Transportation Builder - May/June 2008

FHWA Funds Test of Work Zone Safety Innovation

Navigating a work zone on a rainy night can be a challenge for drivers, but the Federal Highway Administration (FHWA) will make that task easier through a grant to the 3M Company to refine and test an all-weather pavement marking system for work zone applications.

FHWA provided the $499,277 grant to the St. Paul, Minnesota, company under its Technology Partnerships Program. The program's goal is to refine and test innovations designed to boost highway safety and quality or cut congestion in real-world settings and move them closer to market.

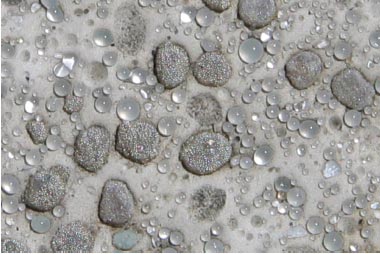

Photo Credit: 3M. Conventional pavement markings can be difficult to see in dark, rainy conditions.

Promoting Innovation & Technology

"The agency's goal is to promote innovation and technology to improve safety performance on the nation's highways" said Jeffrey A. Lindley, FHWA associate administrator for safety. "By supporting the transportation community in refining innovations and making them industry ready, we can enhance safety for both workers and drivers."

The 3M grant was one of five awarded under the FHWA program, designed to advance development of technologies now at the prototype stage in partnership with transportation agencies. FHWA also provided funds to companies to develop an automated pavement marker placement system, an asphalt binder cracking device, an intelligent asphalt compaction analyzer and an aggregate imaging system.

Enhancing Driver Safety

Driving through a work zone with an unfamiliar traffic pattern can be tough enough for drivers, but the addition of dark, rainy conditions that obscure lane markings can make it even harder. The problem is that water reduces the retroreflectivity of conventional pavement markings, which consist of glass beads dropped onto paint, making it difficult for drivers to see the markings on wet nights.

Photo Credit: 3M. The all-weather pavement marking system makes it easier for drivers to navigate wet roads, enhancing work zone safety.

3M has developed a dual-optics, all-weather paint system that is highly reflective in both dry and rainy conditions. The system consists of high-build waterborne paint and standard glass beads, which provide good visibility under dry conditions. The system also includes optical elements made of a ceramic core surrounded by tiny, high-refractive index beads. It's this second set of beads that provides retroreflectivity under wet conditions, particularly rain.

The company plans to use its FHWA Technology Partnerships grant to customize the product for use in work zones, said Dr. Fuat Aktan of 3M's Traffic Safety Systems Division. Such a product would meet the needs of state transportation agencies looking for a cost-effective work zone marking system with wet-weather reflectivity similar to 3M's all-weather paint system.

"Enhancing the visibility of pavement markings under wet nighttime conditions makes it easier for drivers to go through work zones," Lindley added.

Adapting to Work Zones

In phase one, the company changed variables in the pavement marking system—such as bead mixture, drop rate, paint type, and paint thickness—to develop more than 20 different samples. The samples were applied to a New Orleans, La., roadway and evaluated under normal traffic conditions. From the results of those tests, the company will choose three samples to undergo visibility and human-factor experiments at the Texas Transportation Institute, 3M's partner on the project.

In phase two, the winning formula will be put to the test in work zones. Some transportation agencies have already volunteered to try the marking system on upcoming projects, but to improve the chances that the system will undergo adequate wet-weather testing, 3M is considering the participation of additional agencies in rainy parts of the country.

Photo Credit: 3M. The 3M system combines standard glass beads with core elements surrounded by tiny, high-refractive beads to maintain optimal visibility in both wet and dry conditions.

These tests will be used to monitor traffic and driver behavior to see whether drivers can see the markings in the rain and find their lanes easily. Through this process, the research team hopes to identify the best system for an all-weather work zone pavement marking system with potential for widespread use to promote driver safety, improve work zone throughput and reduce congestion.

To Learn More

For more information on FHWA's Technology Partnerships Program or on participating in tests of the technologies, contact Julie Zirlin, Technology Partnerships Program coordinator, at (202) 366-9105 or julie.zirlin@dot.gov.

For more information on 3M's all-weather pavement marking system, contact Fuat Aktan at (651) 733-5041 or faktan@mmm.com.