U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-17-090 Date: January 2018 |

Publication Number: FHWA-HRT-17-090 Date: January 2018 |

This chapter details the comparison of the time-series trends of performance measures against documented M&R treatments to assess the effects of the treatments. The trends in individual metrics and the overall pavement condition ratings over time were reviewed against recorded M&R treatments to determine whether they demonstrated any type of change in response to those treatments. For this analysis, the last survey prior to the M&R treatment was compared to the first survey after the M&R treatment. The surveys were not necessarily taken immediately before and after the M&R treatments. In some cases, a year or more transpired between the placing of the M&R treatment and the survey date.

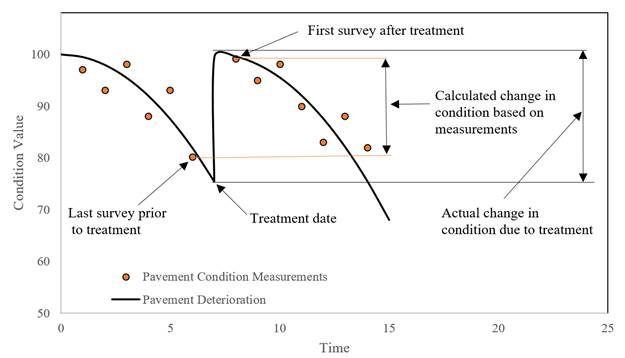

The potential effect on the calculated change in condition versus the actual change in condition, depending on how closely the last survey prior to treatment and the first survey after treatment are measured, is illustrated in figure 3 and figure 4. As an example, in figure 3, the last survey prior to treatment was taken a year prior to the treatment date, and the first survey after treatment was taken a year after the treatment date. The actual change in condition as a result of the treatment was an improvement of 24 points. However, the condition improvement calculated based on the condition at the time of the last survey prior to treatment and the condition at the time of the first survey after treatment was only 19 points due to the time between survey measurements and treatment application. This results in a difference between the calculated change in condition based on the measurements at the time of survey and the actual change in condition due to treatment of more than 20 percent.

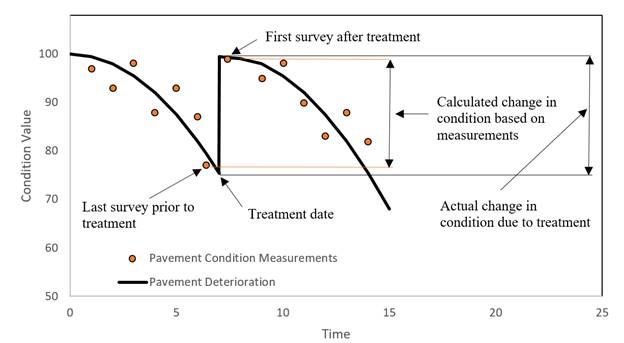

Similarly, in figure 4, the last survey prior to treatment was taken 7 months prior to the treatment date, and the first survey after treatment was taken 5 months after the treatment date. The actual change in condition as a result of the treatment was again 24 points. With the time between survey measurements and the treatment application being reduced from the first example, the improvement in condition value calculated based on the last survey prior to treatment and the first survey after treatment was 22 points. The difference between the calculated change in condition based on measurements and actual change in condition due to treatment was reduced to about 8 percent.

These two examples illustrate the importance of considering the time of survey dates as they relate to the treatment date. The closer the timing of the before and after treatment surveys to the time of treatment application, the more reliable the data in terms of M&R effects.

Source: FHWA.

Figure 3. Graph. Effect of survey dates on difference in change in condition—2 years between surveys.

Source: FHWA.

Figure 4. Graph. Effect of survey dates on difference in change in condition—1 year between surveys.

Figure 5 presents a flowchart detailing the steps required to assess the effects of M&R treatments on overall pavement condition.

The steps shown in figure 5 are as follows:

For multiple and different improvements for a single construction event, the improvement should be grouped based on the treatment expected to have the greatest influence on pavement surface. For example, crack sealing and shoulder restoration should be classified as crack sealing, since shoulder restoration has no impact on the pavement metrics or overall condition rating.

For illustration purposes, the various treatment types present within the LTPP data were grouped into categories based on similarity as shown in table 12 through table 14 by pavement type—AC, JPCC, and CRCP, respectively. For AC pavements, for example, the treatment categories include crack seal, grinding, mill and overlay, overlay, patch, and surface treatment. The treatment types in these tables represent the various types of treatments grouped together under each category. In table 12, for example, mill and overlay, mill existing pavement and overlay with hot-mix recycled AC, and mill off AC and overlay with AC are different treatment types that have been grouped together as mill and overlay. The paired treatments in the three tables are those that were applied at the same time as the treatment type but that are not expected to have as much influence on the surface. For example, in table 12, AC shoulder restoration applied at the same time as AC overlay is grouped as overlay, since the AC overlay treatment is expected to have more of an effect on the pavement surface condition.

This section addresses the characterization of the effect of M&R treatments on the individual pavement metrics. Figure 6 illustrates an AC pavement segment that received an overlay in January 2013. The last survey prior to the treatment was taken in February 2011, when the percent cracking was 21 percent (i.e., in poor condition according to table 1). The first survey after treatment was in December 2014, when the percent cracking was 3.1 percent (i.e., in good condition according to table 1). Therefore, the effect of the overlay on the percent cracking condition of the AC pavement in question was to improve it from poor to good.

Figure 7 illustrates a pavement segment that received a patch in year 5. Most often, patching does not positively affect the percent cracking for AC pavements, as documented in the companion research study report that led to these guidelines.(4) The percent cracking may be reduced a small amount as a result of patching, as depicted in figure 7. In this example, the last survey prior to treatment had a percent cracking of 8.5 percent (in fair condition according to table 1). The first survey after treatment had a percent cracking of 6 percent (in fair condition according to table 1). Although the percent cracking improved slightly, the percent cracking condition remained fair according to table 1 (i.e., no change in metric condition).

Figure 8 illustrates a pavement segment that received a patch in year 4. Unlike the previous example, this figure depicts pavement condition (in terms of the percent cracking metric) worsening or deteriorating as a result of the patch. Again, the application of a patch has little effect on the percent cracking. The last survey prior to treatment had a percent cracking of 4 percent (in good condition according to table 1). The first survey after treatment had a percent cracking of 5.6 percent (in fair condition according to table 1). Therefore, the percent cracking condition deteriorated from good to fair after the application of the patch (i.e., worse condition).

These examples have provided more detail on sample scenarios for when the effect of M&R treatment results in no change in condition, worse condition, or improved condition. These examples are not exhaustive of scenarios that could be encountered but illustrate only one possible situation that results in the effect on condition. Once the effect of M&R treatments on the metric condition is characterized in step 3, the same process is used to characterize the effect of M&R treatments on overall condition in step 4 above.

Measurement error can also contribute to the condition deteriorating over time or after the application of a treatment. As shown in figure 2, due to the range of likely measurable values, it is possible for the measured value to decrease or have a negative growth rate due to the intervals of likely measurable values.

The effect of the M&R treatment on AC cracking by treatment type is presented in table 15. The table shows that mill and overlay and overlay most often improve the cracking condition and, to a lesser degree, surface treatment. The other treatments largely do not affect the percent cracking condition or result in a reduction in condition.

Once the effects of M&R treatments are assessed for each metric, the next step is to develop a treatment matrix that summarizes the M&R treatments that improved the metric conditions. Table 16 presents the percent improvement of the metric conditions by M&R treatment for AC pavements based on a subset of LTPP data. As shown, the mill and overlay and overlay treatments are the most effective ones at improving all three metric conditions. The percent improvement shown in table 16 is based on the pre-treatment and post-treatment conditions. For example, the mill and overlay treatment improves the roughness condition 41 percent of the time, which may appear to be low. However, a closer look at the data reveals that the roughness condition for the remaining 59 percent did not change; that is, the pre-mill and overlay condition and post-mill and overlay condition were both good, and therefore there was no change in condition. On the other hand, for those pavement sections where the pre-treatment roughness was not in good condition (remaining 41 percent of the time) and a mill and overlay treatment was applied, the roughness condition always improved.

Once the effect of M&R treatments at the individual metric level is understood, the effect of M&R treatments on the overall condition should be assessed. The overall condition is assigned as good, fair, or poor based on the pavement segment metric condition combinations, as explained in chapter 1 of these guidelines. Similar to the metric-level analysis, the condition after the treatment is then compared to the condition prior to treatment, and the effect of the treatment on pavement condition is characterized as no change, worse, or improved. LTPP data were used to illustrate the effect on overall condition by M&R treatments presented in table 17. As shown in this table, the treatments that are most likely to improve the overall condition for AC pavements are mill and overlay and overlay, while grinding, patching, and surface treatments are much less likely to improve overall condition.

The overall pavement condition of the pavement sections used to develop table 18 was then determined by combining the metric conditions. Table 19 presents the effect of M&R treatments on overall condition for these LTPP JPCC pavement sections. The table shows that most treatments do not have an effect on the overall condition for JPCC pavements. Treatments that do improve the overall condition include grinding, joint seal, and slab replacement. However, these treatments improve the overall condition for less than 5 percent of all the JPCC LTPP pavement sections analyzed. It should be noted that the crack seal, shoulder, and slab replacement treatments are based on limited data. It will be important for State DOTs to perform similar analysis on the JPCC pavements in their network to understand the effects of M&R treatments on the pavement metrics and overall condition.

| Treatment | Roughness (%) | Cracking (%) |

|---|---|---|

| Patch | 5 | 0 |

| PCC overlay | 50 | 23 |

Note: Since patching results in an increase in percent cracking based on how CRCP percent cracking is defined, it is reasonable that patching would not improve the percent cracking and could potentially contribute to condition deterioration.

Table 21 presents the effect on overall condition by M&R treatments for CRCPs. The table shows that only PCC overlay is effective at improving the overall condition of CRCPs in the LTPP dataset.

| Treatment | No Change (%) | Improve (%) | Reduce (%) |

|---|---|---|---|

| Patch | 90 | 0 | 10 |

| PCC overlay | 15 | 85 | 0 |