Field Evaluation of Detection-Control System

CHAPTER 3. DATA COLLECTION SYSTEM

TTI used a real-time data collection system for assessing the MOEs used to evaluate the performance of the traffic signal system before and after activating the D-CS system at an intersection. The following MOEs were used to evaluate the traffic signal system performance:

- Number of RLRs.

- Number of times a phase reached the max1 green during the day.

- Number of vehicles caught in the dilemma zone at the onset of yellow on main street phases.

The following real-time data elements were among those elements required to calculate the above-mentioned MOEs:

- Change in phase status (green, yellow, red).

- Status of various detectors installed at the intersection.

- Location and travel time to stop line of vehicles on the main approaches at the onset of yellow.

- Video recording of about 7 s before and after the onset of red on main-street approaches to verify the number of RLRs.

TTI used two data collection modules running simultaneously on an industrial PC to collect the real-time data elements required to evaluate the traffic signal system performance. Each data-collection module required several hardware components to collect the necessary data. For example, each intersection required an industrial PC together with enhanced BIUs to interface with TS2 traffic controller cabinets to monitor the change in phase status (green, yellow, red) and status of detectors (D-CS upstream detectors, stop-line detectors, and red-light-running detector) installed at an intersection. The following sections describe in detail the software and hardware components of the data-collection system.

The software component of the real-time data collection system consisted of two modules, one developed by TTI and the other by Wavetronix™. The module developed by TTI researchers, called Real-Time Traffic Data Collection System (RTTDCS), served the purpose of monitoring the traffic signal system events and detecting RLRs. Wavetronix™ provided the second data collection module, which facilitated collecting information about vehicles caught in the dilemma zone at the onset of yellow phase. This action required the use of a Wavetronix™ advance sensor installed at the stop line on main street approaches. Both systems ran simultaneously on the same industrial PC and used the PC’s system time to timestamp the events and data collected by each system. Consequently, data elements collected by both systems were synchronized because they used the same reference to timestamp the events (i.e., the PC system time).

TTI researchers developed components of the RTTDCS over a period of time, but refinement of some components occurred in this research project. The RTTDCS interfaces with a traffic controller cabinet (TCC) and monitors the following traffic signal system events at an intersection:

- Phase status (green, yellow, red).

- Detector status (on/off).

- Phase hold.

- Phase on.

- Phase check.

- Ring status bits (A, B, and C).

- Ring force-off.

- Priority preempts.

- Other available input and output events available in a TCC.

Depending on the type of the TCC (i.e., TS2 or TS1), the RTTDCS uses either enhanced BIUs or a digital input/output (I/O) PC card to interface with the TCC. All of the intersections selected for data collection except one (Waco) had TS2 cabinets. Consequently, enhanced BIUs were involved in all cabinets but the one in Waco. An enhanced BIU is similar to a standard BIU except for an additional RS-232 port on the front of the enhanced BIU. TTI researchers used the RS-232 port on the front of the enhanced BIU to monitor special inputs and outputs available on that BIU. For example, TTI used BIU #1 to monitor phase status of phases 1 to 8 in the cabinet. TTI also replaced detector BIUs #1 and #2 in the cabinets with enhanced BIUs to monitor the status of up to 32 detectors in each TS2 cabinet.

To monitor RLRs on main street approaches, TTI researchers installed a video detection camera to monitor the area immediately downstream of the stop line on main street approaches. This action required configuring a RLR detector in each main street approach downstream of the stop line. The RTTDCS monitors the status (on/off) of these RLR detectors. Anytime the RTTDCS detects a change in the status of these detectors while the correspondent main street phase is red, it timestamps and records the RLR events in a daily RLR log file. Also, anytime the RTTDCS detects a change of phase status from yellow to red on main street approaches, it triggers a DVR to record about 7 s of buffered video before and after the start of the red phase from the RLR camera monitoring the approach. TTI used the timestamped RLR events in the log file and the recorded video to verify the number of RLRs at each main street intersection before and after installation of D-CS. The process also involved a video titler whose purpose was to overlay a text message on the video image. This message included the industrial PC timestamp and main street phase status recorded by the DVR from the RLR camera. The reason for overlaying the main street phase status and the PC’s timestamp on the recorded video was to simplify the post-processing synchronization of the timestamped events recorded in the RLR log file and video clips recorded by the DVR.

Finally, the RTTDCS receives and logs the contact-closure signal sent by the Wavetronix™ Advance, which indicates whether a vehicle was in the dilemma zone at the onset of yellow. This positioning of each vehicle was necessary for subsequent verification using the recorded video. TTI installed one Advance at the stop line of each main street approach of every evaluated intersection. The Advance has a detection zone area that extends from 100 to 500 ft from the sensor location. The sensor samples the detection zone about every 100 ms and provides the location and speed of every vehicle detected in that zone. The user defines the beginning and end of the dilemma zone as a range in the number of seconds of travel time to the stop line of the approach monitored by the Advance sensor. The Advance sensor uses the installed range of travel times to calculate the dilemma zone of every vehicle detected in its 400‑ft zone each time it wakes up. If there is at least one vehicle in this zone expected to arrive in the dilemma zone, the Advance sends a presence signal to the cabinet. The RTTDCS receives the presence signal; timestamps the event; records the vehicle identifier, speed, and distance; and logs the event into the daily log file. Installers used the same Advance configuration parameters as programmed into the D-CS; in other words, the beginning of the dilemma zone was 6 s of travel time from stop line, and the end of the dilemma zone was 2 s of travel time from the stop line on each approach.

The RTTDCS logs the events and data elements it collects in real time to daily log files, and it closes these log files at midnight every day and immediately opens new files. The daily log files include the following files:

- Phase Status (.PHS files): The RTTDCS saves the change in phase-status events it detects into the phase-status file. For example, when the RTTDCS detects a change in phase status from green to yellow, yellow to red, or red to green, it logs an event into the file indicating the type of change in phase status, along with a time stamp. When the phase status changes from red to green, the RTTDCS writes the following records into the daily phase status file.

- Red-Light Running (.RLR files): Anytime the RTTDCS detects an actuation on the video detectors downstream of the stop line on main street approaches while the corresponding approach phase is red, it timestamps the detector actuation and logs it into the RLR file.

- Detector Status (.SBD files): The RTTDCS logs changes in detector status (on/off) of every detector installed at the intersection into the .SBD file.

- Upstream D-CS Loop Trap (.SPD files): The RTTDCS monitors the D-CS trap loops to detect vehicles and calculate the speed of each vehicle on the main street approaches. The RTTDCS calculates the average speed of each detected vehicle and logs the information into the .SPD file.

- Wavetronix™ Advance (.WAS files): The RTTDCS monitors the Advance (on/off) signal indicating detection of a vehicle in the dilemma zone between 100 and 500 ft from the location of the sensor.

- BIU (.BIU files).

- Detector Failure (.DetFail files).

- Daily Real-Time Log.

The appendixes have a sample of data headers to assist future analysts in understanding the data output.

Wavetronix™ provided TTI researchers with a software application to intercept real-time speed and distance messages sent by the WavetronixTM SmartSensor Advance (WSSA) sensor over its RS-232 port. With the help of Wavetronix™ engineers, TTI researchers configured the Advance sensors to send messages over the serial connection about every 100 ms containing the speed and location of every vehicle in the dilemma zone. The Wavetronix™ data collection system receives these real-time messages and logs them into a log file that contained the following information:

- The date.

- The industrial PC system timestamp.

- The vehicle identification.

- The vehicle speed.

- Distance of vehicle from the stop line.

- Vehicle travel time to the stop line.

TTI researchers used the collected information to verify the number of vehicles that were in the dilemma zone on the main street approaches at the onset of yellow.

Equipment Available from the Government

Table 11 lists the equipment that the Government made available from a previous contract. Besides this list, the Federal Highway Administration (FHWA) had a Naztec 2070 cabinet, a Naztec 2070 controller, and two rolls of coaxial cable. TTI used Government-provided equipment to the extent that was feasible. TTI’s proposed budget included costs for PCs other than the ones available from the Government because those PCs (PC-104) did not offer the level of performance needed for efficient completion of the TTI work plan. In fact, the newly purchased PCs were not powerful enough either. As TTI tested the new PCs prior to and during the initial data collection efforts at the first sites in Florida, it became increasingly obvious that the newly purchased PCs would not be able to handle the large amounts of data that would be generated by field data collection units. TTI resorted to its existing Kontron™ industrial PCs to collect and store data throughout the project.

TTI also elected not to use the Traficon™ video detection units, choosing instead to use its own Autoscope™ detectors. The reason for this swap was partly because of greater familiarity with TTI’s Autoscope™ video processors and partly because of the additional features offered by the Autoscope™ RackVision systems. TTI had not used Traficon™ video detectors for red-light-running detection prior to this project. TTI provided sufficient equipment (processors, racks, etc.) for two intersections operating simultaneously but used cameras provided by the Government.

Equipment from the list that was useful to TTI included the enhanced BIUs, the video monitor, camera mounting hardware, video quad processors, the black-and-white monitor, and various cables and connectors. In addition to the equipment listed, an earlier contract had resulted in the installation of eight cameras at two Illinois intersections. TTI was able to use four of these cameras during the data collection that occurred during this contract.

Table 11. Equipment list available from FHWA.

Box Number |

Shipment Contents |

1 |

10 Data Express hard drives (some labeled as DCS2) 4 100-ft CCTV video power cables 4 high-resolution color quad processors 4 AC/DC switch adapters 4 GPS modules 4 chips (apparently quad processors) |

2 |

3 Naztec BIU power racks |

3 |

2 PC 104s (Sys 3a and Sys 10a) 1 PC 104 case |

4 |

14 plastic bags screws and bands from TRI-M labeled “Container Parts Kit” 1 bag of WinSystems™ cables 7 cables for connecting parts inside PC 104 4 bags of Diamond PC104 prototype board kit 14 Winsystem™ chip cards (about 2 by 2 inches size) 1 stack of chips 2 bags of keys and screws |

5 |

3 Naztec BIU power racks 2 cables |

6 |

9 PC 104 PCs (Sys 11a, 7a, 9a, 1, 8a, 6a, 12a, and 13a) |

7 |

4 camera mounting tubes |

8 |

4 sets of camera mounting brackets |

9 |

1 9-inch B/W monitor |

10 |

2 Naztec/Traficon™ video processors 1 Naztec Pwr/Panel/Video 1 Traficon™ camera adjuster |

11 |

8 BIUs 24 9-pin RS232 cables |

12 |

18 BIUs |

13 |

1 camera |

14 |

1 camera |

15 |

1 camera |

16 |

1 camera |

AC/DC = alternate current/direct current.

CCTV = closed-circuit television.

GPS = global positioning system.

TRI-M = TRI-M Technologies Inc.

Equipment Purchased Using Project Funds

Table 12 lists equipment purchased with project funds. Even though TTI specified the two industrial PCs purchased with project funds should be more powerful than ones used for similar research, they were not useful to this project. Upon connecting all the data collection equipment at the first site in Florida, the new PC would typically operate for a short interval and then lock up because of the tremendous flow of data, especially from the Wavetronix™ detectors. TTI resorted to using two existing Kontron™ industrial PCs for the entirety of the field data collection.

Table 12. Equipment purchased with project funds.

Description |

Quantity |

Unit Price |

Total |

Industrial PC |

2 |

$1,750.00 |

$3,500.00 |

National Instruments™ Digital I/O Cards |

2 |

$780.12 |

$1,560.24 |

Digi™ 4 port serial Card |

2 |

$225.42 |

$450.84 |

Digi™ cellular modem |

2 |

$1,263.00 |

$2,526.00 |

Digi™ modem service (months) |

14 |

$100.00 |

$1,400.00 |

Wavetronix™ Advance |

2 |

$6,300.00 |

$12,600.00 |

Wavetronix™ Advance (loan) |

2 |

— |

— |

Videostamp text overlay device |

4 |

$224.14 |

$896.56 |

DVR (Pelco™) |

2 |

$2,606.00 |

$5,212.00 |

Shipping cost estimate |

1 |

$ 200.00 |

$200.00 |

Total |

$28,345.64 |

—Not applicable.

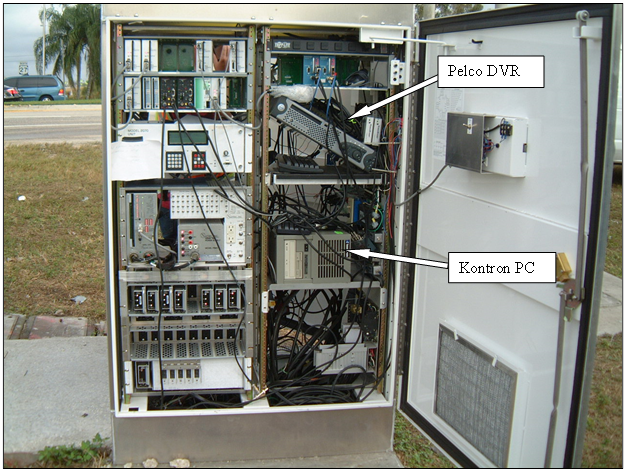

Figure 3 shows a photograph of an equipment cabinet in Florida showing some of the monitoring equipment used for this research, along with the controller and other equipment used to operate the intersection. The following major components were needed in each equipment cabinet:

- Kontron™ industrial computer with six RS-232 serial ports and one 10/100 Ethernet port.

- Digital I/O card: The National Instruments™ peripheral component interconnect (PCI) 6527 digital I/O card with 24 digital inputs and 24 digital outputs.

- Video titler.

- DVR: Pelco™ 5100 series.

The industrial PC triggered the DVR to start recording about 7 s of buffered video before the onset of the red phase and continuing until about 7 s after red. The industrial PC continuously output a timestamp to be recorded on the video in addition to the phase-status indication (i.e., G, Y, or R) from the controller. Ideally, this process required two cameras per approach, for a total of four cameras per intersection. One camera covered the stop-line area while the other covered the area upstream of the stop line. This project required one DVR at each intersection to record video from the four cameras at the onset of red on main street phases.

Researchers used all six of the available serial ports. The system needed two of the serial ports to interface with BIU #1 and the first detector BIU in the cabinet. It used two other serial ports to receive the real-time vehicle information messages from the WSSA sensors. The last two serial ports communicated with the two video titlers to overlay text messages onto recorded video. These text messages included the industrial PC timestamp and main street phase status. The 10/100 Ethernet port allowed remote monitoring of the industrial PC using a cellular modem. Finally, the digital I/O PCI card monitored the RLR video detector status and the presence call from the WSSA sensors indicating the presence of a vehicle in the dilemma zone.

Figure 3. Photo. Naztec cabinet in Florida with D-CS monitoring equipment.