self-priming paver (top) and surface texture of an UTBWC (bottom).34

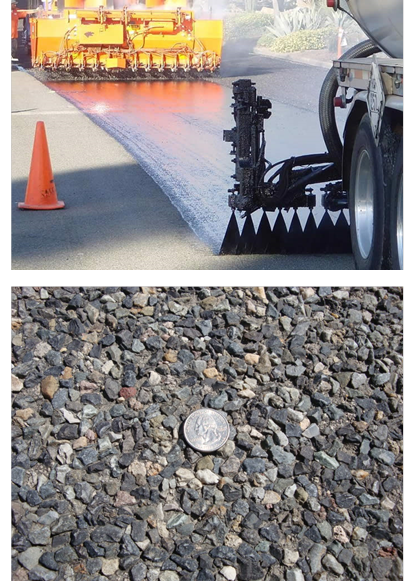

Chip seals or seal coats are a common bituminous pavement preservation treatment used to seal fine cracks in the underlying pavement surface and prevent water intrusion into the underlying pavement structure, while sustaining or improving pavement friction.(35) Chip seals are constructed by first applying a bituminous membrane onto the existing pavement followed by a layer of aggregate or "chips," which are dropped onto the surface then rolled to embed them in the binder. (See figure 8.) The bituminous membrane is typically a polymer-modified asphalt emulsion, but can also be a liquid asphalt material (asphalt cement or cutback), including rubberized asphalt. Chip seals are typically only applied to existing asphalt pavement or bituminous surface treatments, but have also been used for unpaved roads. Chip seals are not a structural layer, but do provide a very durable wearing surface. They are susceptible to chip loss, which can result in flying chips and broken windshields, and are therefore not commonly used on heavily traveled urban roadways. However, they are commonly used on rural high-speed roadways, including rural interstates and State highways. There are several varieties of chip seals, including single, double, and triple layer treatments that may use a variety of aggregate sizes in the different layers, as well as different types of aggregate such as lightweight material.

Sources: top: California Chip Seal Association; bottom: The Transtec Group, Inc.

Figure 8. Photo. Placement of a chip seal (top) and surface texture of a single layer chip seal (bottom).36

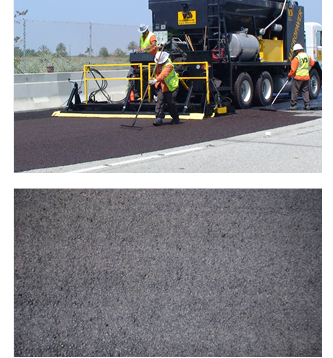

Slurry seal is a low-cost bituminous surface treatment used to seal the underlying surface from water infiltration, fill surface cracks and voids, and improve friction and appearance of an existing pavement.(24) Slurry seal is a mixture of emulsified asphalt, water, fine aggregate, and mineral filler that is mixed into a slurry and applied or screeded onto the pavement surface in a thin layer using squeegees or a spreader box (figure 9). Slurry seals do not provide any structural benefit to the pavement, but are a very cost-effective treatment for preserving the existing pavement surface, improving appearance, and restoring or enhancing friction.

Source: Ace Asphalt

Figure 9. Photo. Placement of a slurry seal (top) and surface texture of a cured slurry seal (bottom).37

Microsurfacing is a surface treatment very similar to slurry seal, but is typically a more durable treatment that is used for higher volume roadways. Like slurry seal, microsurfacing is a slurry mixture consisting of emulsified asphalt, water, fine aggregate, and mineral filler. Microsurfacing, however, typically uses a polymer-modified asphalt emulsion, which gives it more flexibility than a conventional asphalt binder. Microsurfacing is primarily used to mitigate raveling and oxidation of asphalt pavement surfaces, but also improves friction and appearance of both asphalt and concrete surfaces. Microsurfacing can be designed with larger aggregate for use in filling shallow to moderate depth ruts in asphalt pavement, and can also seal low-severity cracks.(31) Microsurfacing is applied in a similar manner to slurry seal, using a spreader box behind a slurry truck. (See figure 10.)

Sources: top: International Slurry Surfacing Association and VSS MacroPaver; bottom: Ace Asphalt

Figure 10. Photo. Microsurfacing placement (top) and surface texture of cured microsurface treatment (bottom).38,37

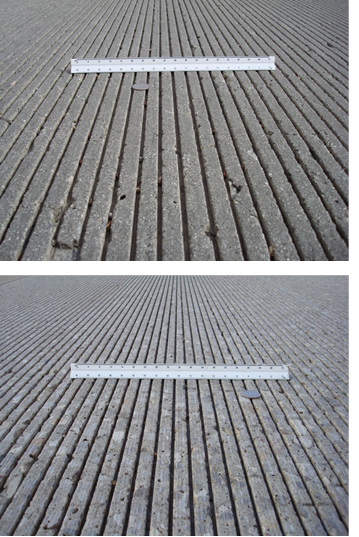

Diamond grinding is a process used to shave a thin layer (typically less than 0.25-inch) of the surface of pavements, primarily for improving ride quality, but also for restoring or improving skid resistance and reducing tire-pavement noise. Diamond grinding is performed using grinding equipment that uses a cutting head consisting of a stack of concrete cutting saw blades with diamond-encrusted teeth. The saw blades on the cutting head are spaced 0.08 to 0.10 inches apart, leaving shallow grooves in the pavement surface that provide macrotexture (figure 11). Although diamond grinding can be used to grind out localized roughness in asphalt pavements, it is most commonly used more for concrete pavements to mitigate slab curing and faulting at joints, and to restore surface texture.

Source: The Transtec Group, Inc.

Figure 11. Photo. Diamond ground concrete pavement surface.

Grooving is a treatment in which narrow grooves are sawcut into the pavement surface, typically in the direction of traffic, and typically 0.75-inches apart. (See figure 12.) The grooves increase pavement macrotexture, providing a path for bulk water drainage. Grooving is a surface treatment that can be used when it is undesirable to apply any topical treatment to the pavement surface (e.g., bituminous surface treatments) or to remove any of the pavement surface (e.g., milling or diamond grinding). Grooving effectively ensures a certain level of macrotexture regardless of how the pavement surface wears over time. Grooving is commonly used for airfield runways and bridge decks, but is becoming more common for highway pavements as well. Grooving is typically used on concrete pavements, but can also be done on asphalt. A surface treatment termed "Next Generation Concrete Surface," which combines diamond grinding and grooving was developed over the past decade and provides a standardized solution for grooving while also improving ride quality.(39)

Source: The Transtec Group, Inc.

Figure 12. Photo. Grooved concrete pavement surface (top) and Next Generation Concrete Surface (bottom).

Micro-milling is a surface treatment in which a milling head is used to remove a thin layer of the pavement surface. Unlike diamond grinding, in which the cutting head shaves or grinds the surface away, micro-milling is an impact technique in which the milling teeth effectively chip away the pavement surface. Micro-milling differs from conventional milling in that the cutting head uses teeth that are spaced closely together, leaving a much less aggressive surface texture than conventional milling (figure 13). Whereas milling is typically used to remove pavement in preparation for an overlay, micro-milling leaves a much less aggressive surface texture that can be opened to traffic as a final surface. Although this is a promising treatment for improving pavement friction, it was excluded from this effort because of its very limited usage to date.

Source: Pavia Systems

Figure 13. Photo. Micro-milled asphalt pavement surface.40

Shotblasting/abrading is a surface treatment in which steel pellets or "shot" are fired at the pavement surface at high velocity to pit or abrade away a superficial layer of the pavement surface (figure 14). Shotblasting removes any loose material from the surface and also pits the surface of the aggregates to improve microtexture. It is frequently used to remove rubber or oil deposits on the pavement surface. This treatment is commonly used by airports to remove rubber deposits on runways.

Source: The Transtec Group, Inc.

Figure 14. Photo. Shotblast asphalt pavement (top) and concrete pavement (bottom).

For roadways, this treatment is more commonly used for surface preparation prior to applying another surface treatment (e.g., HFS) to bridge decks or highway pavements. This treatment was ultimately excluded from consideration under this study because of the lack of highway treatment sites.

Cape seal is a surface treatment consisting of a chip seal followed by a slurry seal. After the chip seal is applied and cured, the slurry seal is used to cover the chip seal. The advantage of this treatment is that the chip seal seals and protects the underlying pavement, while the slurry seal helps to protect the chip seal, locking the chip seal aggregate in place to minimize chip/aggregate loss and providing a smoother final surface. Ultimately, this treatment was excluded from this study because of the limited number of States that use the treatment (and therefore the limited number of lane-mi), but also because the finished surface will be similar to that of a slurry seal or microsurface, which are already considered separately.

A scrub seal is a treatment in which a bituminous material (emulsion or asphalt binder) is literally scrubbed into the surface of a heavily cracked asphalt pavement using brushes (figure 15). A cover aggregate is then broadcast over the surface, in a similar manner to a chip seal. The scrubbing action helps to ensure the bituminous seal penetrates any cracks in the pavement surface to help preserve the asphalt and seal the surface from water infiltration through the cracks. This treatment is more suitable for heavily cracked asphalt pavements whose underlying pavement structure is still sound. Scrub seals were excluded from this study because of the limited number of lane-mi available for study, and also because the finished surface is effectively the same as a chip seal. Although it has slightly different applications, such as for more distressed pavement, the surface properties (texture and friction) should not differ significantly from a chip seal.

Source: FP2, Inc.

Figure 15. Photo. Emulsion material is scrubbed into the pavement surface for a scrub seal surface treatment.41

HFS is a specialty pavement treatment used specifically to restore or enhance friction. It is commonly used for spot treatments of curves, intersections, and steep grades where friction demand is higher than can be provided by conventional paving materials. HFS is installed by spreading a resin binder (epoxy, methacrylate, polyester, etc.) over the pavement surface followed by broadcasting or dropping a 1- to 3-mm abrasion and polish-resistant aggregate onto the resin (figure 16). Calcined bauxite, which exhibits exceptional polish resistance, is the most commonly used aggregate for HFS worldwide. However, similar aggregates that maintain excellent microtexture properties over time have also been used as the aggregate. Although a form of HFS has been used extensively for bridge decks and provides the additional benefit of sealing the bridge deck surface, it does not provide any documented preservation benefit for pavements. However, it is one of the treatments considered in this study that is typically used specifically as a safety improvement. Recognizing the safety benefit of HFS, FHWA recently deployed HFS as a focus technology under the Every Day Counts 2 program.(42)

Source: The Transtec Group, Inc.

Figure 16. Photo. Installation of HFS (top) and finished surfaces (bottom).

The properties of the various treatments considered under this study vary widely from State to State and project to project. Unfortunately, it was not possible to quantify these properties for each treatment site considered under this study for use in the statistical analysis. Although there is no codified typical friction value for any given treatment, some typical macrotexture depths for the various treatments are provided in table 3 . As discussed in chapter 2, several studies have documented the importance of pavement macrotexture (texture depth) and its effect on crash rates. Good friction, however, is not guaranteed by good macrotexture.

Table 3 . Typical macrotexture depth for various pavement treatments.

Pavement Treatment |

Typical Macrotexture Depth(3) |

|---|---|

Slurry Seal |

0.3 to 0.6 mm |

Thin Hot Mix Asphalt Overlay |

0.4 to 0.6 mm (Dense Graded) |

Microsurfacing |

0.5 to 1.0 mm |

Diamond Grinding |

0.7 to 1.2 mm |

Grooving |

0.9 to 1.4 mm |

Ultra-Thin Bonded Wearing Course (UTBWC) |

> 1.0 mm |

Chip Seal (various binder types) |

> 1.0 mm |

Open Graded Friction Course (OGFC) |

1.5 to 3.0 mm |

High Friction Surfacing (HFS) |

> 1.5 mm |