Field Evaluation of Detection-Control System

CHAPTER 5. D-CS IMPLEMENTATION GUIDE

TTI developed D-C S to improve the safety of high-speed, signalized intersections. This system uses a unique detector configuration to monitor approaching vehicles and hold the green until they are safely clear of the intersection, as well as provide some priority for trucks. This installation guide provides an overview of D-CS operations and offers guidance to installing agencies on controller settings and field installation procedures.

D-CS is similar to a traditional advance detector system in that it uses information from detectors located upstream from the intersection to extend the green. However, it differs from the traditional advance detector system because it processes vehicle speed and length information to find the best time to terminate the major road through phase. This time is based on a forecast of the number of vehicles that will be in the dilemma zone [2] in the immediate future, as well as the number of minor movements waiting for service. D-CS reevaluates this information continuously and updates it in real time.

D-CS uses a two-loop detector trap in each approach lane to obtain the necessary information about vehicles approaching the intersection. Each detector trap is located 700 to 1,000 ft upstream of the intersection. The exact location is not critical. However, distances nearer 1,000 ft are better because they provide D-CS with a larger time horizon for evaluating future arrivals to the dilemma zone.

A key feature of D-CS is that it can predict, in real time, when each vehicle will arrive at and depart from its dilemma zone on the intersection approach. This feature takes advantage of the fact that the dilemma-zone boundaries are defined in terms of travel time to the stop line. D-CS measures each arriving vehicle’s speed, forecasts its dilemma-zone arrival and departure times, and holds the green phase when a vehicle is in its dilemma zone.

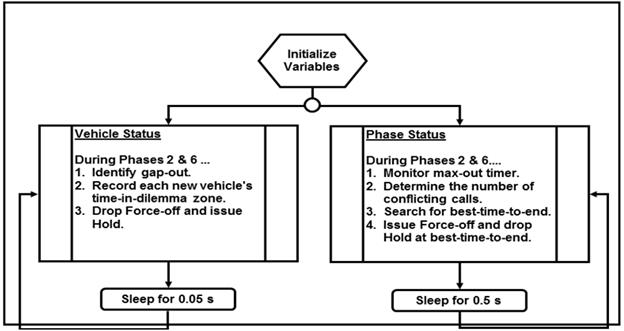

This section describes the logic used in the detection-control algorithm, primarily through the use of three flowcharts. The first flowchart, figure 36, indicates the two components of D-CS: a vehicle-status component and a phase-status component. The primary function of the vehicle-status component is to monitor the output from the classifier and record each vehicle’s time of arrival at and departure from the dilemma zone. This component repeats its checks every 0.05 s. The primary function of the phase-status component is to determine the best time to end the phase and then send the appropriate instructions to the signal controller. This component repeats its function every 0.05 s. The next section describes each component in more detail.

Source: TTI/Karl Zimmerman, used with permission.

Figure 36. Chart. Detection-control algorithm flowchart.(2)

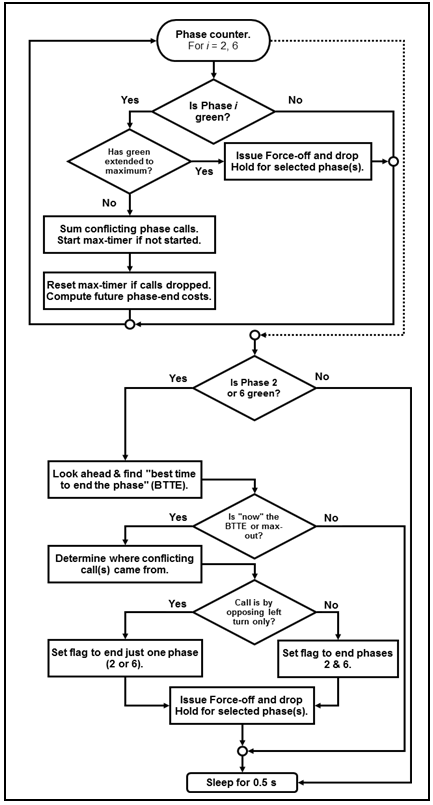

Figure 37 shows the vehicle status component of the algorithm. It sequentially checks the detector output (via the classifier) for each approach lane served during the major road signal phase (i.e., phases 2 and 6). The algorithm only takes action when the subject phase is in service (i.e., showing a green indication). At the start of each phase, it resets the system variables to zero and issues a phase Hold command to the controller. While the phase is green, this component processes vehicles measured by the classifier and adds them to a “dilemma zone matrix” representing the number and length of vehicles present during each second within the look-ahead time interval.

If a vehicle is traveling faster and will arrive behind a slower vehicle, the vehicle status component adjusts the faster vehicle’s speed to equal that of the slower vehicle. Its arrival time at and departure time from the dilemma zone lags that of the slower vehicle by 1.5 s. This algorithm is most applicable to single-lane intersection approaches and high-volume multilane approaches. Its use at low-to-moderate volume multilane approaches is generally conservative because it will always assume a car-following mode when, in fact, faster drivers may pass slower drivers.

Source: TTI/Karl Zimmerman, used with permission.

Figure 37. Chart. Vehicle-status component algorithm flowchart.(2)

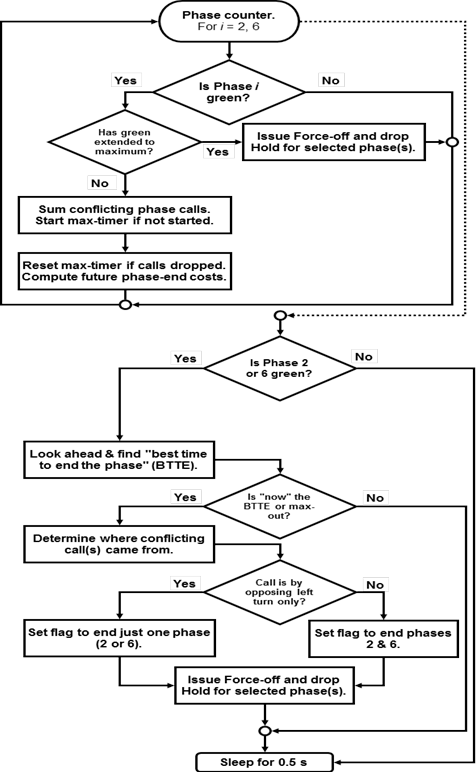

Figure 38 shows the phase-status component of the D-CS algorithm. This component checks the dilemma zone matrix during the major road through phase. The algorithm only takes action when the subject phase is in service (i.e., showing a green indication). While the phase is green, the algorithm monitors a maximum green setting internal to the algorithm. If this maximum is reached, this component immediately causes a phase termination by dropping all phase Hold commands and issuing a Force-Off command for both rings.

The phase-status component is primarily concerned with monitoring the dilemma zone matrix and finding the “best time to end the phase” (BTTE) based on the current look-ahead interval. This interval is defined as the travel time between the detection zone and the beginning of the dilemma zone for a vehicle traveling in the 99th-percentile speed. When the detection zone is located 1,000 ft from the stop line and the 99th-percentile speed is 70 mi/h, the look-ahead time is approximately 2.8 s.

Determination of the BTTE is based on two checks. The first check requires that the dilemma zone contain fewer vehicles than a specified maximum value for any current or future time interval. All intervals that have the same (or fewer) number of vehicles than the maximum value are candidates to be the BTTE.

The algorithm uses two maximum values. The first portion of the phase (or stage) uses one maximum value, and the last stage of the phase uses a second value. The maximum value is established at zero during the first stage. However, during the second stage, the maximum value is relaxed to allow up to one passenger car (no trucks) per lane in the dilemma zone. This “relaxation” of the maximum value is intended to prevent the phase from maxing out while still limiting the number of vehicles caught in the dilemma zone to a minimum value.

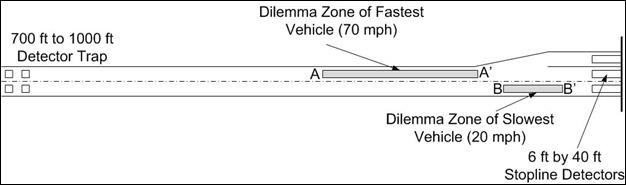

To illustrate the implications of D-CS’s dynamic dilemma zone monitoring process, consider the following example. A vehicle traveling at 70 mi/h is at point A in figure 39, and a vehicle traveling at 20 mi/h is at point B. Neither vehicle is in its respective dilemma zone, so D-CS could terminate the phase at this instant in time. In contrast, both vehicles are almost certainly in the zone protected by the traditional multiple advance detector system, and both vehicles would unnecessarily extend the phase. As a result, a D-CS controlled phase could end at this point in time, whereas the traditional system would continue to extend the green interval. This example uses an extreme speed differential to make its point. However, the concept applies to the full range of speeds and allows D-CS to consistently end the phase sooner than the traditional system. Over time, this capability ensures that D-CS will operate with less delay and catch fewer vehicles in the dilemma zone than the traditional advance detector system.

The real-time nature of D-CS operation allows it to dynamically accommodate changes in speed that occur at the intersection throughout the day, week, and year. Its performance is not compromised when traffic speeds change, as would be the case for traditional advance detection systems because their detectors are precisely located for a specified design speed.

Source: TTI/Karl Zimmerman, used with permission.

Figure 38. Chart. Phase-status component algorithm flowchart.(2)

Source: TTI/Karl Zimmerman, used with permission.

Figure 39. Illustration. Comparison of dilemma zones for fast and slow vehicles.(1)

In short, D-CS is designed to dynamically identify the dilemma zone for each vehicle, in real time, and predict the best time to terminate the phase. This design allows D-CS to provide safe and efficient signal operation for the full range of intersection traffic volumes and speeds. To assist the installer, the following narrative provides guidance on some of the controller settings to set up D-CS. This guidance is specific to the Naztec 2070 controller.

The Naztec 2070 controller has the following two input screens for D-SC:

- Speed detectors.

- Lane setup.

There is also a status screen for monitoring D-CS operation.

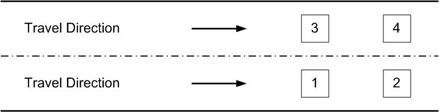

D-CS uses a pair of detectors in each lane in a speed trap configuration. Each speed trap is set up in the speed detector screen, accessed by MM -> 5 (Detectors) -> 8 (V/O-Speed) -> 2 (Speed Detectors). Table 42 shows an example speed detector screen. Each row describes one speed trap. Speed traps 1, 2, 3, and 4 are defined in figure 39. The following screens provide an explanation of the values shown for each speed trap. D-CS can monitor one speed trap per lane in as many as eight lanes, so the maximum number of speed traps is also eight.

Table 42. Speed detector screen.(1)

UpDet |

DnDet |

ZoneLen |

Loop/CarLen |

|

1 |

9 |

10 |

20.0 |

6.0 |

2 |

11 |

12 |

20.0 |

6.0 |

3 |

13 |

14 |

20.0 |

6.0 |

4 |

15 |

16 |

20.0 |

6.0 |

5 |

— |

— |

0.0 |

0.0 |

6 |

— |

— |

0.0 |

0.0 |

— |

— |

0.0 |

0.0 |

—No data.

UpDet

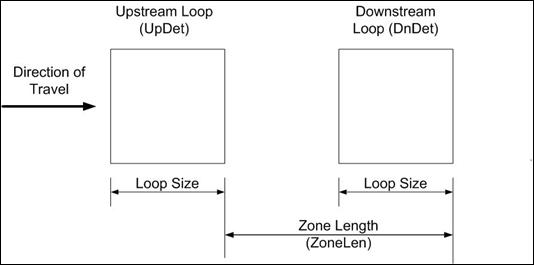

UpDet is the detector channel number for the upstream detector in a speed trap (figure 40).

DnDet

DnDet is the detector channel number for the downstream detector in the trap (figure 40).

Source: TTI/Karl Zimmerman, used with permission.

Figure 40. Illustration. Speed trap configuration.(1)

ZoneLen

ZoneLen is the distance from the downstream end of UpDet to downstream end of DnDet in feet. The minimum ZoneLen is 20 ft, although a longer trap may be used if desired.

Loop/CarLen

Loop/CarLen is the size of the UpDet and DnDet detector loops, in feet.

For D-CS to function properly, both loops in each trap must be the same size.

The lane setup is performed after the detector traps are assigned. The lane setup screen is accessed by MM -> (Detectors) -> 8 (V/O-Speed) -> 4 (DCS Menu) -> 1 (table 43).

Table 43. Lane setup screen.(1)

DCS Setup |

Lane1 |

Lane2 |

Lane3 |

Lane4 |

> |

Phase |

2 |

2 |

6 |

6 |

|

SpeedTrap |

1 |

2 |

3 |

4 |

|

TrapDistance |

1,000 |

1,000 |

1,000 |

1,000 |

|

DZArrival |

6.0 |

6.0 |

6.0 |

6.0 |

|

DZExit |

2.0 |

2.0 |

2.0 |

2.0 |

|

StagePercent |

70 |

70 |

70 |

70 |

|

MaxSpeed |

70 |

70 |

70 |

70 |

|

MaxLength |

65 |

65 |

65 |

65 |

Lane1, Lane2, Lane3…

Each lane controlled by D-CS has a detector trap assigned to it. As many as eight approach lanes can be monitored by D-CS.

Phase

Phase is the D-CS controlled phase associated with this lane.

SpeedTrap

SpeedTrap is the speed trap number assigned to this lane from the speed detector screen.

TrapDistance

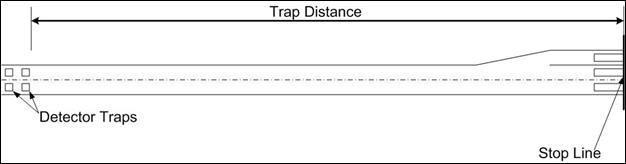

TrapDistance is the distance from the downstream end of the detector trap to the stop line of the intersection, in feet (figure 41). The traps should be located between 700 ft and 1,000 ft from the stop line.

Source: TTI/Karl Zimmerman, used with permission.

Figure 41. Illustration. Trap distance measurement.(1)

DZArrival

DZArrival is the travel time from the upstream end of the dilemma zone to the stop line, in seconds. The DZArrival time cannot be smaller than DZExit.

DZExit

DZExit is the travel time from the downstream end of the dilemma zone to the stop line, in seconds. The DZExit time cannot be larger than DZArrival.

StagePercent

The maximum green time is divided into two stages. Stage 1 occurs first, followed by stage 2. The StagePercent is the percentage of the maximum green time that is allocated to stage 1. Phase termination during this stage requires that all dilemma zones are clear (i.e., no vehicles are in the dilemma zone). The balance of the maximum green time is allocated to stage 2. During stage 2, D-CS searches for a time when the number of vehicles in the dilemma zone is at a minimum. It terminates the phase when this minimum is reached.

MaxSpeed

MaxSpeed is the maximum acceptable vehicle speed for D-CS, in mi/h. Vehicle speeds reported to D-CS that are faster than the maximum speed are considered to be errors, and the maximum speed is reported instead.

MaxLength

MaxLength is the maximum acceptable vehicle length for D-CS, in feet. Vehicle lengths reported to D-CS that are longer than the maximum length are considered errors, and the maximum length is reported instead.

The Naztec 2070 controller also has a D-CS status screen so a user can monitor D-CS operation in the field. This screen is accessed by MM -> 8 (V/O-Speed) -> 4 (DCS Menu) -> 7 (Status) (table 44).

Each column’s entries have the data for one phase. Non-zero values in the last five rows indicate that phases 2 and 6 are the D-CS controlled phases.

PhaseOn

PhaseOn indicates whether this phase is (X) or is not (.) currently active. A phase is “active” when it is timing the green, yellow, or all-red intervals. In the example, the active phases are phases 2 and 6.

D-CS Setup |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

PhaseOn |

. |

X |

. |

. |

. |

X |

. |

. |

PhsCall |

. |

. |

. |

X |

. |

. |

X |

. |

DCSActv |

. |

X |

. |

. |

. |

X |

. |

. |

EGWUsed |

0 |

16 |

0 |

0 |

0 |

16 |

0 |

0 |

Thrshold |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Holding |

. |

X |

. |

. |

. |

X |

. |

. |

QueClear |

. |

X |

. |

. |

. |

X |

. |

. |

PhsCall

PhsCall indicates whether this phase has (X) or does not have (.) a call for service. In the example, phases 4 and 7 have calls for service.

DCSActv

DCSActv indicates whether D-CS is (X) or is not (.) active for this phase. D-CS is “active” when it is searching for a safe time to terminate the phase. D-CS can only be active for two of the eight phases at any one time, and only when those two phases are green. In the example, D-CS is active on phases 2 and 6.

EGWUsed

EGWUsed is the current total vehicle length in the dilemma zone. If the total length value shown is 16, then one 16-ft vehicle is currently in the dilemma zone for the corresponding phase. If 32 is shown, then two vehicles are in the dilemma zone, and so on.

Thrshold

Thrshold is the maximum total vehicle length in the dilemma zone at the time of phase termination. Thrshold can have the following two different states for an active D-CS phase:

- When D-CS is in stage 1, Thrshold is 0.

- When D-CS is in stage 2, Thrshold is greater than 0.

There are three ways to terminate a D-CS controlled phase:

- In stage 1.

- In stage 2.

- By max-out.

EGWUsed and Thrshold can be used together to determine how each D-CS controlled phase ended. To terminate a phase in stage 1 or stage 2, the EGWUsed value must be less than or equal to Thrshold. In stage 1, D-CS requires that all dilemma zones must be clear before the phase is allowed to terminate. For this reason, Thrshold is set to 0 during stage 1, and the EGWUsed must equal 0 in each lane before the phase can be terminated.

In stage 2, D-CS relaxes the requirement that all dilemma zones must be clear to terminate the phase. In this stage, a phase can be terminated when there is no more than one passenger car in the dilemma zone. To provide truck priority, D-CS maintains the requirement in stage 2 that all dilemma zones be clear of trucks (defined as vehicles with length of 25 ft or more). For this reason, Thrshold is set to 24 during stage 2, and the EGWUsed must be less than 24 in each lane before the phase can terminate.

When the maximum green limit is reached, the phase is terminated (i.e., maxes out), regardless of the Thrshold or EGWUsed values.

Holding

Holding indicates whether D-CS is (X) or is not (.) holding the phase in its green interval. This variable will show both indications while an active D-CS controlled phase is timing, depending on whether vehicles are in the dilemma zone. It will show (.) when the phase terminates.

QueClear

QueClear indicates whether or not D-CS has determined that the stopped queue has cleared. D‑CS will not terminate a phase until the stopped queue clears. D-CS checks one of two different conditions to determine whether the queue has cleared. These two conditions are as follows:

- Gap out of a presence detector near the stop line.

- The end of minimum green, whichever occurs later.

If presence detection is not provided near the stop line, the end of minimum green is used exclusively to make this determination.

D-CS has relatively few input settings. However, some key settings are interrelated, and their values must be adjusted in combination to optimize D-CS operation. The key D-CS settings are as follows:

- Dilemma-zone boundaries (DZArrival and DZExit).

- Maximum green.

- Stage 1 percentage.

- Minimum green.

Recommendations for each of these settings are discussed below.

Dilemma Zone Boundaries (DZArrival and DZExit)

Research studies have shown that the dilemma zone begins at 5.5 s of travel time from the stop line and ends at 2.5-s travel time from the stop line. The physical location of the dilemma zone can be easily identified when the vehicle travels at a constant speed. D-CS makes this assumption when it determines the location of each vehicle’s dilemma zone. This determination is made soon after the vehicle crosses the detector trap. In fact, studies have shown that most drivers maintain a relatively constant speed on the intersection approach, so the assumption is reasonable. However, drivers may occasionally alter their speed on the intersection approach after crossing the detector trap. For this situation, it is recommended that 0.5 s be added to the dilemma zone arrival time and that 0.5 s be subtracted from the dilemma zone exit time. Therefore, the recommended value for DZArrival is 6 s, and the recommended value for DZExit is 2 s.

Maximum Green

The maximum green setting for D-CS should be somewhat longer than the typical maximum green setting used at an isolated intersection with conventional detection and control. D-CS requires this longer maximum green duration to find the safest time to terminate the phase and provide adequate truck priority. However, D-CS is highly efficient in finding safe termination times and rarely extends the green interval to its maximum limit. Research studies have shown that delay is lower with D-CS operation than with conventional detection and control.

The recommended maximum green setting for D-CS is equal to the sum of the stage 1 and stage2 durations. Stage 1 should be as long as the typical maximum green setting, which may range from 35 to 60 s, depending on the location. Stage 1 should always be longer than the longest queue clearance time to maximize the safety benefits of D-CS. The recommended stage 2 duration is about 20 s. Hence, the maximum green setting should range from 55 to 80 s, with larger values in this range preferred for the reasons stated in the previous paragraph.

Stage 1 Percentage

The stage 1 percentage is the ratio of the stage 1 duration divided by the length of the maximum green duration, expressed as a percentage. As noted previously, stage 1 should range from 35 to 60 s, and the maximum green duration should range from 55 to 80 s. Therefore, the stage 1 percentage should ideally range from 65 to 75 percent, but it should not be less than 60 percent.

Minimum Green

D-CS operation is very sensitive to the length of the minimum green for the phases it controls. There are two reasons for this sensitivity. First, D-CS does not control the intersection until after queue clearance or the end of minimum green, whichever occurs later. D-CS uses the stop line detectors to determine whether the queue has cleared. However, a slow-starting vehicle may create a gap in the queue large enough to gap out the detector even though the queue has not cleared. This situation can result in premature phase termination by D-CS.

Second, the D-CS algorithm assumes that the distance from the detector trap to the stop line is clear of vehicles at the start of the green interval. It has no knowledge of vehicle presence on the intersection approach at the start of this interval and cannot extend the green interval for them. Thus, the minimum green duration must be sufficiently long enough to allow any moving vehicle that is between the detector trap and the stop line at the start of the green interval to reach the inside edge of the dilemma zone before the minimum green expires. If this opportunity is not available, D-CS may terminate the phase prior to this vehicle being served.

To avoid these two situations, the minimum green duration should be at least 15 s for phases with approach speed limits of 55 mi/h or higher. The minimum green duration should be at least 17 s for phases with approach speed limits of 45 or 50 mi/h. Longer minimum green times may be used, although a minimum green time greater than or equal to the stage 1 duration is not recommended.

If presence detection is not available in the vicinity of the stop line, then the minimum green must be long enough to allow the stopped queue to adequately clear. Otherwise, D-CS may end the phase before the stopped queue clears. If D-CS ends a phase before the queue clears and no presence detection is available, it is likely that subsequent phases may also end before the queue clears. This pattern will persist until the queue is able to clear within the minimum green. This situation is undesirable and should be avoided if possible, either with a long minimum green or the addition of presence detection near the stop line.

If volume density operation is being used, the 15-s (or 17-s) recommended minimum green for D-CS operation must be supplied even if no actuations occur during the yellow and red intervals.

Table 45 summarizes the recommended values of the D-CS settings described in this section. The recommended values for the minimum green duration are the minimum recommended values for reliable D-CS operation.

Table 45. D-CS recommended settings.(1)

Setting |

Recommended Value |

DZArrival |

6 s |

DZExit |

2 s |

Maximum green duration |

55 to 80 s (larger values will improve D-CS performance) |

Stage 1 percentage |

65 to 75 percent preferred, but not less than 60 percent |

Minimum green duration |

Minimum of 15 s for approach speed limits of 55 mi/h or higher Minimum of 17 s for approach speed limits of 45 mi/h or 50 mi/h Larger values may be needed if presence detection is not available near the stop line. |

INDUCTIVE LOOP FIELD INSTALLATION PROCESS

This section contains the procurement, installation, and performance requirements for D-CS. The distance between the loops and the stop line does not have to be precisely defined and is not dictated by speed. It is best to install the loops between 700 and 1,000 ft upstream of the stop line. Distances nearer 1,000 ft are encouraged because they are better from the standpoint of providing some improvement in system performance, but they are not critical if they are difficult to achieve. For example, if a culvert or driveway is located at 850ft and would be expensive to cross, then installing the loops at 840 ft is acceptable.

Vehicle Detection System Components

The text of the following section was originally published in Intelligent Detection-Control System for Rural Signalized Intersections and has been adapted for this report.(2)

Materials and Hardware

Inductive Loop Detectors: The D-CS uses two 6-ft by 6-ft inductive loops in each through travel lane, placed upstream of the intersection. A special feature of this design is that each loop has six turns of wire. The detector loop wire is stranded copper No. 14 AWG XHHW cross-linked-thermosetting-polyethylene insulated conductor conforming to IMSA 51-3.(2)

Detector Loop Lead-In Cable: One lead-in cable is provided for each loop detector. A special feature of this design is that the cable is shielded twisted No. 12 AWG. Otherwise, the design meets all of the requirements of IMSA 50-2.

Loop Amplifier: A two-channel loop amplifier (or detector unit) is provided for each pair of inductive loop detectors (i.e., one amplifier per through travel lane). These loop amplifiers may be stand-alone or rack mounted. The amplifier should be operated in the “fast response” mode. This mode minimizes the lag time associated with call filtering and thereby improves the accuracy of D-CS speed estimation.

Installation and Testing of D-CS Loop Detectors

There are two loops per travel lane. The spacing of the loops are 20 ft from trailing edge to trailing edge, and the loops are centered in each through lane.(2) The trailing edge of the trailing loop is at a distance from the stop line specified on the plan sheets. A special feature of this design is that each loop is provided with its own lead-in cable to the cabinet.

Inductive Loop Layout: Each loop layout is 6 ft by 6 ft square with 8.5 ft between each pair of diagonally opposite corners. When cutting the pavement, the contractor should not deviate more than 0.5 inches from the chalk line on leading edges of loops and no more than 1inch on all other sides of the square loops. A special feature of this design is that the contractor should round the corners to a minimum of a 1-inch radius for the full depth of the cuts.(2) All sharp edges at corners and elsewhere should be removed. The contractor should not create excessive “gaps” at loop corners. All saw cuts should be filled with loop sealant flush with the pavement surface.

Inductive Loop Saw Cuts: The saw cut depth allows six turns of loop wire to be placed such that each turn in the leading edge of each loop is “stacked” on the previous turn. Each successive wire turn touches the one installed below it (or before it), and the wire turns remain contiguous following application of the loop sealant. A backer rod is not required. The contractor should install all turns in a clockwise direction and mark the beginning end on each loop.

The saw cuts should be vertical and at least wider than the diameter of the loop wire, up to a maximum of 0.25 inches. The top wire may be as much as 1.5 inches below the surface but not less than 1.0 inch below the surface. The saw cut depth should be a minimum of 2.5 inches and a maximum of 3 inches, measured at any point along the loop perimeter.(2)

The width of home-run saw cuts should be at least 0.25 inches wider than twice the diameter of the loop wire, up to a maximum of 0.5 inches. The top wire in the home-run cut may be as much as 1.5inches below the surface, but not less than 1 inch below the surface.(2)

Wire Twists in Home-Run Cut: A special feature of this design is that the contractor should twist loop wire leads a minimum of five twists per ft from feeder slot to the first ground box.

Testing Loop Wires: The contracting agency should test all loop wires at the first ground box prior to the contractor applying loop sealant. If any failures are discovered in the loop wire conductor, the contractor will be required to replace the loop wire.

Loop Sealant: The contractor should completely encapsulate the loop conductors with sealant both in the loop proper and along the wire leads. A minimum of 1 inch of sealant should be provided between the top of the conductors and the top of the saw cut.(2) The contractor should fill saw cuts completely with sealant such that it is flush with the top of the saw cuts. The sealant should be either 3-M loop sealant or TA-500.

Installation and Testing of D-CS Lead-In Cable

A special feature of this design is that each loop is provided with its own lead-in cable to the cabinet.

Loop Lead-In Cable: A special feature of this design is that the loop lead-in cables are long enough to extend from the first ground box to the cabinet without splicing. Some additional length should be provided to allow sufficient slack to make connections at each end.

The contractor should pull the lead-in cables from the first ground box to the cabinet. The shield should be left unconnected, insulated at the splice point, and grounded only in the control cabinet until inspected by the contracting agency. If the led-in cable fails testing, the contractor should remove the defective cable and replace it.

Cable Splices: A special feature of this design is that there is only one splice between the loop and the cabinet. That one splice is in the first ground box and connects the loop to the lead-in cable. The contractor should solder and seal all connections in the first ground box with 3-M Scotchcast.

Ground Boxes: The ground boxes should be consistent with the local operating agency’s specifications for ground boxes.

Conduit: The lead-in cable should be inside a conduit that is in conformance with the local operating agency’s specifications.

Installation and Testing of D-CS Loop Amplifiers

The loop amplifiers (or detector units) for the D-CS should be installed as stand-alone or rack-mounted. Each loop should be assigned to a separate amplifier channel. These channels should be dedicated solely for the use of D-CS (i.e., they should not also be assigned to other signal phases). Loop amplifier function should be tested according to local agency requirements. Figure 42 and table 46 show a recommended setup for a Reno A&E model S-1200-SS detector unit.

Source: TTI/Karl Zimmerman, used with permission.

Figure 42. Illustration. Numbering of inductive loops in the roadway.(1)

Table 46. Settings for Reno A&E model S-1200-SS.(1)

Detector |

Channel |

Frequency1 (KHz) |

Sensitivity Setting2 |

Fast Response3 |

1 |

1 |

1 or 2 |

4 |

On |

2 |

2 |

7 or 8 |

4 |

On |

3 |

3 |

7 or 8 |

4 |

On |

4 |

4 |

1 or 2 |

4 |

On |

1Goal with frequency is to have 5 KHz separation between loops in adjacent lanes.

2Set sensitivity as high as possible without causing loop to “stick” in the on mode. Too low a value will result in missed trucks. Typical values are 4 to6.

3Not on by default; used for speed trap applications.

The D-CS is intended for use at isolated, full-actuated intersections on high-speed roadways. The intersection should consist of a major road and a minor road where the major road approach has an 85th-percentile speed (or posted speed limit) of 45 mi/h or higher. The agency must install detection zones for the system in each lane of both major road approaches, and the intersection must operate in isolation of other adjacent signalized intersections. A left-turn bay is required for each major road approach, and a right-turn bay (or full-width shoulder) is desirable.

The installing agency should consider using D-CS at new intersections meeting the above requirements whenever multiple advance detection might otherwise be a good fit. For existing intersections with multiple advance detectors, decisionmakers should consider replacing the existing system with D-CS when the existing system’s design life is finished.

Extensive simulation and field study have shown that the system is able to function safely and efficiently for all levels of traffic demand. However, its performance degrades with frequent turning activity from the major road approaches. For this reason, its benefits will diminish as the total turn percentage (i.e., the sum of the left-turn percentage and the right-turn percentage) increases. Performance has been acceptable when the turn percentage is less than 40 percent.

Other conditions that make D-CS even more desirable are as follows:

- Higher than normal truck traffic.

- Locations where approach speeds vary significantly.

- Locations with high crash rates.

The types of crashes to be particularly mindful of are angle plus RE crashes.

Table 47 summarizes the criteria discussed above and the recommended threshold values that justify the use of D-CS. The last two entries in this table, truck traffic and crash frequency, are considered important, but the other criteria are more critical in determining when to use D-CS.

Table 47. Guidance on the use of D-CS.

Criterion |

Threshold |

Isolated full-actuated intersection |

N/A |

Intersection of major road and minor road |

N/A |

85th-percentile speed (or speed limit) |

> 45 mi/h |

Total turn percentage (right plus left) |

< 40 percent |

Truck traffic |

> 10 percent in off-peak hours, > 5 percent in peak hours |

Crash rates for rear-end and right angle |

> similar intersections in the area |

N/A = not applicable.

[2]The dilemma zone represents a length of roadway on the intersection approach within which drivers are collectively indecisive regarding whether to stop or continue when presented with a yellow signal indication. The upstream edge of this zone is typically defined as 5.5 s travel time from the stop line. The downstream edge of this zone is typically defined as 2.5 s travel time from the stop line.