U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

|

| This report is an archived publication and may contain dated technical, contact, and link information |

|

Publication Number: FHWA-RD-02-082 Date: August 2006 |

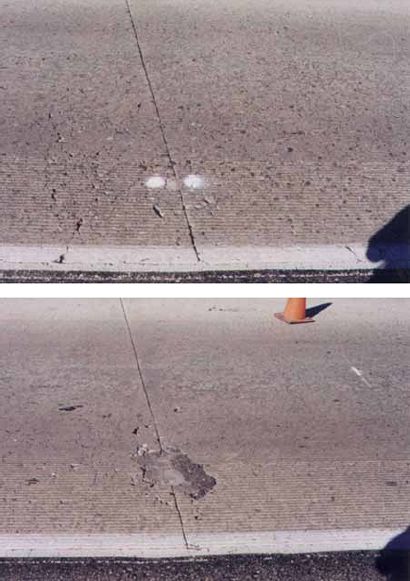

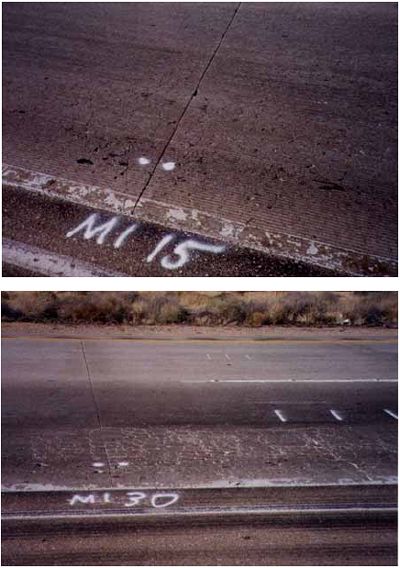

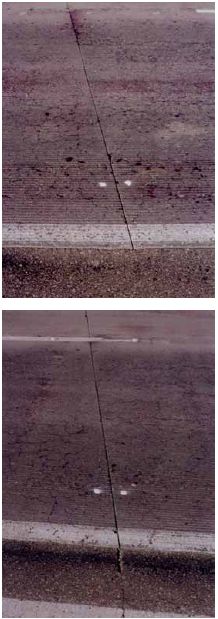

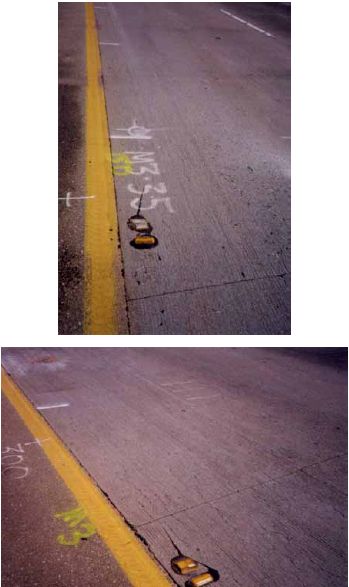

Figure C1. Photographs showing typical areas of each section (Boron, CA).

(a) Control section 1 (C1)

(b) Methacrylate section 1 (M1)

(c) Methacrylate section 2 (M2)

(d) Control section 3 (C3)

(e) Methacrylate section 3 (M3)

Petrographic Report for Boron, CA, 1997

Two sections from each of the cores were cut and lapped. These sections were then soaked overnight, dried, and the entire lapped surface was traversed under a stereo microscope. The lapped surface was divided into five or more traverses and examined at magnifications of 10 to 0 times. All instances of cracks, alkali-silica gel, and deteriorated or reacted aggregate particles were counted.

Boron OH No. 1: The surface is worn and partially coated. This core is of smaller diameter than the other cores, and only 8 traverses were made. Twenty-two instances of cracks were counted, with no gel or distressed aggregate particles. The core is classified as slightly to moderately distressed. The core is poorly air-entrained with an estimated air content of 3 percent.

Core 97-C1-3: The surface is moderately worn with moderately frequent popouts over coarse and fine aggregate particles. One hundred ninety cracks and 67 instances of alkali-silica gel were counted. Eight coarse and 20 fine aggregate particles showed evidence of distress or reaction. The core is classified as severely distressed. The core is air-entrained with an estimated air content of 5.5 percent.

Core 97-C2-30: The surface is moderately worn with occasional popouts over aggregate particles. One hundred seventy-four cracks and 24 instances of alkali-silica gel were counted. Eleven coarse and 23 fine aggregate particles showed evidence of reaction or distress. The core is classified as severely distressed. It is air-entrained with an estimated air content of 6 percent.

Core 97-C2-32: The surface is worn and cracked with occasional popouts over aggregate particles. One hundred ninety cracks and 44 instances of alkali-silica gel were counted. Twenty six coarse and 30 fine aggregate particles showed evidence of distress or deterioration. The core is classified as severely distressed. It is air-entrained with an estimated air content of 6 percent.

Core 97-M1-33: The surface is worn with occasional popouts over aggregate particles. One hundred ninety-one cracks and 65 instances of alkali-silica gel were counted. Twenty-three coarse and 33 fine aggregate particles showed evidence of distress or reaction. The core is classified as severely distressed. It is air-entrained with an estimated air content of 5.5 percent.

Core 97-M2-33: The surface is worn and partially coated. Popouts over aggregate particles are occasionally present. On hundred thirty-five cracks and 59 instances of alkali-silica gel were counted. Twenty-nine coarse and 24 fine aggregate particles show evidence of distress or reaction. The core is classified as moderately severely distressed. It is poorly air-entrained and with estimated air content of 3.5 percent.

Core 97-M3-32: The surface is worn and partially coated. Occasional popouts over aggregate particles are present. One hundred thirty-four cracks and 46 instances of alkali-silica gel were counted. Thirty-one coarse and 32 fine aggregate particles show evidence of reaction or distress. The core is classified as moderately severely distressed. It is air-entrained with an estimated air content of 4 percent.

Petrographic Report for Boron, CA, 1998

Sections from each of the cores were cut and lapped. These sections were then soaked overnight, dried, and the entire lapped surface was traversed under a stereo microscope. Each lapped surface was divided into five or more (except the Boron OH cores) traverse areas and examined at magnifications of 10 to 30 times. Due to their smaller diameter (95.25 mm), the Boron OH cores were divided into 4 traverses. All instances of cracks, alkali-silica gel, and deteriorated or reacted aggregate particles were counted.

Boron OH-98-1: The wearing surface is moderately worn. Two cracks intercepting each other at approximate right angles are evident on the surface, and appear to have been repaired with an elastomeric material. The core is moderately severely distressed. Two macroscopic and 29 microcracks were counted. Twenty-one instances of alkali-silica gel were counted. Seven coarse and 8 fine aggregate particles show evidence of reaction or distress. The core is non-air-entrained with an estimated air content of 3 percent.

Boron OH-98-4: The wearing surface is moderately worn. Two cracks intercepting each other at approximate right angles are evident on the surface, and appear to have been repaired with an elastomeric material. The core is moderately severely distressed. One large and 29 microcracks were counted. Thirty-six instances of alkali-silica gel were counted. Eleven coarse and 7 fine aggregate particles showed evidence of reaction or distress. The core is non-air-entrained with an estimated air content of 1.5 percent.

98-C1-40: The wearing surface is severely worn with frequently exposed fine aggregate particles. Two large cracks form a "Y" shaped intercept on the wearing surface. The core is severely distressed. Five large and 86 microcracks were counted, and 49 instances of alkali-silica gel were counted. Twenty-two coarse and 21 fine aggregate particles show evidence of distress or reaction. The core is air-entrained with an estimated air content of 5 percent.

98-C1-42: the wearing surface is moderately severely worn with frequently exposed aggregate particles. Two distinct popouts over aggregate particles are present. The core is severely distressed. Sixty microcracks and 41 instances of alkali-silica gel were counted. Twenty-three coarse and 21 fine aggregate particles show evidence of distress or reaction. The core is airentrained with an estimated air content of 5 percent.

98-C3-41: The wearing surface is severely worn with frequently exposed aggregate particles and worn popouts. The core is severely distressed. Three large cracks, 50 microcracks, and 28 instances of alkali-silica gel were counted. Eleven coarse and 8 fine aggregate particles show evidence of reaction or distress. The core is poorly air-entrained with an estimated air content that varies locally from 2 to 5 percent.

98-C3-42: The wearing surface is severely worn with frequently exposed fine aggregate particles. The core is severely distressed. Two large and 63 microcracks were counted, as were 14 instances of alkali-silica gel. Twelve coarse and 10 fine aggregate particles showed evidence of reaction or distress. The core is air-entrained with an estimated air content of 6 percent.

98-M1-41: The wearing surface is severely worn with frequently exposed aggregate particles.The core is moderately severely distressed. One large and 51 microcracks were counted, and 20 instances of alkali-silica gel were noted. Nine coarse and nine fine aggregate particles showed evidence of distress or reaction. The core is marginally air entrained with an estimated air content of 4 percent.

98-M1-42: The wearing surface is severely worn with frequently exposed aggregate particles.The core is severely distressed. Six major and 84 microcracks were counted, and there were 32 occurrences of alkali-silica gel. Seventeen coarse and 15 fine aggregate particles showed evidence of reaction or distress. The core is poorly air-entrained with an estimated air content of 3.5 percent.

98-M2-40B: The wearing surface is severely worn. Aggregate particles are frequently exposed and polished. The core is severely distressed. Three major and 72 microcracks were counted, and there were 12 instances of alkali-silica gel. Twelve coarse and seven fine aggregate particles show evidence of distress or reaction. The core is marginally air-entrained with an estimated air content of 4 percent.

98-M2-41: The wearing surface is severely worn. Aggregate particles are frequently exposed and polished. The core is severely distressed. Three major and 89 microcracks were counted, as well as 23 occurrences of alkali-silica gel. Eighteen coarse and 16 fine aggregate particles show evidence of reaction or distress. The core is marginally air-entrained with an estimated air content of 4.5 percent.

98-M3-41: The wearing surface is severely worn, with very frequently exposed and polished aggregate particles. The core is moderately severely distressed. Sixty-six microcracks and 29 instances of alkali-silica gel were counted. Fourteen coarse and 7 fine aggregate particles show evidence of distress or reaction. The core is air-entrained and has an estimated air content of 8 percent.

98-M3-42: The wearing surface is severely worn, with very frequently exposed and polished aggregate particles. The core is moderately severely distressed. Sixty-seven microcracks and 24 instances of alkali-silica gel were counted,. Ten coarse and 13 fine aggregate particles showed evidence of reaction or distress. The core is air-entrained with an estimated air content of 6 percent.

| Type | Identification code | Unit | 2/28/95 | 11/8/95 | 12/9/96 | 10/14/97 | 9/29/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 0 | 0 | 0 | 0 | 0 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 0 | 0 | 0 | 0 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 0 | 0 | 0 | 0 | 0 |

| 4L | m | 0 | 0 | 0 | 0 | 0 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 0 | 0 | 0 | 0 | 0 | |

| 4M | m | 0 | 0 | 0 | 0 | 0 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 0 | |

| 4H | m | 0 | 0 | 0 | 0 | 0 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | N | N | N | N | N |

| 5Al | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 0 | 0 | 0 | 0 | 0 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 1 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 32 | 0 | 0 | 0 | 0 |

| 7L(length) | m | 117 | 0 | 0 | 0 | 0 | |

| 7M | no. | 1 | 31 | 11 | 17 | 4 | |

| 7M(length) | m | 3.7 | 113.3 | 40.2 | 67.2 | 14.6 | |

| 7H | no. | 0 | 2 | 22 | 16 | 29 | |

| 7H(length) | m | 0 | 7.4 | 80.2 | 58.5 | 106.1 | |

| Map cracking (for 2/28/95 survey, the 8aL and 8aM amounts were combined due to grading rule changes) | 8aL | no. | remainder | remainder | remainder | remainder | remainder |

| 8aL | m2 | 524.5 | 499.0 | 496.5 | 449.4 | 387.3 | |

| 8aM | no. | 32 | 59 | 47 | 51 | 39 | |

| 8aM | m2 | 32.9 | 56.3 | 40.5 | 74.8 | 86.3 | |

| 8aH | no. | 0 | 2 | 19 | 15 | 27 | |

| 8aH | m2 | 0 | 2.1 | 20.4 | 33.2 | 83.8 | |

| Flexible patch deterioration | 15fL | no. | 4 | 0 | 7 | 7 | 7 |

| 15fL | m2 | 0.5 | 0 | 0.3 | 0.3 | 0.3 | |

| 15fM | no. | 1 | 0 | 0 | 0 | 0 | |

| 15fM | m2 | 0.1 | 0 | 0 | 0 | 0 | |

| 15fH | no. | 0 | 3 | 1 | 1 | 1 | |

| 15fH | m2 | 0 | 0.4 | 0.1 | 0.1 | 0.1 | |

| Rigid patch deterioration | 15rL | no. | 1 | 0 | 1 | 1 | 1 |

| 15rL | m2 | 0.1 | 0 | 0.1 | 0.1 | 0.1 | |

| 15rM | no. | 0 | 0 | 1 | 1 | 1 | |

| 15rM | m2 | 0 | 0 | 0.1 | 0.1 | 0.1 | |

| 15rH | no. | 0 | 0 | 1 | 1 | 1 | |

| 15rH | m2 | 0 | 0 | 0.3 | 0.3 | 0.3 | |

| Bleeding and pumping | 16 | no. | 0 | 0 | 0 | 0 | 0 |

| 16 | m | 0 | 0 | 0 | 0 | 0 | |

| Other | WP-L | no. | 0 | 0 | 0 | 0 | 0 |

| WP-M | no. | 27 | 0 | 6 | 10 | 10 | |

| WP-H | no. | 5 | 32 | 26 | 22 | 22 | |

| CL-L | no. | 26 | 0 | 3 | 1 | 0 | |

| CL-M | no. | 6 | 32 | 22 | 26 | 26 | |

| CL-H | no. | 0 | 0 | 7 | 5 | 6 | |

| Total joint length at level (from sheet 6) | L | m | 117.8 | 62.5 | 33.8 | 30.8 | 0.0 |

| M | m | 2.4 | 53.3 | 76.5 | 82.6 | 99.1 | |

| H | m | 0.5 | 4.9 | 10.4 | 7.6 | 22.2 | |

| Total joint length (from sheet 6) | Total | m | 120.7 | 120.7 | 120.7008 | 121 | 121.3 |

| Percent L | – | 98 | 52 | 28 | 25 | 0 | |

| Percent M | – | 2 | 44 | 63 | 68 | 82 | |

| Percent H | – | 0 | 4 | 9 | 6 | 18 | |

| Map cracking | Total | no. | 0 | 0 | 0 | 0 | 0 |

| Total | m | 557.4182 | 557.4182 | 557.4182 | 557.4182 | 557.4182 | |

| Percent L | – | 94 | 90 | 89 | 81 | 69 | |

| Percent M | – | 6 | 10 | 7 | 13 | 15 | |

| Percent H | – | 0 | 0 | 4 | 6 | 15 | |

| Spalling of transverse joints (using 10 rule) | Total | no. | 33 | 33 | 33 | 33 | 33 |

| Total | m | 120.7 | 120.7 | 120.4 | 125.7 | 120.7 | |

| Percent L | – | 97 | 0 | 0 | 0 | 0 | |

| Percent M | – | 3 | 94 | 33 | 53 | 12 | |

| Percent H | – | 0 | 6 | 67 | 47 | 88 | |

| Type | Identification code | Unit | 2/28/95 | 11/8/95 | 12/9/96 | 10/14/97 | 9/29/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | not tested | 0 | 0 | ||

| 1M | no. | not tested | 0 | 0 | |||

| 1H | no. | not tested | 0 | 0 | |||

| Durability cracking | 2L | no. | not tested | 0 | 0 | ||

| 2L | m2 | not tested | 0 | 0 | |||

| 2M | no. | not tested | 0 | 0 | |||

| 2M | m2 | not tested | 0 | 0 | |||

| 2H | no. | not tested | 0 | 0 | |||

| 2H | m2 | not tested | 0 | 0 | |||

| Longitudinal cracking | 3L | m | not tested | 0 | 0 | ||

| 3L(sealed) | m | not tested | 0 | 0 | |||

| 3M | m | not tested | 0 | 0 | |||

| 3M(sealed) | m | not tested | 0 | 0 | |||

| 3H | m | not tested | 0 | 0 | |||

| 3H(sealed) | m | not tested | 0 | 0 | |||

| Transverse cracking | 4L | no. | not tested | 0 | 0 | ||

| 4L | m | not tested | 0 | 0 | |||

| 4L(sealed) | m | not tested | 0 | 0 | |||

| 4M | no. | not tested | 0 | 0 | |||

| 4M | m | not tested | 0 | 0 | |||

| 4M(sealed) | m | not tested | 0 | 0 | |||

| 4H | no. | not tested | 0 | 0 | |||

| 4H | m | not tested | 0 | 0 | |||

| 4H(sealed) | m | not tested | 0 | 0 | |||

| Transverse joint seal damage | Sealed | y/n | not tested | N | N | ||

| 5Al | no. | not tested | 0 | 0 | |||

| 5aM | no. | not tested | 0 | 0 | |||

| 5aH | no. | not tested | 0 | 0 | |||

| Longitudinal joint seal damage | No. Sealed | no. | not tested | 0 | 0 | ||

| 5b | m | not tested | 0 | 0 | |||

| Spalling of longitudinal joints | 6L | m | not tested | 0 | 0 | ||

| 6M | m | not tested | 0 | 0 | |||

| 6H | m | not tested | 0 | 0 | |||

| Spalling of transverse joints | 7L | no. | not tested | 0 | 0 | ||

| 7L(length) | m | not tested | 0 | 0 | |||

| 7M | no. | not tested | 33 | 37 | |||

| 7M(length) | m | not tested | 120.78 | 98.82 | |||

| 7H | no. | not tested | 0 | 6 | |||

| 7H(length) | m | not tested | 0 | 21.96 | |||

| Map cracking (for 2/28/95 survey, the 8aL and 8aM amounts were combined due to grading rule changes) | 8aL | no. | not tested | remainder | remainder | ||

| 8aL | m2 | not tested | 505.2982 | 387.3 | |||

| 8aM | no. | not tested | 65 | 66 | |||

| 8aM | m2 | not tested | 52.12 | 53.51 | |||

| 8aH | no. | not tested | 0 | 0 | |||

| 8aH | m2 | not tested | 0 | 0 | |||

| Flexible patch deterioration | 15fL | no. | not tested | 0 | 0 | ||

| 15fL | m2 | not tested | 0 | 0 | |||

| 15fM | no. | not tested | 0 | 0 | |||

| 15fM | m2 | not tested | 0 | 0 | |||

| 15fH | no. | not tested | 0 | 0 | |||

| 15fH | m2 | not tested | 0 | 0 | |||

| Rigid patch deterioration | 15rL | no. | not tested | 0 | 0 | ||

| 15rL | m2 | not tested | 0 | 0 | |||

| 15rM | no. | not tested | 0 | 0 | |||

| 15rM | m2 | not tested | 0 | 0 | |||

| 15rH | no. | not tested | 0 | 0 | |||

| 15rH | m2 | not tested | 0 | 0 | |||

| Bleeding and pumping | 16 | no. | not tested | 0 | 0 | ||

| 16 | m | not tested | 0 | 0 | |||

| Other | WP-L | no. | not tested | 0 | 0 | ||

| WP-M | no. | not tested | 32 | 32 | |||

| WP-H | no. | not tested | 0 | 0 | |||

| CL-L | no. | not tested | 8 | 5 | |||

| CL-M | no. | not tested | 24 | 27 | |||

| CL-H | no. | not tested | 0 | 0 | |||

| Total joint length at level (from sheet 6) | L | m | not tested | 60.7 | 8.84 | ||

| M | m | not tested | 60.0 | 109.73 | |||

| H | m | not tested | 0 | 21.3 | |||

| Total joint length (from sheet 6) | Total | m | 120.7 | 120.7 | |||

| Percent L | 50.3 | 7.3 | |||||

| Percent M | 49.7 | 90.9 | |||||

| Percent H | 0.0 | 1.8 | |||||

| Map cracking | Total | no. | 0 | 0 | |||

| Total | m | 557.4182 | 557.4182 | ||||

| Percent L | 91 | 90 | |||||

| Percent M | 9 | 10 | |||||

| Percent H | 0 | 0 | |||||

| Spalling of transverse joints (using 10 rule) | Total | no. | 33 | 33 | |||

| Total | m | 120.78 | 120.78 | ||||

| Percent L | 0 | 0 | |||||

| Percent M | 100 | 82 | |||||

| Percent H | 0 | 5 | |||||

| Type | Identification code | Unit | 2/28/95 | 11/8/95 | 12/9/96 | 10/14/97 | 9/29/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | not tested | 0 | 0 | 0 | 0 |

| 1M | no. | not tested | 0 | 0 | 0 | 0 | |

| 1H | no. | not tested | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | not tested | 0 | 0 | 0 | 0 |

| 2L | m2 | not tested | 0 | 0 | 0 | 0 | |

| 2M | no. | not tested | 0 | 0 | 0 | 0 | |

| 2M | m2 | not tested | 0 | 0 | 0 | 0 | |

| 2H | no. | not tested | 0 | 0 | 0 | 0 | |

| 2H | m2 | not tested | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | not tested | 0 | 0 | 0 | 0 |

| 3L(sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 3M | m | not tested | 0 | 0 | 0 | 0 | |

| 3M(sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 3H | m | not tested | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | not tested | 0 | 0 | 0 | 0 |

| 4L | m | not tested | 0 | 0 | 0 | 0 | |

| 4L(sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 4M | no. | not tested | 0 | 0 | 0 | 0 | |

| 4M | m | not tested | 0 | 0 | 0 | 0 | |

| 4M(sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 4H | no. | not tested | 0 | 0 | 0 | 0 | |

| 4H | m | not tested | 0 | 0 | 0 | 0 | |

| 4H(sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | not tested | N | N | N | N |

| 5Al | no. | not tested | 0 | 0 | 0 | 0 | |

| 5aM | no. | not tested | 0 | 0 | 0 | 0 | |

| 5aH | no. | not tested | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | not tested | 0 | 0 | 0 | 0 |

| 5b | m | not tested | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | not tested | 6.8 | 12 | 12 | 12 |

| 6M | m | not tested | 0 | 0 | 0 | 0 | |

| 6H | m | not tested | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | not tested | 32 | 19 | 2 | 0 |

| 7L(length) | m | not tested | 117 | 69.5 | 7.32 | 0 | |

| 7M | no. | not tested | 0 | 13 | 30 | 32 | |

| 7M(length) | m | not tested | 0 | 47.5 | 109.8 | 117 | |

| 7H | no. | not tested | 0 | 0 | 0 | 0 | |

| 7H(length) | m | not tested | 0 | 0 | 0 | 0 | |

| Map cracking (for 2/28/95 survey, the 8aL and 8aM amounts were combined due to grading rule changes) | 8aL | no. | not tested | remainder | remanider | remainder | remainder |

| 8aL | m2 | not tested | 557.4182 | 547.6182 | 531.4982 | 509.1082 | |

| 8aM | no. | not tested | 0 | 35 | 50 | 66 | |

| 8aM | m2 | not tested | 0 | 9.8 | 25.92 | 48.31 | |

| 8aH | no. | not tested | 0 | 0 | 0 | 0 | |

| 8aH | m2 | not tested | 0 | 0 | 0 | 0 | |

| Flexible patch deterioration | 15fL | no. | not tested | 0 | 0 | 0 | 0 |

| 15fL | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15fM | no. | not tested | 0 | 0 | 0 | 0 | |

| 15fM | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15fH | no. | not tested | 0 | 0 | 0 | 0 | |

| 15fH | m2 | not tested | 0 | 0 | 0 | 0 | |

| Rigid patch deterioration | 15rL | no. | not tested | 0 | 0 | 0 | 0 |

| 15rL | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15rM | no. | not tested | 0 | 0 | 0 | 0 | |

| 15rM | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15rH | no. | not tested | 0 | 0 | 0 | 0 | |

| 15rH | m2 | not tested | 0 | 0 | 0 | 0 | |

| Bleeding and pumping | 16 | no. | not tested | 0 | 0 | 0 | 0 |

| 16 | m | not tested | 0 | 0 | 0 | 0 | |

| Other | WP-L | no. | not tested | 2 | 5 | 1 | 0 |

| WP-M | no. | not tested | 31 | 28 | 32 | 29 | |

| WP-H | no. | not tested | 0 | 0 | 0 | 4 | |

| CL-L | no. | not tested | 32 | 30 | 30 | 4 | |

| CL-M | no. | not tested | 1 | 3 | 3 | 29 | |

| CL-H | no. | not tested | 0 | 0 | 0 | 0 | |

| Total joint length at level (from sheet 6) | L | m | not tested | 117 | 100.7 | 80.6 | 2.4 |

| M | m | not tested | 0 | 16.3 | 36.4 | 114.3 | |

| H | m | not tested | 0 | 0 | 0 | 0.3 | |

| Total joint length (from sheet 6) | Total | m | 0 | 117 | 117 | 11.7 | 117 |

| Percent L | 0 | 100 | 86.1 | 68.9 | 2.1 | ||

| Percent M | 0 | 0 | 13.9 | 31.1 | 97.7 | ||

| Percent H | 0 | 0 | 0.0 | 0.0 | 0.3 | ||

| Map cracking | Total | no. | 0 | 0 | 0 | 0 | 0 |

| Total | m | 0 | 557.4182 | 557.4182 | 557.4182 | 557.4182 | |

| Percent L | 0 | 100 | 98 | 95 | 91 | ||

| Percent M | 0 | 0 | 2 | 5 | 9 | ||

| Percent H | 0 | 0 | 0 | 0 | 0 | ||

| Spalling of transverse joints (using 10 rule) | Total | no. | 0 | 32 | 32 | 32 | 32 |

| Total | m | 0 | 117 | 117 | 117.12 | 117 | |

| Percent L | 0 | 100 | 59 | 6 | 0 | ||

| Percent M | 0 | 0 | 41 | 94 | 100 | ||

| Percent H | 0 | 0 | 0 | 0 | 5 | ||

| Type | Identification code | Unit | 2/28/95 | 11/8/95 | 12/9/96 | 10/14/97 | 9/29/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 0 | 0 | 0 | 0 | 0 |

| 3L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 0 | 0 | 0 | 0 | |

| 3M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 0 | 0 | 0 | 0 | 0 |

| 4L | m | 0 | 0 | 0 | 0 | 0 | |

| 4L(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 0 | 0 | 0 | 0 | 0 | |

| 4M | m | 0 | 0 | 0 | 0 | 0 | |

| 4M(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 0 | |

| 4H | m | 0 | 0 | 0 | 0 | 0 | |

| 4H(sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | N | N | N | N | N |

| 5Al | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. Sealed | no. | 0 | 0 | 0 | 0 | 0 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 6.1 | 0 | 0 | 0 | 0 |

| 6M | m | 0 | 0 | 0 | 0 | 0 | |

| 6H | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 29 | 0 | 0 | 0 | 0 |

| 7L(length) | m | 106.1 | 0.0 | 0.0 | 0.0 | 0.0 | |

| 7M | no. | 2 | 32 | 32 | 30 | 24 | |

| 7M(length) | m | 7.3 | 117.0 | 117.0 | 109.8 | 87.8 | |

| 7H | no. | 0 | 0 | 0 | 2 | 8 | |

| 7H(length) | m | 0.0 | 0.0 | 0.0 | 7.3 | 29.3 | |

| Map cracking (for 2/28/95 survey, the 8aL and 8aM amounts were combined due to grading rule changes) | 8aL | no. | remainder | remainder | remainder | remainder | remainder |

| 8aL | m2 | 510.0182 | 511.1182 | 506.6182 | 481.1482 | 456.5282 | |

| 8aM | no. | 26 | 61 | 60 | 63 | 64 | |

| 8aM | m2 | 38.5 | 46.3 | 49.1 | 76.27 | 100.89 | |

| 8aH | no. | 5 | 0 | 1 | 0 | 0 | |

| 8aH | m2 | 8.9 | 0 | 1.7 | 0 | 0 | |

| Flexible patch deterioration | 15fL | no. | 1 | 0 | 0 | 0 | 0 |

| 15fL | m2 | 0.2 | 0 | 0 | 0 | 0 | |

| 15fM | no. | 0 | 0 | 0 | 0 | 0 | |

| 15fM | m2 | 0 | 0 | 0 | 0 | 0 | |

| 15fH | no. | 0 | 0 | 0 | 0 | 0 | |

| 15fH | m2 | 0 | 0 | 0 | 0 | 0 | |

| Rigid patch deterioration | 15rL | no. | 0 | 0 | 2 | 2 | 2 |

| 15rL | m2 | 0 | 0 | 0.3 | 0.3 | 0.3 | |

| 15rM | no. | 0 | 0 | 0 | 0 | 0 | |

| 15rM | m2 | 0 | 0 | 0 | 0 | 0 | |

| 15rH | no. | 0 | 0 | 0 | 0 | 0 | |

| 15rH | m2 | 0 | 0 | 0 | 0 | 0 | |

| Bleeding and pumping | 16 | no. | 0 | 0 | 0 | 0 | 0 |

| 16 | m | 0 | 0 | 0 | 0 | 0 | |

| Other | WP-L | no. | 1 | 0 | 3 | 22 | 0 |

| WP-M | no. | 32 | 33 | 30 | 11 | 33 | |

| WP-H | no. | 0 | 0 | 0 | 0 | 0 | |

| CL-L | no. | 31 | 13 | 33 | 33 | 8 | |

| CL-M | no. | 2 | 20 | 0 | 0 | 25 | |

| CL-H | no. | 0 | 0 | 0 | 0 | 0 | |

| Total joint length at level (from sheet 6) | L | m | 119.1 | 39.6 | 64.6 | 52.7 | 28.7 |

| M | m | 1.6 | 80.5 | 55.5 | 63.7 | 83.8 | |

| H | m | 0.0 | 0.0 | 0.6 | 0.6 | 4.6 | |

| Total joint length (from sheet 6) | Total | m | 117 | 117 | 117 | 117 | 117 |

| Percent L | – | 102 | 34 | 55 | 45 | 25 | |

| Percent M | – | 1 | 69 | 47 | 54 | 72 | |

| Percent H | – | 0 | 0 | 1 | 1 | 4 | |

| Map cracking | Total | no. | 0 | 0 | 0 | 0 | 0 |

| Total | m | 557.4182 | 557.4182 | 557.4182 | 557.4182 | 557.4182 | |

| Percent L | – | 91 | 92 | 91 | 86 | 82 | |

| Percent M | – | 7 | 8 | 9 | 14 | 18 | |

| Percent H | – | 2 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints (using 10 rule) | Total | no. | 31 | 32 | 32 | 32 | 32 |

| Total | m | 113.4 | 117 | 117 | 117.12 | 117.12 | |

| Percent L | – | 94 | 0 | 0 | 0 | 0 | |

| Percent M | – | 6 | 100 | 100 | 94 | 75 | |

| Percent H | – | 0 | 0 | 0 | 6 | 25 | |

| Type | Identification code | Unit | 2/28/95 | 11/8/95 | 12/9/96 | 10/14/97 | 9/29/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | 0 | 0 | 0 | 0 | 0 |

| 1M | no. | 0 | 0 | 0 | 0 | 0 | |

| 1H | no. | 0 | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | 0 | 0 | 0 | 0 | 0 |

| 2L | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2M | no. | 0 | 0 | 0 | 0 | 0 | |

| 2M | m2 | 0 | 0 | 0 | 0 | 0 | |

| 2H | no. | 0 | 0 | 0 | 0 | 0 | |

| 2H | m2 | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | 0 | 0 | 0 | 0 | 0 |

| 3L (sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3M | m | 0 | 0 | 0 | 0 | 0 | |

| 3M (sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 3H | m | 0 | 0 | 0 | 0 | 0 | |

| 3H (sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | 0 | 0 | 0 | 0 | 0 |

| 4L | m | 0 | 0 | 0 | 0 | 0 | |

| 4L (sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4M | no. | 0 | 0 | 0 | 0 | 0 | |

| 4M | m | 0 | 0 | 0 | 0 | 0 | |

| 4M (sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| 4H | no. | 0 | 0 | 0 | 0 | 0 | |

| 4H | m | 0 | 0 | 0 | 0 | 0 | |

| 4H (sealed) | m | 0 | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | N | N | N | N | N |

| 5aL | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aM | no. | 0 | 0 | 0 | 0 | 0 | |

| 5aH | no. | 0 | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. sealed | no. | 0 | 0 | 0 | 0 | 0 |

| 5b | m | 0 | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | 1 | 0 | 0 | 0 | 0 |

| 6M | m | 1 | 0 | 0 | 0 | 0 | |

| 6H | m | 1 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | 32 | 0 | 3 | 0 | 0 |

| 7L (length) | m | 82.3 | 0 | 11 | 0 | 0 | |

| 7M | no. | 0 | 32 | 29 | 32 | 31 | |

| 7M (length) | m | 0 | 63.4 | 106.1 | 117.1 | 113.5 | |

| 7H | no. | 0 | 0 | 0 | 0 | 1 | |

| 7H (length) | m | 0 | 0 | 0 | 0 | 3.7 | |

| Map cracking (for 2/28/95 survey, the 8aL and 8aM amounts were combined due to grading rule changes) | 8aL | no. | remainder | remainder | remainder | remainder | remainder |

| 8aL | m2 | 510.8 | 527.7 | 521.4 | 509.0 | 505.6 | |

| 8aM | no. | 30 | 39 | 52 | 55 | 52 | |

| 8aM | m2 | 44.4 | 29.7 | 36.0 | 48.5 | 51.9 | |

| 8aH | no. | 2 | 0 | 0 | 0 | 0 | |

| 8aH | m2 | 2.2 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Flexible patch deterioration | 15fL | no. | 0 | 0 | 0 | 0 | 0 |

| 15fL | m2 | 0 | 0 | 0 | 0 | 0 | |

| 15fM | no. | 0 | 0 | 0 | 0 | 0 | |

| 15fM | m2 | 0 | 0 | 0 | 0 | 0 | |

| 15fH | no. | 0 | 0 | 0 | 0 | 0 | |

| 15fH | m2 | 0 | 0 | 0 | 0 | 0 | |

| Rigid patch deterioration | 15rL | no. | 0 | 0 | 0 | 0 | 0 |

| 15rL | m2 | 0 | 0 | 0 | 0 | 0 | |

| 15rM | no. | 0 | 0 | 0 | 0 | 0 | |

| 15rM | m2 | 0 | 0 | 0 | 0 | 0 | |

| 15rH | no. | 0 | 0 | 0 | 0 | 0 | |

| 15rH | m2 | 0 | 0 | 0 | 0 | 0 | |

| Bleeding and pumping | 16 | no. | 0 | 0 | 0 | 0 | 0 |

| 16 | m | 0 | 0 | 0 | 0 | 0 | |

| Other | WP-L | no. | 0 | 0 | 17 | 19 | 0 |

| WP-M | no. | 32 | 33 | 15 | 14 | 33 | |

| WP-H | no. | 1 | 0 | 1 | 0 | 0 | |

| CL-L | no. | 33 | 33 | 30 | 33 | 27 | |

| CL-M | no. | 0 | 0 | 3 | 0 | 6 | |

| CL-H | no. | 0 | 0 | 0 | 0 | 0 | |

| Total joint length at level (from sheet 6) | L | m | 80.7 | 17.4 | 81.7 | 70.6 | 41.0 |

| M | m | 1.6 | 46.0 | 35.4 | 46.2 | 75.7 | |

| H | m | 0.0 | 0.0 | 0.0 | 0.0 | 0.3 | |

| Total joint length (from sheet 6) | Total | m | 82.3 | 63.4 | 117.0432 | 116.8 | 117 |

| Percent L | - | 98 | 27 | 70 | 60 | 35 | |

| Percent M | - | 2 | 73 | 30 | 40 | 65 | |

| Percent H | - | 0 | 0 | 0 | 0 | 0 | |

| Map cracking | Total | no. | 0 | 0 | 0 | 0 | 0 |

| Total | m | 557.4182 | 557.4182 | 557.4182 | 557.4182 | 557.4182 | |

| Percent L | - | 91.6 | 94.7 | 93.5 | 91.3 | 90.7 | |

| Percent M | - | 8.0 | 5.3 | 6.5 | 8.7 | 9.3 | |

| Percent H | - | 0.4 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Spalling of transverse joints (using 10 rule) | Total | no. | 32 | 32 | 32 | 32 | 32 |

| Total | m | 82.3 | 63.4 | 117.1 | 117.1 | 117.1 | |

| Percent L | - | 100 | 0 | 9 | 0 | 0 | |

| Percent M | - | 0 | 100 | 91 | 100 | 97 | |

| Percent H | - | 0 | 0 | 0 | 0 | 1 | |

| Type | Identification code | Unit | 2/28/95 | 11/8/95 | 12/9/96 | 10/14/97 | 9/29/98 |

|---|---|---|---|---|---|---|---|

| Corner breaks | 1L | no. | not tested | 0 | 0 | 0 | 0 |

| 1M | no. | not tested | 0 | 0 | 0 | 0 | |

| 1H | no. | not tested | 0 | 0 | 0 | 0 | |

| Durability cracking | 2L | no. | not tested | 0 | 0 | 0 | 0 |

| 2L | m2 | not tested | 0 | 0 | 0 | 0 | |

| 2M | no. | not tested | 0 | 0 | 0 | 0 | |

| 2M | m2 | not tested | 0 | 0 | 0 | 0 | |

| 2H | no. | not tested | 0 | 0 | 0 | 0 | |

| 2H | m2 | not tested | 0 | 0 | 0 | 0 | |

| Longitudinal cracking | 3L | m | not tested | 0 | 0 | 0 | 0 |

| 3L (sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 3M | m | not tested | 0 | 0 | 0 | 0 | |

| 3M (sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 3H | m | not tested | 0 | 0 | 0 | 0 | |

| 3H (sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| Transverse cracking | 4L | no. | not tested | 0 | 0 | 0 | 0 |

| 4L | m | not tested | 0 | 0 | 0 | 0 | |

| 4L (sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 4M | no. | not tested | 0 | 0 | 0 | 0 | |

| 4M | m | not tested | 0 | 0 | 0 | 0 | |

| 4M (sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| 4H | no. | not tested | 0 | 0 | 0 | 0 | |

| 4H | m | not tested | 0 | 0 | 0 | 0 | |

| 4H (sealed) | m | not tested | 0 | 0 | 0 | 0 | |

| Transverse joint seal damage | Sealed | y/n | not tested | N | N | N | N |

| 5aL | no. | not tested | 0 | 0 | 0 | 0 | |

| 5aM | no. | not tested | 0 | 0 | 0 | 0 | |

| 5aH | no. | not tested | 0 | 0 | 0 | 0 | |

| Longitudinal joint seal damage | No. sealed | no. | not tested | 0 | 0 | 0 | 0 |

| 5b | m | not tested | 0 | 0 | 0 | 0 | |

| Spalling of longitudinal joints | 6L | m | not tested | 2.7 | 2 | 2 | 2 |

| 6M | m | not tested | 0 | 0 | 0 | 0 | |

| 6H | m | not tested | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints | 7L | no. | not tested | 8 | 16 | 14 | 1 |

| 7L (length) | m | not tested | 5.1 | 26.2 | 51.2 | 3.7 | |

| 7M | no. | not tested | 12 | 16 | 19 | 29 | |

| 7M (length) | m | not tested | 13 | 29.6 | 69.5 | 106.1 | |

| 7H | no. | not tested | 0 | 0 | 0 | 3 | |

| 7H (length) | m | not tested | 0 | 0 | 0 | 11.0 | |

| Map cracking | 8aL | no. | not tested | remainder | remainder | remainder | remainder |

| 8aL | m2 | not tested | 551.7182 | 551.0182 | 551.0182 | 534.1982 | |

| 8aM | no. | not tested | 6 | 17 | 17 | 43 | |

| 8aM | m2 | not tested | 5.7 | 6.4 | 6.4 | 23.22 | |

| 8aH | no. | not tested | 0 | 0 | 0 | 0 | |

| 8aH | m2 | not tested | 0 | 0 | 0 | 0 | |

| Flexible patch deterioration | 15fL | no. | not tested | 0 | 0 | 0 | 0 |

| 15fL | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15fM | no. | not tested | 0 | 0 | 0 | 0 | |

| 15fM | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15fH | no. | not tested | 0 | 0 | 0 | 0 | |

| 15fH | m2 | not tested | 0 | 0 | 0 | 0 | |

| Rigid patch deterioration | 15rL | no. | not tested | 0 | 0 | 0 | 0 |

| 15rL | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15rM | no. | not tested | 0 | 0 | 0 | 0 | |

| 15rM | m2 | not tested | 0 | 0 | 0 | 0 | |

| 15rH | no. | not tested | 0 | 0 | 0 | 0 | |

| 15rH | m2 | not tested | 0 | 0 | 0 | 0 | |

| Bleeding and pumping | 16 | no. | not tested | 0 | 0 | 0 | 0 |

| 16 | m | not tested | 0 | 0 | 0 | 0 | |

| Other | WP-L | no. | not tested | 31 | 31 | 17 | |

| WP-M | no. | not tested | 2 | 3 | 17 | ||

| WP-H | no. | not tested | 0 | 0 | 0 | ||

| CL-L | no. | not tested | 33 | 33 | 30 | ||

| CL-M | no. | not tested | 3 | 0 | 6 | ||

| CL-H | no. | not tested | 0 | 1 | 4 | ||

| Total joint length at level (from sheet 6) | L | m | not tested | 7.9 | 43.2816 | 82.9 | 82.6 |

| M | m | not tested | 14 | 10.0584 | 12.5 | 37.2 | |

| H | m | not tested | 0 | 0 | 0 | 9 | |

| Total joint length (from sheet 6) | Total | m | 0 | 21.9 | 53.34 | 95.4 | 120.7 |

| Percent L | - | 0 | 36 | 81 | 87 | 68 | |

| Percent M | - | 0 | 64 | 19 | 13 | 31 | |

| Percent H | - | 0 | 0 | 0 | 0 | 1 | |

| Map cracking | Total | no. | 0 | 0 | 0 | 0 | 0 |

| Total | m | 0 | 557.4182 | 557.4182 | 557.4182 | 557.4182 | |

| Percent L | - | 0 | 99 | 99 | 99 | 96 | |

| Percent M | - | 0 | 1 | 1 | 1 | 4 | |

| Percent H | - | 0 | 0 | 0 | 0 | 0 | |

| Spalling of transverse joints (using 10 rule) | Total | no. | 0 | 20 | 32 | 33 | 33 |

| Total | m | 0 | 18.1 | 55.8 | 120.78 | 120.78 | |

| Percent L | - | 0 | 28 | 47 | 42 | 3 | |

| Percent M | - | 0 | 72 | 53 | 58 | 88 | |

| Percent H | - | 0 | 0 | 0 | 0 | 9 | |