U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-13-050 Date: November 2013 |

Publication Number: FHWA-HRT-13-050 Date: November 2013 |

This chapter further describes the implementation steps introduced in chapter 3 to reinforce the RSI concept and process. Specifically, three hypothetical examples addressing the six RSI implementation steps are provided for illustration purposes.

LCC analyses are used as part of step 5 in the three examples; it is assumed that they are performed on each set of viable construction events described in the respective examples and that the lowest LCC scenario from the possible combinations of constructions events is selected for the pavement segment in question. Because of their importance to RSI, LCC considerations are discussed in a separate section at the end of this chapter.

The PHT analysis tool was developed by FHWA for the Highway Economic Requirements System and the National Pavement Cost model, but it is also used by other SHAs. It is an engineering software application used for determining and reporting the health of pavement networks. The pavement models used in this tool are based on concepts developed for the AASHTO MEPDG, but they have been simplified (both models and procedures) for purposes of the tool.(5) Both structural (distress) and functional (IRI) pavement performance models are included in the tool. The primary source data for the tool is the 2010+ version of the HPMS program data tables. Data items (state or material type defaults) not provided by the HPMS program but are required by the new pavement models are provided as default data tables developed mostly using Long-Term Pavement Performance data and MEPDG default data tables. Alternatively, an SHA can input data from its PMS.

In this example, the RSI concept is adapted by an SHA using the PHT analysis tool within the context of pavement network-level analyses, where the network is comprised of primary routes (i.e., State routes). To limit its scope, only composite hot mix asphalt (HMA) overlays on jointed plain concrete pavements (JPCPs) are addressed in this example.

1. Setting Construction Triggers

The PHT analysis tool makes use of simplified MEPDG pavement performance models. Accordingly, the construction triggers for HMA/JPCP pavements are reflection cracking and pavement smoothness (IRI).

2. Setting Threshold Limits

Because the RSI concept is adapted for pavement network-level analysis, threshold limits have been established for the following construction events:

The resulting construction trigger-threshold limits matrix for reflection cracking or IRI is provide in table 1.

Table 1. Reflection cracking or IRI construction triggers-threshold limits.

Construction Event |

Reflection Cracking (percent) |

IRI, inches/mi (m/km) |

|---|---|---|

Do nothing |

No cracking |

< 90 (< 1.42) |

Corrective maintenance |

> 0 to 15 percent |

90 to 150 (1.42 to 2.37) |

Rehabilitation |

15 to 25 percent |

150 to 250 (2.37 to 3.94) |

Reconstruction |

> 25 percent |

> 250 (> 3.94) |

3. Selecting or Developing Expectancy Performance Curves

Simplified MEPDG reflection transverse cracking and smoothness (IRI) models are used in the PHT analysis tool for HMA/JPCP pavements. Accordingly, these models are used in this demonstration of the RSI concept. The reflection cracking model is given as follows:(5)

![]()

Figure 13. Equation. Reflection cracking model.

Where:

RCRK = Percent of cracks reflected (percent area of reflection cracking assumes a reflected crack width of 1 ft (0.305 m)).

AGE = Pavement age (years after asphalt overlay placement).

a = 3.5 + 0.75 × Heff.

b = -0.688 − 3.373 × Heff − 0.9154.

c = 1.0.

Heff = HHMA − 1 (for JPCP with good joint load transfer efficiency (i.e., faulting < 0.03 inches (0.76 mm)) or HHMA − 3 (for JPCP with poor joint load transfer efficiency (i.e., faulting ≥ 0.03 inches (0.76 mm)).

HHMA = Asphalt layer thickness.

The values of the reflective cracking model parameter d are presented in table 2.

Table 2. Reflective cracking model parameter d.

Effective Asphalt Overlay Thickness, inches (mm) |

Delay Cracking by |

Accelerate Cracking by 2 Years |

|---|---|---|

< 4 (< 100 mm) |

0.6 |

3.0 |

4 to 6 (100 to 150 mm) |

0.7 |

1.7 |

> 6 (>150 mm) |

0.8 |

1.4 |

The IRI prediction model is as follows:

![]()

Figure 14. Equation. IRI prediction model.

Where:

IRI = Predicted IRI (inches/mi).

INI_IRI = Initial IRI (inches/mi; use MEPDG default of 63.4 inches/mi (1.0 m/km)).

MRUT = Total rutting (inches).

CRACK = Alligator cracking (percent lane area).

TRANS_CK = Transverse cracking (ft/mile).

SF = Site factor (function of mean annual precipitation; amount of fine sand, silt, and clay size particles in subgrade; mean annual freezing index; subgrade soil plasticity index; and age of pavement after asphalt overlay placement).

4. Identifying Collection of Inputs

To support the expectancy performance curves detailed in step 3, the following input data are required for each pavement segment in the network:

5. Establishing a Strategy Selection Process

For each pavement segment in the network, LCC analyses are performed to identify the strategy having the lowest LCC.

For those segments having more than 25 percent reflection cracking and/or an IRI value greater than 250 inches/mi (3.94 m/km) (RSI = 0 years), the LCC analysis is limited to the reconstruction strategy. For all other segments, more than one construction treatment, hence RSI, are considered. For example, for a segment having 5 percent reflective cracking and an IRI value of 120 inches/mi (1.89 m/km), the following scenarios developed using the PHT analysis tool will be considered (each having a unique RSI in terms of years to construction event):

A 30-year LCC analysis will be performed for each of the viable construction events described, and the lowest LCC scenario will be selected for the pavement segment in question.

Due to budgetary constraints, the agency will prioritize the LCC results for all the pavement segments in the network to select those segments that will receive some sort of treatment in a given year. The prioritization will be done based on annual average daily traffic (AADT) and percent trucks. Once the segments that will receive a construction treatment have been selected, the project-level design of the construction event and subsequent construction will be turned over to the districts for implementation.

6. Performing Periodic Assessments and Updates

Implementing the RSI concept is anticipated to be completed within 1 year. Once finished, the agency will perform an assessment of the resulting system at the end of 1 year and every other year afterwards. Updates to the system will be planned based on the results of the assessments. In addition, the agency will implement necessary updates to keep pace with technology (e.g., improved expectancy curves and possible additional inputs, improved pavement monitoring equipment and analysis software, etc.).

A State transportation department is using the 1972 AASHTO Interim Guide for Design of Pavement Structures pavement equations for both design and management purposes.(7) As such, the pavement condition of roads in its network is being monitored and forecasted in terms of PSR. The agency plans on implementing the RSI concept at both the project and network levels. The agency’s network is comprised of roads having multiple functional classifications, but all of them are either new HMA pavement or existing HMA pavement overlaid with HMA.

1.Setting Construction Triggers

Because the agency is using the 1972 AASHTO Interim Guide for Design of Pavement Structures pavement equations for both design and management purposes, the construction trigger for all pavement segments in the network will be PSR.(7)

2. Setting Threshold Limits

The RSI concept is to be adapted for pavement network- and project-level analyses. Accordingly, threshold limits have been established for the following construction events:

Network level:

Project level:

The resulting construction triggers-threshold limits matrices are provide in table 3 and table 4 for the network and project levels, respectively.

Table 3. Network-level construction trigger-threshold limits.

Construction Event |

Functional Class |

PSR |

|---|---|---|

Do nothing |

All |

> 3.8 |

Maintenance |

Primary |

3.0–3.8 |

Secondary |

2.8–3.8 |

|

Tertiary |

2.6–3.8 |

|

Rehabilitation |

Primary |

2.0–3.0 |

Secondary |

1.8–2.8 |

|

Tertiary |

1.6–2.6 |

|

Reconstruction |

Primary |

< 2.0 |

Secondary |

< 1.8 |

|

Tertiary |

< 1.6 |

Table 4. Project-level construction trigger-threshold limits.

Construction Event |

Functional Class |

PSR |

|---|---|---|

Do nothing |

All |

> 3.8 |

Preventive maintenance |

Primary |

3.2–3.8 |

Secondary |

3.0–3.8 |

|

Tertiary |

2.8–3.8 |

|

Corrective maintenance |

Primary |

2.8–3.2 |

Secondary |

2.6–3.0 |

|

Tertiary |

2.4–2.8 |

|

Mill/thin HMA overlay |

Primary |

2.4–2.8 |

Secondary |

2.2–2.6 |

|

Tertiary |

2.0–2.4 |

|

Mill/thick HMA overlay |

Primary |

2.0–2.4 |

Secondary |

2.0–2.2 |

|

Partial reconstruction |

All |

1.6–2.0 |

Full reconstruction |

All |

< 1.6 |

3. Selecting or Developing Expectancy Performance Curves

The 1972 AASHTO Interim Guide for Design of Pavement Structures flexible pavement design equation is used for both design and management purposes.(7) Accordingly, this equation, shown in figure 15, will be used in the implementation of the RSI concept.

![]()

Figure 15. Equation. Flexible pavement design equation.(7)

Where:

Wt18 = Equivalent 18-kip (40-kN) single-axle load application.

R = Regional factor.

Si = Soil support value.

The number equivalent 18-kip (40-kN) single-axle load applications, or Wt18, is computed as a function of the AADT, direction split, percent trucks, lane distribution, and traffic growth factor. Equivalency factors are used to relate different axle loads to 18-kip (40-kN) single-axle load applications. For pavement management purposes (i.e., for RSI), Wt18 is also expressed in terms of time (years), which are computed using the same inputs just referenced.

The structural number (SN) is defined as follows:

Where:

ai = Structural layer coefficient of the various layer that make up the pavement structure

(a function of material type and properties).

di = Thickness of the various layers that make up the pavement structure.

The regional factor or R value varies between 0.2 and 5.0 depending on subsurface moisture and temperature conditions, while the soil support or Si value is established based on correlations with standard soil tests (e.g., California bearing ratio, R, triaxial strength, etc.).

To account for differences in predicted versus actual PSR values, the agency has developed a linear shift factor for the expectancy curve based on time/traffic (i.e., Wt18).

4. Identifying Collection of Inputs

To support the expectancy performance curve detailed in step 3, the following input data will be required for each pavement segment in the network:

5. Establishing a Strategy Selection Process

For network-level analyses, the same strategy selection process as described in example 1 will be used (i.e., LCC analyses are performed for each pavement segment to identify the strategy having the lowest LCC). For example, for primary segments having a PSR less than 2.0 (RSI = 0 years), the LCC analysis is limited to the reconstruction strategy. The same applies for secondary segments having a PSI less than 1.8 and tertiary segments having a PSR less than 1.6. For all other segments, more than one construction treatment, hence RSI, are considered. For example, for a primary segment having a PSR of 3.0, the following scenarios developed using the 1972 AASHTO Interim Guide for Design of Pavement Structures pavement design equation are considered (each having a unique RSI, in terms of years to construction event):(7)

A 30-year LCC analysis is performed for each viable construction event, and the lowest LCC scenario is selected for the pavement segment in question.

Like the first example, due to budgetary constraints, the agency prioritizes the LCC results for all pavement segments in the network to select the segments that will receive some sort of treatment in a given year. The prioritization is done based on functional class, AADT, and percent trucks.

LCC analyses are also performed at the project level using the expanded (project-level) construction events trigger-level matrix. According to this matrix, pavement segments having a PSI less than 1.6 (RSI = 0 years) will undergo full reconstruction, while pavement segments having a PSI of 1.8 may undergo partial reconstruction (RSI = 0 years) or full reconstruction (RSI > 0 years). Similarly, for a primary segment with a PSI of 3.6, the following possible construction treatments (hence RSIs) will be considered:

Unlike the network-level analysis, however, the chosen construction event (and hence RSI) at the project level is not selected based solely on LCC. Rather, the LCC analysis is supplemented with cost engineering considerations specific to each project segment (i.e., cost/benefit analysis of alternative construction treatments using tool developed for the agency). Moreover, each construction event (e.g., overlay thickness) is designed based on project-specific data (i.e., not a standard treatment for each construction event but tailored to the project).

6. Performing Periodic Assessments and Updates

Implementation of the RSI concept is anticipated to be completed within 18 months. The first 12 months will be spent setting up and fully testing the system, while the remaining 6 months will be spent rolling out the RSI concept within the agency, including training agency personnel. Once implemented, the agency plans on assessing the resulting system on an annual basis. Changes and updates to the system will be implemented based on the results of the assessments as well as on new technology. In addition, because the agency plans on migrating to the AASHTO MEPDG in 5 years, a targeted effort will be dedicated to updating the RSI system within the context of the MEPDG performance models, including the assessment and/or revisions to construction triggers, threshold limits, expectancy curves, collection of inputs, strategy selection process, and future assessments and updates.

Consider a pavement network consisting of three primary roadways, two secondary roadways, and a tertiary roadway. For this small network, it is assumed that the regional factor would be equal throughout, and the typical average annual value of 1 is used. Soil type throughout the network ranges from silty clay to sandy gravel, and the age of the pavements and traffic loadings account for some of the variation and rate of change in PSR values.

Table 5 contains the current PSR value and the predicted PSR value after 3 and 10 years. The PSR values degrade at different rates due to the differences in traffic loading, pavement age, and structural properties. Based on the construction trigger-threshold limits matrix for the network level, the years to construction event (RSI) is given for each type of construction treatment based on the 1972 AASHTO Interim Guide for Design of Pavement Structures pavement design equation for the given PSR values (see figure 15).(7)

Table 5. RSI based on PSR values and construction treatment.

|

Pavement ID |

Functional Class |

PSR Current |

PSR |

PSR |

Construction Treatment |

Current |

3-Year RSI (years) |

10-Year RSI (years) |

|---|---|---|---|---|---|---|---|---|

1 |

Primary |

3.6 |

3.2 |

2.3 |

Maintenance |

0 |

0 |

N/A |

Rehabilitation |

6 |

3 |

N/A |

|||||

Reconstruction |

15 |

11 |

3 |

|||||

1 |

Primary |

3.0 |

2.7 |

2.1 |

Maintenance |

0 |

N/A |

N/A |

Rehabilitation |

4 |

2 |

< 1 |

|||||

Reconstruction |

9 |

7 |

1 |

|||||

2 |

Primary |

2.8 |

2.3 |

1.3 |

Maintenance |

N/A |

N/A |

N/A |

Rehabilitation |

3 |

2 |

N/A |

|||||

Reconstruction |

8 |

3 |

0 |

|||||

3 |

Secondary |

3.4 |

3.1 |

2.5 |

Maintenance |

0 |

0 |

N/A |

Rehabilitation |

6 |

4 |

2 |

|||||

Reconstruction |

15 |

12 |

6 |

|||||

4 |

Secondary |

2.9 |

2.7 |

2.2 |

Maintenance |

1 |

N/A |

N/A |

Rehabilitation |

4 |

3 |

1 |

|||||

Reconstruction |

10 |

8 |

4 |

|||||

5 |

Tertiary |

3.2 |

3.0 |

2.6 |

Maintenance |

3 |

2 |

0 |

Rehabilitation |

6 |

4 |

2 |

|||||

Reconstruction |

15 |

13 |

7 |

Some pavement sections have PSR values below the threshold limit for the respective construction trigger; therefore, that construction type is not applicable to that pavement section, and the next construction type must be considered.

The RSI values are based on the threshold limits for each construction trigger and not the age of the pavement section. This explains why the difference between the current RSI and the RSI after 10 years (or 3 years) is not always 10 years (or 3 years).

An SHA manages a large network made up of primary State routes only that are comprised entirely of JPCP of varying ages ranging from less than 1 year to 15 years. After several months of deliberations and planning, the agency has recently embarked in the migration of their pavement design and management procedures from the 1986 AASHTO Guide for Design of Pavement Structures.(4) As part of this migration, the agency has decided to include pavement structural capacity and surface friction as additional pavement performance indicators. Moreover, the agency has decided to move forward with the adoption of the RSI concept but is making no distinction between network- and project-level analyses based on the intensive data collection activities they currently have in place.

1. Setting Construction Triggers

The agency has embarked in the implementation of the RSI concept using multiple performance indicators. Those indicators include the following:

2. Setting Threshold Limits

Because the RSI concept is to be adapted for both network- and project-level analyses, without distinction in terms of construction events, threshold limits have been established for the following construction events:

The resulting construction trigger-threshold limits matrix is provide in table 6.

Table 6. Construction trigger-threshold limits matrix.

Construction Event |

Transverse Cracking (Percent Area) |

Transverse Joint Faulting, inches (mm) |

IRI, inches/mi (m/km) |

Effective PCC Thickness Ratio |

FN |

|---|---|---|---|---|---|

Do nothing |

0 |

< 0.05 |

< 90 (< 1.42) |

> 0.95 |

> 60 |

Preventive maintenance |

> 0–1 |

N/A |

N/A |

N/A |

N/A |

Corrective maintenance |

1–3 |

N/A |

N/A |

N/A |

N/A |

Diamond grinding |

N/A |

0.05–0.10 (1.27–2.54) |

90–120 |

N/A |

40–60 |

Grooving |

N/A |

N/A |

N/A |

N/A |

< 40 |

CPR |

3–5 |

N/A |

N/A |

0.95–0.85 |

N/A |

Ultra-thin PCC overlay |

5–10 |

0.10–0.15 (2.54–3.81) |

120–175 (1.89–2.76) |

0.85–0.75 |

N/A |

PCC overlay |

10–15 |

0.15–0.25 (3.81–6.35) |

175–250 (2.76–3.94) |

0.75–0.65 |

N/A |

Removal and replacement of PCC |

15–25 |

> 0.25 |

> 250 |

0.65–0.50 |

N/A |

Removal and replacement of pavement |

> 25 |

N/A |

N/A |

< 0.50 |

N/A |

3. Selecting or Developing Expectancy Performance Curves

Since the SHA is migrating from the 1986 AASHTO Guide for Design of Pavement Structures to the AASHTO MEPDG, the pavement performance models contained in the latter guide have been selected for implementing the RSI concept without deviations.(4,5) These models are applicable to the following pavement performance indicators:

For the pavement structural capacity performance indicator, the agency will use the ratio of current to initial (at time of construction or overlay) effective PCC thickness, where thickness is determined in terms of an equivalent standard modulus of 4,000,000 psi (27,560 MPa) using backcalculated layer moduli data and equivalencies based on the stiffness equation. The agency has chosen to proceed with this ratio as a result of the extensive FWD deflection testing program it has had carried out over the past 15 years. Specifically, effective PCC thickness ratio prediction models have been developed for the various regions in the State from the massive amount of deflection data collected and analyzed over the years.

To account for the seasonal variations in the deflection data, the agency has also developed temperature and moisture correction factors to adjust the effective PCC thickness ratio to a standard temperature and moisture state. In addition, the agency has developed shift factors for the prediction models to account for differences between predicted and measured ratios.

In terms of the pavement surface friction performance indicator, the SHA has been working closely with a neighboring SHA to develop a FN performance model based on data they have gathered over the past decade on JPCP pavements. Jointly, these two agencies have determined that the initial FN for their pavements is 65 on average and that there is a constant rate of deterioration (decrease in FN) equal to -0.80 FN per year. For example, a new pavement that has been in service for 10 years is expected to have a FN = 57. Similarly, a pavement that presently has a FN = 42 is expected to fall below FN = 40 in less than 3 years. As was the case with the effective PCC thickness ratio, the agency has developed shift factors for the FN prediction model to account for differences between predicted and measured FN values.

4. Identifying Collection of Inputs

To support the expectancy performance curves detailed in step 3, the following input data will be required for each pavement segment in the network:

5. Establishing a Strategy Selection Process

The strategy selection process that will be used is the same for both network- and project-level analyses; an LCC analysis-based optimization technique developed by the State’s main university will be used to identify the optimal construction treatments at the appropriate times. The only distinction will be the amount of data that will be used to support project-level analyses (i.e., FWD deflection and skid testing at shorter intervals (as compared to those described in step 4) within the segment units.

To illustrate the strategy selection process, the following example is provided. A 5-year-old pavement segment has been determined (through measurements and/or predictions using expectancy curves) to be in the following condition: transverse cracking = 2 percent, transverse joint faulting = 0.12 inches (3 mm), IRI = 80 inches/mi (1.26 m/km), effective PCC thickness ratio = 0.90, and FN = 50.

Based on the performance condition information and using the selected and developed expectancy curves, the RSIs for the segment in question and the associated construction treatments are summarized in table 7.

Based on the information in the table, it should be apparent that corrective maintenance, ultra-thin PCC overlay, and diamond grinding are required (i.e., RSI = 0 years) to address transverse cracking, transverse joint faulting, and FN, respectively. Clearly, the ultra-thin PCC overlay trumps the other two construction treatments, but this does not imply that the agency will proceed with this construction treatment or one of the other two, as it may be more cost effective to place a PCC overlay in 6 years.

Table 7. RSI based on construction treatments.

Construction Event |

Transverse Cracking |

Transverse Joint Faulting |

IRI |

Effective PCC Thickness Ratio |

FN |

|---|---|---|---|---|---|

Do nothing |

N/A |

N/A |

0 years |

0 years |

N/A |

Preventive maintenance |

N/A |

N/A |

N/A |

N/A |

N/A |

Corrective maintenance |

0 years |

N/A |

N/A |

N/A |

N/A |

Diamond grinding |

N/A |

N/A |

5 years |

N/A |

0 years |

Grooving |

N/A |

N/A |

N/A |

N/A |

13 years |

CPR |

4 years |

N/A |

N/A |

7 years |

N/A |

Ultra-thin PCC overlay |

12 years |

0 years |

14 years |

13 years |

N/A |

PCC overlay |

18 years |

6 years |

21 years |

20 years |

N/A |

Removal and replacement of PCC |

24 years |

12 years |

28 years |

26 years |

N/A |

Removal and replacement of pavement |

32 years |

19 years |

N/A |

30 years |

N/A |

Based on this example, it is apparent that selecting the timing and the type of construction treatment to be applied to the segment in question or any other segment in the network is not an easy task. In turn, this is the reason the agency has decided to use the LCC analysis-based optimization technique to facilitate the strategy selection process. The technique uses the following steps for each segment in the network:

Once the three steps are completed, the total network budget requirements for the next 5 years are considered. If the requirements are greater than the available funds, additional analyses are performed by considering other options beyond the lowest LCC. More specifically, the same three steps are completed by looking at the next lowest LCC value for each segment having lower costs within the first 5 years until the optimum network solution is identified.

6. Performing Periodic Assessments and Updates

Given the scope of work, the effort is anticipated to be completed in 2 years. Once finished, the agency will perform assessments every 6 months during the first 2 years and annual assessments afterwards. Changes and updates to the system will be implemented based on the results of these assessments. In addition, the agency will perform updates to incorporate improved AASHTO MEPDG, structural capacity, and/or FN performance models. Moreover, in their efforts to fully automate all of their pavement performance data collection, the agency plans on replacing its current FWD fleet in 5 years with a moving pavement deflection testing device capable of measuring deflection basins. As such, an updated version of the effective PCC thickness ratio model will be required in support of the RSI processes.

LCC analyses were purposely used as part of the strategy selection process (step 5) in all three examples due to their importance to the decisionmaking process. A summary of LCC analysis, as presented by FHWA, is as follows:(8)

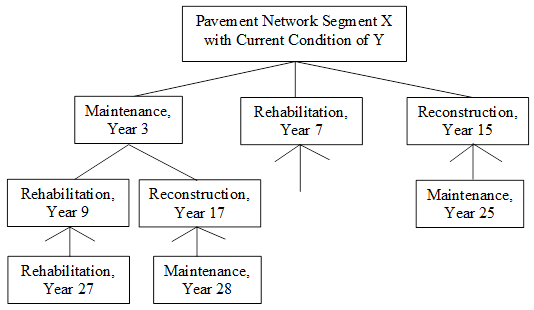

In the three examples presented in this chapter, it was assumed that LCC analyses were performed for each of the viable construction events described in the respective examples and that the lowest LCC scenario from the possible combinations of constructions events was selected for the pavement segment in question. In the first example, the combinations of construction events considered over the selected 30-year analysis period included corrective maintenance, rehabilitation, and reconstruction. A partial set of possible combinations of construction events and schedule of activities for the first example is provided in figure 17.

It is important to note that in all three examples, the RSI for reconstruction is not independent of preservation and/or rehabilitation considerations nor is the RSI for rehabilitation independent of preservation considerations in the life-cycle assumptions used as the basis for the determination. The streams of LCCs consist of a future stream of activities, which include preservation, rehabilitation, and reconstruction treatments. To a large extent, the level of dependency is dictated by the pavement performance expectancy curves selected as part of the RSI process.

Figure 17. Flowchart. Partial set of construction event combinations and schedule of activities for example 1.

It is also important to note that the lowest LCC option may not necessarily be implemented when other considerations such as risk, available budgets, and political and environmental concerns are taken into account. LCC analysis provides critical information to the overall decisionmaking process but does not necessarily provide the final answer. This is the case in the third example, where options other than the lowest LCC may need to be considered and selected in order to determine a total network budget for the next 5 years that is within the available funds.