| Next >> |

Prefabricated Bridge Elements and Systems Cost Study: Accelerated Bridge Construction Success Stories

Introduction

The prefabricated bridge elements and systems (PBES) cost study documents the details related to savings in time and money on nine PBES projects in states across the country. All nine projects are replacement projects, and as such reducing the impact of onsite construction to motorists was a priority. Each project is an example of how various combinations of prefabrication and effective contracting strategies were used to achieve the accelerated onsite construction timeline.

In all cases the onsite construction time was significantly reduced relative to conventional construction, and five of the replacement projects were completed with no impact to rush-hour traffic. The combined construction cost savings on these nine projects is $30M, where savings are defined as the difference between engineer's estimate and awarded bid.

Projects

The owner, the project name, and the year of completion are shown below for each of the nine projects included in this cost study.

- Colorado Department of Transportation's State Highway 86 Bridge over Mitchell Gulch - 2002

- Maryland State Highway Administration's MD Route 24 Bridge over Deer Creek - 2001

- New Hampshire Department of Transportation's Mill Street Bridge over Lamprey River - 2004

- New Jersey Department of Transportation's Route 1 Bridges over Olden Avenue & Mulberry Street - 2005

- New York City Department of Transportation's Belt Parkway Bridge over Ocean Parkway - 2004

- Ohio Department of Transportation's U.S. Route 22 Bridge over Scioto River in Pickaway County - 2003

- Texas Department of Transportation's State Highway 66 Bridge over Lake Ray Hubbard - 2003

- Virginia Department of Transportation's Interstate 95 Bridge over James River - 2002

- Washington State Department of Transportation's SR 433 Lewis & Clark Bridge over Columbia River - 2004

A number of prefabricated bridge projects have been constructed to date across the country. The following nine projects are examples of how prefabrication was used to accelerate onsite construction time. The awarded bids for these projects were also typically lower than the engineer's estimate.

For each project, first an overview is given that includes the name, location, date of construction, owner, brief description of project, benefits including reduced impact to traffic, and duration compared to conventional construction. The construction process is then briefly described, followed by contract requirements that include incentives and disincentives. Construction costs are then discussed, including engineer's estimate, number of bidders, low bid and second lowest bid, savings both in time and money, and incentives paid.

All nine projects are replacement projects, and as such reducing the impact of onsite construction to motorists was a priority. Each project is an example of how various combinations of prefabrication and effective contracting strategies were used to achieve the accelerated onsite construction timeline. In all cases the onsite construction time was significantly reduced, and five of the replacement projects were completed with no impact to rush-hour traffic.

The combined construction cost savings on these nine projects is $30M, where savings are defined as the difference between engineer's estimate and awarded bid.

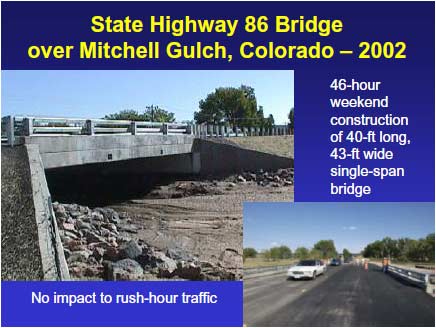

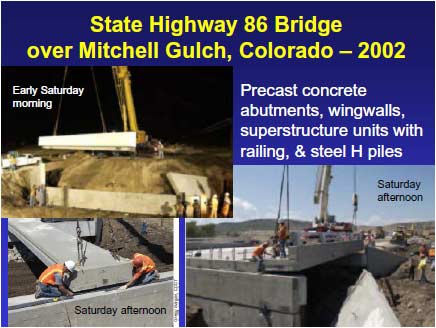

The State Highway 86 Bridge over Mitchell Gulch between Castle Rock and Franktown in Douglas County southeast of Denver was a timber bridge built in 1953 and rated in 2002 as one of Colorado's worst 10 bridges. That year the Colorado Department of Transportation accepted a value engineering proposal from the contractor and his design team to build a totally prefabricated bridge over a weekend in August 2002. During construction the bridge was closed and the 12,000 vehicles per day were diverted to a short detour around the bridge site.

The existing 40-ft long 2-span bridge was 26-ft wide with two 11-ft lanes and two 1.5-ft shoulders. The new 40-ft long bridge with 35-ft-clear single span was 43-ft wide to accommodate two 12-ft lanes and two 8-ft shoulders.

The new prefabricated bridge was opened just 46 hours after closure. Construction occurred over a weekend, with no impact to rush-hour traffic. Construction would have taken 2 to 3 months using conventional methods.

The State Highway 86 Bridge over Mitchell Gulch between Castle Rock and Franktown in Douglas County southeast of Denver was a timber bridge built in 1953 and rated in 2002 as one of Colorado's worst 10 bridges. That year the Colorado Department of Transportation accepted a value engineering proposal from the contractor and his design team to build a totally prefabricated bridge over a weekend in August 2002. During construction the bridge was closed and the 12,000 vehicles per day were diverted to a short detour around the bridge site.

The existing 40-ft long 2-span bridge was 26-ft wide with two 11-ft lanes and two 1.5-ft shoulders. The new 40-ft long bridge with 35-ft-clear single span was 43-ft wide to accommodate two 12-ft lanes and two 8-ft shoulders.

The new prefabricated bridge was opened just 46 hours after closure. Construction occurred over a weekend, with no impact to rush-hour traffic. Construction would have taken 2 to 3 months using conventional methods.

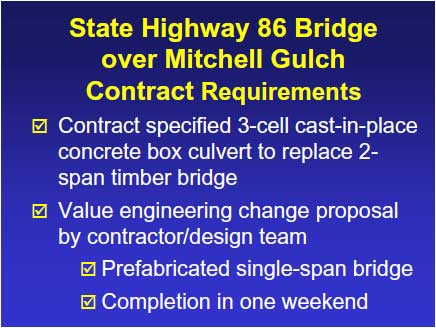

The Colorado DOT awarded the construction contract to replace the deteriorated bridge with a conventional 3-cell cast-in-place concrete box culvert. However, the contractor, Lawrence Construction Company, was concerned about the safety of his construction crews on this project because of the steep downward grade of the highway approach from the west in combination with the nearby curve of the detour around the bridge site. The contractor teamed with Wilson & Company, a local design firm, to submit a value engineering change proposal to build the single-span totally prefabricated bridge over a weekend to limit the onsite exposure time of his crew.

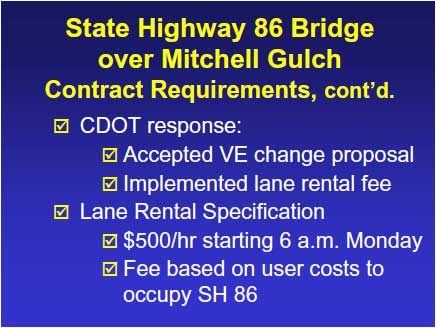

The Colorado DOT accepted the value engineering change proposal, with no change to the project funding. However, as part of the acceptance of the proposal, CDOT implemented a lane rental specification that imposed significant costs should the contractor exceed the allowed weekend closure. If the bridge wasn't opened by 6 a.m. on Monday, the contractor was required to pay a lane rental fee of $500 per hour or portion of an hour of lane closures on SH 86. The lane rental was based on road user costs to occupy SH 86.

No incentives were included in the contract.

| Next >> |