PowerPoint Presentation - Asphalt Binder Cracking Device (ABCD)

Slide 1

Project Team: EZ Asphalt Technology, LLC, PRI Asphalt Technologies

Award: $239,386

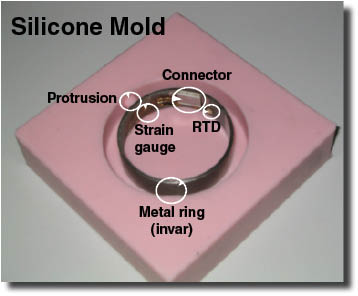

ABCD ring in silicone mold

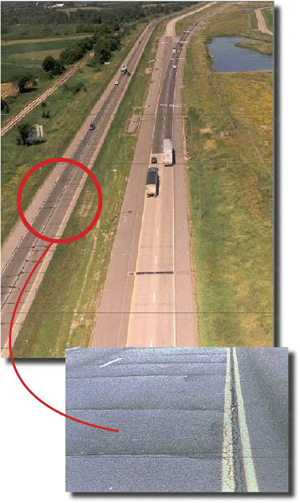

Low temperature thermal cracking

Slide 2 – What Is It?

- ABCD is a test fixture that induces thermal stresses in asphalt binder up to the point of fracture

- Unlike the current standard test, the ABCD test simulates cracking in the field

Slide 3 – Need

- Low temperature thermal cracking (contraction of the pavement) is a major type of asphalt pavement failure

- Nationally, tens of billion dollars are spent to fix cracked pavements every year

Anticipated Advantages:

- A more practical and meaningful laboratory test than the current industry standard specification

- Simpler procedure developed

- Less equipment needed

- Closer approximation to field conditions

- Very promising and supported with data from exploration under the NCHRP IDEA program

Slide 4 – How Does the Test Work?

A ring of metal with very low thermal contraction is instrumented to measure temperature and strain

Asphalt binder is poured around the ring then cooled to very low temperatures in a controlled manner

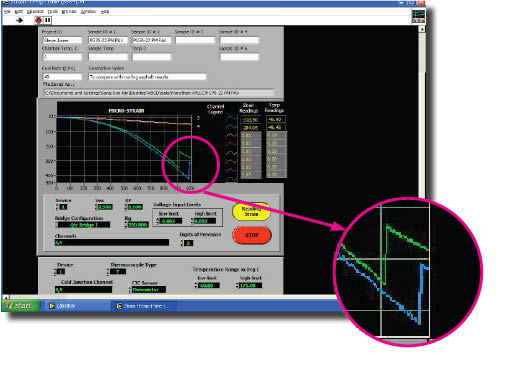

Slide 5 – Cracked specimens collected from the ABCD test

Cracked specimens collected from the ABCD test.

The asphalt binder contracts more than the metal restricting the binder, which induces tensile stresses.

The asphalt binder fractures, and the temperature of fracture is registered in a computer data acquisition system.

Magnified area: Specimen strain jump due to cracking.

Slide 6 – Planned Refinements

Free Piston Sterling Cooler

VS.

Conventional Environmental Chamber

- Simplifications to both the software and the hardware

- Replaces the need for a large temperature cooling chamber

- Lightweight

- Operator friendly

- Smaller in size

- Little to no moving parts

- Automatic data processing and analysis after test completed