Center for Accelerating Innovation

America’s transportation system faces unprecedented challenges. Aging roads and bridges that carry greater traffic volumes and heavier loads than ever need extensive rehabilitation. Limited resources—both staff and budgets—at transportation agencies across the country create the need to work more efficiently and focus on technologies and processes that produce the best results.

At the same time, Americans continue to expect a multimodal transportation system that is safe, accessible, reliable, and convenient. They want to experience a minimum of traffic congestion, whether they are going about their daily lives in their communities or traveling across the country. They also want accountability for the tax dollars that support the building, maintenance, and repair of roads and bridges.

Addressing these challenges requires the transportation industry to pursue ways of doing business that are better, faster, and smarter. It requires harnessing the power of innovation to dramatically change the way highways are built. The FHWA Center for Accelerating Innovation, established in 2011, provides national leadership on deploying innovation to meet today’s transportation challenges. The center houses Every Day Counts—an initiative launched in 2009 by FHWA to shorten project delivery, enhance roadway safety, and protect the environment—and Highways for LIFE—the agency’s initiative to build roads and bridges faster, better, more safely, and with less impact on the traveling public.

|

Accelerating Project Delivery in MAP-21 The Moving Ahead for Progress in the 21st Century Act builds on the Every Day Counts initiative with provisions designed to speed up the project delivery process several ways:

|

This chapter discusses the goals of the Center for Accelerating Innovation initiatives and the benefits they generate for America’s highway system. It also highlights the progress of the initiatives between 2005 and 2012 in helping the highway community use innovation to improve the way the transportation infrastructure is built.

Highways for LIFE: Improving the American Driving Experience

Highways for LIFE, a pilot program established in 2005 by the Safe, Accountable, Flexible, Efficient Transportation Equity Act: A Legacy for Users, has three goals: improve safety during and after construction, reduce congestion caused by construction, and improve the quality of highway infrastructure. To achieve these goals the program focuses on using sophisticated marketing approaches and dedicated teams to deploy innovations faster and more effectively; it gives highway agencies incentives to use innovations and customer-focused performance goals to build highways better; and it helps industry move promising innovations from the prototype to the market-ready stage, where they can benefit the traveling public.

Through the Highways for LIFE Vanguard Technologies effort, FHWA developed a model technology deployment process that combines multidisciplinary teams, marketing techniques, and focused effort to move innovations all the way to full implementation. The process is designed to deploy technology quickly and efficiently so that years don’t elapse between the time that research is done and the time that highway users benefit from an innovation. FHWA also created a training program (Leap Not Creep: Accelerating Innovation Implementation) and a guide to developing marketing plans (FHWA’s Guide to Creating an Effective Marketing Plan) that organizations are using to launch their own innovation deployment efforts.

Highways for LIFE helps highway agencies try new approaches by offering financial incentives for construction projects that employ proven but little-used innovations. From fiscal years 2006 to 2012, the program provided incentives totaling about $65 million for 70 projects in 35 States, the District of Columbia, and Puerto Rico. These projects featured innovations such as accelerated bridge construction techniques, precast concrete pavement systems, and new contracting methods. Many projects include showcases to draw transportation professionals from around the country to view innovations in person and learn from their peers what it takes to deploy them.

To qualify for incentive funding, highway agencies had to set project performance goals by defining desired results for safety, speed of construction, mobility, quality, and user satisfaction, and committing to measuring their success in meeting those goals. A change from the traditional practice of specifying how a project should be built, performance goals spur agencies and contractors to use creativity and flexibility in developing solutions to meet project goals and challenges. By documenting and comparing project results to the performance goals set, agencies get data on which to base future decisions.

Recognizing that the private sector is a reservoir of innovation that can benefit the highway system, FHWA developed the Technology Partnerships Program to move useful innovations into routine practice. The program offers grants to help industry turn promising prototypes into market-ready products and fosters partnerships with highway agencies to demonstrate the technologies under real-world conditions. FHWA has funded eight Technology Partnerships projects with grants ranging from $200,000 to $500,000 for a total of nearly $2.8 million. It also launched a program to provide independent evaluation of worthwhile safety technologies with limited U.S. use.

Through Highways for LIFE, the highway community has begun to harness the power of innovation by deploying available technologies with immediate, tangible benefits. As a result, highway community stakeholders are adopting a customer-focused performance model and making innovations that enhance the highway system standard practice. They are changing the way the Nation builds highways to improve the American driving experience.

Every Day Counts: Creating a Sense of Urgency

The Every Day Counts Initiative was launched by FHWA in 2009 to identify and deploy market-ready innovations aimed at speeding up project delivery, making roads safer, and protecting the environment. The idea behind the initiative is to create a new sense of urgency in pursuing better, faster, and smarter ways to build highway infrastructure.

Working on the premise that technology deployment needs to occur much more rapidly to meet today’s transportation needs, FHWA created a State-based model in which FHWA teams work with State departments of transportation (DOTs) and other highway community stakeholders to make innovations standard practice. Every Day Counts focuses on high-priority initiatives to accelerate technology and innovation deployment and open highway projects to the public faster. From that menu of technologies, tactics, and techniques, each State chooses the options that work best for its highway program. FHWA teams work closely with the States to mainstream their selected initiatives over a 2-year period and develop performance measures to gauge their success.

Every Day Counts focuses on two key components:

- Accelerating technology and innovation deployment. This category involves identifying market-ready technologies that can benefit the highway system and accelerating their widespread use. This effort is aimed at advancing solutions that enhance safety, reduce congestion, and keep America moving and competitive.

- Shortening project delivery. To help the highway community deliver projects faster, FHWA developed a toolkit of strategies for using flexibilities available under current law and eliminating duplicate efforts in the planning and environmental review process. The agency is also recommending innovative contracting practices that accelerate project delivery as standard business practices.

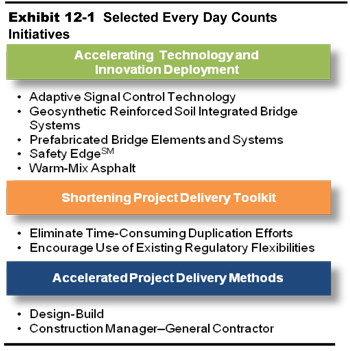

In choosing candidates for the first round of Every Day Counts initiatives that began in October 2010, FHWA sought input from stakeholders throughout the highway community, including industry experts, the American Association of State Highway and Transportation Officials (AASHTO), the American Road and Transportation Builders Association, and the Associated General Contractors of America. Through this collaborative process, FHWA designated five initiatives to focus on in the accelerating technology and innovation category and 10 in the shortening project delivery category (Exhibit 12-1). FHWA identified agency experts to champion each initiative and assembled deployment teams.

Working with AASHTO, FHWA advanced the Every Day Counts program nationwide through a series of regional summits in the autumn of 2010. FHWA invited Federal, State, and local agency representatives, industry leaders, and technical experts with direct involvement in delivering Federal-Aid Highway Program projects to participate.

After the summits, each State formed a State Transportation Innovation Council to provide leadership for its Every Day Counts effort. States selected a minimum of five initiatives to pursue over a 2-year period and developed action plans. Many chose to incorporate all of the initiatives into their Every Day Counts effort. This State-based approach recognizes that DOTs serve as the innovation leaders for their States and, by partnering with local and county agencies and industry stakeholders, they can play a key role in innovation deployment.

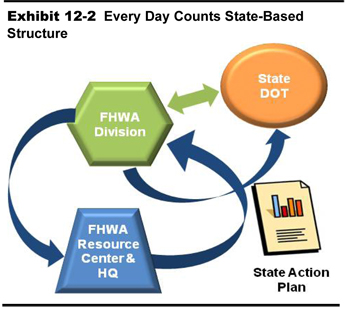

On an ongoing basis, FHWA staff support the State DOTs by offering recommendations on maximizing the effectiveness of Every Day Counts activities. FHWA also provides training and guidance to help State DOTs achieve the goals they set in their action plans (Exhibit 12-2). For example, the team focusing on accelerating project delivery conducted regional peer exchanges on the construction manager–general contractor (CM-GC) and design-build initiatives. At each, participants from several States heard perspectives and best practices from DOTs with experience using the contracting approaches, examined case studies, and participated in group exercises. FHWA also uses Web conferences to expedite dissemination of information on technology initiatives. Target audiences include staff from State, regional, and local transportation agencies and the contracting industry.

As well as being rapidly deployable, the initiatives are performance based and measurable. Accountability is inherent to the process of pursuing better, faster, and smarter ways of doing business. As steward of the Nation’s transportation system, FHWA is responsible for delivering products and services that engender public trust. The performance goals FHWA set for each initiative help the agency track its progress. All of the initiatives are moving forward as teams implement them across the country. The following sections take a closer look at how several are succeeding in making innovative technologies and construction methods standard practice and shortening project delivery.

|

Every Day Counts Highlights In its first 2 years, the Every Day Counts initiative helped States deploy innovations that benefit road users nationwide:

|

Accelerating Technology and Innovation Deployment

Accelerating technology and innovation deployment is about taking effective, proven, and market-ready technologies and putting them into widespread use. FHWA is working with State, local, and industry partners to implement the following technologies to improve safety, reduce congestion, and keep people and goods moving.

Safety EdgeSM. Pavement edge drop-off on highways has been linked to many serious crashes and fatalities. Rather than leave a vertical drop-off at the pavement shoulder, the Safety Edge shapes the edge of the pavement to a 30-degree angle, making it easier for drivers to steer back onto the roadway for drivers who stray off the travel lane (see Safety Edge discussion in Chapter 4).

The Safety Edge is installed during paving, using a commercially available shoe that attaches to existing paving equipment in just a few minutes. The Safety Edge also decreases pavement edge raveling and contributes to longer pavement life. The benefits of Safety Edge have encouraged 34 State DOTs and all three Federal Lands Highway Divisions to adopt the Safety Edge as a standard for paving projects.

|

Safety Edge The Iowa Department of Transportation (DOT) has made the Safety Edge a standard practice, and requires it on all projects with a paved shoulder less than 4 feet wide. In addition to using it on asphalt paving projects, the Iowa DOT was the first in the country to try it on a Portland cement concrete paving project. |

Warm-mix asphalt (WMA). Composed in various fashions, WMA enables construction crews to produce and place asphalt on a road at lower temperatures than possible using conventional hot-mix methods. In most cases, the lower temperatures result in significant cost savings because fuel consumption during WMA production is typically 20 percent lower. WMA production also generates fewer emissions, making conditions for workers healthier, and has the potential to extend the construction season, enabling agencies to deliver projects faster.

By July 2012, 45 State DOTs and all three Federal Lands Highway Divisions had adopted a standard specification for WMA use. Twenty-four State DOTs and Federal Lands Highway Divisions had set usage goals ranging from 46,000 to 600,000 tons of WMA per year, or 20 percent to 50 percent of all applicable projects. In 2010, more than 47 million tons of WMA were produced nationwide, a nearly 150-percent increase over 2009. That saved more than 30 million gallons of fuel worth more than $80 million and removed 800,000 tons of CO2 from the air, which equates to taking more than 150,000 cars off the road.

According to the National Asphalt Paving Association, current data indicate that WMA will capture more than 25 percent of the market in the next year and will be the industry standard for asphalt mixtures in 3 to 5 years.

|

Warm-Mix Asphalt The New Hampshire DOT placed about 243,000 tons of WMA in 2011, 41 percent of all pavement the State placed during the year. The Delaware DOT used WMA on about 40 percent of its paving projects in 2011 and plans to use it on all projects by 2015. In Puerto Rico, more than 60,000 tons of WMA were placed on three 2012 projects, resulting in a 30-percent reduction in fuel costs. (Source: Federal Highway Administration, The Best of EDC, May 2012, www.fhwa.dot.gov/everydaycounts/pdfs/bestofedc.pdf.) |

Geosynthetic reinforced soil integrated bridge system (GRS-IBS). While utilizing traditional equipment and materials, GRS-IBS uses alternating layers of compacted granular fill material and fabric sheets of geotextile reinforcement to provide support. The technology is particularly advantageous in the construction of small bridges (less than 140 feet long), reducing construction time and generating cost savings of 25 to 60 percent compared to conventional construction methods. It facilitates design flexibility conducive to construction under variable site conditions, including soil type, weather, utilities and other obstructions, and proximity to existing structures.

From October 2010 to July 2012, 85 bridges across the country were designed or built using GRS-IBS. Thirty-seven State DOTs and Federal Lands Highway Divisions are implementing GRS-IBS.

|

GRS-IBS Defiance County, OH, used GRS-IBS to build a bridge in just 6 weeks, compared to the months required for traditional construction methods.1 The county saved nearly 25 percent on the project, not only because of the reduced labor costs resulting from shorter construction time and simpler construction, but also because fewer materials were required for the GRS bridge abutments. GRS-IBS technology helped Clearfield County, PA, build a bridge on a school bus route in just 35 days, saving months of time and 50 percent on costs.2 Another bridge built using GRS-IBS technology in St. Lawrence County, NY, realized a 60-percent cost savings.3 1Federal Highway Administration, Every Day Counts, GRS-IBS Case Studies, www.fhwa.dot.gov/everydaycounts/technology/grs_ibs/casestudies.cfm.2Randy Albert, Pennsylvania Department of Transportation, “Every Day Counts,” EDC Forum, www.fhwa.dot.gov/everydaycounts/forum/post.cfm?id=27 3Federal Highway Administration, Every Day Counts, GRS-IBS Case Studies, www.fhwa.dot.gov/everydaycounts/technology/grs_ibs/casestudies.cfm. |

Adaptive signal control technology. These technologies coordinate the control of traffic signals across a network by adjusting the lengths of signal phases based on prevailing traffic conditions. This improves travel time reliability, reduces congestion, and creates smoother traffic flow.

According to the Information Technology and Innovation Foundation’s 2010 report titled Explaining International IT Application Leadership: Intelligent Transportation Systems, applying real-time traffic data to traffic signals can cut red-light delays by as much as 40 percent, CO2 emissions by 22 percent, and gas consumption by 10 percent. Although adaptive signal control technology has been used in the United States for about 20 years, it had been deployed on less than 1 percent of the Nation’s 260,000 traffic signals before its adoption as an Every Day Counts technology in October 2010. By July 2012, 44 State DOTs were implementing the technology.

|

Adaptive Signal Control Technology Topeka, KS, installed new traffic signals equipped with cameras and processors on the 21st Street corridor. The system saves drivers on the corridor an estimated 123,000 gallons of gasoline and 191,000 pounds of CO2 a year. Crashes dropped by 30 percent during the system’s first year of operation.1 The city of Temecula, CA, deployed the technology at 83 intersections spanning 18 miles of roadway. As a result, drivers have enjoyed a 14 percent reduction in travel time, a 17 percent increase in corridor speed, and a 29 percent reduction in stops. That translates to annual savings of about $2.6 million in travel time and $437,000 in fuel costs.2 1Federal Highway Administration, The Best of EDC, May 2012, www.fhwa.dot.gov/everydaycounts/pdfs/bestofedc.pdf.2Federal Highway Administration, Every Day Counts, Adaptive Signal Control Case Studies, www.fhwa.dot.gov/everydaycounts/technology/adsc/casestudies.cfm. |

Prefabricated bridge elements and systems (PBES). With PBES, prefabricated components are constructed off-site and moved to the work zone for rapid installation, reducing the level of traffic disruption typically associated with bridge replacement. In some cases, PBES makes it possible to remove the old bridge overnight while putting the new bridge in place the next day. Because PBES components are usually fabricated under controlled conditions, weather has less impact on the quality and duration of the project.

Forty-seven State DOTs and Federal Lands Highway Divisions are implementing PBES as part of Every Day Counts. Between October 2010 and July 2012, 675 replacement bridges were designed or constructed using PBES. About 18 percent of all replacement bridges using Federal-aid funds have at least one major prefabricated bridge element.

|

Prefabricated Bridge Elements and Systems The Massachusetts DOT used prefabricated bridge elements on a project to replace 14 bridge superstructures on I-93 in Medford, shrinking a 4-year bridge replacement project to just one summer. The agency built the bridge superstructures in sections off-site and installed them on weekends during 55-hour windows to minimize impact on travelers. |

Accelerating Project Delivery Methods

The sooner highway agencies can complete major projects, the sooner the public can begin enjoying their benefits. With the traditional design-bid-build (DBB) construction method, highway projects can take years to deliver. The accelerated project delivery method initiative is aimed at reducing the time it takes to complete highway projects by as much as 50 percent. Every Day Counts is focusing on two innovative contracting methods that can trim years from project schedules and is encouraging State DOTs to adopt them as standard business practices.

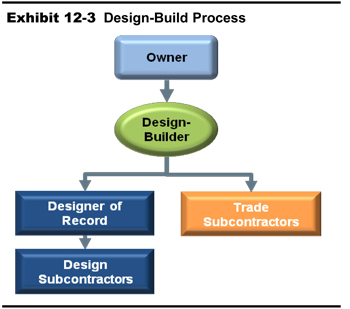

Design-build contracting. Design-build (DB) is a project delivery method in which the design and construction phases are combined into one contract, allowing some aspects of design and construction to take place at the same time (Exhibit 12-3). This approach can provide significant time savings compared to the traditional DBB approach, in which the design and construction phases take place sequentially. The designer-builder assumes responsibility for most of the design work and all construction activities. Along with greater responsibility and risk, DB allows the designer-builder more flexibility to innovate. Twenty-eight DOTs and all three Federal Lands Highway Divisions are implementing the initiative, and DB was used on about 200 projects from 2010 to 2012. Twenty-four States expanded their DB statutory authority in 2011 and 2012, according to the Design-Build Institute of America.

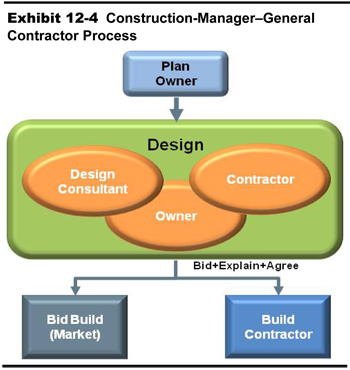

Construction manager–general contractor. Another alternative to the traditional DBB contracting method is the CM-GC approach. The CM-GC process has two phases. In the design phase, the highway agency hires a construction manager to work with the designer and agency to identify risks, provide cost projections, and refine the project schedule. The construction manager and agency negotiate a price for the construction contract and, if both parties agree, the construction manager becomes the general contractor for the construction phase. As with the DB approach, agencies can save time because of the contractor’s ability to undertake several activities concurrently. It also allows State DOTs to remain active in the design process while assigning risks to the parties most able to mitigate them. Sixteen DOTs and all three Federal Lands Highway Divisions are implementing the CM-GC project delivery method. Twenty projects were constructed in the past 3 years using CM-GC, and 25 more were planned for 2012 and 2013 (Exhibit 12-4).

|

Alternative Contracting Methods The Michigan DOT used CM-GC to develop and deliver a complex slope-stability project quickly, safely, and cost-effectively. Both DB and CM-GC have helped the Utah DOT streamline production, reduce risk, and cut costs on many projects over the past decade. When the Utah DOT needed to complete a $1.5-billion project to rebuild a highway in time for the 2002 Salt Lake Winter Olympics, DB accelerated project completion by an estimated 4 years. On an I-80 widening job that included 14 bridges, CM-GC resulted in user cost savings of $25 million on a $140-million project. Since 2010, the Maine DOT has advanced nine DB projects and the DB method has become an established accelerated project delivery practice for the agency. |

Shortening Project Delivery Toolkit

Highway projects that require environmental impact statements under the National Environmental Policy Act (NEPA) typically take 12 to 13 years to complete. In order to deliver needed projects faster, FHWA created the Shortening Project Delivery Toolkit to encourage greater use of regulatory flexibilities available under current laws. The following highlights how State DOTs are using the initiatives to streamline projects.

Expanded use of programmatic agreements. Programmatic agreements establish streamlined processes for handling routine environmental requirements on common project types. A programmatic agreement spells out the terms of a formal agreement between a State DOT and other State or Federal agencies and sets up a process for consultation, review, and compliance with applicable Federal laws. Such agreements save time in the project delivery process by specifying clear roles and responsibilities, standardizing coordination and compliance procedures, and improving relationships among DOT and regulatory agency staff.

Thirty-seven States have at least two active programmatic agreements. Since October 2010, 56 programmatic agreements have been initiated.

|

Programmatic Agreements The Nebraska Department of Roads developed a programmatic agreement for a biological evaluation process. When the programmatic conditions are met at the project level, the agency no longer needs to coordinate with or obtain concurrence from FHWA, the U.S. Fish and Wildlife Service, or the Nebraska Game and Parks Commission. This agreement results in a minimum savings of 5 weeks in the project schedule for an estimated 80 percent of the projects in the State’s transportation program. In another case, the Oklahoma DOT's American Burying Beetle Programmatic Biological Opinion has expedited projects by as much as a year, and it minimizes schedule uncertainty on projects where American Burying Beetles, a critical endangered species, might be present. |

Enhanced technical assistance. FHWA is providing additional technical assistance to help States identify NEPA-related challenges and implement solutions to resolve project delays where feasible. Interagency coordination at all levels of government is helping move projects forward in a streamlined manner.

FHWA is focusing on new projects that are expected to experience delays and ongoing projects for which no record of decision has been issued 60 months or more after the project’s notice of intent was published. Of the 10 projects on which assistance is being provided, four—in Alaska, Nebraska, North Carolina, and Utah—had a record of decision or withdrawal of the notice of intent by July 2012.

Use of in-lieu fees and mitigation banking. In-lieu fees are those charged to perform environmental enhancement activities throughout an entire watershed rather than at a particular site. Mitigation banking refers to restoring or enhancing wetlands, streams, or other resources to offset unavoidable adverse impacts related to a highway project in another area. FHWA is encouraging highway agencies to use both approaches where allowed. Thirteen of the 23 States participating in the initiative have active agreements for mitigation banking programs, and seven of those agreements extend to local agencies. Six States have agreements in place for in-lieu fees.

|

In-Lieu Fees and Mitigation Banking The Alaska Department of Transportation and Public Facilities has used the in-lieu fee program to meet wetland mitigation commitments on more than 70 projects since the Every Day Counts program began. Additionally, the Mississippi DOT has streamlined the compensatory mitigation permitting process for wetland and stream impacts on all applicable transportation projects. The Mississippi DOT now owns wetland and stream credits in 18 mitigation properties, perpetually conserving some 20,000 acres of land. |

Planning and environmental linkages. This initiative set up a framework for considering and incorporating planning documents and decisions from the earliest stages of project planning into the environmental review process. Linking planning and environmental considerations can lead to a seamless decision-making process that minimizes duplication of effort, promotes environmental stewardship, and reduces project delays. To ensure that planning information and decisions are properly coordinated for use in the NEPA review process, FHWA is recommending use of the Planning and Environmental Linkages (PEL) Questionnaire, which was adapted from a questionnaire developed for use in Colorado. By July 2012, 18 of the 32 States and Federal Lands Highway Divisions participating in the initiative had made use of the PEL Questionnaire or an equivalent process.

|

Planning and Environmental Linkages The Louisiana Department of Transportation and Development created a National Best Practice Planning and Environmental Linkages Checklist and is using it on all new projects to save time and money. The Montana DOT has standardized its corridor planning process through its Corridor Planning Study Checklist. |

Every Day Counts Round Two

In July 2012, FHWA announced a new round of innovative technologies and processes under its Every Day Counts initiative that can shorten the time needed to open highway projects to the public and enhance safety and environmental outcomes. Over the next 2 years, expert teams will work with State transportation agencies and the design and construction industries to deploy 13 innovations.

Programmatic agreements. Also part of the first round of Every Day Counts, programmatic agreements establish streamlined approaches for handling routine environmental requirements. In this round, some of the newly developed agreements will be applied in additional States or expanded to include regions.

Locally administered Federal-aid projects. FHWA has developed a three-pronged strategy to help local agencies navigate the complexities of the Federal-Aid Highway Program. The strategies include certification and qualification-type programs, indefinite delivery–indefinite quantity consultant contracts, and stakeholder committees.

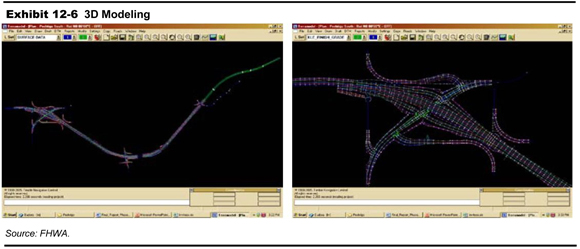

Three-dimensional modeling technology. With 3D modeling software, design and construction teams can connect virtually to collaborate on project designs throughout the design and construction phases. This technology allows for faster, more accurate, and more efficient planning and construction, in many cases increasing productivity by up to 50 percent.

Intelligent compaction. When pavement cracks prematurely, a potential cause is that it was not compacted properly during construction. Intelligent compaction—using global positioning system (GPS)-based mapping and real-time monitoring to enable adjustment of the compaction process—improves the quality, uniformity, and lifespan of pavements.

Accelerated bridge construction. FHWA is advancing three technologies to replace bridges faster, more safely, and sometimes at less cost. They are PBES, in which components are built off-site and moved into place quickly; slide-in bridge construction, in which a bridge is built next to an existing structure and slid into place; and GRS-IBS, which uses geosynthetic reinforcement and granular soils as a composite material to build abutments and approach embankments.

Design-build and construction manager–general contractor project delivery methods. FHWA is continuing its deployment of DB and CM-GC methods, accelerated project delivery methods that can shorten construction project schedules by years. Accelerated project delivery also provides opportunities for significant cost savings and safety improvements.

Alternative technical concepts. Through this flexible contracting process, contractors can recommend innovative, cost-effective solutions that are equal to or better than a State’s design and construction criteria. The approach promotes competition and gives highway agencies the opportunity to choose design and construction solutions that offer the best value.

High-friction surface treatment. This pavement technology reduces crashes, injuries, and fatalities. It involves applying high-quality aggregate with friction values far exceeding conventional pavement friction to existing or potential high-crash areas to help drivers maintain better control in dry and wet conditions.

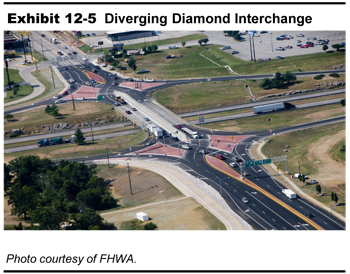

Intersection and interchange geometrics. Innovative designs can reduce or move crossover or conflict points in intersections and interchanges, increasing safety for motorists, pedestrians, and bicyclists. Roundabouts, diverging diamond interchanges, and intersections with displaced left-turns or variations on U-turns are among the effective alternatives to traditional designs.

Geospatial data collaboration. This initiative uses cloud-based geographic information system services, which are used to build maps, to improve data sharing within agencies and among project delivery stakeholders. Collaborative analyses and rapid updating of shared maps will lead to faster consensus building, improved decisions, and better scheduling on highway projects.

Quality environmental documentation. FHWA is promoting recommendations to improve the quality and reduce the size of NEPA documents developed for construction projects. The initiative will help make NEPA documents more effective in disclosing to the public and participating agencies the information that is used to make project decisions. That, in turn, will help project proponents accelerate project delivery and achieve better environmental outcomes.

First responder training. Crashes, disabled vehicles, and road debris create unsafe driving conditions and cause about 25 percent of all traffic delays. This initiative offers the first national, multidisciplinary traffic incident management process and training program. It promotes understanding among first responders of the requirements for safe and quick clearance of traffic incidents, prompt and open communications, and motorist and responder safeguards.

A New Way of Doing Business

Through the Center for Accelerating Innovation, FHWA provides both national leadership and State-based assistance in the effort to shorten project delivery, improve roadway safety, and protect the environment. Having access to the flexibilities and technologies available through Every Day Counts can help highway agencies add value to projects or expedite project delivery where appropriate. This collaborative approach facilitates accelerated deployment of proven solutions that can make a difference. It will result in development of a national network of transportation professionals skilled in the rapid deployment of innovation.

Ultimately, the focus of FHWA innovation initiatives such as Every Day Counts is greater than specific technologies or strategies. The long-term goal of the Center for Accelerating Innovation is to institutionalize innovations by incorporating them into the standards, specifications, and manuals that highway professionals use every day. Its aim is to foster a culture of innovation throughout the highway community. The result will be a new way of doing business that embraces innovation and uses it to meet the Nation’s transportation needs in the 21st Century.

To view PDF files, you need the Acrobat® Reader®.