U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Federal Highway Administration Research and Technology

Coordinating, Developing, and Delivering Highway Transportation Innovations

| REPORT |

| This report is an archived publication and may contain dated technical, contact, and link information |

|

| Publication Number: FHWA-HRT-16-008 Date: May 2016 |

Publication Number: FHWA-HRT-16-008 Date: May 2016 |

ABC is becoming more popular in the United States due to the advantages obtained in terms of safety, cost-effective construction, and congestion mitigation. The use of prefabricated concrete elements is a key part of ABC; however, the field-casting of the connections between these elements tends to be a critical and challenging part of making the overall system work successfully. The connections are typically made with grout-type materials, frequently cement-based grouts. The performance of these materials is crucial for the serviceability of the whole structure. Consequently, considerable research on how these materials behave has been done during the last decades. However, recent research shows the wide range of performance that can be obtained from grouts, as well as the propensity of the materials to undergo volumetric deformations (i.e., expansion and/or contraction). The main objective of this chapter is to provide an overview of the concepts of: (1) prefabricated bridge elements and systems (PBES), (2) grout-type materials and their general properties, (3) previous research performed on grout-type materials, and (4) the emerging use of IC technology in concrete materials.

ABC has become common for both new and replacement bridge construction. ABC was developed due to the need to provide a fast and efficient manner to construct bridges without causing too much disruption to the facility. ABC uses innovative planning, materials, design, and methods that provide a faster and safer way to construct a bridge. ABC commonly uses PBEs that are built offsite and includes features that reduce the onsite construction time and mobility impact time that occur from conventional construction methods. Because these structural components are built off the critical path and produced under controlled environmental conditions, there are improvements in the product quality and the component long-term durability. ABC has been growing in prevalence around in the United States for about 20 years. Early projects focused on specific prefabricated elements such as bridge decks. More recently, ABC projects that use PBES have spread to all bridge elements.(4-6) The use of PBES in ABC has shown many benefits, including improved safety and working conditions for workers, reduced impact to users, improved quality of delivered product, and reduced cost to society in general. A photographic example of one type of PBE connection being completed through the casting of the grout is shown in figure 1.

Figure 1. Photo. Casting of a grout-type material in the connections between PBEs.

Grout-type materials are widely used in the construction industry for different applications such as joint sealing, flooring, and structural repair, among others. (See references 7 through 13.) The most common grout type is based on cement or cementitious materials. It is generally a mixture of cement, sand, water, and powder chemical admixtures, and it is commonly referred to as non-shrink cementitious grout. Other types are also available, such as epoxy-based, fly-ash-based, and magnesium phosphate-based grouts, to name just a few. Grout-type materials are normally proprietary materials that are prepackaged and ready to mix on site.

As previously mentioned, one common use for grouts is in ABC within connections between prefabricated bridge structural elements.(6) These prefabricated structural components are produced under controlled environmental conditions, thus improving the quality of the product. Non-shrink cementitious grouts are most often used to easily and efficiently provide a connection between these precast concrete elements. Other types of grout may be acceptable for precast connections, but they are typically more expensive than cementitious grouts and may introduce the need for non-standard considerations on the part of the designer. Typically, the field casting of the connections is a labor-intensive, critical part of the overall long-term performance of the system. This is the reason why grout-type materials need to meet several high-level performance criteria, including high fluidity, low permeability, high early strength, corrosion protection, sulfate resistance, and, in some cases, frost durability.

One of the main aspects that cementitious grout manufacturers focus on when designing grouts is making them dimensionally stable. Ideally, non-shrink cementitious grouts would not exhibit dimensional changes in the plastic or hardened stages. Manufacturers try to eliminate the inherent shrinking behavior of any cement-based material by adding expansive agents such as gas generation or ettringite.(6) However, comparatively little independent research has been done on this topic.

Several research studies on the general mechanical performance of grout-type materials have been carried out in the last decades. (See references 6 and 14 through 16.) However, the field-cast grout-type materials specified for use in bridge connections have undergone limited research as to their relevance within this application. Graybeal conducted extensive research in which the performance of different grout-type materials intended to be used as bridge connections was evaluated.(17) One of the outcomes of that research was the wide range of grout performance that can be obtained, as well as the propensity of the materials to undergo volumetric deformations (e.g., expansion and/or contraction).

IC has become more popular during the last years within the concrete community.(18-20) It is a technology that has shown multiple benefits in terms of concrete durability, especially in reducing shrinkage cracking. (See references 21 through 25.) While IC has been fortuitously included in concrete (particularly lightweight concrete) for many years, it is only within recent years that this technology has been intentionally incorporated into the system through the use of a variety of materials, including prewetted LWAs, superabsorbent polymers (SAPs), and prewetted wood fibers.

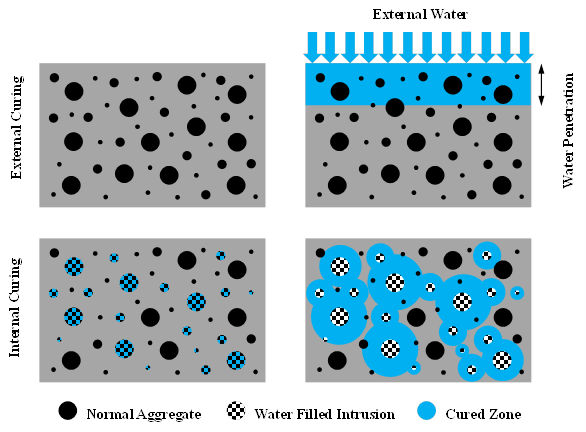

The concept supporting IC is the supply of highly porous particles in the concrete that can act as internal water reservoirs. These reservoirs will release the water from the inside of the concrete when negative pressure occurs in the cement matrix due to the formation of voids associated with chemical shrinkage. This process will provide a more homogeneous curing of the concrete, particularly for lower permeability (i.e., low water-to-cement ratio (w/c) concretes), which are more difficult to externally cure. A conceptual illustration of IC is provided in figure 2.

Figure 2. Illustration. The differences between external curing and IC.

The amount of IC water needed in a cementitious system is based on the chemical shrinkage occurring in the sample, as described by Bentz et al.(26) They formulated an equation that permits the calculation of the amount of LWA needed (see figure 3).

![]()

Figure 3. Equation. Amount of IC water needed based on the chemical shrinkage occurring in the sample.

Where MLWA lb/ft3 (kg/m3) is the mass of LWA (in a dry state) that needs to be prewetted to provide water to fill in the voids created by chemical shrinkage, Cf lb/ft3 (kg/m3) is the binder content of the mixture, CS (oz (mL) of water per lb (g) of binder) is the measured infinite chemical shrinkage of the binder as per ASTM C1608, αmax (unitless) is the expected maximum degree of hydration, S (unitless) is the expected degree of saturation of the LWA and is typically taken as 1 when the dry LWA are water-soaked for 24 h (if absorption capacity is also measured at 24 h), and ΦLWA (lb (kg) of water/lb (kg) of dry LWA) is the absorption capacity of the LWA (typically taken as the 24-h absorption measured value as per ASTM C1761).(27,28)

The implementation of this approach in grout-type materials has some difficulties, one being that the amount of reactive material in the solid fraction of a grout is typically unknown to the end-user. This is important in order to estimate the binder content (Cf), chemical shrinkage (CS), and maximum expected degree of hydration (αmax) in figure 3. The approach followed in this study will be further discussed later in the report.