This chapter provides more examples of typical mitigation techniques and options. Information provided is not to be considered all-inclusive, nor is it intended to limit the ingenuity or resourcefulness of designers, contractors, and inspectors, or create a strategy uniquely suited to the characteristics of a specific project.

Table 7.1 Overview of mitigation options.

| Design Options |

|---|

| Design and Project Layout |

| Sequence of Operations |

| Alternative Construction Methods |

| Contract Specifications/Special Provisions |

| Operational Constraints |

| Time Periods and Duration |

| Specified Equipment |

| Noise-Related Incentives/Disincentives |

| Training Programs for Contractor |

| Mitigation at the Source |

| Stationary Equipment |

| Mobile Equipment |

| Selection of Equipment |

| Inspection/Maintenance Programs |

| Equipment Operation Training |

| Mitigation Along the Path |

| Natural Shielding |

| Temporary Shielding |

| Permanent Shielding |

| Mitigation at the Receiver |

| Building Envelope Improvements |

| Masking |

| Relocation of Residents |

| Public Involvement and Project Coordination |

| Critical components of the overall mitigation strategy. Should be considered during all phases of a project. |

The level of detail in a contract required to address construction noise mitigation is dependant on the complexity of the project, the amount and type of work required, and the sensitivity of the area beyond the project boundary. Therefore, not all projects require the same amount of detail. Such detail could range anywhere from the inclusion of a standard specification requiring the contractor to be governed by local noise ordinances, to realigning the highway, providing for abatement structures, and/or relocation of residents.

The effective control of highway construction noise can be achieved in much the same manner as the control of operational traffic by considering the following techniques:

Another effective technique is the inclusion of operational conditions via contract specifications and special provisions.

Public Involvement and project coordination are also essential components of the overall mitigation strategy worthy of consideration during all phases of a project. For a more detailed discussion of this topic, refer to Chapter 8.

Most of the options presented in this chapter can be employed independently or in combination, depending on the scope of the project and the resultant effects that are desired. While reductions in noise levels will vary with the method employed, consideration of all practical and feasible options is essential during all stages of the project development from planning through design and construction to final evaluation.

Noise impacts can occur on any project involving the construction of a highway facility. While the magnitude of the impact construction noise may have on a community may not be known early in the project development stages, measures can be implemented during the design phase that can help to reduce the anticipated noise impacts at sensitive receptors. However, design changes and modification to project layout are not always practical or feasible. Also, the magnitude of the noise reduction attained from some of these techniques is usually difficult to determine prior to and possibly even during construction.

In addressing construction noise mitigation during the design phases of a project, abatement opportunities can be considered for a variety of areas and features including those listed below:

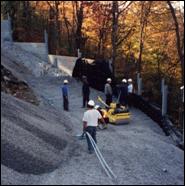

Figure 7.1 Storage area in highway right-of-way (Photo #177)

Figure 7.2 Partial shielding of storage area in residential area (Photo #247)

Figure 7.3 Storage area in remote location (Photo #1257)

|

Figure 7.4 Designated haul routes (Photo #560) |

Figure 7.5. Shifting of traffic to accommodate construction. (Photo #1261)

|

Figure 7.6 Existing retaining wall acting as noise barrier during construction (Photo #543) |

The sequencing and scheduling of construction operations is equally important in addressing and mitigating construction-related noise:

Figure 7.7 Early construction of noise barriers (Photo #447)

Alternatives to standard construction techniques may also be available and determined to be more practical and/or cost-effective in dealing with construction noise impacts and perceptions. Examples associated with several operations are discussed below.

|

Figure 7.8 Alternative to pile driving (Photo #509) |

|

Figure 7.9 Diesel compressor with baffled housing (Photo #69) |

Contract specifications and special provisions are typically produced during the design stages of project development and may be included in the project plans and contract documents. Ideally, use of these documents is considered in conjunction with other control methods to achieve an overall construction noise strategy. Examples of such specificationsref023, ref028, ref103, and ref053 are referenced in this Handbook.

When establishing suitable noise criteria limits for specifications and special provisions, they can be characterized as either being "relative" or "absolute" or a combination of both. These can be defined even further by dividing the set limits into specific time periods during the day, such as daytime, evening, and nighttime. Experience has shown that the "absolute" criteria combined with the "relative" criteria levels appears to be more realistic and tends to be self-adjusting to varying conditions, particularly when defined for the various periods of the day. An example of one such set of construction noise criteria is shown in Table 7.2.

Table 7.2 Example of Absolute and Relative Construction Noise Criteria Limits.

| Lot-Line Construction Noise Criteria Limits A-weighted in dB, RMS slow | ||||||

|---|---|---|---|---|---|---|

| Noise Receptor Locations and Land-Uses | Daytime (7 AM - 6 PM) | Evening (6 PM - 10 PM) | Nighttime (10 PM - 7 AM) | |||

| L10 | Lmax | L10 | Lmax | L10 | Lmax | |

| Noise-Sensitive Locations: (Residences, Institutions, Hotels, etc.) | 75 or Baseline + 5 (whichever is louder) | 85 90 (impact) | Baseline + 5 | 85 | Baseline + 5 > (if Baseline <70) >Baseline + 3 (if Baseline 70) | 80 |

| Commercial Areas: (Businesses, Offices, Stores, etc.) | 80 or Baseline + 5 | None | None | None | None | None |

| Industrial Areas: (Factories, Plants, etc.) | 85 or Baseline + 5 | None | None | None | None | None |

Notes: L10 noise compliance readings are averaged over 20 minute intervals. Lmax noise compliance readings can occur instantaneously. Baseline noise conditions must be measured and established prior to construction work, commencing in accordance with the noise specification, which requires baseline noise readings over three 24-hour periods at each receptor lot-line location.

Source: Adapted from Central Artery/Tunnel Noise Specification and Table 2 in Appendix A.

As shown in Table 7.2, the noise specification's lot-line criterion is primarily a relative criterion in which construction noise levels, in general, can not exceed baseline (preconstruction) L10 noise levels by more than 5 dB at identified noise sensitive receptor locations. Lmax noise limits also apply at the lot lines and are intended to address loud impact-type noise events. In the above criteria, the following three types of receptor land uses have been suggested:

The lot-line criteria limits are more stringent for residential receptors than for commercial or industrial receptors in lieu of the more sensitive nature of residential land uses. In addition, there are different criteria limits depending on various times of day, with the most restrictive noise limits applied to the more sensitive nighttime period.

As shown in Table 7.3, contract specifications can also contain an absolute noise criterion which can be applied to generic classes of heavy equipment to limit their noise emissions. Equipment-specific A-weighted Lmax noise limits, in dBA, evaluated at a reference distance of 50 feet, are defined in the noise specification. Thus, contract specifications could contain two types of noise criteria limits (relative lot-line limits and absolute equipment emissions limits), defining compliance requirements for the contractor. Consequently, if measured or anticipated construction noise levels exceed the allowable noise criteria limits, noise mitigation measures may be warranted during similar work activities.

Table 7.3 Example of Possible Construction Equipment Noise Emission Criteria Limits.

| Equipment Description | Lmax Noise Limit at 50 ft, dB, slow |

Equipment Description | Lmax Noise Limit at 50 ft, dB, slow |

|---|---|---|---|

| All other equipment > 5 HP | 85 | Gradall | 85 |

| Auger Drill Rig | 85 | Grader | 85 |

| Backhoe | 80 | Horizontal Boring Hydraulic Jack | 80 |

| Bar Bender | 80 | Hydra Break Ram | 90 |

| Blasting | 94 | Impact Pile Driver (diesel or drop) | 95 |

| Boring Jack Power Unit | 80 | Insitu Soil Sampling Rig | 84 |

| Chain Saw | 85 | Jackhammer | 85 |

| Clam Shovel | 93 | Mounted Impact Hammer (hoe ram) | 90 |

| Compactor (ground) | 80 | Paver | 85 |

| Compressor (air) | 80 | Pickup Truck | 55 |

| Concrete Batch Plant | 83 | Pneumatic Tools | 85 |

| Concrete Mixer Truck | 85 | Pumps | 77 |

| Concrete Pump | 82 | Rock Drill | 85 |

| Concrete Saw | 90 | Scraper | 85 |

| Crane (mobile or stationary) | 85 | Slurry Plant | 78 |

| Dozer | 85 | Slurry Trenching Machine | 82 |

| Dump Truck | 84 | Soil Mix Drill Rig | 80 |

| Excavator | 85 | Tractor | 84 |

| Flat Bed Truck | 84 | Vacuum Street Sweeper | 80 |

| Front End Loader | 80 | Vibratory Concrete Mixer | 80 |

| Generator (25 KVA or less) | 70 | Vibratory Pile Driver | 95 |

| Generator (more than 25 KVA) | 82 | Welder | 73 |

Source: Adapted from Central Artery/Tunnel Noise Specification

Time constraints and use of equipment regulations can be effective in reducing the impacts caused during sensitive time periods. In addition, operating noisy equipment only when necessary and switching off such equipment when not in use can minimize noise impacts.

Figure 7.10 Nighttime bridge construction (Photo #661)

Figure 7.11 Nighttime demolition operation (Photo #1049)

Another effective noise mitigation technique involves use of the quietest practical type of equipment. To avoid confusion and misinterpretations, such types should be specified in the contract specifications and special provisions.

Another technique worthy of consideration involves the inclusion of incentives and/or disincentives in the contract specifications to encourage contractors to participate in the mitigation program and to make the contractors more accountable for impacts.

It may be appropriate to require contractors to participate in training programs related to project-specific noise requirements, specifications, and/or equipment operations. Such training may be provided by agency or project management personnel, outside consultants, and/or equipment manufacturers or suppliers. For example, project personnel (or consultants assigned to the project) may train the contractor in the measurement of construction-related noise levels that may be required to meet the contract specifications.

The contractor may also receive onsite training related to noise-specific issues and noise-critical areas and sites adjacent to the project. Equipment manufacturers and/or suppliers may be available to provide training to the contractor on the proper use of the noise abatement features of specific pieces of construction equipment. Any training requirements that are envisioned to be required would typically be described or referenced within the contract's specifications and special provisions.

Source control is, in general, the most effective form of noise mitigation and involves controlling a noise source before it is able to emit potentially offensive noise levels. Construction noise (exclusive of blasting) is typically generated by two source types:

Noise levels from both types of noise sources are dependent on equipment characteristics and their operation.

The following discussions relate to both stationary and mobile construction equipment:

|

|

Figure 7.12 In some instances, using a less noisy piece of equipment (right) may be possible, as opposed to using more conventional and sometimes noisier equipment (left) to perform the same operation (Photos #505 & #506)

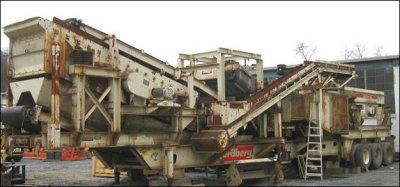

Figure 7.13 Muffler system on recycling equipment (Photo #1287)

Figure 7.14 Unshielded, non-baffled equipment (Photo #74) |

Figure 7.15 Shielded compressor (Photo #18) |

|

|

Figure 7.16 Examples of pile driver shielding and dampening (Photos #1277, #1281 & #1308) |

|

|

Figure 7.17 Bubble curtain (Photo #57) |

See References 030, 036, 046, 054, 060, 061, and 102 for information related to aquatic effects.

Figure 7.18 Bubble curtain air release ring (Photo #51)

Figure 7.19 Bubble curtain (Photo #52)

|

Figure 7.20 Straw bail enclosure for stationary equipment (Photo #58) |

Figure 7.21 Blasting mats constructed with black tires (in foreground of photo) (Photo #261)

Figure 7.22 Blasting mats being placed into position (Photo #1341)

Figure 7.23 Older equipment may be as efficient as new, but may not meet noise emission requirements (Photo #809)

Figure 7.24 Newer paving equipment (Photo #813)

Figure 7.25 Regular service of equipment is an essential component to quietest operation possible. Equipment suppliers may also be valuable sources of training related to proper use of equipment. (Photo #827)

Whenever possible, positioning stationary noise sources such as generators and compressors as far away as possible from noise sensitive areas should be considered. Temporary barriers can be employed and/or enclosures can be built around noisy equipment. These techniques can significantly reduce noise levels and, in many cases, are relatively inexpensive. These barriers can typically be constructed on the work site from common construction building material (plywood, block, stacks, or spoils). Enclosures are often constructed from commercial panels lined with sound absorbing material to achieve the maximum possible shielding effect. To be effective, the length of a barrier should be greater than its height, the noise source should not be visible, and any barrier should be located as close as possible to either the noise source or the receiver. In addition, providing increased distance between a noise source and a noise receiver can also be considered a form of abatement. |

Figure 7.26 Temporary shielding of stationary equipment (Photo #1340) |

Figure 7.27 Temporary barrier around stationary activity (Photo #1339)

Many construction operations are mobile and tend to progress along the length of a project at varying rates. Noise levels at the receiver tend to vary considerably, not only as the speed and power of the equipment varies, but also as the equipment is constantly changing in terms of its distance from the receivers and its relative location. To address this, all the equipment noise mitigation techniques listed in Section 7.4.1 are worthy of consideration with the exception of the enclosures. Enclosing mobile equipment is usually not possible, unless the operation is slow moving and the enclosures can be easily moved.

In some situations, such as in urban areas or on isolated sections of a project, it may be beneficial and necessary to construct barriers adjacent to the work area or at the right-of-way. These can take the form of natural shielding, temporary shielding, and/or permanent shielding.

Utilizing existing shielding such as berms, existing noise barriers, or structures for relatively static equipment such as pumps, generators, compressors, air ventilation, batch plants, and storage areas may be appropriate.

Figure 7.28 Existing noise barrier left in place until replacement noise barrier is constructed (Photo #483)

Figure 7.29 Equipment and storage area shielded by existing structures (Photo #558)

Advantage may also be taken of the screening effect of any nearby object such as parapet walls, buildings, trailers, or temporary site offices.

|

|

|

|

Figure 7.30 Use of existing structure and temporary plywood on chain link fence plus absorptive mats to shield recycling equipment (Photos #690, #390, #395 & #679)

Figure 7.31 Temporary barrier of plastic material (Photo #194)

Other temporary abatement techniques include the use of temporary and/or movable shielding for both specific and nonspecific operations. Some mobile shielding is capable of being moved intact or being repeatedly erected and dismantled to shield a moving operation. An example of such a barrier utilizes noise curtains in conjunction with trailers to create an easily movable, temporary noise barrier system.

|

|

|

Figure 7.32 Storage trailers modified to act as temporary noise barrier (Photos #1030 & #1029) |

As mentioned in Section 7.2.2, shielding of certain construction activities may be accomplished by specifying that the construction of permanent noise barriers be implemented as early as possible during the project's construction phase. Obviously, some noise-producing activities will likely be required before such barriers can be constructed. In addition, the actual erection of the noise barriers is a noise generating activity.

Figure 7.33 Early construction of permanent noise barriers (Photo #472)

Mitigation at a receiver can vary in its complexity, ranging anywhere from relocating residents for a day to insulation of a building. Even after mitigation measures have been applied, the outcome may still be unpredictable with no guarantees that the implemented methods achieve expected results. Therefore, mitigation at the receiver should only be considered as a last alternative. However, there are cases where creative techniques have been successfully implemented.

Building envelope mitigation to reduce construction noise can include techniques such as sealing existing building elements, providing new sealed windows and doors, adding building insulation, etc. Such techniques, while effective, may also require modification of the building's heating, ventilation, and air conditioning system. Prior to proposing such treatments, thorough consideration of the costs and implications of such modifications is suggested.

|

|

|

|

Figure 7.34 Installation of a complete air handling system and window treatments at urban school solely to abate construction noise due to future conversion of arterial to depressed expressway (Photos #1300, #1303 & #1304)

The following discussion of window treatments is based on information provided in Reference 009. The reader is directed to this reference document for more information.

Acoustical window treatments to improve the noise reduction qualities of residential window openings represents a proven successful means to implement receptor noise control. In general, window openings are the weak link in a structure's external façade, allowing noise infiltration into the building. When properly specified and installed, window treatments can provide for a significantly quieter interior noise environment, particularly in multi-story buildings with upper floors that may not benefit from typical noise barriers. In general, window treatments are most cost-effective when a relatively few or widely scattered number of receptors require noise mitigation. Window treatments have the added attraction of reducing noise from all noise sources, such as traffic noise, aircraft noise, and general community noise, in addition to reducing construction noise.

Several forms of acoustical window treatments are available. Each has its pros and cons:

The recommended type of window treatment for a given receptor should be evaluated on an individual basis. If the existing windows and frames are in decent physical condition and if the window frame depth will allow the necessary air space (~ 3 inches), then the most cost-effective treatment may involve insertion of interior storm sashes. If, however, an existing window or frame is in disrepair, then a full replacement acoustic window may be more appropriate.

Timing and logistic issues that may challenge any window treatment program could include:

In light of these issues, a project should consider evaluating any window treatment options based on some eligibility criterion that evaluates the need and justifies window treatments on a case-by-case basis.

It is recommended that any type of noise abatement treatment applied to a building be verified as to its proper installation and performance. Providing funding for such treatments directly to a property owner without such a performance and verification program is not recommended and, in fact, would be against federal regulations.

Noise masking is a technique that is still in the developmental stage but may have potential in isolated cases. Masking considerations could include techniques such as constructing water falls or other cascading water designs, employment of noise cancellation technologies, changing "background" noise levels, etc. Such techniques require a consideration of the type of noise generator (stationary, mobile, etc.), the source's noise frequency content, variability of the noise source in terms of its magnitude and duration, and the noise environment of the receptor being protected.

|

|

Figure 7.35 Experimental sound system used to mask nighttime construction noise in the community (Photos #42 & #38)

In certain instances it may be appropriate, and possibly more cost-effective, to temporarily relocate a resident or residents from the construction area. By temporarily eliminating the noise receptor, noisy construction activities may be able to be undertaken unimpeded and completed in far less time than would be required under a noise-restrictive procedure. Such a technique was employed when several spans of a damaged interstate highway structure required demolition in close proximity to a row of residences. The residents were relocated to a hotel for a weekend while the damaged bridge structure was completely demolished. Another project which included relocation of residents as a mitigation measure is discussed in Reference 103.

After the potential impacts resulting from the construction activities have been established, the next step in the process is the selection of appropriate control measures to be implemented on the project. This can typically be accomplished by identifying all feasible measures that could be used, selecting the most suitable techniques, and assembling them into a final mitigation strategy.

This stage involves identification of control strategies that could be implemented to bring about the desired reductions in noise impacts. Some of the factors that influence this identification process are:

Based on these and other factors, various noise mitigation strategies can be examined to determine what measures are best suited for implementation on a specific project. Factors influencing this selection include:

This stage involves the selection of a reasonable control strategy from the methods examined in the identification stage. The measure or measures chosen should be weighed as to their benefits compared to their adverse effects. This weighting should take into consideration:

Regardless of the types of noise abatement strategies and techniques employed on any particular project, successes or failures are ultimately determined by resultant effects on noise levels at sensitive sites and the adherence of the resultant noise levels to the stated construction noise level criteria.

Evaluation of such success or failure is typically addressed by a program, the requirements of which are usually detailed in the contract specifications and special provisions. An adequate program requires:

On those projects where construction noise impacts require a significant level of physical and operational mitigation, the ability to successfully monitor construction noise is closely tied to the commitment to meet the requirements detailed in the contract specifications and special provisions.

To be able to successfully enforce any project's construction noise requirements, it is essential that the project's specifications and special provisions embody the following:

While 23 CFR 772 requires the evaluation of construction noise and the consideration of mitigation for identified construction noise impacts, it does not include specifications or specific language related to construction noise mitigation techniques, criteria, or restrictions. Such detail is included in various State and local documents, some of which are included as References 001, 009, 053, 077 and 103 and/or referred to in Table 10.1 of this Handbook.