U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

Research & Technology Transporter This newsletter is an archived publication and may contain dated technical, contact, and link information. |

|

| Publication Number: N/A Date: August 2005 |

Publication Date: August 2005

|

When engineers design highways and bridges, they must balance several tasks. In addition to solving transportation problems and addressing the public's travel demands, they must develop a safe and efficient highway system, and meet design guidelines and regulations. The choices that designers make are important because each decision can affect the cost of a project and the overall budget available for other transportation projects.

The Missouri Department of Transportation (MoDOT) recently launched an initiative that addresses the choices facing designers when they are planning highway and bridge construction projects. Under a new concept called Practical Design, MoDOT engineers are striving to build the most efficient solutions to transportation problems instead of routinely applying generic design standards across the board. As a result of the initiative, MoDOT expects to save nearly $400 million over the next 5 years. MoDOT unveiled the design concept and project savings at a June 2005 meeting of the Missouri Highways and Transportation Commission.

Missouri's Practical Design initiative began last winter when staff members from the Federal Highway Administration's (FHWA) Missouri Division were invited to participate in discussions with MoDOT engineering and district staff on the concept. Using the Practical Design concept, MoDOT will begin customizing projects to include only what is essential to address a project's purpose and need while modifying those project features that might be desirable but not necessary. At the winter meeting, FHWA staff expressed their support for MoDOT's efforts to apply a commonsense approach to designs for State roads.

|

| These two drawings illustrate the difference between traditional design and Practical Design. The illustration on top shows the original design for Route 54 in Camden County, MO, with four travel lanes, a full median and retaining walls. The bottom illustration shows the "Practical Design," with four travel lanes, a concrete barrier and rock slope stabilization. |

To implement the Practical Design concept, MoDOT officials challenged engineers in the State's 10 district offices to re-evaluate construction projects planned for the next 5 years and to determine whether they were proposing a "more-is-better" design when a more efficient solution would suffice. To provide incentives, MoDOT permitted the districts to keep any savings and transfer them into additional projects. As a result, district engineers cut almost $400 million from estimated construction costs over the 5-year period. Without the implementation of Practical Design, the State would have needed the equivalent of a 3-cent increase in the gasoline sales tax to raise the same amount of additional revenue.

One example of the Practical Design approach is an updated plan to build a new section of Route 54 in Camden County, MO. The original plan required an estimated $136.5 million for the four-lane divided highway, while the revised design will cost $99 million, saving $37.5 million. Savings will come from using a concrete barrier between the northbound and southbound lanes instead of a grassy median and substituting rock slopes for some of the retaining walls included in the original design.

Over the next year, MoDOT plans to revise its design manual and instructions to consultants to institutionalize the Practical Design approach into its business practices. For more information, contact:

Mary Ridgeway 573-638-2616 mary.ridgeway@fhwa.dot.gov

The Federal Highway Administration (FHWA) has established that the load and resistance factor design (LRFD) specifications for highway bridges, issued by the American Association of State Highway and Transportation Officials (AASHTO), shall be used on all new bridge designs after October 2007. Because LRFD specifications are probability-based and incorporate working stress design and load factor design (LFD) while accounting for "extreme events" like ship collisions and earthquakes, they can help produce more reliable structures. Because of its applicability across disciplines, this comprehensive set of specifications also can help improve communication between structural and geotechnical specialists.

To date, some States have adopted the new LRFD specifications to varying degrees, while others are designing bridges exclusively in accordance with the traditional standard specifications. To help States obtain the practical and hands-on technical training needed for their transition to an LRFD platform, FHWA's Office of Bridge Technology and the National Highway Institute (NHI) are introducing a new course, LRFD for Highway Bridge Substructures and Earth Retaining Structures (#130082A).

Since no national consensus exists on the design of bridges and structures, States follow either the allowable stress or the LFD platforms. NHI's course strives to unify the Nation's design approach by presenting all participants with the most up-to-date guidance, including a proposed specification rewrite for structural foundations.

As a replacement for the former NHI course, LRFD for Highway Bridge Substructures (#13068), the new course also covers current national practices and procedures for structural design, along with geotechnical design and foundation engineering. Upon completion of the course, participants should be able to:

The LFRD course targets a variety of infrastructure specialists, including mid-level bridge and geotechnical journeymen and design engineers. The course also can accommodate entry-level designers with LRFD experience and experienced designers who have worked with allowable stress design or LFD but not LRFD.

The new course will help address any concerns that the LRFD transition could be complex, difficult, and costly, or result in designs that are either too conservative or not conservative enough. Two experienced instructors deliver each course installment in an onsite classroom format.

To schedule this course, contact the NHI Training Coordinator at 703-235-0500 or nhitraining@fhwa.dot.gov. For additional information, visit www.nhi.fhwa.dot.gov or contact:

Jerry A. DiMaggio 202-366-1569 jerry.dimaggio@fhwa.dot.gov

On April 1, 2005, the U.S. Department of Transportation (USDOT) Secretary Norman Y. Mineta announced the launch of the "Be Ready. Be Buckled." campaign to promote the use of safety belts by truck drivers. The new campaign responds to the low number of truck drivers who buckle up and the possible severe consequences to those who fail to use safety belts. A 2003 study by USDOT found that only 48 percent of all truck drivers used their safety belts compared to 80 percent of passenger vehicle drivers. The study also showed that of the 620 truckers killed in crashes in that year, more than half were not wearing safety belts. In addition, nearly 80 percent of the 171 truckers who were ejected from their trucks in crashes were not wearing safety belts.

At the launch of the "Be Ready. Be Buckled." campaign, Federal Motor Carrier Safety Administration (FMCSA) Administrator Annette M. Sandberg told drivers, "Commercial drivers already have a life-saving piece of equipment in their vehicles-safety belts. [Safety belts] help ensure you remain securely in your seat, do your job safely, and return home to the ones you love."

The campaign is part of an out-reach effort by the Commercial Motor Vehicle Safety Belt Partnership, created by Secretary Mineta, which focuses on educating the more than six million working drivers of large trucks and buses about the critical importance of wearing a safety belt. Members of the partnership include USDOT, truckers, trucking companies, shippers, law enforcement agencies, and truck stop operators.

|

| The "Be Ready. Be Buckled." campaign logo. |

Since 2003, FMCSA and the partnership have worked together diligently to determine the reasons why many truck drivers do not use their safety belts and to identify actions that motor carriers can take to encourage safety belt use. With the endorsement of the partnership and funding from FMCSA, for example, the Transportation Research Board (TRB) conducted a literature review, surveyed truck drivers and safety managers, held structured interviews, and conducted focus groups to learn more about the attitudes of commercial motor vehicle (CMV) drivers toward safety belt use.

The researchers determined that drivers had several objections, including poor fit or comfort, personal choice, and general dislike. The researchers also identified several reasons why some CMV drivers do choose to use safety belts, including concern for safety, legal or company requirements, personal habit, or personal experience in or observation of crashes.

In addition, the researchers identified several methods used by safety managers to promote safety belt use, such as observing whether drivers use the belts while on duty, providing rewards or recognition for observed use, and punishing or reprimanding drivers for not wearing their belts. According to the TRB study, safety managers tend to use multiple approaches to encourage the use of belts, with the highest rated method being industry and government programs showing vehicle crash tests using test dummies with and without their safety belts.

To spread the safety belt message, the partnership has reached out to the media, especially SIRIUS Satellite Radio and XM Satellite Radio, resulting in the production of programs encouraging safety belt use. TransCoreTM, an information services company, also displays safety belt use messages hourly on its load monitoring systems located in truck stops throughout the country.

For more information, visit www.fmcsa.dot.gov/safetybelt or contact:

Janet Kumer 202-493-0538 janet.kumer@fmcsa.dot.gov

Between 1975 and 2000, safety belts prevented 135,000 fatalities and 3.8 million injuries, according to the National Highway Traffic Safety Administration (NHTSA). Despite the effectiveness of safety belts in preventing fatalities and injuries, 56 percent of the occupants of passenger vehicles killed in crashes in 2003 were not wearing the restraints, according to NHTSA. Because of statistics like these, Secretary of Transportation Norman Y. Mineta has declared highway fatalities a national epidemic and encourages all drivers and passengers to view wearing safety belts as a form of preventive medicine.

To increase safety belt use, NHTSA recently launched the Click It or Ticket campaign with the support of the Federal Highway Administration. Supported by numerous government agencies, schools, community organizations, and other groups, this highly visible campaign combines active law enforcement with paid advertising. To draw attention to the campaign, law enforcement agencies and media outlets across the Nation recently participated in a weeklong event known as the Click It or Ticket Mobilization.

During the mobilization, State and local law enforcement officers ticketed unbelted drivers and passengers, while the media ran advertisements and stories about the campaign. The goal was not to give out tickets, but to influence drivers and passengers to use their safety belts. Research shows that the certainty of receiving a ticket and costly fine often convinces people to use their safety belts. During the mobilization, more than 12,000 law enforcement agencies in all 50 States, the District of Columbia, and Puerto Rico conducted safety belt checkpoints and other activities.

In addition to assisting with the mobilization, NHTSA helped States implement other aspects of the Click It or Ticket program and aided local law enforcement agencies in conducting their own intensive, high-publicity campaigns to promote the use of safety belts. In the spring of 2005, for example, staff from the Alaska Highway Safety Office and NHTSA's Northwest Regional office helped officials post more than 100 road signs with the message, "Seat Belts Must Be Worn In Alaska-Click It or Ticket," at locations throughout the State. The road sign initiative was one component of Alaska's comprehensive safety belt enforcement effort, which began with the mobilization and continued for 11 weeks.

|

| Members of Alaska's law enforcement community, shown here, met at the inaugural Click It or Ticket summit earlier this year to discuss plans to increase belt use to 90 percent in Alaska by the end of 2005. Participants at the summit represented 19 police agencies and 95 percent of the State's population. |

In addition, key members of Alaska's law enforcement community gathered in Anchorage earlier in 2005 to attend the inaugural Click It or Ticket summit, which focused on implementing the sign initiative and other elements of Alaska's ambitious plan to boost seat belt use. At the summit's conclusion, participants established a shared goal of increasing belt use to 90 percent in Alaska by the end of 2005, which would bring the State's use to the same level as other States on the West Coast.

For more information on Alaska's Click It or Ticket plan, contact Lorie Dankers, NHTSA regional program manager for Alaska at 206-220-7640. For more information on the Click It or Ticket campaign, contact:

Philip Gulak, NHTSA Occupant Protection Division 202-366-2725 philip.gulak@nhtsa.dot.gov

John Balser 202-366-9212 john.balser@fhwa.dot.gov

State and local transportation agencies are turning increasingly to intelligent transportation systems (ITS) to boost the efficiency of the Nation's transportation network and reduce congestion. Although implementing just one or two ITS technologies in a transportation corridor can be useful, widespread deployment throughout an entire corridor or urban area is even more effective because the technologies can work together. For this reason, the U.S. Department of Transportation (USDOT) and many local agencies are encouraging the deployment of comprehensive ITS networks. Financial constraints and technical and institutional barriers, however, have impeded full deployment in many metropolitan areas. Because few areas have implemented entire networks, most recent analyses and evaluations of ITS deployments focused only on the benefits of single ITS technologies, rather than those of entire ITS networks.

|

| FHWA's new report, Benefits and Costs of Full Operations and ITS Deployment: A 2025 Forecast for Tucson demonstrates that ITS technologies can be cost-effective investments. |

To fill this research gap, the Federal Highway Administration (FHWA) embarked on a 14-month study to explore the potential benefits of implementing a full suite of available operations and ITS strategies in a metropolitan area. To conduct the study, researchers from USDOT and FHWA selected Tucson, AZ; Cincinnati, OH; and Seattle, WA, to represent small, medium, and large metropolitan areas, respectively. The researchers then consulted with State and local transportation agencies to identify scenarios that represented a complete deployment of ITS technologies at an appropriate scale for each city. Finally, the researchers assessed the potential benefits and costs of implementation by comparing the full deployment scenario to a baseline scenario that did not feature any ITS technologies.

The analysis of the benefits and costs for the full deployment and ITS deployment scenario was conducted using the ITS Deployment Analysis System (IDAS). The IDAS tool is designed to estimate the specific benefits and costs of ITS deployments based on observed, real-world costs and benefits. This analytic tool was used to estimate benefits, including changes in travel time, travel time reliability, number and severity of crashes, vehicle emissions, fuel use, and other important measures.

In the full deployment scenario, the researchers assumed that each region would widely deploy arterial traffic management systems that featured coordinated signals, transit signal priority, signal preemptions for emergency vehicles, and arterial dynamic message signs. The researchers also assumed that all three regions would implement freeway management systems with ramp metering, traffic surveillance, highway advisory radio, and dynamic message signs. Finally, all three locations were assumed to have extensive transit management, incident management, emergency response, and traveler information systems. These advanced systems were assumed to be integrated and highly coordinated on a region-wide basis.

|

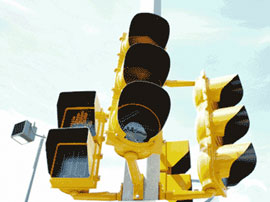

| FHWA's research on the benefits and costs of full ITS deployments evaluated the impacts of implementing a full suite of ITS technologies, including signal preemptions for emergency vehicles, such as the fire truck shown above. |

The study showed that full deployment of ITS technologies would produce numerous positive results compared with the baseline scenario. For all three regions, researchers found that widespread deployment of ITS decreased travel times, increased vehicle speeds, reduced traffic delays, decreased the number and severity of crashes, and limited the negative environmental impacts. In addition, the researchers found some of the most significant benefits provided by ITS technologies were related to improvements in travel time reliability resulting from reductions in delays caused by traffic incidents.

|

| ITS strategies, including the coordination of traffic signals, such as the lights shown above, would provide $6.03 in benefits for every $1 invested in Tuscon in the year 2025. |

Tucson's study, completed first, presented the costs and benefits of operating ITS technologies in the year 2025. According to the study results, widespread investment in operations and ITS strategies in Tucson would return $6.03 in benefits in 2025 for every $1 invested. A report on the Tucson study, Benefits and Costs of Full Operations and ITS Deployment: A 2025 Forecast for Tucson (FHWA-JPO-04-032), is available at www.itsdocs.fhwa.dot.gov/JPODOCS/REPTS_TE/13978.htm.

After completion of the Tucson study, members of a steering committee reviewed the research and concluded that the results would be even more meaningful if the analysis indicated the benefits possible today, rather than in the future. Although it was too late to revise the Tucson study, researchers modified the approach in the Cincinnati and Seattle studies to reflect year 2003 benefits.

For the Cincinnati study, the researchers evaluated the same factors as in the Tucson study but also analyzed the benefits of using operations and ITS strategies to mitigate the impact of construction activity and inclement weather on traffic. With these additional strategies, the researchers found that the return on investment in Cincinnati was higher than in Tucson, with every $1 invested in 2003 earning $11.80 in year 2003 benefits. The Cincinnati study, Benefits and Costs of Full Operations and ITS Deployment: A 2003 Simulation for Cincinnati (FHWA-JPO-04-031), is available at www.itsdocs.fhwa.dot.gov/JPODOCS/REPTS_TE/13979.htm.

In the Seattle study, researchers found even greater benefits with the full deployment of ITS technologies. According to the study, every $1 invested in ITS and operations strategies earned $12.20 worth of benefits in 2003. The study of Seattle, documented in Benefits and Costs of Full Operations and ITS Deployment: A 2003 Simulation for Seattle (FHWA-JPO-04-033), is available at www.itsdocs.fhwa.dot.gov/JPODOCS/REPTS_TE/13977.htm.

Thus, all three studies demonstrated that the benefits of operations and ITS strategies far out-weigh the costs. In addition, the authors concluded that future benefits may be even greater than indicated in the reports because they treated several factors, such as incident delay, conservatively.

For more information on ITS, visit the USDOT's ITS Joint Program Office Web site at http://www.its.dot.gov/.

Joe Peters 202-366-2202 joe.peters@fhwa.dot.gov

The increasing volume of waste and byproduct materials generated throughout the Nation and the growing cost of disposal create incentives to recycle these materials for use in other applications. Given the volume of materials required for pavement construction projects, highway agencies have become natural and integral participants in national recycling efforts by using materials such as industrial byproducts and reusing old pavement materials. To use these materials effectively, however, engineers need information about the environmental and engineering properties of the materials, how they can be used, and any limitations the materials may have.

To assist State agencies interested in using recycled materials in pavement construction, the Recycled Materials Resource Center and the Federal Highway Administration (FHWA) are conducting a series of 2-day workshops called Beneficial Use of Recycled Materials in Transportation Applications. The purpose of the workshop series is to update participants on the use of recycled materials in highway construction and provide information on where to learn more about the topic. The most recent workshop, held May 2005 in Raleigh, NC, brought together materials engineers and environmental scientists from departments of transportation (DOTs) and FHWA division offices in 12 southeastern States, Puerto Rico, and Washington, DC.

|

| Workers inject flowable fill containing recycled foundry sand to fill the spaces between the pipelines on this roadway construction project. |

Dr. Paul Tikalsky, associate professor of civil and environmental engineering at Pennsylvania State University, gave a presentation on the use of foundry sand-an industrial byproduct of metal casting-in flowable fills. Flowable fills, typically mixtures of sand and water, are self-leveling, liquid-like materials used in applications such as filling narrow utility repair trenches before they are topped with asphalt. Since sand is the chief component of flowable fill, replacing natural sand with foundry sand is a beneficial reuse application that can reduce construction costs and the amount of material sent to landfills. For more information on using foundry sand in pavement construction, visit www.foundryrecycling.org/library/librarytable.html and http://www.epa.gov/epaoswer/osw/conserve/foundry/index.htm.

In another presentation, David Rettner, a principal engineer at American Engineering Testing, Inc., discussed ways of using recycled concrete aggregate (RCA) in roadway construction projects. Studies and experiences at several transportation agencies have shown that RCA can be used instead of virgin aggregate to construct a durable, cost-effective roadway base. RCA can be crushed in place at the construction site using the deteriorated concrete pavement or made from material from off-site sources such as concrete structures or buildings that have been torn down. An FHWA report on the use of RCA, Transportation Applications of Recycled Concrete Aggregate (FHWA-IF-05-013), is available at www.rmrc.unh.edu/Resources/PandD/RCAReport/RCAREPORT.pdf.

Blair Barnhardt, operations engineer with Blount Construction Company Inc. of Marietta, GA, gave a presentation on the use of foamed asphalt in full-depth reclamation (FDR) on highway reconstruction projects. FDR is a technique in which the existing asphalt surface and part of the underlying gravel on a roadway are recycled in place to produce a new roadway base that can be covered with an asphalt or concrete surface. Once the existing asphalt and gravel are churned up with FDR equipment, foamed asphalt-a mixture of asphalt and hot water-is injected into the recycled material to rebind it, creating a material with greater strength than a typical aggregate base. Because FDR uses the existing asphalt and gravel in the new roadway base, it saves money and material. FHWA's National Highway Institute course, Asphalt Pavement Recycling Technologies (#131050A), covers FDR techniques. Course information is available at http://www.nhi.fhwa.dot.gov/training/course_detail.aspx?num=FHWA-NHI-131050&cat=&key=&num=131050&loc=&sta=%25&tit=&typ=&lev=&ava=&str=&end=&drl=.

For more information on recycled materials for highway construction, visit FHWA's pavement recycling Web site at www.fhwa.dot.gov/pavement/recycling/index.cfm and see FHWA's electronic report, User Guidelines for Waste and Byproduct Materials in Pavement Construction (FHWA-RD-97-148), at www.fhwa.dot.gov/publications/research/infrastructure/structures/97148/.

Jason Harrington 202-366-1576 jason.harrington@fhwa.dot.gov

Intelligent transportation systems (ITS) encompass a broad range of communications-based information and electronics technologies. When integrated into the Nation's transportation infrastructure or into vehicles themselves, ITS technologies can relieve congestion, improve safety, and enhance the productivity of the Nation's transportation system. The U.S. Department of Transportation's (USDOT) ITS program currently supports investments in major ITS initiatives, exploratory studies, and deployment efforts.

A clear presentation of USDOT's ITS program and improved site navigation were the guiding principles in creating a new Web site for the ITS Joint Program Office (JPO) at www.its.dot.gov. The JPO, which coordinates the ITS activities of the Federal Highway Administration and other USDOT agencies, unveiled the new site in May 2005 at the ITS America Annual Meeting & Exposition in Phoenix, AZ. The site showcases the ITS program's new major and exploratory initiatives. In addition, the site features new tools that help users to access information on specific ITS technologies.

On the home page, users can click on links to important resources-including news, USDOT initiatives, and ITS activities-organized by topic and by the agency that manages the initiative or activity. In addition, users can find information using USDOT's GoogleTM-enabled search engine or the site's subject index. The easily accessible navigation bar on the left side of the home page provides links to additional information on programs and topics such as ITS architecture and standards. The navigation bar also provides easy access to the ITS learning center and the ITS JPO's deployment support resources, including databases on the benefits, costs, and lessons learned from the implementation of ITS technologies.

The resources button at the top of the home page provides access to technical assistance resources. Included in the resources section is a link to the popular National Transportation Operations Coalition newsletter, which was formerly known as the ITS Cooperative Deployment Network newsletter. Other buttons take site users to the ITS electronic document library, press room, and frequently asked questions sections. Each month, the Web site will highlight an ITS benefit and an ITS initiative, along with new additions to the electronic document library. The ITS JPO staff welcomes feedback on the site at itsweb.master@fhwa.dot.gov.

Susan Slye 202-366-1068 susan.slye@fhwa.dot.gov