U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

| This report is an archived publication and may contain dated technical, contact, and link information |

|

Publication Number: FHWA-HRT-06-106 Date: September 2009 |

CHAPTER 5. FIELD APPLICATIONS AND TEST RESULTSINTRODUCTIONExperimental tests and results discussed in chapter 4 show that FRP dowels can provide sufficient LTE under heavy traffic load rating (HS25 load and 1.5 times HS25). The purpose of the field test program was to investigate FRP dowel performance and FRP-concrete interaction in full-scale highway pavement slabs under realistic loading and field exposure conditions. Field application and tests were done in collaboration with the WVDOT DOH. FRP dowels were used for new pavement construction and rehabilitation of damaged pavement sections. FRP dowel joints were used for new highway pavement construction on Route 219 and Route 33 East in Elkins, WV, from September to November 2001. Field tests were conducted in July 2002 and June 2003. FRP dowels were used for pavement rehabilitation at the junction of Routes 119 and 857, University Avenue, Morgantown, WV, during October 2002. FRP DOWELS FOR NEW HIGHWAY PAVEMENT CONSTRUCTIONFRP dowels were used during the construction of new highway Route 219 and Route 33 East in Elkins, WV. The installation and field test setup are discussed in this section. Field test results are also analyzed and discussed. Field LocationsTwo locations separated by about 6.4 km (4 mi) were selected for field installations in corridor H highway at Route 219 and Route 33 in Elkins, WV. Location 1 (figure 55 and figure 56) was westbound, and location 2 (figure 57 and figure 58) was eastbound.

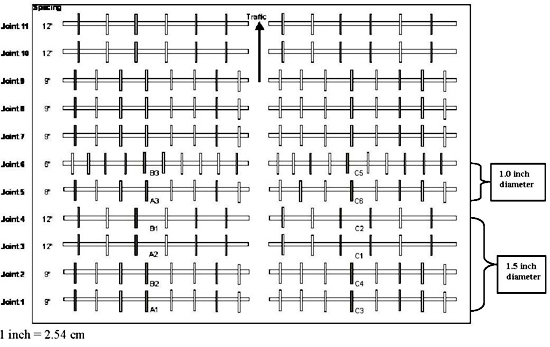

Only dowels with shading in figure 56 were instrumented.  Figure 57. Photo. FRP dowel bars at location 2 of corridor H, Route 219, Elkins, WV. Side pipes carried wires from instrumented dowels to the outside of the shoulder region (figure 57).  Figure 58. Diagram. Only dowels with shading in figure 58 were instrumented. Field InstallationFRP dowels were instrumented with strain gauges (figure 59) to monitor strains in dowel bars installed in the field. Embeddable concrete strain gauges (figure 60) were also installed to monitor strains in the pavement. Dowel bars with 2.54-cm (1.0-inch) diameter (figure 60) and 3.81-cm (1.5-inch) diameter (figure 61) were supported by plastic baskets at design spacings of 30.48, 22.86, 20.32, or 15.24 cm (12, 9, 8, or 6 inches) (figure 56 and figure 58). Plastic baskets were anchored by either steel stakes (figure 60) or plastic stakes (figure 61). Construction was carried out as shown in figure 62 and figure 63. Wires from instrumented dowels were carried through hollow polyvinyl chloride pipes to the outside of the pavement shoulder (figure 63).

FIELD TESTSFigure 64 shows a standard AASHTO Type 3 truck load that was used to carry out field evaluations before and after opening the pavement to the traffic.(12) Strain gauge readings were recorded prior to and after pavement construction (November 2001) and also during the field testing conducted in July 2002 and June 2003. The automatic data acquisition system was used to collect test data. Field Test Before Opening Highway to Traffic in July 2002A field test was completed before opening the pavement to traffic in July 2002. Static and dynamic tests including brake tests were conducted during this test. Parameters used for field testing are provided in table 24. Table 24. Parameters of the field test at location 2, July 2002.

Test SetupA WVDOT truck with calibrated loads was used in the tests (table 24). The truck was positioned at required locations to apply load on instrumented dowels (figure 58 and figure 64). The loading test for a joint consisted of guiding a truck slowly toward the designated joint from about a 15.24-m (50-ft) distance. The unloading test for a joint consisted of guiding a truck initially placed on the pavement joint to leave the joint slowly. All strain gauges on FRP dowels and embeddable concrete gauges were connected to data acquisition (figure 65). Dial gauges were fixed on a long, adjustable stand system. Dial gauges were positioned according to the spacing of dowels (figure 55 through figure 58) at the pavement joint considered for testing. The span of the dial gauge stand system was long enough to support it on adjacent pavement to avoid the influence of support deflections. Strains in dowels and deflection of pavement on loaded and unloaded sides of the joint were recorded.

Test Results and AnalysisStrain Data from Field Static Tests:About 60 percent of strain gauges installed on FRP dowels were found to be working properly after field installation and pavement construction. It was also found that some strain data recorded by the data acquisition system contained significant noise. Field test results of four cases of FRP dowels were analyzed. Joints with different diameters and spacing have been described in this section. Data for brake tests and dynamic tests from different vehicle speeds are included. Performance of FRP dowels with different diameters and/or spacings chosen from the field installation (table 25) are discussed in the next several sections with respect to the following:

Table 25. Joint details used for analysis.

Figure 66. Diagram. Dowel A1 (3.81-cm (1.5-inch) diameter, 22.86-cm (9-inch) spacing);

Figure 67. Chart. Strains in dowel during loading and unloading cases for gaugeA1-LT

Figure 68. Diagram. Dowel A2 (3.81-cm (1.5 inch) diameter, 30.48-cm (12-inch) spacing);

Figure 69. Chart. Strains in dowel during loading and unloading cases for gauge A2-LT

Figure 70. Diagram. Dowel C5 (2.54-cm (1.0-inch) diameter, 15.24-cm (6-inch) spacing);

Figure 71. Chart. Strains in dowel during loading case for gauge C5-U1 (2.54-cm (1.0-inch) diameter,

Figure 72. Diagram. Dowel C6 (2.54-cm (1.0-inch) diameter, 20.32-cm (8-inch) spacing);

Figure 73. Strains on dowel during loading case for gauge C6-U1 (2.54-cm (1.0-inch) Strain Data from Dynamic Tests: Dynamic tests were conducted in this field evaluation. The loaded WVDOT truck with speeds of 16.09, 32.19, 48.28, and 80.47 km/h (10, 20, 30, and 50 mi/h) crossed the selected joint containing instrumented FRP dowels. Data were collected through the automatic data acquisition system during truck speeding and braking of the speeding truck at 48.28 km/h (30 mi/h) close to the joint. Test results are shown in figure 74 and figure 75. Figure 74. Chart. Strain from gauge A1-LT (3.81-cm (1.5-inch)-diameter FRP dowel

Figure 75. Chart. Strain from gauge A2-LT (3.81-cm (1.5-inch)-diameter FRP dowel Dynamic test results recorded contained significant noise, and hence, data are not further discussed. Analysis of test result:Figure 66 through figure 73 show changes in dowel strain near pavement joints during truck loading and unloading. Stresses at points on inpidual dowels can also be obtained according to the stress-strain relationship under bending. Table 26 contains a summary of the above strain values. Table 26. Summary of FRP dowel strain during loading and unloading.

1 inch = 2.54 cm The following can be found from table 26:

Deflection Data:The WVDOT truck was guided toward the pavement joint on top of the chosen dowel location so that a heavier wheel load, which was located in the rear axles, could be applied. Pavement deflections increased when the WVDOT truck slowly approached the joint, but most of the deflection changes were less than the detectable range of the dial gauges with a count of 0.0254 cm (0.001 inch). In the second field test, LVDTs were used instead of dial gauges for better precision in deflection detection. Field Test after Highway Opened to Traffic, June 2003This field test was conducted about 1 year after opening the pavement to traffic. Test parameters are listed in table 27. They are similar to those for the first field test, except that the deflection measurements were made using LVDTs, and there were no dynamic/brake tests. The main purpose of this field test was to investigate deflection behavior and LTE of concrete pavement joints with different diameters and spacing of FRP dowel bars. Figure 76 through figure 79 show details of the field test setup. Table 27. Parameters of the field test, June 2003.

It should be noted that the wheel load due to AASHTO HS25 is 9.071 metric tons (20,000 lbs), which is about twice the WVDOT truck wheel load used for this test. Under the AASHTO wheel load, larger deflections and strains can be expected. Figure 76. Photo. WVDOT truck used for field tests.

Test Results from Field TestFour concrete pavement joints with instrumented dowels were tested during the second field test. Details of the joints and FRP dowels are shown in table 28. Table 28. Pavement joint for deflection analysis.

Test results are shown in figure 80 through figure 86 and further analyzed in the next section.

1 inch = 2.54 cm >Summary and Analysis of Test ResultsA summary of the test results shown in figure 80 through figure 84 is provided in table 29 in terms of pavement deflection, LTE, and RD for pavement joints having 3.81- and 2.54-cm (1.5- and 1.0-inch)-diameter FRP dowels with different spacings of 30.48, 22.86, 20.32, and 15.24 cm (12, 9, 8, and 6 inches). Table 29. Summary of joint deflection under maximum loading force.

1 inch = 2.54 cm Values in table 29 cannot be compared to each other directly because, in addition to diameter and spacing, deflections depended on combinations of other parameters such as base/sub-base properties, contact area between concrete and base, and others. It should also be noted that truck wheel load position on dowels embedded in concrete may vary from one dowel to the other. The pavement surface was serrated to provide friction, and hence, there was the possibility of LVDT shaft tips sliding into those slots and showing slightly higher deflections. However, additional tests will be conducted in the future to compare LTE and RD. For this field test, LTE is shown in figure 85 and table 30, and RD is shown in figure 86 and table 31. Figure 85. Graph. Comparison of LTE from field test (average value was used for joint 2).

Table 30. Values for LTE Comparison from field test.

Figure 86. Graph. Comparison of RD from field test (average value was used for joint 2).

1 inch = 2.54 cm Table 32. Comparing joint 2 and 3.

1 inch = 2.54 cm The following can be observed from this table:

FRP DOWELS USED FOR HIGHWAY PAVEMENT REHABILITATIONFRP dowels were used for pavement rehabilitation at the junction of Routes 119 and 857, University Avenue, Morgantown, WV. Two joints were selected; one with 3.81-cm (1.5-inch)diameter FRP dowels and 30.48-cm (12-inch)-c/c spacing, the other with 3.81-cm (1.5-inch) diameter steel dowels at 30.48-cm (12-inch)-c/c spacing. Dowel installation and field test setup are discussed in this section. Test results from both FRP and steel dowels are analyzed and discussed under the results and analysis subsection. Field LocationTwo joints were selected for rehabilitation of an existing pavement near the junction of Routes 119 and 857, University Avenue, Morgantown, WV, as shown in figure 87. Rehabilitation was carried out in October 2002.

Field InstallationDeteriorated concrete slabs were cut by a special concrete sawcutting machine and then lifted out. Next, 3.81-cm (1.5-inch)-diameter holes were drilled through the concrete slabs up to 22.86 cm (9 inches) deep (half of dowel length). Each pavement joint consisted of 11 dowels with 3.81-cm (1.5-inch) diameters spaced at 30.48 cm (12 inches) c/c. Each joint was provided with two instrumented dowels. Strain gauges were bonded onto both top and bottom surfaces of those dowels prior to installation. Strain gauges were about 1.27 cm (0.5 inch) away from the centerline of the joint. After positioning dowels in the drilled holes, epoxy resin was filled into the circumferential gap between concrete and dowel. Rehabilitation carried out using FRP and steel dowels is shown in figure 88 through figure 91.

FIELD TESTSTest SetupA standard truck load was not used for field loading purposes. Strain readings due to regular traffic (figure 87), including some loaded trucks driving at 32.2–64.4 km/h (25–40 mi/h) were recorded using an automatic data acquisition system (figure 92). Due to the heavy traffic volume existing at this road section, pavement deflection measurements were not recorded.

Results and AnalysisBoth strain gauges were installed in the vehicle-approaching side (figure 89 through figure 91) of the pavement joint. Hence, before a vehicle wheel crossed the joint, the strain gauge side of the joint remained the loaded side, and, right after the wheel crossed a joint, the strain gauge side became the unloaded side. Strain readings due to a truck load from regular traffic are shown in figure 93 and figure 94. FRP Dowel GroupStrain gauge readings from two instrumented FRP dowels (dowel A and dowel B in figure 89) are discussed in this section. Data from strain gauges mounted on top of these dowels are shown in figure 93. Note that not all data due to continuous traffic are plotted in figure 93; only strain values from a truck load with maximum values are shown.  Figure 93. Chart. Strain from FRP dowels in rehabilitated pavement. Strain gauge data between recorded traffic time of 345.9 and 346.5 s correspond to the movement of the first wheel load. Due to truck load, maximum strains (-52.52 and -65.8 microstrain) occurred when the wheel loads were close to the joint in adjacent dowels. Based on strain values, it appears that the front axle carried more load than the rear axle, and vehicle impact factor could have also played a role. Strain gauge data between the recorded traffic time of 346.7 and 347.5 s correspond to the movement of the last wheel load crossing the joint. During this time period, gauges from FRP dowels A and B experienced a strain change from loaded status (-28.17 and -36.24 microstrain) to unloaded status (31.04 and 17.16 microstrain), respectively. The total strain change was 59.21 (28.17 + 31.04) microstrain for dowel A and 53.4 (36.24 + 17.16) microstrain for dowel B. The ratio of unloaded value to loaded value was 31.04/28.17 = 1.10 (dowel A) and 17.16/36.24 = 0.47 (dowel B). These ratios indicate the possibility of the wheel loads crossing at an angle over the dowel. It should be noted that the pavement was on an upward gradient with respect to traffic direction. Steel Dowel GroupStrain gauge readings from one instrumented steel dowel (dowel C in figure 90) are discussed here. Data from the strain gauge mounted on top of this dowel are shown in figure 94. Note that not all data due to continuous traffic are plotted in figure 94; only strain values in dowel C from a truck load with maximum values are shown.

Strain gauge data between traffic time 151.2 and 151.6 s correspond to the movement of the first wheel load crossing the joint. Maximum compressive strains occurred at the beginning of the load, which was -11.49 microstrain, which may partly include vehicle impact effect. Strain gauge data between traffic time 151.8 and 152.2 s correspond to the movement of the last wheel load crossing the joint. During this time period, gauges from steel dowel C experienced a strain change from loaded status (-8.14 microstrain) to unloaded status (12.93 microstrain), respectively. The total strain change was 21.07 (8.14 + 12.93) microstrain for dowel C. The ratio of unloaded value to loaded value was 12.93/8.14 = 1.59 (dowel C). The following factors contributed to this ratio of unloaded/loaded strain > 1, where readings appeared to be from those vehicles just beginning to accelerate from their stopped position near traffic lights at junction:

CONCLUSIONFrom both the first and second field tests conducted on the newly constructed highway in Elkins, WV (see chapter 5), it is concluded that change in strain value for the same dowel during loading and unloading cases was almost the same. Effect of Dowel Spacing

Effect of Dowel DiameterBoth 3.81-cm (1.5-inch)-diameter FRP dowel groups and 2.54-cm (1.0-inch)-diameter FRP dowel groups with spacing varying from 30.48 to 15.24 cm (12 to 6 inches) provided very good LTE (greater than LTE of 60 percent, which corresponds to ACPA's 75 percent joint effectiveness value). Currently, there is no requirement or limitation for the RD from AASHTO's Guide for Pavement Structures.(1) From field tests, the maximum RD was 17.78 × 10-3 mm (0.70 × 10-3 inch), but, from lab testing, it was a maximum of 10.922 × 10-3 mm (43 × 10-3 inch) (table 16). It should be noted that joint width was due to different joint models and thermal variables. From field tests conducted on the rehabilitated pavement in Morgantown, WV (see chapter 5), the following is concluded:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||