U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

R&T NOW This newsletter is an archived publication and may contain dated technical, contact, and link information. |

|

| Publication Number: Date: May/June 2017 |

Publication Date: May/June 2017

|

PDF files can be viewed with the Acrobat® Reader®

FHWA Participates in SCOR Meeting

FHWA’s Office of Research, Development, and Technology recently participated in a meeting held by the American Association of State Highway and Transportation Officials (AASHTO) Standing Committee on Research (SCOR). The committee reviewed the 2018 ballot of problem statements and selected final projects for the 2018 National Cooperative Highway Research Program (NCHRP). The total available for the 2018 program is estimated at $34 million. About 3,000 projects have been undertaken by NCHRP since 1962.

SCOR acts as AASHTO’s driving force for high-quality transportation research and innovation to improve the Nation’s mobility of people and goods. Its mission is to support AASHTO and the transportation community by delivering strategic, high-quality research results while addressing development, technology transfer, and implementation.

SCOR’s responsibilities are to:

For more information, contact Jack Jernigan, 202-493-3363, jack.jernigan@dot.gov.

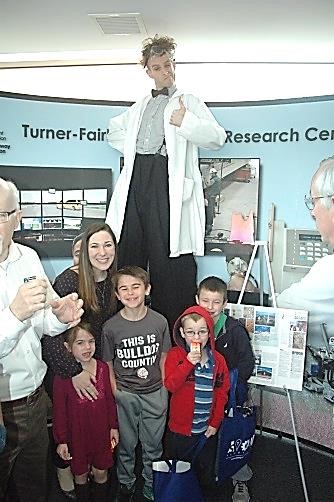

FHWA Takes Part in K-12 STEM Symposium

On March 25, 2017, staff from FHWA’s Turner-Fairbank Highway Research Center (TFHRC) participated in the 2017 K-12 STEM Symposium at The Nysmith School for the Gifted in Herndon, Virginia. The symposium provided an opportunity for children to discover new and exciting possibilities in the fields of science, technology, engineering, and mathematics (STEM) within the National Capital Region, including those with the U.S. Department of Transportation (USDOT) and FHWA.

|

| Students visiting TFHRC’s display learned about pavement and bridge engineering and connected vehicle technologies. |

Michael Trentacoste, FHWA’s Associate Administrator for Research, Development, and Technology, and about 10 other Federal staff employees from TFHRC and Eastern Federal Lands presented and displayed research and development technologies and discussed related activities. Activities for the day included hands-on experiences, such as student robotics teams, flight simulator competitions, three dimensional printers, and other science and mathematics exhibits.

Students visiting TFHRC’s display learned about pavement and bridge engineering and connected vehicle technologies. Attendees also received information about high school and college STEM internships in government and industry.

|

| Students discovered new and exciting possibilities in the STEM fields. |

Speakers at the symposium included Congressional Representative Barbara Comstock (R-VA 10th District), National Aeronautics and Space Administration Astronaut Lawrence J. DeLucas who discussed “STEM in Space,” and many other luminaries in technology and STEM education. Organizers of the event estimate that over 4,400 parents, students, and teachers attended.

For more information, contact Hiwot Abdi, 202-493-3999, hiwot.abdi@dot.gov.

Infravation Program Advances Research to Field Demonstrations

The Infravation Program, which stands for infrastructure plus innovation, is a cross-Atlantic research effort to advance innovative, near-market materials or processes that will make highway infrastructure last longer, perform more efficiently, and cost less. A cooperative research initiative between FHWA and the Forum of European Highway Research Laboratories (FEHRL), the program is moving promising research from the laboratory forward into field demonstrations. The Infravation Program has made nine awards that total about $11 million. Seven of the nine awards included U.S. research entities, which participated in conducting the research and gained access to the results.

FHWA is supporting attendance from State departments of transportation at field demonstrations to gain practitioner feedback on the viability of certain technologies and determine interest in additional technology development or demonstrations in the United States.

On May 3, 2017, in Tampa, FL, researchers held a demonstration on sustainable concrete using seawater, salt-contaminated aggregates, and non-corrosive reinforcement (SEACON). They demonstrated the safe utilization of seawater and salt-contaminated aggregates (natural or recycled) for a sustainable concrete production when combined with noncorrosive reinforcement to construct durable and economical concrete infrastructures.

In September 2017, in Atlanta, GA, researchers plan to demonstrate the integration of advanced remote sensing technologies, including terrestrial laser scanning, video, and photogrammetry to rapidly and accurately capture the state of a bridge. This project, called Semantic Enrichment Engine for Bridges (SEEBRIDGE), has the potential to advance work in intelligent construction technologies.

In Arizona, later this year (in November or December), researchers will demonstrate how to incorporate phase change materials for applications in concrete to improve concrete performance and durability. The project is called Enhancing Concrete Life in Infrastructure through Phase Change Systems (ECLIPS).

Visit https://www.fhwa.dot.gov/research/resources/infravation.cfm for more information, or contact David Kuehn, 202-493-3414, david.kuehn@dot.gov.

FHWA Utilizes TRL Scale and Assessment Process

Starting with FHWA’s Exploratory Advanced Research Program and extending to other parts of its portfolio in the Office of Research, Development, and Technology, FHWA is using a Technology Readiness Level (TRL) scale and assessment process for describing the maturity of highway research products. Based on a system originally developed by the National Aeronautics and Space Administration, TRL assessments document and communicate the maturity of research and suggest detailed steps that might advance the maturity of a given research product.

Visit https://www.fhwa.dot.gov/advancedresearch/trl_h.cfm for more information, or contact David Kuehn, 202-493-3414, david.kuehn@dot.gov.

FHWA’s Test Method for Lime Adopted as a Permanent Standard

AASHTO recently adopted a test method, referred to as T-362, to determine if the correct amount of lime has been added to hot mix asphalt. Developed by FHWA’s Chemistry Laboratory at the Turner-Fairbank Highway Research Center, T-362 is now a permanent standard test method. In 2008, AASHTO had given the test method provisional status under TP-72, which was titled, “Quantitative Determination of the Percentage of Lime in Hot Mix Asphalt.”

Asphalt pavements are made by mixing hot aggregate with molten asphalt, then placing the mixture and rolling it while it is still hot. Some States treat the aggregate with lime (calcium hydroxide) to improve the moisture resistance of the pavement. Whether the lime has been added to the mix or not has been an issue in the past. With T-362, State departments of transportation can now readily determine if the correct amount of lime has been added to the hot mix asphalt.

For more information, contact Terry Arnold, 202-493-3305, terry.arnold@dot.gov.

Report Covers Assessment of Weld Geometries for Bridge Decks

FHWA recently published the report, “Optimization of Rib-to-Deck Welds for Steel Orthotropic Bridge Decks” (FHWA-HRT-17-020), which documents fatigue testing results of full-scale geometries of various orthotropic rib-to-deck weld geometries. FHWA undertook this study to assess these weld geometries and potentially provide performance data that might alleviate restrictive fabrication specifications. Currently, these restrictions are reducing the competitiveness of orthotropic steel decks versus other alternatives.

Researchers explored such parameters as the welding process, weld penetration, and fit-up tolerance. When the project began, the current practice in the United States was to use a one-sided partial penetration weld joining the rib and deck plates together with a minimum of 80-percent penetration requirement. Melt-through and blow were also considered rejectable defects. Such restrictive requirements result in a very narrowly defined welding procedure with little tolerance for variation. In practice, this leads to numerous weld repairs and rigorous inspection requirements that drive up the cost of orthotropic deck fabrication.

Researchers found that the 80-percent penetration requirement can be significantly relaxed because fatigue performance was largely dictated by weld size and not penetration. A simple correlation is provided between weld size and penetration to guarantee AASHTO Category C fatigue performance that should provide for more relaxed fabrication specifications. Finally, specimens fabricated with purposeful fit-up gaps were found to close provided the original gap did not exceed 0.020 inch.

This report is expected to benefit those interested in the design and fabrication of steel orthotropic bridge decks, including State transportation departments, steel bridge fabricators, design consultants, and researchers.

This document is available to download at www.fhwa.dot.gov/publications/research/infrastructure/structures/bridge/17020/index.cfm.

For more information, contact Justin Ocel, 202-493-3080, justin.ocel@dot.gov.

Summary Report Examines Cracking in Jointed Plain Concrete Pavements

FHWA has published the summary report, “Analysis of Cracking in Jointed Plain Concrete Pavements” (FHWA-HRT-16-073), which discusses an investigation of the trends of longitudinal and transverse cracking in jointed concrete pavements based on Long-Term Pavement Performance (LTPP) Program Strategic Study of Structural Factors for Rigid Pavements (SPS-2) data. LTPP SPS-2 is an excellent resource for studying long-term performance of jointed concrete pavements because of the availability of data for pavement performance, material properties, environmental data, and traffic data.

Researchers identified the impacts of slab properties, base type, traffic volume, and environmental factors on the occurrence and extent of longitudinal and transverse cracking from a simple analysis of the raw cracking data. They selected SPS-2 sites in Arizona and Arkansas to investigate cracking mechanisms in detail, proposed a new hypothesis for the prevalence of premature cracking on these sites, and tested the hypothesis by numerical simulations.

Researchers found that longitudinal and transverse cracking were more sensitive to slab thickness and base type than other construction variables. Surface cracking was worse in dry climatic zones than wet zones. Most transverse cracks initiated from the slab edge close to the shoulder, and two forms of longitudinal cracks can initiate from transverse edges of slabs: a single long crack or multiple short cracks along the whole section. In addition to inadequate compaction of the base layers during construction and rehabilitation, the major contribution to premature longitudinal cracking appeared to be voiding beneath the outer edge of the pavement. This is caused by localized plastic deformation of “depressurized” soil, which occurs principally due to slab curl.

This document is available to download at www.fhwa.dot.gov/publications/research/infrastructure/pavements/ltpp/16073/index.cfm.

For more information, contact Deborah Walker, 202-493-3068, deborah.walker@dot.gov.

Talking Freight Webinar Focuses on Connected Trucks

On March 22, 2017, FHWA participated in a Talking Freight Webinar, which focused on connected trucks and related research and implementation initiatives. Osman Altan, who was one of the speakers and is a research transportation specialist at Turner-Fairbank Highway Research Center, provided an overview of TFHRC’s current truck-oriented vehicle-to-infrastructure and vehicle-to-vehicle research initiatives. The discussion focused on truck platooning and related topics, and how heavy vehicles adjust their speed profiles to traffic signal timings in real time to account for higher truck traffic volumes and reduced fuel consumption through intersections. Steve Boyd of Peloton Technology, who was also a speaker, discussed efforts to utilize vehicle-to-vehicle communications technology to increase the efficiency of truck platooning, help reduce fuel emissions, and enhance truck safety. Over 250 people attended the webinar.

For more information, contact Osman Altan, 202-493-3391, osman.altan@dot.gov.

AMCD Project Complete, Team to Present Results and Recommendations

The Advanced Messaging Concept Development (AMCD) project—which was led by FHWA’s Office of Operations Research and Development and the Intelligent Transportation Systems Joint Program Office and conducted by the Crash Avoidance Metrics Partnership consortium and the Virginia Tech Transportation Institute—is complete. In April, the research team provided a final project briefing. This innovative connected vehicle messaging project demonstrated new multivehicle data messaging (through infrastructure to vehicle and vehicle to infrastructure technology) and Transportation Management Center message transmission control strategies in real-world driving conditions for non-safety critical applications. The project team will present findings, lessons learned, and future research recommendations leading to early prototyping and deployment opportunities. The final results report will be available in July 2017.

For more information, contact Dale Thompson, 202-493-3270, dale.thompson@dot.gov.

Integrated Prototype Evolutionary Framework Project Discussed at Meeting

On May 15, 2017, FHWA’s Office of Operations Research and Development hosted a 1-day workshop focused on connected-automated vehicle (CAV) research. The event offered an opportunity to present the next evolution of cutting edge technology research currently underway at the Saxton Transportation Operations Laboratory, including a new endeavor called the CAV Integrated Prototype I – Evolutionary Framework. This framework is expected to serve as a visionary roadmap for CAV research and development over the next few years. Input from those who attended could shape the design of this framework and the direction of future connected-automation research.

Attendees included a large group of internal and external research partners and stakeholders. Senior technical staff from various modal administrations (such as the National Highway Traffic Safety Administration, Federal Motor Carrier Safety Administration, and Federal Transit Administration) engaged with external research partners (such as the U.S. Army Aberdeen Test Center, the Volpe Center, and the Saxton Transportation Operations Laboratory) to offer feedback and ideas on the evolutionary framework and architecture being developed. Research teams from the Saxton Laboratory, Volpe Center, and Aberdeen Test Center delivered presentations on CAV Integrated Prototype research and led technical discussions on various architectural topics.

For more information, contact Taylor Lochrane, 202-493-3293, taylor.lochrane@dot.gov.

FHWA Releases New Version of IHSDM

FHWA has released version 12.1.0 of the Interactive Highway Safety Design Model (IHSDM), a suite of software analysis tools for evaluating safety and operational effects of project-level geometric design decisions on highways. The new version includes revisions to the Policy Review Module to reflect revised controlling criteria for the design of projects on the National Highway System. Changes were also made in other areas, including improvements to the Crash Prediction Module and the Traffic Analysis Module. The software is available to download for free on the IHSDM Web site, www.ihsdm.org, which includes information related to case studies, past webinar materials, and frequently asked questions. IHSDM technical support is available via IHSDM.Support@dot.gov and 202-493-3407.

IHSDM, which supports the Data-Driven Safety Analysis initiative that is part of FHWA’s Every Day Counts 3 efforts, includes six evaluation modules applicable to rural two-lane highways: crash prediction, design consistency, intersection review, policy review, traffic analysis, and driver/vehicle. The crash prediction module serves as a faithful implementation of AASHTO’s Highway Safety Manual, Part C: Predictive Methods. The module deals with two-lane rural highways, multilane rural highways, urban and suburban arterials, freeways and ramps/interchanges.

For more information, contact Abdul Zineddin, 202-493-3288, abdul.zineddin@dot.gov.

Meeting Covers Early Findings in Using SHRP2 Safety Databases

Representatives from FHWA, AASHTO’s Second Strategic Highway Research Program (SHRP2) Safety Task Force, the National Highway Traffic Safety Administration, and the Transportation Research Board gathered at the National Highway Institute in Arlington, Virginia to hear about progress in the second phase of the “Concept to Countermeasure—Research to Deployment Using the SHRP2 Safety Databases” research effort. Nine teams participating in this effort delivered presentations on early research findings.

The presentations showed potential for future new or improved safety countermeasures, driver education efforts, and enforcement strategies in eight critical safety areas based on insights gained in using the SHRP2 Naturalistic Driving Study (NDS). Examples of critical safety areas include, work zones, pedestrian crossings, and lighting and weather impacts on drivers. Because of contractual and funding logistics, FHWA will need to determine which teams will advance to Phase 3 and the amount of funding that will be awarded to each before most of the Phase 2 research is completed. The ultimate goal is to use the innovative SHRP2 NDS and Roadway Information Database to improve our understanding of human behavioral components of safety, resulting in implementable countermeasures that improve safety performance.

For more information contact Aladdin Barkawi, 202-493-3312, aladdin.barkawi@dot.gov.

Public Roads—March/April 2017

This issue includes: Providing a Shoulder to Drive On; The Times They Are Definitely Changing; Doubling Down on Safety Innovations; States Learning From Each Other; Onward and Upward; and Working Smarter, Together.

It is available online via www.fhwa.dot.gov/publications/publicroads/17marapr/index.cfm.

For more information, contact Lisa Shuler, lisa.a.shuler@dot.gov.

Innovator: Accelerating Innovation for the American Driving Experience—May/June 2017

This issue includes: Making Transportation Safer for Every Pedestrian; Innovation Makes Rapid Work of Minnesota Bridge Project; Taking Data-Driven Safety Analysis to the Local Level; Incentive Funds Help States Standardize Innovations; Summit Showcases e-Construction Benefits; States Innovate!; and Events.

The issue is available online via www.fhwa.dot.gov/innovation/innovator/issue60/3dIssue/.

For more information, contact Nichole Causey, nichole.causey@dot.gov.

Turner-Fairbank Highway Research Center: www.fhwa.dot.gov/research/tfhrc/

Resource Center: www.fhwa.dot.gov/resourcecenter/

National Highway Institute: www.nhi.fhwa.dot.gov/home.aspx

Please forward this newsletter to others you think might find it interesting and/or useful.

Suggestions may be submitted to: FHWA_Now@fhwa.dot.gov