U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

Research & Technology Transporter This newsletter is an archived publication and may contain dated technical, contact, and link information. |

|

| Publication Number: N/A Date: December 2003 |

Publication Date: December 2003

|

In the early 1990s, transportation engineers recognized that specifications for steel curved girder bridges were based on testing performed in the 1970s. Design and construction experience had shown that the outdated specifications could result in overly conservative bridge designs. In addition, the specifications were not compatible with the load and resistance factor design code that the American Association of State Highway and Transportation Officials (AASHTO) had developed to provide more uniform levels of safety in the design of steel bridges.

In 1994, the Federal Highway Administration (FHWA) launched a major long-term project to produce data for a new design code to increase safety and reduce the construction costs associated with curved girder bridges. The final phase of the project currently is underway. Researchers in FHWA’s Structures Laboratory at the Turner-Fairbank Highway Research Center in McLean, VA, are conducting the largest-ever indoor test on a curved girder bridge. After testing is complete, AASHTO will use the data to develop new design specifications.

The goal of the final test is to determine the ultimate strength and safety factors for a complete curved girder bridge system. FHWA is conducting the test on a full-scale bridge made of three curved girders with a 203-millimeter (8-inch)-thick, cast-in-place concrete deck. Researchers will apply loads to the bridge to simulate the weight of an overloaded truck. Once a load causes the bridge to fail, they will use information about the failure to determine the bridge’s maximum capacity.

The researchers are using a state-of-the-art computer simulation model to generate thousands of data points on how the loads affect the bridge components. According to FHWA’s Office of Infrastructure Research and Development, the model is the most extensive instrumentation ever performed for a bridge test, and will enable researchers to analyze real-time data as they apply the loads.

|

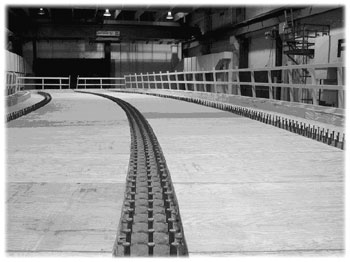

| The plywood deck is ready for rebar placement. Welded studs on top of the three girders provide the connection between the girders and the concrete deck. |

|

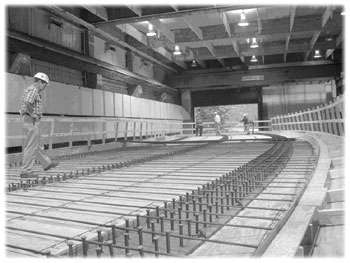

| Reinforcing steel is placed before the concrete deck is poured. |

Prior to the latest round of testing, researchers conducted 16 additional tests to quantify the strength of the curved girder components. They studied the effects of shear loading—the stress resulting from friction between parts of the girder—bending, and a combination of shear loading and bending. The researchers also investigated construction issues associated with bridges with horizontally curved steel girders.

By June 2004, AASHTO plans to use the data from FHWA’s tests to develop updated design specifications for steel bridges. Developing the new specifications is an essential step toward meeting FHWA and AASHTO’s goal of all States using the new design code by 2007 for bridges constructed with Federal-aid funds.

Bill Wright 202–493–3053 bill.wright@fhwa.dot.gov

Researchers developing new technologies and methods to build stronger and more durable bridges and highway structures face the challenge of delivering those technologies to engineers at State and local transportation agencies and in private industry. In the past, the lack of a centralized location where bridge developers, engineers, and researchers could access expertise and technical assistance on bridge technologies added to the problem.

To facilitate the delivery of these new technologies, the Federal Highway Administration (FHWA) recently created six Bridge Program Technology Deployment Teams. Under the leadership of FHWA’s Office of Bridge Technology and the structures technical service team at FHWA’s Resource Center, the teams include experts from FHWA headquarters in Washington, DC, the Resource Center, Turner-Fairbank Highway Research Center, and the Federal Lands Highway Program. The teams will leverage resources from each office to help the FHWA Division Offices and State and local transportation agencies identify the best ready-to-use technologies, and effectively deploy them in the field.

In August 2003, the teams met for the first time in Baltimore, MD. More than 25 engineers began working on action plans for deploying technologies in six focus areas: high-performance steel, high-performance concrete, load and resistance factor design, bridge management and inspection, bridge and tunnel safety and security, and accelerated construction/prefabricated bridge components. When complete, each plan will follow a standard template, providing a systematic and uniform approach to identifying and deploying bridge technologies effectively. The plans will describe the various products available to assist with deployment, such as manuals, CD-ROMs, and specifications. In addition, the plans will outline opportunities for outreach to State highway agencies and other technology users through workshops, conference presentations, and publications. The plans also will identify team members who can provide assistance and training to State agencies.

|

| FHWA's new Bridge Technology Deployment Teams will create action plans for delivering technology and technical assistance to State highway agencies responsible for developing and managing bridges. |

The team dealing with load and resistance factor design, for example, is working on plans to help States adopt a new specification that will improve the safety and reliability of bridge structures by applying statistically determined factors to the design. The teams focusing on high-performance concrete and steel are developing plans to promote the benefits of using these new materials to build stronger, longer-lasting bridges.

FHWA will post the completed plans in a searchable database on the Web at www.fhwa.dot.gov/bridge. By consolidating information on technologies and training resources in one location on the Internet, FHWA will help engineers save time and resources when

Ian Friedland 202–366–6712 ian.friedland@fhwa.dot.gov

Shoukry Elnahal 410–962–2362 shoukry.elnahal@fhwa.dot.gov

Well-designed drainage systems for roadways in urban areas can use a combination of drainage structures to intercept surface runoff, which can help prevent storm-related safety hazards and infrastructure damage. Without such drainage systems, rain or snow can reduce pavement friction, obstruct driver visibility, decrease roadway capacity, and increase the risk of crashes if drivers lose directional control over their vehicles. In addition, excess surface water can flood underpasses and damage roadbeds. In the United States, decades of research have led to the development of state-of-the-art drainage system designs and guidance, which greatly enhance the safety of the Nation’s highways. These advances are of interest in other countries with less developed urban drainage systems.

In August 2003, Jorge Pagán, a senior hydraulics engineer at the Federal Highway Administration (FHWA), traveled to Uruguay to present the latest practices in the design of urban drainage systems. FHWA’s Office of Bridge Technology and the Office of International Programs’ Pan American Institute of Highways, and the Association of Highways of Uruguay sponsored the trip.

While in Uruguay, Pagán taught a modified version of the National Highway Institute’s course on urban drainage design to approximately 40 highway engineers. Using interactive lectures, videos, and problem-solving sessions, he also covered the key concepts presented in FHWA’s Hydraulic Engineering Circular No. 22 (HEC-22), titled “Urban Drainage Design Manual.”

Pagán reviewed hydrologic definitions and concepts, and mathematical equations for estimating surface runoff for a range of storm frequencies, gutter flows, and water depths at curbs. He also discussed the interception capacity and efficiency of different types of grate inlets, and other drainage structures for intercepting runoff from pavement surfaces. In addition, Pagán referenced guidance issued by the American Association of State Highway and Transportation Officials for selecting the design frequency of a storm event and the design spread of runoff on pavement surfaces based on the road classification and its design speed.

Pagán also explained the criteria for selecting grate inlets, and taught participants how to optimize an urban drainage system based on the placement, location, and orientation of grate inlets. For example, the space between grate inlets should be based on the pavement drainage area that will be contributing runoff into the urban water system. Another good practice is to place grate inlets just beyond intersections, rather than directly at them, to avoid inconvenience, hazards, and nuisances at pedestrian crossings. Likewise, parallel grate inlets with narrowly spaced bars are efficient drainage structures for intercepting pavement surface runoff. However, they may be susceptible to clogging, while those with widely spaced bars may cause injury for pedestrians or bicyclists. To maximize efficiency and safety, the bars of parallel grate inlets should orient parallel to gutter flow with lateral or transverse rods.

For more information on FHWA’s Hydraulic Engineering Circular No. 22 on “Urban Drainage Design,” visit http://199.79.179.19/OLPFiles/FHWA/010593.pdf.

Jorge Pagán 202-366-4604 jorge.pagan@fhwa.dot.gov

Until a few years ago, many computer programs ran on the disk operating system (DOS), which required users to enter data through a series of command prompts. Today, most programs function through more user-friendly systems that enable users to spend less time entering commands and more time simply pointing and clicking. Programs that model air quality, however, have not kept pace, and DOS continues to make the task of simulating airflow and pollution near highways a challenging one.

To make the jobs of transportation professionals easier, the Air Quality Technical Service Team at the Federal Highway Administration (FHWA) Resource Center is designing a new, easy-to-use interface for two air quality models—the U.S. Environmental Protection Agency’s (EPA) California Line Source Dispersion Model (CALINE3) for freeways and the CAL3QHC model for signalized intersections. With the new interface, the models will run on the Microsoft® Windows® operating system, and will include interactive graphical forms for entering data.

To operate the new interface, the user starts by entering input control data, such as the title of the job, and selects which of the two models to run. Next, the user chooses one of three data-input options that FHWA included in the new interface to extend the functionality of CALINE3 and CAL3QHC. Depending on the available data and the goal of the project, the user can enter all of the required data, use EPA-recommended default data, or enter all the data except the location-specific mobile source emission factor.

|

| The interface for entering input control data. |

The next step involves choosing the most representative freeway or intersection configuration from a list of predefined layouts. After that, the user enters any additional information, such as the location of the site to be analyzed and meteorological data, into three other input screens. Finally, the user clicks on the “Run” and “Results” icons to execute the model and see the results, which are displayed on a summary table that the user can print or save.

At the bottom of each input screen, the interface includes instructions to assist new users. The screens also contain a status “dashboard” to remind the user of the options they selected and the data entered.

Although the new interface is still under development, FHWA soon will conduct a second round of reviews. Once complete, FHWA will distribute the interface to air quality modeling practitioners and researchers at State departments of transportation and metropolitan planning organizations.

For more information, contact:

Michael Claggett 303–716–2284 michael.claggett@fhwa.dot.gov

In 2001, nearly 220,000 crashes occurred as a result of drivers running red lights at intersections. These crashes led to approximately 900 fatalities and 180,000 injuries, and cost the Nation’s economy more than $12 billion. Overall, a staggering 55.8 percent of Americans admit to running red lights, while 96 percent of drivers report fearing that motorists who run red lights will strike them at intersections.

To improve safety and raise awareness about the dangers, the Federal Highway Administration (FHWA), the American Trauma Society, and the Institute of Transportation Engineers sponsored the sixth annual National Stop on Red Week in the fall of 2003. During the week-long event, communities across the country raised awareness of the hazards of running red lights through press conferences, increased enforcement, distribution of educational materials, and other activities.

Throughout the week, for example, Louisiana State Police Troop I intensified its enforcement of the red light and stop sign laws. During the first day of the enforcement period, the police troop issued 58 traffic citations for red light violations alone. In Ithaca, NY, police at Cornell University set up extra traffic patrols at all stop signs and stop lights on campus. During the patrols, the police issued 158 citations for various traffic violations.

|

| Participants in National Stop on Red Week helped raise awareness of the hazards of running red lights at intersections, such as the one shown here. |

In addition to the events held during National Stop on Red Week, several partnerships are working continually to help educate citizens about the dangers of red light running and implement strategies to reduce preventable deaths and injuries. In California, the Sacramento County Red Light Safety Program—a partnership between the Sacramento County Sheriff’s Department, the California Highway Patrol, and Sacramento County Traffic Engineering—has reduced red light collisions dramatically since the partnership started using a photo enforcement system. Since the program’s inception in 2001, the system has photographed 42,323 red light violations, and law enforcement agencies have issued 15,954 citations. As part of its participation in the national campaign, Sacramento County added red light photo enforcement to two new intersections and camera equipment to capture the numbers on rear license plates.

In addition, FHWA, the American Trauma Society, the Institute of Transportation Engineers, and several other organizations, including the National Highway Traffic Safety Administration and the National Cooperative Highway Research Program, are developing materials that will provide guidance, support, and assistance to local communities. Materials on engineering, education, enforcement, and emergency response and care will help encourage drivers to avoid running red lights.

National Stop on Red Week is part of FHWA’s Stop Red Light Running Program, which provides technical and program support for local initiatives. For more information, visit http://safety.fhwa.dot.gov/intersection/redlight/srlr/.

Lori Irving 202-366-0660 lori.irving@fhwa.dot.gov

TaMara McCrae 202-366-4021 tamara.mccrae@fhwa.dot.gov

Hari Kalla 202-366-5915 hari.kalla@fhwa.dot.gov

The key to building roads that are cost-effective and durable is an understanding of why some pavements perform better than others. To collect data and improve understanding, the Federal Highway Administration (FHWA), in partnership with various transportation agencies in Canada and the United States, formed the Long-Term Pavement Performance (LTPP) program. Since 1987, researchers for the LTPP program have been conducting the largest and most comprehensive pavement performance test in history. The test, which is ongoing, uses data from rigorous, long-term experiments that monitor pavements in Canada and the United States made from asphalt and portland cement concrete. However, collecting data for the LTPP program is challenging because many of the agencies providing the necessary information do not use consistent testing methods or uniform language to describe pavements.

Recently, FHWA published the fourth revised edition of the Distress Identification Manual for the Long-Term Pavement Performance Program (FHWA-RD-03-031), which provides a consistent, uniform basis for collecting distress data for the LTPP program. The manual also serves as a dictionary of terminology that members of the pavement community, such as officials at highway agencies, airports, and parking facilities, can use to improve communications by fostering more uniform and consistent definitions of terms related to pavement distress.

|

| The Distress Identification Manual for the Long-Term Pavement Performance Program will help the LTPP Program and other members of the pavement community collect data and evaluate pavement distresses. |

The manual describes how to conduct distress surveys for the LTPP program, ranging from obtaining faulting data on portland cement concrete pavements to measuring the cracks in asphalt concrete. Sample forms for recording and reporting the data are included. In addition, the manual contains standardized language for describing cracks, potholes, rutting, and other distresses monitored by the LTPP program. Color photographs and drawings illustrate the distresses found in three types of pavement surfaces—asphalt concrete, jointed portland cement concrete, and continuously reinforced concrete. Drawings illustrating various types of distresses provide a reference for assessing their severity. The manual also outlines methods for measuring the size of distresses and assigning severity levels, and explains how to calibrate and operate measurement devices, including the digital faultmeters used to measure joint faulting in concrete.

In addition to the LTPP program and members of the pavement community, colleges and universities also use the manual as a training tool in highway engineering courses. State highway agencies use it in their pavement management programs as a tool for identifying specific problems and planning repairs efficiently, thus saving both time and money.

The manual is available online at https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/ltpp/reports/03031/index.cfm, and in print from the Research and Technology Product Distribution Center at report.center@dot.gov.

Aramis López 202–493–3143 aramis.lopez@fhwa.dot.gov

The average age of highway bridges in the United States is more than 40 years old, and most of them were designed with an estimated lifespan of 50 years. More than 25 percent of the nearly 600,000 highway structures listed in the National Bridge Inventory are classified as structurally or functionally deficient and require major repair, rehabilitation, or reconstruction. Compounding the problem is the fact that while the infrastructure continues to age, the volume of traffic that highway structures must accommodate increases each year. To preserve these critical links in the highway system, transportation engineers need strategies and techniques that are cost-effective and easy to implement.

In October 2003, representatives from the Federal Highway Administration (FHWA), consulting firms, and academia, and engineers from other Federal and State agencies, traveled to Tsukuba, Japan, for the 19th annual U.S.–Japan Bridge Engineering Workshop. Organized by the U.S.–Japan Cooperative Program in Natural Resources, the workshop enables transportation professionals from the United States and Japan to meet peers facing similar challenges and to share information, technologies, and techniques for designing, maintaining, and preserving bridges.

Much of the 2.5-day workshop, and subsequent 3-day tour, focused on several ongoing projects in Japan, such as a study to examine the corrosion-resistant steel bridges along Japan’s Muroran Shindo (National Highway 36). Used as a bypass to relieve traffic congestion in Muroran City, the highway includes eight bridges made of more than 7,076 metric tons (7,800 tons) of corrosion-resistant steel. The Japanese development agency performing the study evaluated the bridges for corrosion caused by several factors, such as windborne sea salt and smoke from industrial factories in the area. The study found mild corrosion on some bridges due to water leakage from the expansion joint and deck. On other bridges, researchers found more serious corrosion, which they suspect is caused by rainwater or runoff that collects at connected sections.

A representative from FHWA’s Office of Bridge Technology discussed several priority areas for research and technology development in the United States—accelerated repair and construction technologies, bridge and tunnel security, preservation of the bridge system, and implementation of load and resistance factor design. He explained that using accelerated repair and construction technologies, maintenance crews can restore bridges in less time and for a lower cost, minimizing the impact on travelers and making the best use of limited financial resources. These technologies also can improve the long-term performance of the bridges, which in turn reduces future maintenance costs.

|

| Representatives from FHWA, and the California, Florida, and New Jersey Departments of Transportation are seen here visiting the Ko-Men Bridge in Japan. |

High-performance concrete and steel, for example, generally weigh less, are easier to weld, and are less susceptible to degradation or cracking than traditional bridge materials. Prefabricated bridge elements, such as bridge caps and deck panels, represent another example of technologies that can accelerate repairs. Manufacturers can assemble prefabricated elements at remote locations and deliver them to construction sites, ready to install. Since the pieces are constructed away from the roadway, prefabricated bridge elements reduce the need for detours and lane closures.

Workshop participants also visited several landmark bridges in Japan, including Tatara Bridge—the world’s longest cable-stayed structure—which links the islands of Honshu and Shikoku. They also visited the all-timber Kintai Bridge, which originally was constructed more than 330 years ago.

At the conclusion of the workshop, participants passed a resolution reaffirming the value of the event and committing support to hold another workshop in 2004. Because the United States and Japan alternate hosting the workshop, FHWA currently is working with officials in Japan to identify a host city in the United States for the event next year.

For more information contact:

Ian M. Friedland 202–366–6712 ian.friedland@fhwa.dot.gov

W. Phillip Yen 202–493–3056 wen-huei.yen@fhwa.dot.gov

Decisions by transportation agencies about whether to repave a highway or build a new bridge involve a complex web of considerations, including the time horizon, economic and engineering factors, and the existing range of assets. Using increasingly powerful computer systems, agency personnel now can assess the tradeoffs among alternative investment options by performing sophisticated analyses of their assets. By evaluating how they manage their infrastructure, transportation officials can make more informed decisions about future investments.

In 1999, the Federal Highway Administration (FHWA) established the Office of Asset Management, affirming its commitment to helping the Nation’s transportation agencies manage their assets more effectively. To fulfill this commitment, FHWA’s National Highway Institute (NHI) is offering a new course—Transportation Asset Management (#131106). The 1-day course targets senior-level executives and managers from different functional lines and units, such as planning, engineering, capital programming, financial management, maintenance and operations, traffic and safety, system operation and management, and information technology. Instructors will introduce attendees to the concepts and principles of asset management through examples of techniques currently used in transportation agencies.

During the course, participants apply lessons from the Transportation Asset Management Guide (NCHRP Project 20-24(11)), recently published by the National Cooperative Highway Research Program. The guide defines asset management, describes state-of-the-art practices, and provides examples of effective practices in four functional areas—policy development; planning and programming; program delivery; and information, analysis, and performance monitoring. A noteworthy feature is the guide’s self-assessment tool, which agencies can use to characterize their existing practices and identify specific opportunities for improvement.

The interactive course combines presentations with class discussions and exercises, including a session devoted specifically to the self assessment. Participants also take part in an exercise that involves helping a hypothetical State transportation agency allocate resources and manage its assets under budget constraints.

Using the self-assessment tool, exercises, and real-world examples, participants learn how to organize their thoughts on managing assets, structure an agenda for detailed planning, and develop consensus among top-level managers on the strengths of the agency and areas that require improvement.

For more information, visit NHI’s Web site at www.nhi.fhwa.dot.gov/home.aspx or contact Ewa Flom at 703–235–0524 or ewa.flom@fhwa.dot.gov.

Nancy Stout 703–235–1260 nancy.stout@fhwa.dot.gov